Modified ternary positive electrode material as well as preparation method and application thereof

A positive electrode material and modification technology, applied in electrode manufacturing, chemical instruments and methods, electrical components, etc., can solve the loss of ternary material capacity and cycle performance, affect cycle performance, safety performance, Li/Ni cation mixing, etc. problems, achieving good cycle stability and interface behavior, inhibiting cation mixing, and high electrochemical reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

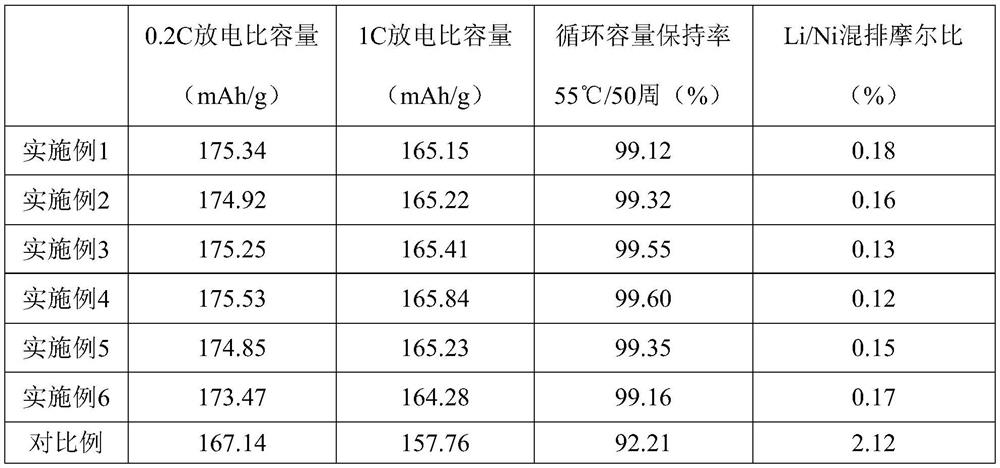

Examples

Embodiment 1

[0046] In this embodiment, the modified ternary cathode material is Cu 0.8 Ni 0.2 GaTe 2 Coating modified cathode material LiNi 0.6 co 0.2 mn 0.2 o 2 , and its specific preparation steps are as follows:

[0047] According to the element molar ratio of Cu:Ni:Ga:Te is 0.8:0.2:1:2, respectively weigh copper powder, nickel powder, gallium powder, tellurium powder, and disperse in absolute ethanol to obtain a solid content of 30%. the mixture one;

[0048] The obtained mixed solution was ball milled at 200rpm for 1h, dried at 90°C for 1h, and then calcined at 300°C for 6h to obtain Cu 0.8 Ni 0.2 GaTe 2 Precursor;

[0049] According to Li:Ni:Co:Mn element molar ratio is 1.01:0.6:0.2:0.2, respectively weigh lithium carbonate, nickel sulfate, cobalt sulfate, manganese sulfate, and disperse in dehydrated ethanol to obtain a solid content of 30% The mixture two;

[0050] Will Cu 0.8 Ni 0.2 GaTe 2 The precursor was added to the mixed solution 2 (Cu 0.8 Ni 0.2 GaTe 2 The...

Embodiment 2

[0052] In this embodiment, the modified ternary cathode material is Cu 0.85 Ni 0.15 GaTe 2 Coating modified cathode material LiNi 0.6 co 0.2 mn 0.2 o 2 , and its specific preparation steps are as follows:

[0053] According to the element molar ratio of Cu:Ni:Ga:Te is 0.85:0.15:1:2, copper chloride, nickel sulfate, gallium powder, tellurium powder were weighed respectively, and dispersed in absolute ethanol to obtain a solid content of 35 % of mixed solution one;

[0054] Disperse the mixed solution by ball milling at 250rpm for 5h, dry at 95°C for 2h, and pre-calcine at 400°C for 8h to obtain Cu 0.85 Ni 0.15 GaTe 2 Precursor;

[0055] According to Li:Ni:Co:Mn element molar ratio is 1.01:0.6:0.2:0.2, respectively weigh lithium hydroxide, nickel chloride, cobalt sulfate, manganese chloride, and disperse in dehydrated ethanol to obtain the solid content 38% mixed solution II;

[0056] Will Cu 0.85 Ni 0.15 GaTe 2 The precursor was added to the mixed solution 2 (the...

Embodiment 3

[0058] In this example, the modified ternary cathode material is Cu 0.9 Ni 0.1 GaTe 2 Coating modified cathode material LiNi 0.6 co 0.2 mn 0.2 o 2 , and its specific preparation steps are as follows:

[0059] According to the elemental molar ratio of Cu:Ni:Ga:Te is 0.9:1:1:2, copper powder, nickel chloride, gallium powder, tellurium powder were weighed respectively, and dispersed in absolute ethanol to obtain a solid content of 45 % of mixed solution one;

[0060] Disperse the obtained mixture by ball milling at 300rpm for 5h, dry at 100°C for 2h, and pre-calcine at 500°C for 10h to obtain Cu 0.9 Ni 0.1 GaTe 2 Precursor;

[0061] Press Li:Ni:Co:Mn element molar ratio is 1.01:0.6:0.2:0.2, take lithium chloride, nickel chloride, cobalt sulfate, manganese nitrate respectively, and disperse in dehydrated alcohol, obtain solid content as 40% mixture II;

[0062] Will Cu 0.9 Ni 0.1 GaTe 2 The precursor was added to the mixed solution 2 (the mass ratio of the two was 0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com