Dual-cavity type solar driven carbonaceous material reaction method and apparatus

A reaction device and solar energy technology, which is applied in the field of solar thermochemistry, can solve the problems of high energy consumption and inability to store solar energy, and achieve the effects of reducing pollution, overcoming uneven and variable focusing spots, and avoiding high temperature sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

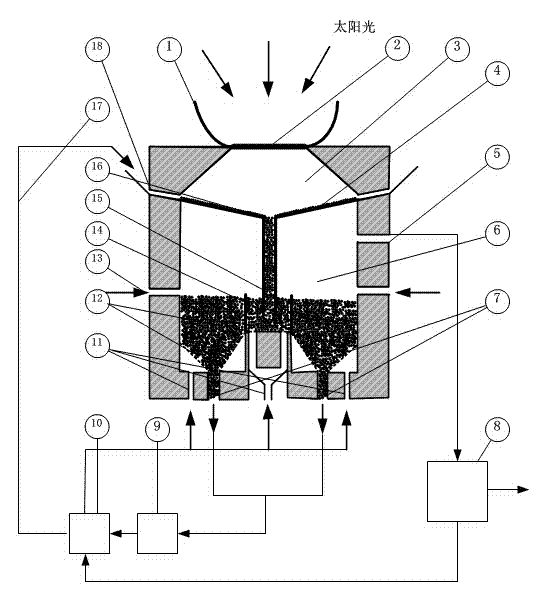

[0021] The dual -cavity solar drive coal reaction device of this embodiment is figure 1The device is shown in the composite parabola, the glass cover, the glass cover, the light -absorbing cavity, the segmentation plate surface, the gas exit, the reaction cavity, the solid exit, the catalytic treatment system of the gas product product, Specifies, pneumatic tubes, pneumatic boxes, exports of downstream pipes, imports in the falling pipe, enhanced pipe pipe, and the inlet of the light -absorbing cavity particles.Among them, the beam after focusing and spanning is focused on the composite parabolic surface concentor, and the glass lid is entered into the light absorption cavity.The box is connected to the reaction cavity, the exit of the reactor solid product is connected to the entrance of the combustion chamber, the exit of the combustion room is connected to the entrance of the heat exchanger, and the heat exchanger export is connected to the entrance of the light -absorbing soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com