High-compaction and high-stability high-nickel cathode material and preparation method thereof, and lithium ion battery

A high-stability, positive electrode material technology, applied in the field of lithium-ion batteries, can solve the problems of deteriorating safety performance and cycle performance of lithium-ion batteries, difficulty in preparing pole pieces, fast water absorption of pole pieces, etc., and achieve excellent rate performance and uniform coating , the effect of increasing energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

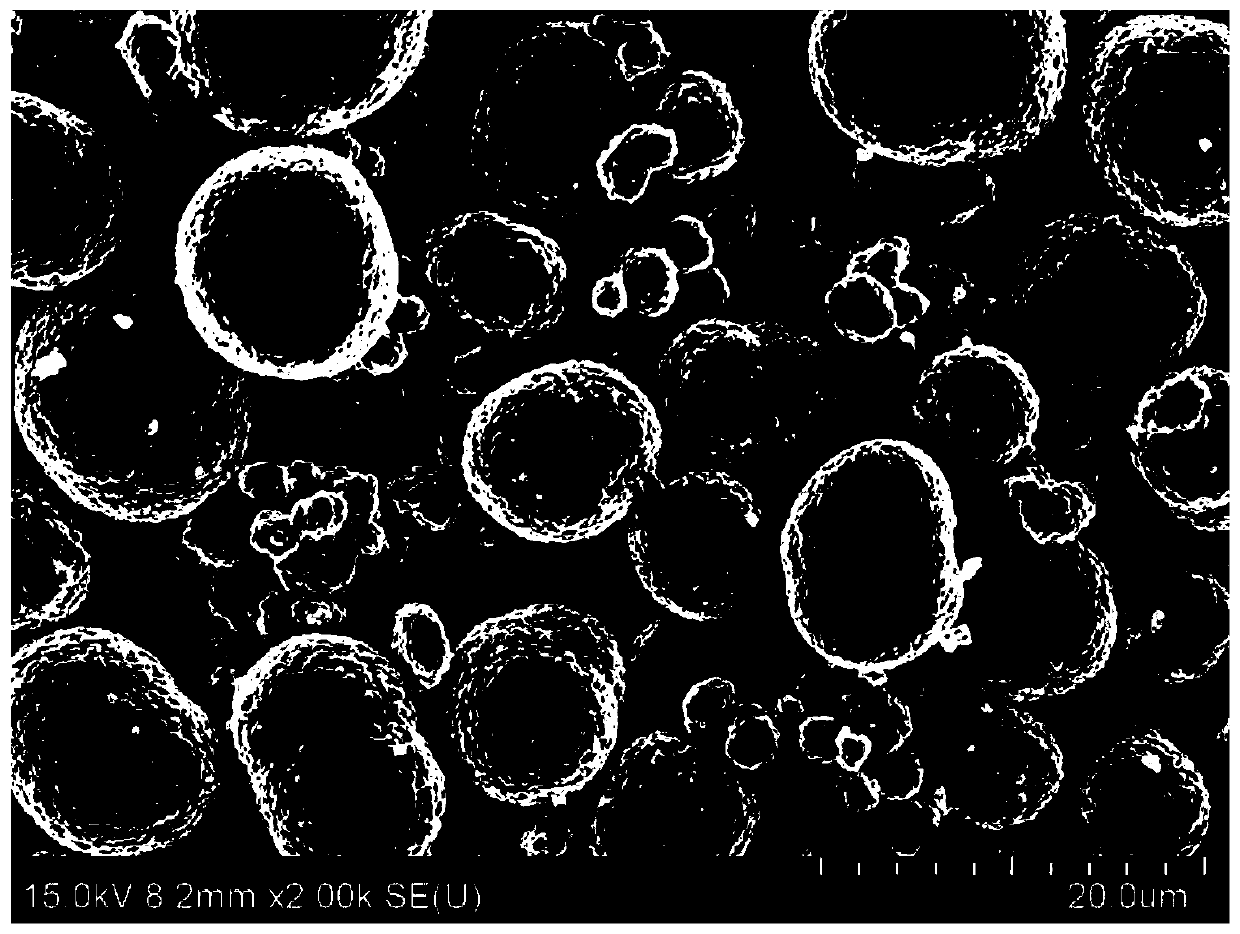

Embodiment 1

[0064] (1) Prepare large particles with a median particle size of 10 microns and small particles with a median particle size of 3 microns:

[0065] Prepare nickel-cobalt mixed sulfate solution, prepare sodium metaaluminate solution, then pump 5 mol / L ammonia solution and 5 mol / L sodium hydroxide solution into the reactor in parallel, and control the Ni: Co: Al atomic ratio to 0.815: 0.15:0.035, the metal ion concentration of the mixed solution is 2.5mol / L. Control the reaction temperature to 45°C, the pH value to 10.0, and the ammonia value to 8g / L. Co-precipitation reaction is carried out. After the particle size reaches the requirement, solid-liquid separation and drying are carried out to obtain the nickel-cobalt-aluminum hydroxide precursor;

[0066] (2) Mix the size particle precursor prepared in (1) in a weight ratio of 3:1, then add lithium hydroxide and titanium oxide, and mix evenly in a high-speed mixer, wherein the molar ratio of Ni: Co: Al: Ti is 81.0:14.8:3.4:0.8...

