Chain type hydrogen and oxygen production integrated method and device

A chain and oxidation reaction technology, applied in chemical instruments and methods, hydrogen, iron compounds, etc., can solve the problems of high energy consumption, purity, long construction period, complicated operation, etc., and achieve the effect of wide distribution, low price and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

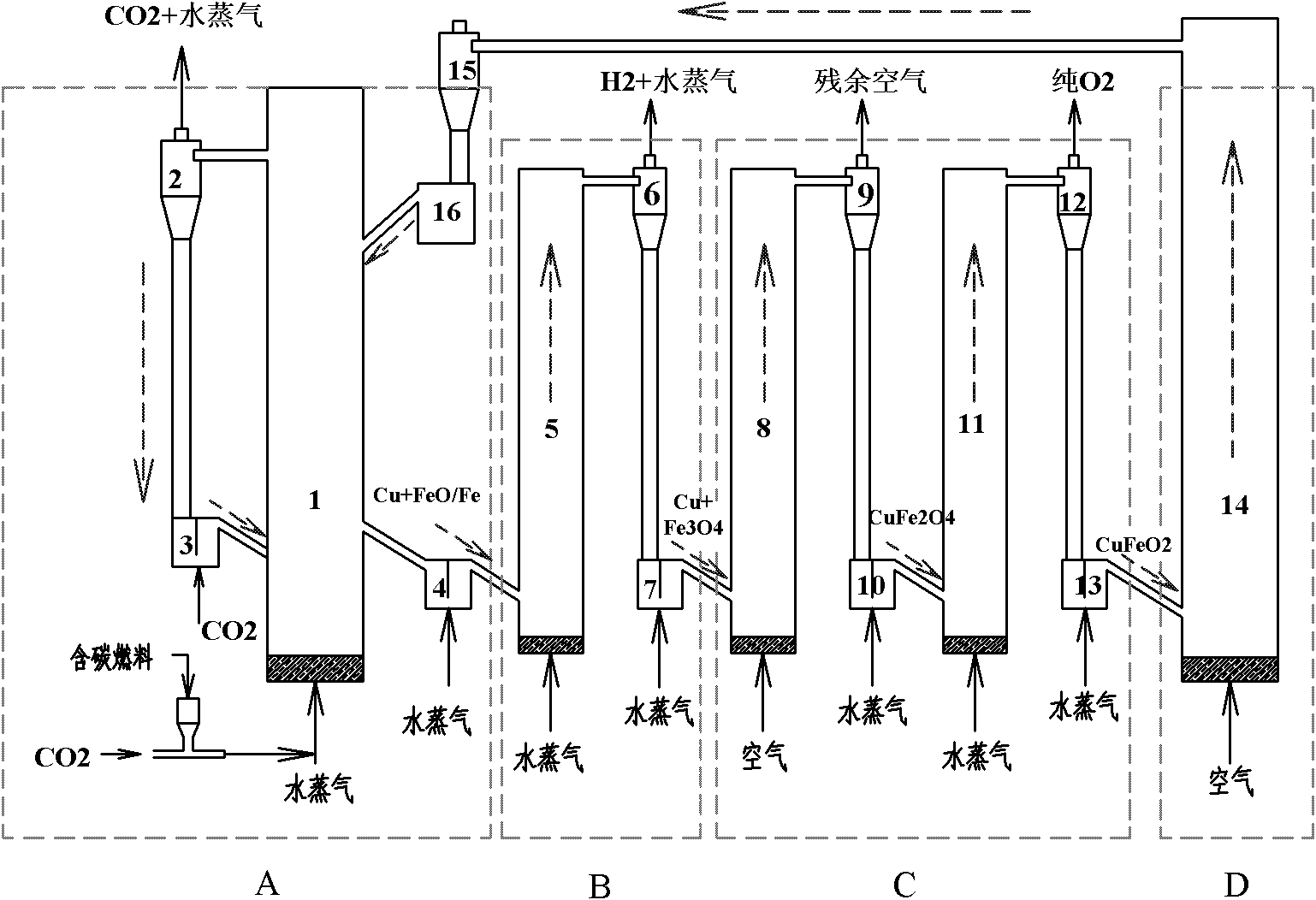

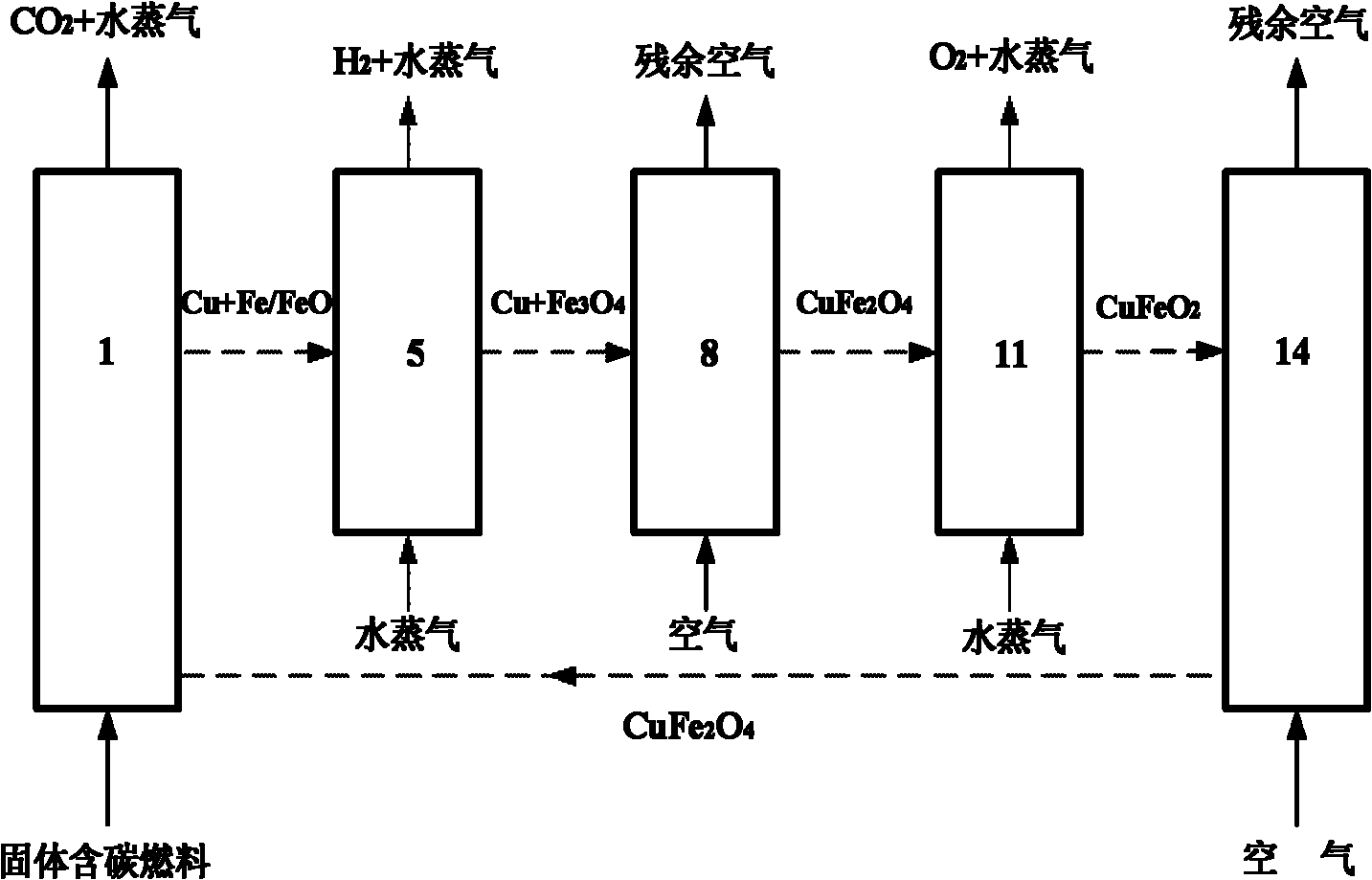

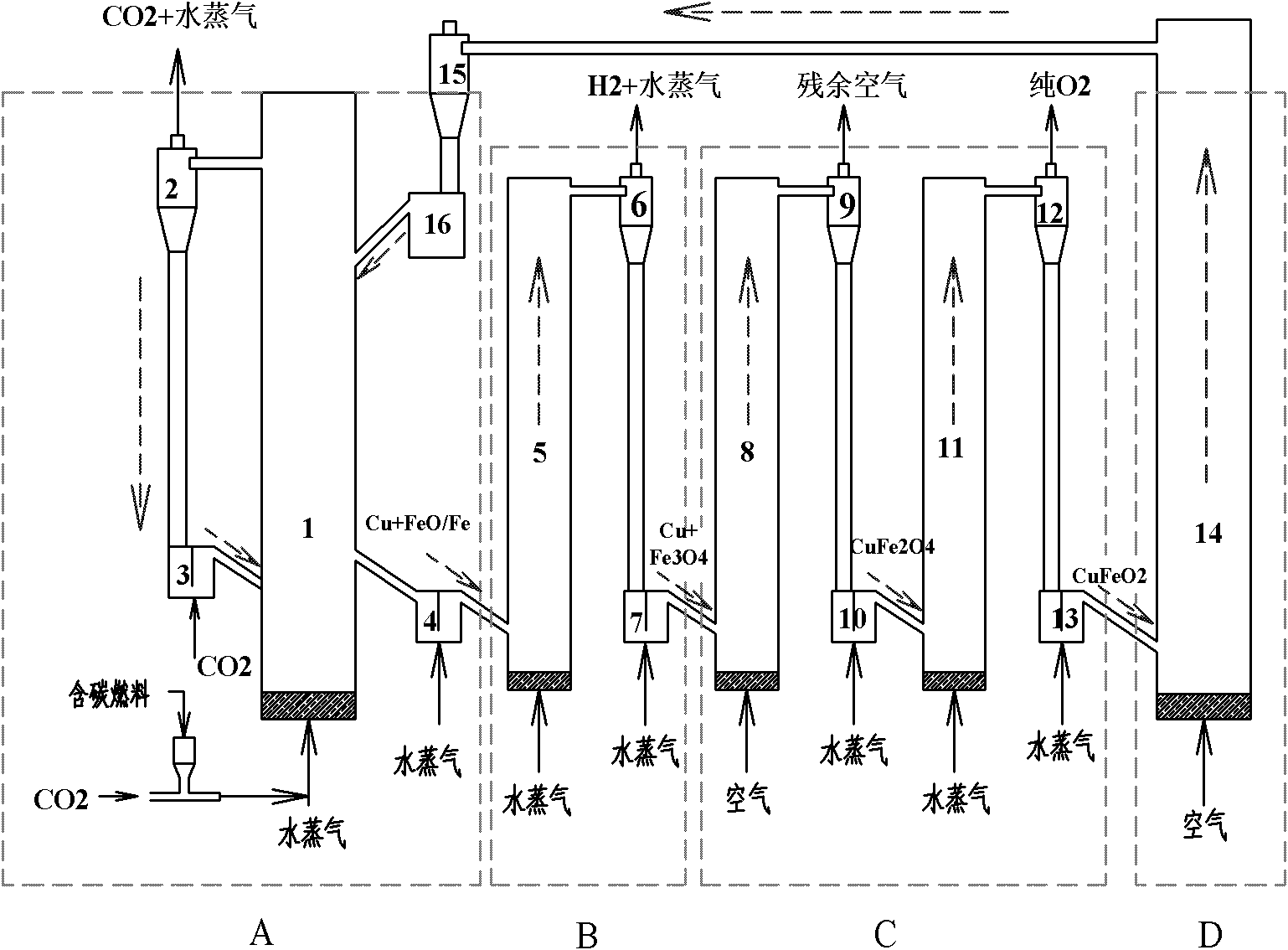

[0054] The chain-type hydrogen and oxygen production integrated device proposed by the present invention, such as structure figure 1 As shown, the oxygen carrier reduction reactor system A is composed of the bubbling bed reduction reactor 1, the cyclone separator 2 for separating the oxygen carrier fine powder and its coke particles, the sealing valve 3 and the sealing valve 4; The hydrogen reactor 5, the cyclone separator 6 and the sealing valve 7 form the hydrogen production system B; furthermore, the bubbling bed primary oxygen production reactor 8, the cyclone separator 9, the sealing valve 10, and the bubbling bed secondary oxygen production reactor 11. The cyclone separator 12 and the sealing valve 13 form the oxygen production system C; finally, the fast fluidized bed air reactor 14, the cyclone separator 15 and the sealing valve 16 form the oxygen carrier regeneration system.

[0055] In view of the residual coke and CuFe remaining after the gasification of carbon-cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com