Pearl-type three-dimensional flow guiding sleeve hole double-layer non-woven sanitary shell fabric

A technology for weaving hygienic and diversion sleeves, which is applied in the fields of medical science, clothing, underwear, etc., can solve the problems of rare disclosure of improved technologies, and achieve the effects of increasing the three-dimensional thickness, reducing the amount of re-infiltration, and preventing re-infiltration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

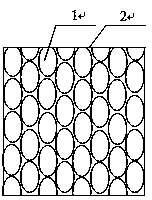

[0024] The invention is based on the hot-air non-woven fabric base cloth, after secondary processing, extruding heat-setting bumps through a mold to form a pearl shape, forming point contact with the diversion layer, and increasing the liquid storage space.

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

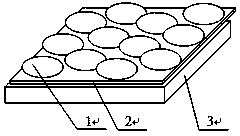

[0026] as attached figure 1 As shown: the upper side of the upper fabric base 2 is evenly distributed with pearl-shaped three-dimensional convex points 1, the lower part of the upper fabric base 2 has a diversion layer 3, the upper side of the upper fabric base 2 is made of fine denier fibers, and the upper fabric base 2 is made of high Fluffy fibers.

[0027] In the above, the production process of the upper fabric cloth base 2 adopts a double carding structure, using random carding on the upper side layer that contacts the skin, and random carding on the three-dimensional structure of the non-contact surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com