Preparation method of single-crystal lithium nickel manganese aluminate positive electrode material

A technology of nickel-manganese-aluminate and cathode materials, which is applied in the field of preparation of nickel-manganese lithium-aluminate cathode materials for single-crystal high-nickel cobalt-free lithium ion batteries, can solve the problem that cobalt is expensive, unfavorable for large-scale use and lack of resources. and other problems, to achieve the effect of improving safety and cycle performance, low cost and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

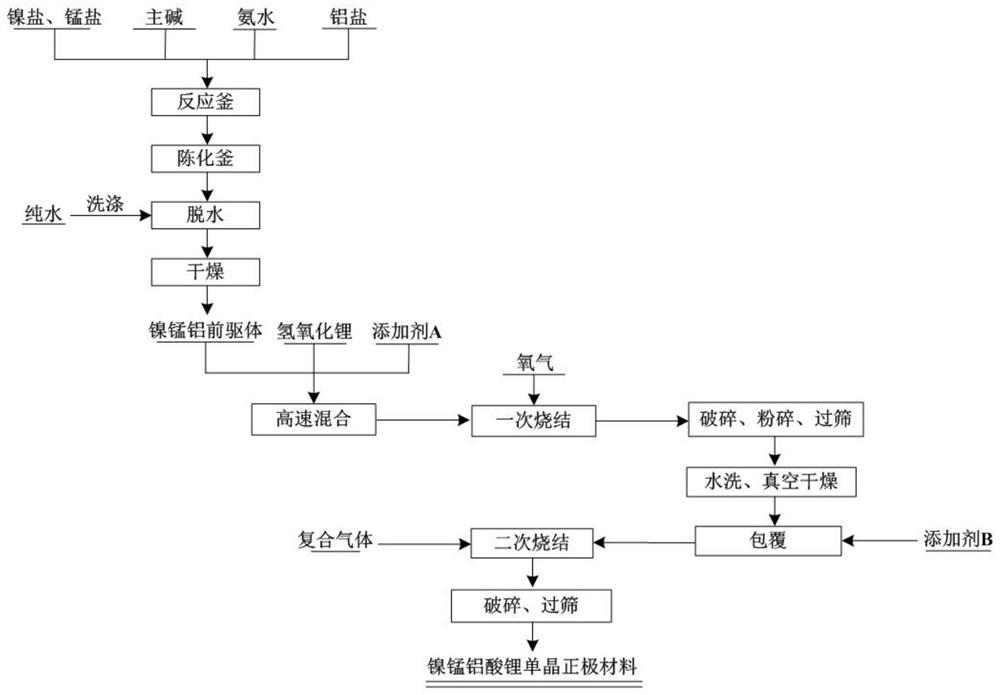

Method used

Image

Examples

Embodiment 1

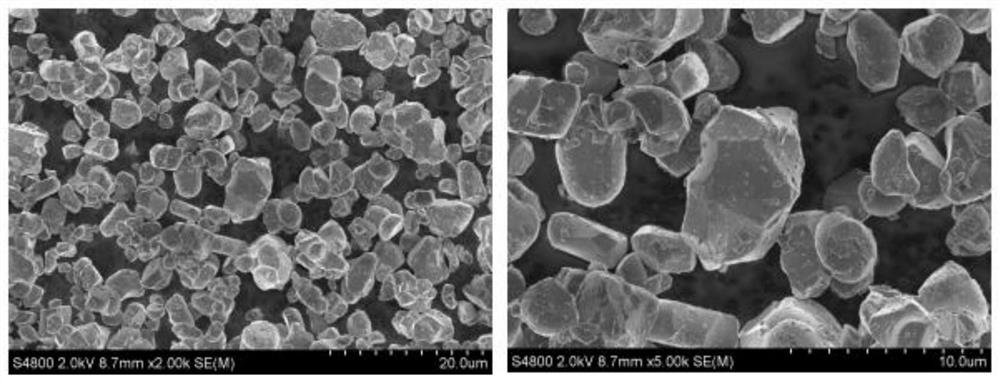

[0080] figure 2 Microscopic topography of the single crystal lithium nickel manganese aluminate cathode material in Example 1 of the present invention (Example 1);

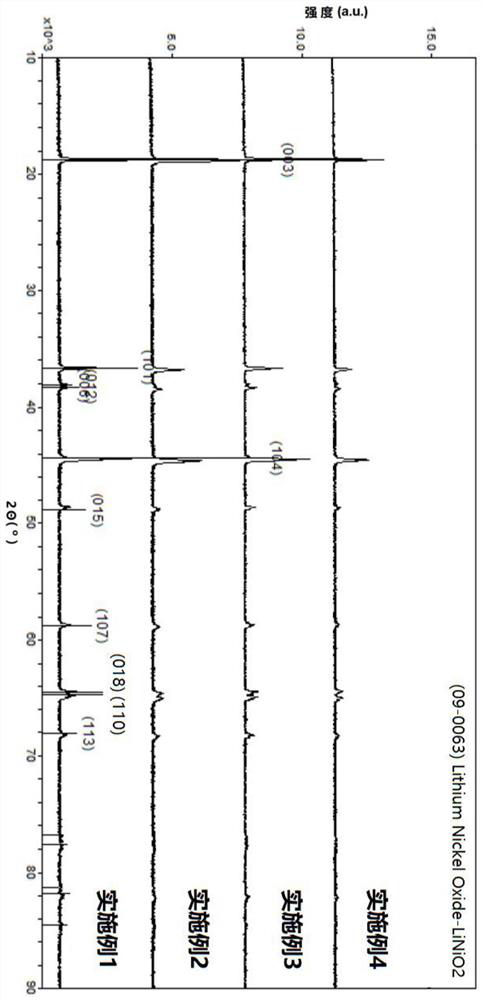

[0081] image 3 XRD diffractograms of the single crystal lithium nickel manganese aluminate cathode materials of Examples 1-4 of the present invention. Detailed ways

specific Embodiment approach

[0082] Example 1

[0083] According to the nickel ion:manganese ion:aluminum ion molar ratio of 0.85:0.1:0.05 solution, the total concentration of metal ions is 1.6mol / L; the concentration of NaOH solution: 5mol / L; the concentration of ammonia solution: 5mol / L; The three solutions were introduced into the reactor at the same time at 30L / h, 20L / h and 2L / h respectively, the pH value was controlled to be 11.2±0.2, the temperature was 50°C, and the reaction was continued for 48h. After aging, centrifugation, washing and drying respectively , to obtain the precursor material Ni with D50 of 3.4um 0.85 Mn 0.1 Al 0.05 (OH) 2 .

[0084] The D50 prepared above is 3.4um small particle ternary precursor material Ni 0.85 Mn 0.1 Al 0.05 (OH) 2 Lithium hydroxide powder and nano-zirconia were placed in a ball-milling jar, subjected to high-speed ball milling for 2 hours, and mixed uniformly; among them, the molar ratio of lithium: precursor metal element was 1.04, and the amount of zi...

Embodiment 2

[0087] The one-sintered single crystal matrix material LiNi after washing and drying in Example 1 0.85 Mn 0.1 Al 0.05 O 2 , mixed with nano-scale cobalt oxide, the amount of cobalt added in the total material is 2000ppmw, and then at V O2 : V CO2 = 1:1 atmosphere condition, carry out secondary sintering, the temperature is 500 ° C, the temperature is 500 ° C, the temperature is kept for 10 h, and the sieve is 400 mesh to obtain the single crystal positive electrode material LiNi 0.85 Mn 0.1 Al 0.05 O 2 ; Its important physical and chemical indicators are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com