A modification method of precipitation white carbon black

A technology of precipitated white carbon black and white carbon black, applied in the direction of silica, silicon oxide, etc., can solve the problems of complex process, high cost, pollution, etc., and achieve the effect of simple equipment and process, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1) Combustion of hydrogen and oxygen at a volume ratio of 1:0.5 forms a high-temperature flame with a flame temperature of 2100°C.

[0017] 2) Precipitated silica enters the high-temperature flame through oxygen transport, and the ratio of carrier gas to silica powder feed is 1m 3 : 0.1kg, the residence time of silica powder in high temperature flame is 10 seconds.

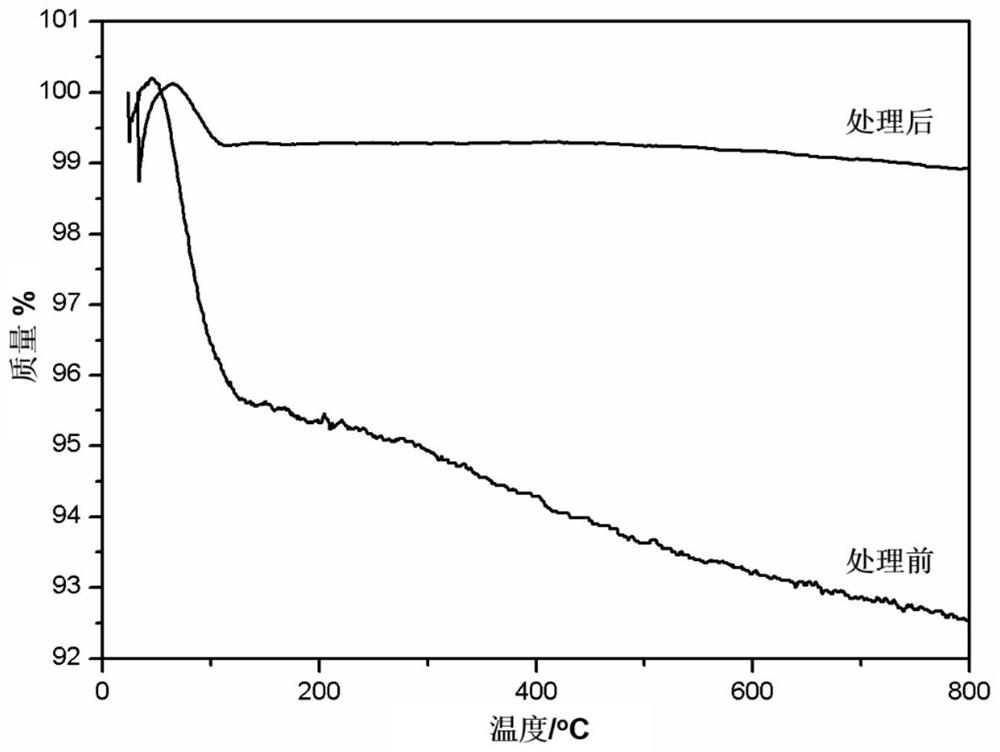

[0018] 3) the thermal gravimetric analysis figure of the white carbon black powder that this example obtains and original powder sees figure 1 ,Depend on figure 1 It can be seen that the water content of the treated white carbon black powder dropped from 7.5% to 1.2%.

