Method for preparing environment-friendly cigarette tows

A technology for tow and tobacco, which is applied in the field of preparation of environmentally friendly tobacco tow, can solve the problems of non-compliance with global sustainable development and domestic conditions, poor adhesion, insufficient drying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

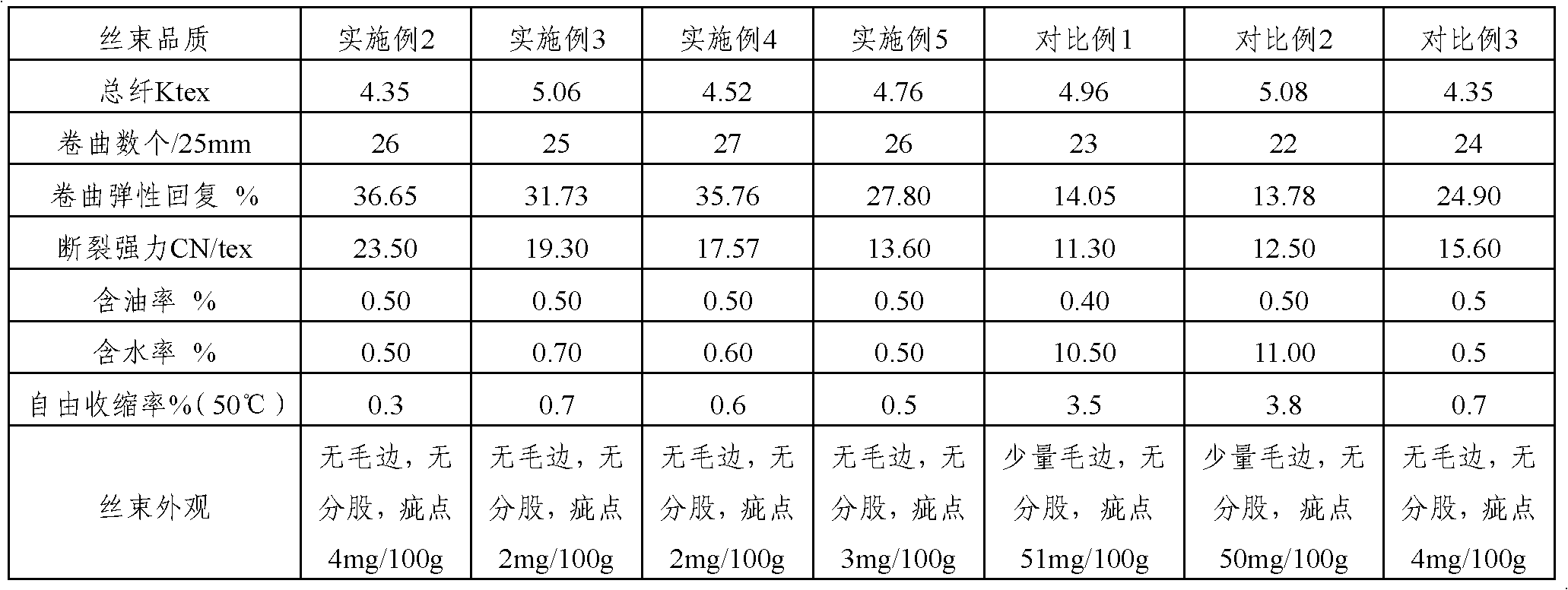

Examples

Embodiment 1

[0043] Embodiment 1: Process investigation of polylactic acid

[0044] First of all, it needs to be explained that the raw material polylactic acid of the present invention can be commercially available, preferably polylactic acid (wherein the dextrorotatory D component weight percentage is 0-3%), or polylactic acid (wherein the dextrorotatory D component weight percent 0-3% content) and other materials blends or copolymers (wherein the proportion of polylactic acid is higher than 70%wt).

[0045] In order to better design the polylactic acid tow preparation process, the characteristics of polylactic acid have been deeply studied.

[0046] 1. The relationship between the physical properties of polylactic acid and the content of dextrorotatory D component

[0047] The synthetic raw material of polylactic acid, lactic acid or intermediate lactide, has stereoisomerism, so polylactic acid should be a homopolymer of the same optically active monomer or a copolymer of different opt...

Embodiment 2

[0058] Embodiment 2: the preparation method of modified polylactic acid tow

[0059] 1. The raw material chips are polylactic acid (component D content is 1%wt), intrinsic viscosity is 1.53dl / g, melt index is 23.5g / 10min (210°C, 2160g), glass transition temperature is 62°C, and melting temperature is 170°C.

[0060] 2. The preparation process of tow is:

[0061] 1) Carry out stepwise heating and drying crystallization in the range of 70-110°C (heating rate 5°C / h, the temperature remains unchanged when the temperature reaches 110°C), the time is 12 hours, and the water content in the polymer is 70ppm;

[0062] 2) Melt spinning, the number of holes in the spinneret is 12000, the spinneret holes are trilobal, the temperature of the spinning screw is controlled at 235±1°C, the temperature of the box is 230±1°C, and the spinning speed is 65m / min , the roller is oiled, the roller speed is 16m / min, the oil concentration is 1%; the cooling air adopts inner ring radiation cooling, the...

Embodiment 3

[0067] Embodiment 3: the preparation method of polylactic acid tow

[0068] 1. The raw material slices are commercially available polylactic acid from Natureworks Company, the brand name is 6400D.

[0069] 2. The preparation process of tow is:

[0070] 1) Carry out stepwise heating and drying crystallization in the range of 50-90°C (heating rate 5°C / h, the temperature remains unchanged when the temperature reaches 90°C), the time is 18 hours, and the water content in the polymer is 85ppm;

[0071] 2) Melt spinning, the number of holes in the spinneret is 12000, the spinneret holes are trilobal, the temperature of the spinning screw is controlled at 225±1°C, the temperature of the box is 220±1°C, and the spinning speed is 65m / min , the roller is oiled, the roller speed is 16m / min, the oil concentration is 1%; the cooling air adopts inner ring radiation cooling, the cooling temperature is 18±1℃, and the wind pressure is 700Pa;

[0072] 3) Five rolls with drafting preheating at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com