Washing method of high-nickel positive electrode material and product and application thereof

A cathode material, high nickel technology, applied in battery electrodes, non-aqueous electrolyte batteries, non-aqueous electrolyte batteries, etc., can solve the problems of poor removal of residual alkali, reduced washing effect, and difficult operation, and achieve structural stability and Good thermal stability, enhanced structural stability and thermal stability, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

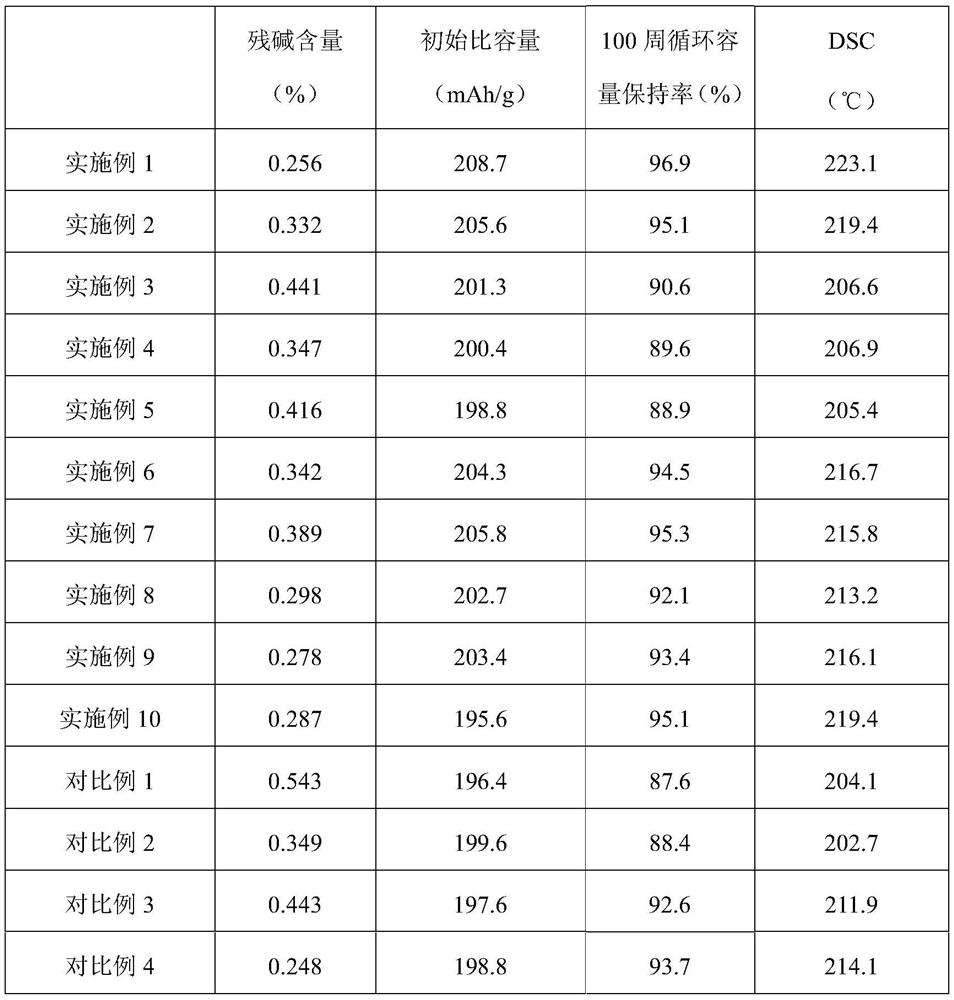

Examples

Embodiment 1

[0050] The molecular formula of the high-nickel cathode material in this embodiment is LiNi 0.83 co 0.1 mn 0.05 Zr 0.02 o 2 , the surface residual alkali content is 0.9%;

[0051] Washing method comprises the following steps in the present embodiment:

[0052] (1) The preparation concentration is 0.1mol / L (NH 4 ) 2 HPO 4 aqueous solution;

[0053] (2) At a temperature of 25°C and a stirring speed of 500rpm, add the high-nickel cathode material into the (NH 4 ) 2 HPO 4 In the aqueous solution, carry out reaction, the reaction time is 30min, obtains suspension; Wherein, (NH 4 ) 2 HPO 4 In aqueous solution (NH 4 ) 2 HPO 4 The ratio of the quality of the material to the quality of the high-nickel cathode material is 0.03;

[0054] (3) Vacuum filter the suspension in step (2), dry it in an oven at 130°C for 5 hours; then sinter it in an air atmosphere in a muffle furnace at 400°C for 6 hours to obtain a high-nickel positive electrode coated with lithium phosphate ...

Embodiment 2

[0056] The difference between this embodiment and embodiment 1 is that in step (1) (NH 4 ) 2 HPO 4 The concentration of the aqueous solution was replaced by 0.3mol / L; other parameters and conditions were exactly the same as in Example 1.

Embodiment 3

[0058] The difference between this embodiment and embodiment 1 is that in step (2) (NH 4 ) 2 HPO 4 In aqueous solution (NH 4 ) 2 HPO 4 The ratio of the quality of the material to the quality of the high-nickel positive electrode material is 0.01, and other parameters and conditions are exactly the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com