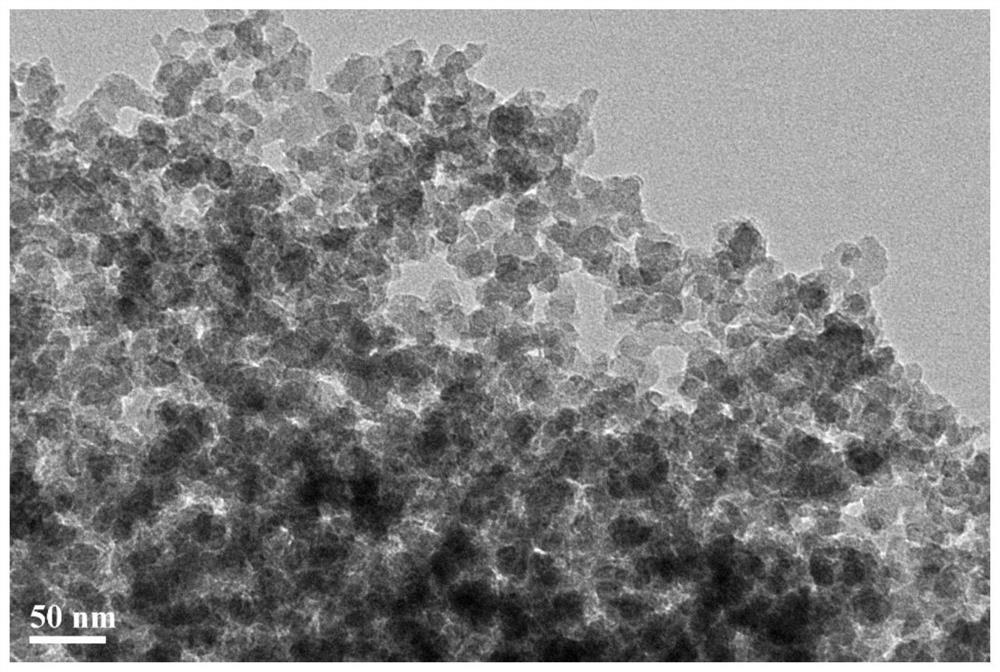

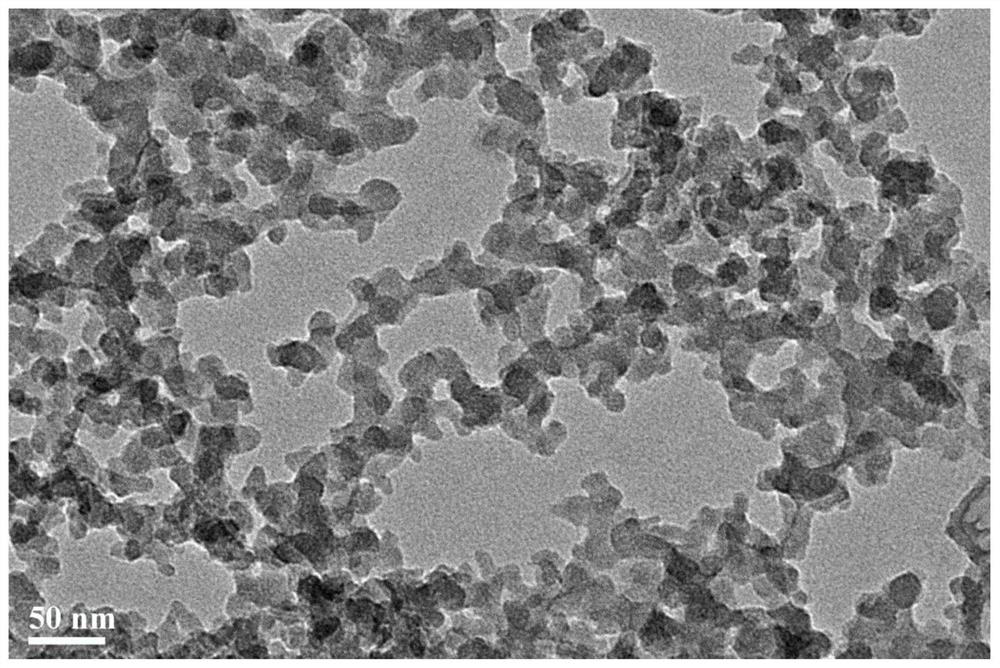

[0019] 4) The white carbon black powder that present embodiment obtains and the TEM figure of original powder see figure 2 and image 3 , it can be seen from the figure that this method can reduce the surface hydroxyl groups of precipitated silica through high-temperature flame treatment, reduce the force between particles, and improve ...

Embodiment 2

[0021] 1) Change the oxidant in Example 1 to air, change the volume ratio of hydrogen to air to 1:3, keep other parameters and steps unchanged, and the water content of the silica powder obtained in this example is 2.5%.

Embodiment 3

[0023] 2) Change the gaseous fuel into acetylene in embodiment 1, change the oxidant into air, change the volume ratio of acetylene and air into 1:10, change the residence time into 1 second, and other parameters and steps are all unchanged, and the present embodiment obtains The moisture content of the white carbon black powder is 4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com