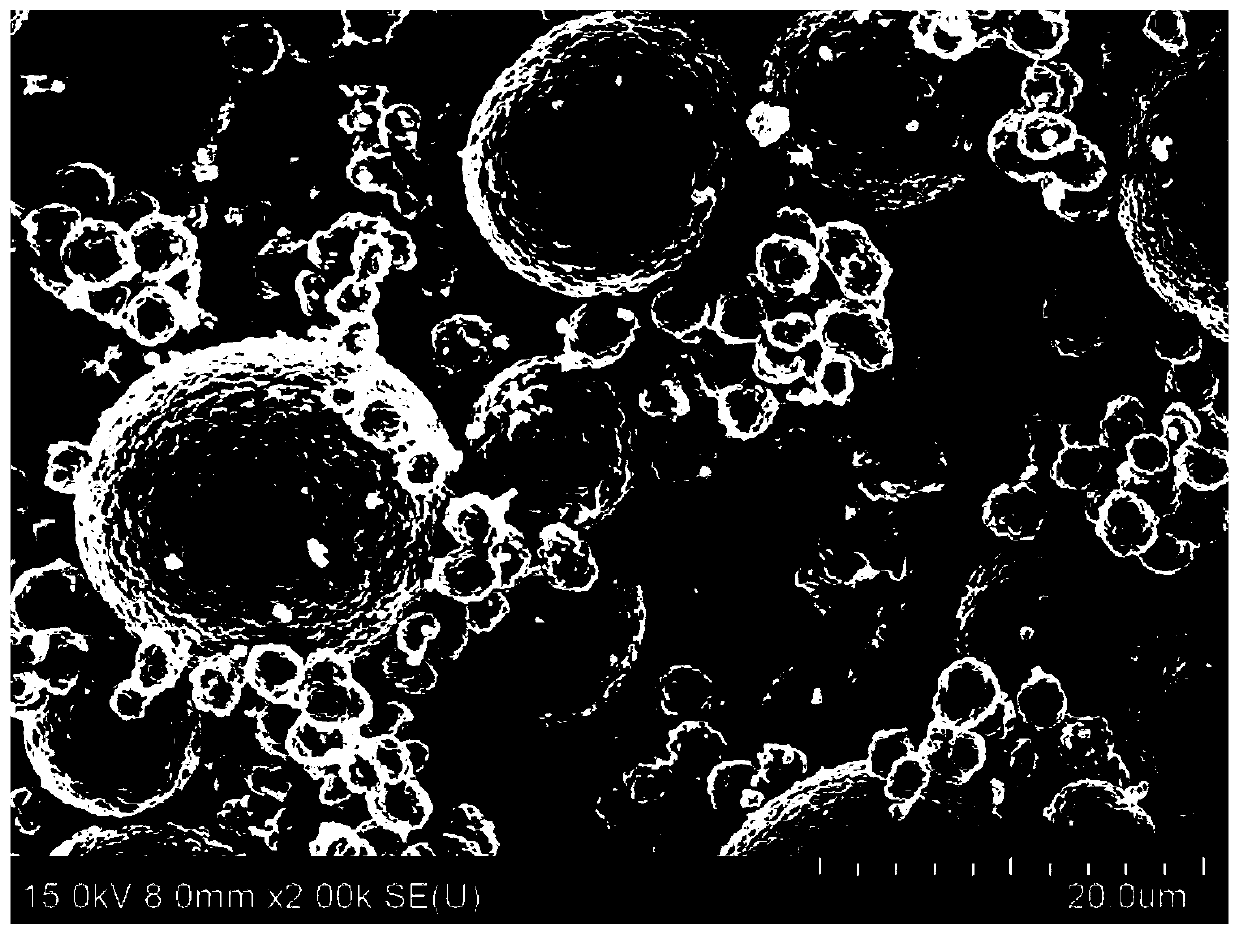

Embodiment 2

[0075] (1) Prepare large particles with a median particle size of 13 microns and small particles with a median particle size of 4 microns:

[0076] Prepare nickel-cobalt-manganese mixed sulfate solution, then pump 8 mol / L ammonia solution and 5 mol / L sodium hydroxide solution into the reaction kettle in parallel, control Ni: Co: Mn atomic ratio to 0.90: 0.05: 0.05, the mixed solution The concentration of metal ions is 4.0mol / L. Control the reaction temperature to 50°C, the pH value to 11.5, and the ammonia value to 8g / L. Co-precipitation reaction is carried out. After the particle size reaches the requirement, solid-liquid separation and drying are carried out to obtain the nickel-cobalt-manganese hydroxide precursor;

[0077] (2) Mix the size particle precursor prepared in (1) in a weight ratio of 4:1, then add lithium hydroxide, lithium source and metal (Ni, Co, Mn) at a molar ratio of 1.03, and mix in a high-speed mixer Uniform;

[0078] (3) Put the ingredients in (2) int...

