High-compaction negative electrode sheet and preparation method thereof and lithium ion battery comprising electrode sheet

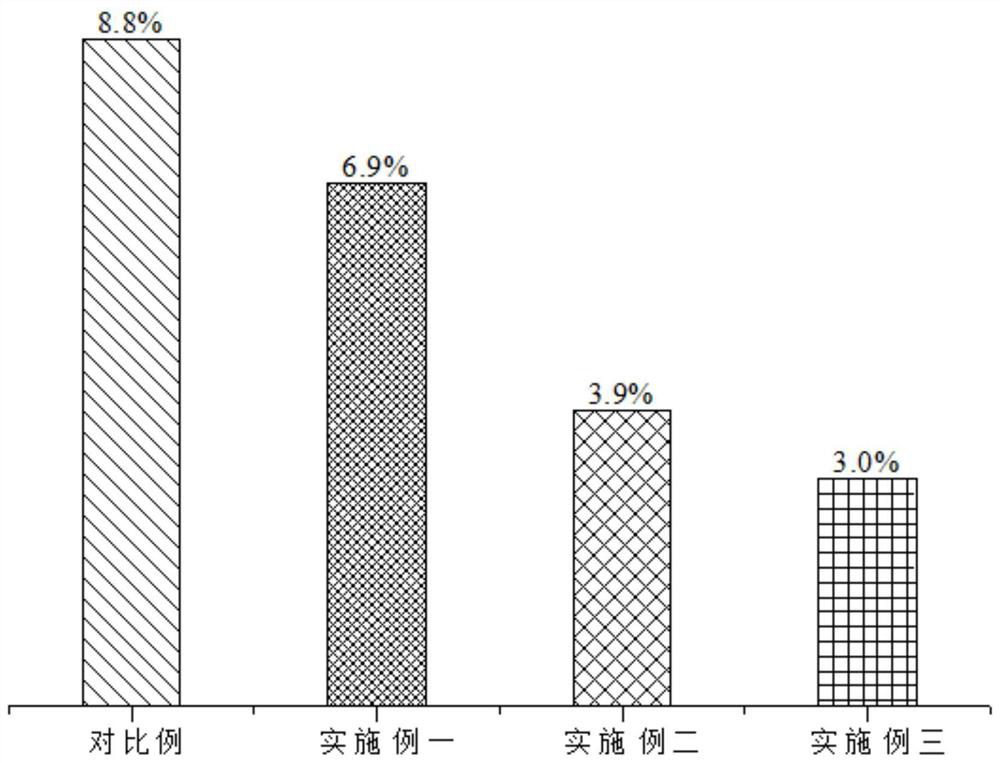

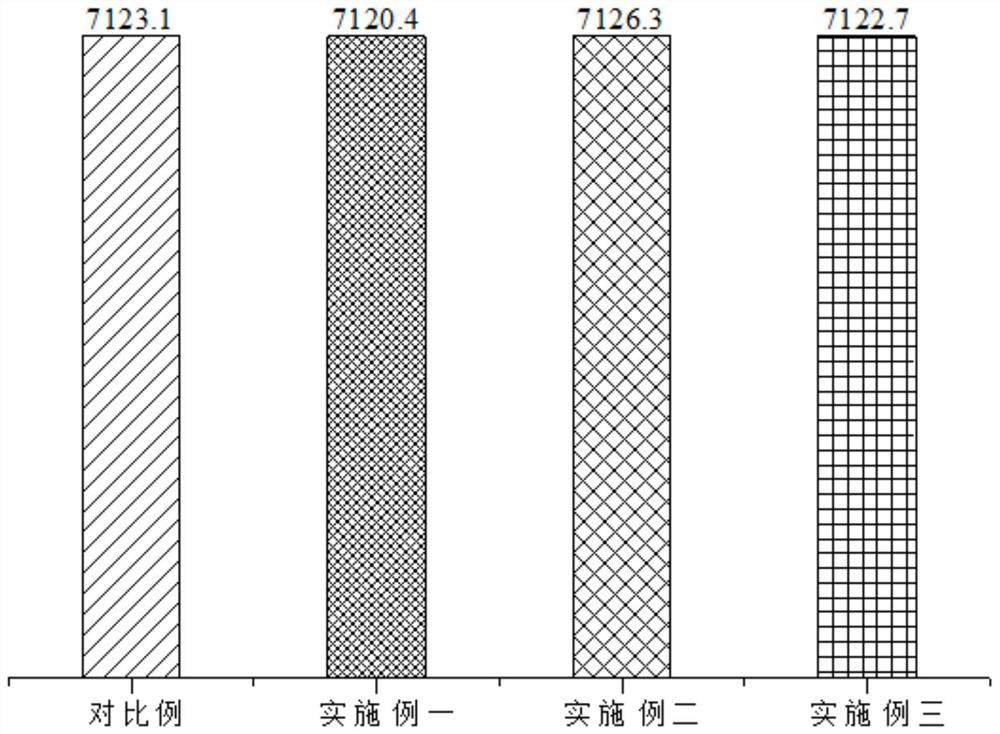

A negative pole piece, high-pressure compaction technology, applied in the direction of negative electrodes, battery electrodes, secondary batteries, etc., can solve the problems of loose contact between active material particles, affecting the electrochemical performance of lithium batteries, and large repulsion force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A preparation method comprising the above-mentioned high-compression negative electrode sheet, comprising the following steps:

