Positive electrode sheet and lithium ion secondary battery with same

A technology for secondary batteries and positive plates, applied in the direction of secondary batteries, battery electrodes, circuits, etc., can solve the problems of increased processing costs, difficulty in recovery, and poor electrical performance, to prevent polymerization, reduce concentration, and easily decompose Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

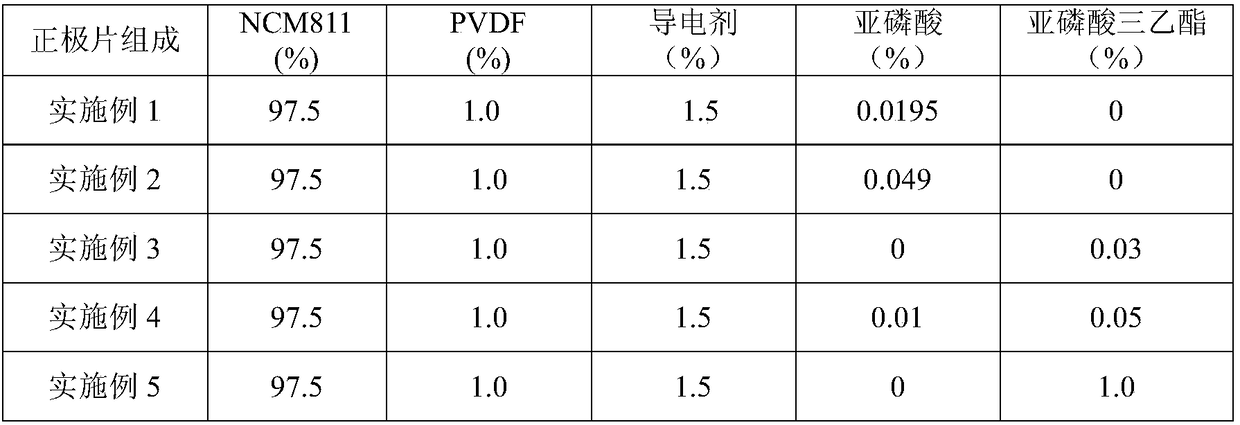

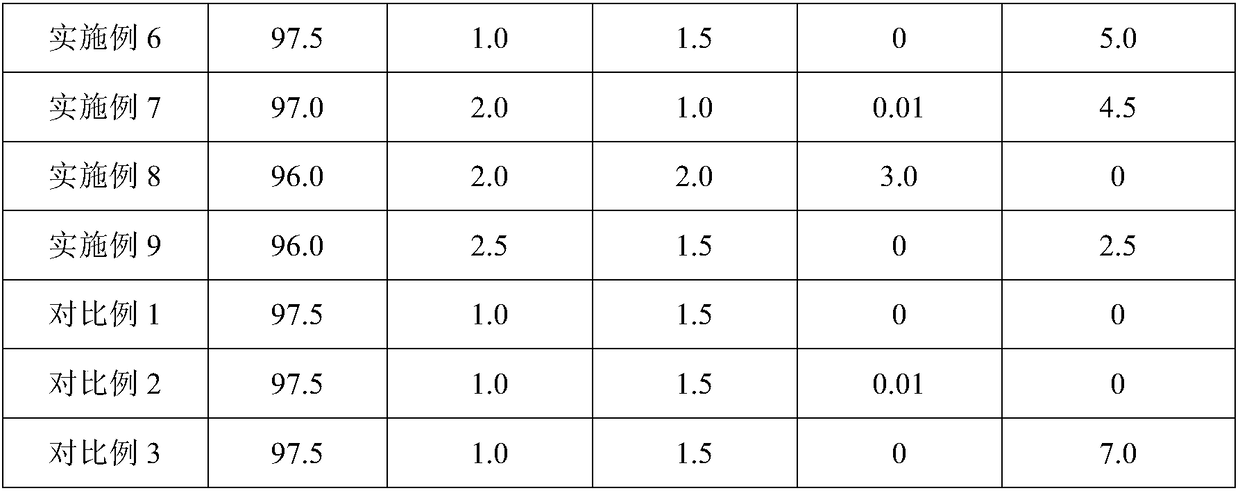

[0086] Example 1-9: Preparation of positive electrode sheet

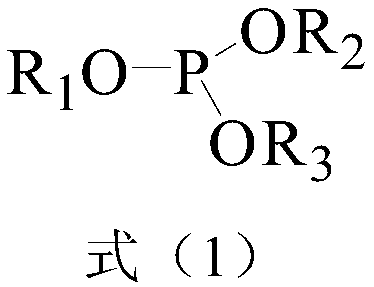

[0087] First prepare 10% binder PVDF (Solef 5130) NMP solution, according to the ternary cathode material NCM811 (D 50 =11.5μm): Conductive agent (carbon nanotubes: Super P=1:2): binder (PVDF)=97.5:1.0:1.5 Weigh the required PVDF NMP solution into the reaction stirring tank, start stirring, then Add a certain mass of phosphite and / or phosphorous acid (here, R1, R2, and R3 in the structural formula (1) are all ethyl groups, that is, the additive is triethyl phosphite), the positive electrode active material, and continue to stir for 20 -30 minutes; add the required conductive agent and stir for 20-30 minutes, check the viscosity, add NMP to adjust the viscosity to 6000±500mPa.S; finally continue to stir under vacuum for 1-6 hours, and control the temperature of the slurry process at (50 ±5)℃, the relative humidity of the environment is controlled within 10%, and the slurry formula is shown in Table 1. The prepared posi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com