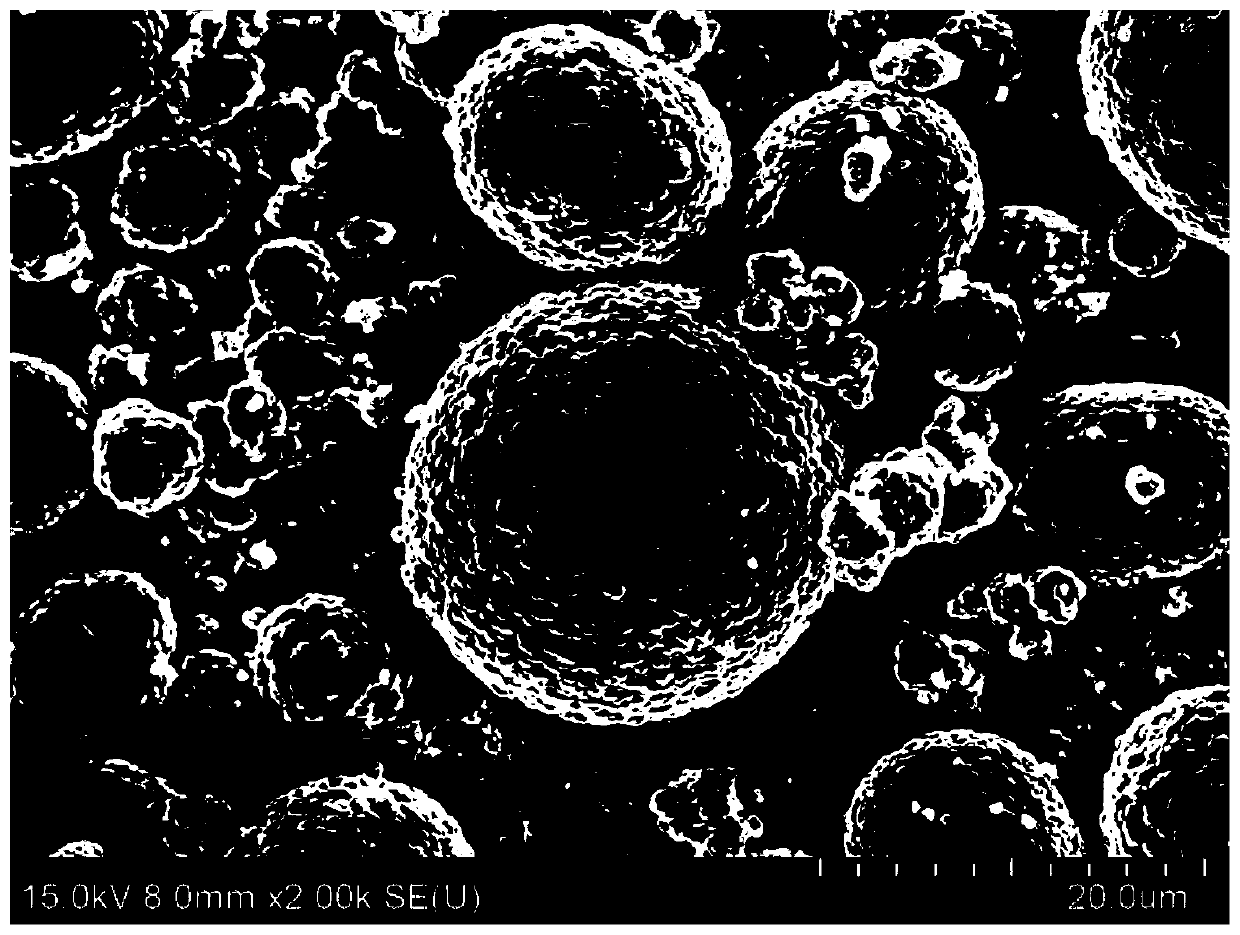

Embodiment 3

[0086] (1) Prepare large particles with a median particle size of 18 microns and small particles with a median particle size of 3 microns:

[0087] Prepare nickel-cobalt mixed sulfate solution, prepare sodium metaaluminate solution, then pump 6 mol / L ammonia solution and 5 mol / L sodium hydroxide solution into the reactor in parallel, and control the Ni: Co: Al atomic ratio to 0.92: 0.04:0.04, the metal ion concentration of the mixed solution is 4.0mol / L. Control the reaction temperature to 55°C, the pH value to 11.5, and the ammonia value to 6.5g / L. Co-precipitation reaction is carried out. After the particle size reaches the requirement, solid-liquid separation and drying are carried out to obtain the nickel-cobalt-aluminum hydroxide precursor;

[0088] (2) Mix the size particle precursor prepared in (1) in a weight ratio of 3:1, then add lithium hydroxide and zirconium oxide, and mix evenly in a high-speed mixer, wherein the molar ratio of Ni:Co:Al:Zr is 91.5 : 3.8: 3.8: 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com