[0044] ①Dissolve the suspending agent in the solvent to prepare a uniform solution;

[0045] ② adding the conductive agent to the solution described in step ①, and mixing evenly to obtain a conductive mixed solution;

[0046] ③ Dry-mixing the high-compaction additive and the negative electrode active material and then adding it to the conductive mixture described in step ②, and after high-speed dispersion and mixing, a uniform mixture is obtained;

[0047] ④ adding the binder to the homogeneous mixture described in step ③, and dispersing evenly at a high speed to prepare a mixed slurry;

[0048] ⑤ adding the solvent to the mixed slurry described in step ④, mixing evenly, and obtaining the negative electrode slurry after vacuum defoaming;

[0049] ⑥Coating the negative electrode slurry described in step ⑤ on the copper foil and obtaining the ...

Embodiment 1

[0054] ①Dissolve 1.3g of suspending agent in pure water to prepare a uniform solution;

[0055] ② Add 1.0g Super P to the solution described in step ①, and mix evenly to obtain a conductive mixed solution;

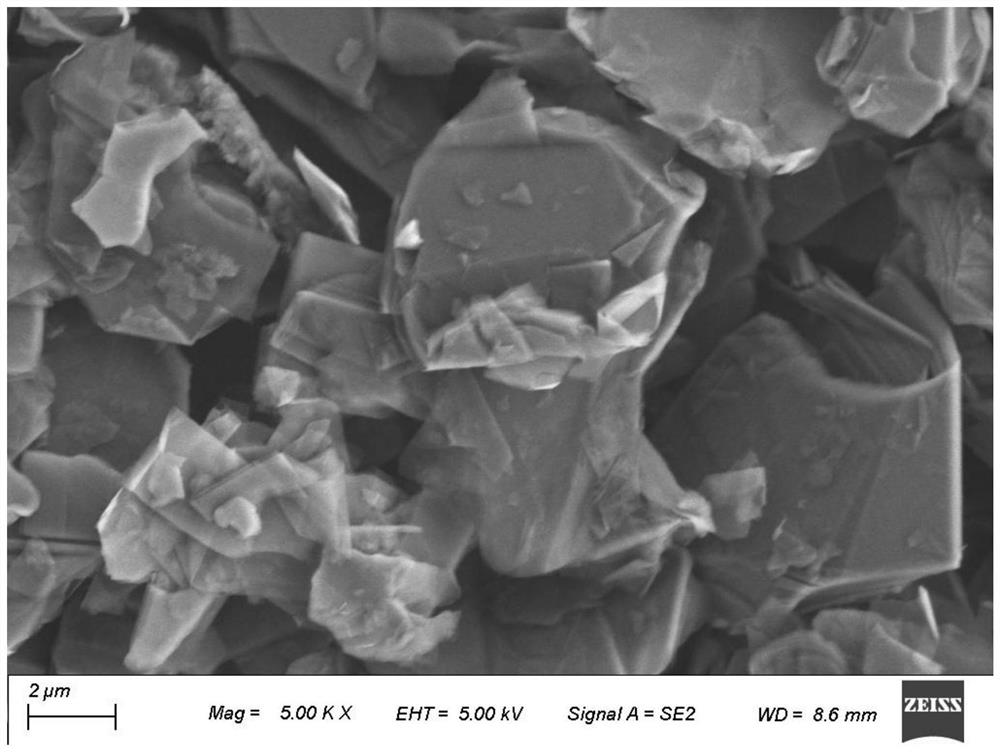

[0056] ③ Take 2.0g, the gram capacity is 370Ah / g, the D50 is 3μm, and the BET is 20m 2 / g of highly anisometric flake graphite and 93.5g of secondary granulated artificial graphite are dry-mixed and pre-dispersed, then added to the conductive mixture described in step ②, and dispersed at a high speed using a double planetary high-speed disperser, and mixed evenly obtain a homogeneous mixture;

[0057] 4. With 2.3g, the styrene-butadiene rubber emulsion with a solid content of 40% is added to the homogeneous mixture described in step 3. After being uniformly dispersed at a high speed, a mixed slurry is obtained;

[0058] ⑤ adding pure water to the mixed slurry described in step ④, mix evenly, and after vacuum defoaming, the negative electrode slurry is obtained;

[0059]...

Embodiment 2

[0063] ①Dissolve 1.3g of suspending agent in pure water to prepare a uniform solution;

[0064] ② Add 0.5g Super P to the solution described in step ①, and mix well to obtain a conductive mixed solution;

[0065] ③ Take 2.0g, the gram capacity is 370Ah / g, the D50 is 3μm, and the BET is 20m 2 / g of highly anisometric flake graphite and 95g secondary granulated artificial graphite are dry-mixed and pre-dispersed, then added to the conductive mixture described in step ②, and dispersed at a high speed using a double planetary high-speed disperser, and mixed evenly to obtain homogeneous mixture;

[0066] 4. With 1.5g, the styrene-butadiene rubber emulsion with a solid content of 40% is added to the homogeneous mixture described in step 3. After being uniformly dispersed at a high speed, a mixed slurry is obtained;

[0067] ⑤ adding pure water to the mixed slurry described in step ④, mix evenly, and after vacuum defoaming, the negative electrode slurry is obtained;

[0068] ⑥Coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com