Method for preparing graphene

A graphene and atmosphere technology, applied in the field of graphene preparation, can solve problems such as unsolved problems, and achieve the effects of easy operation and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

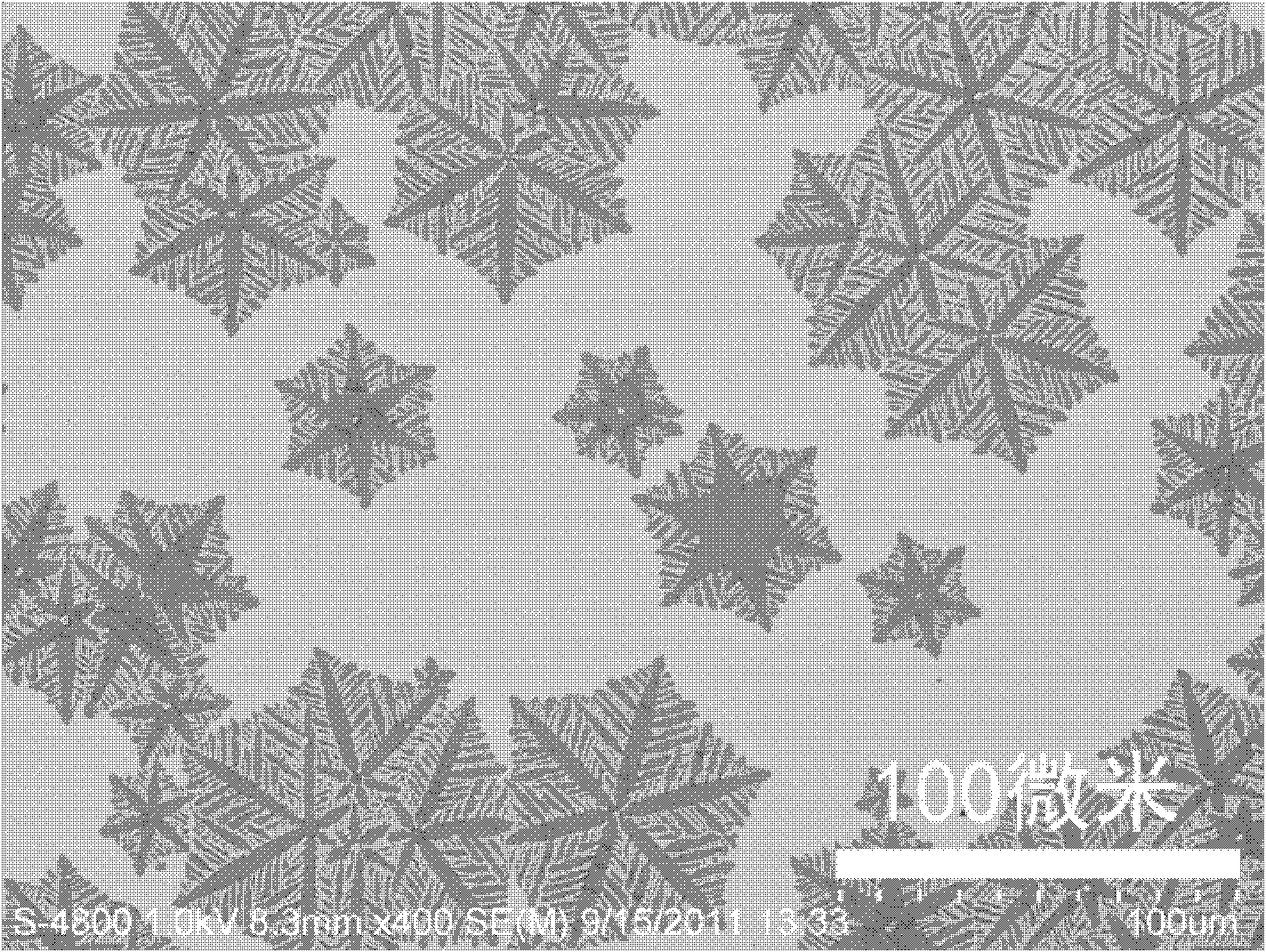

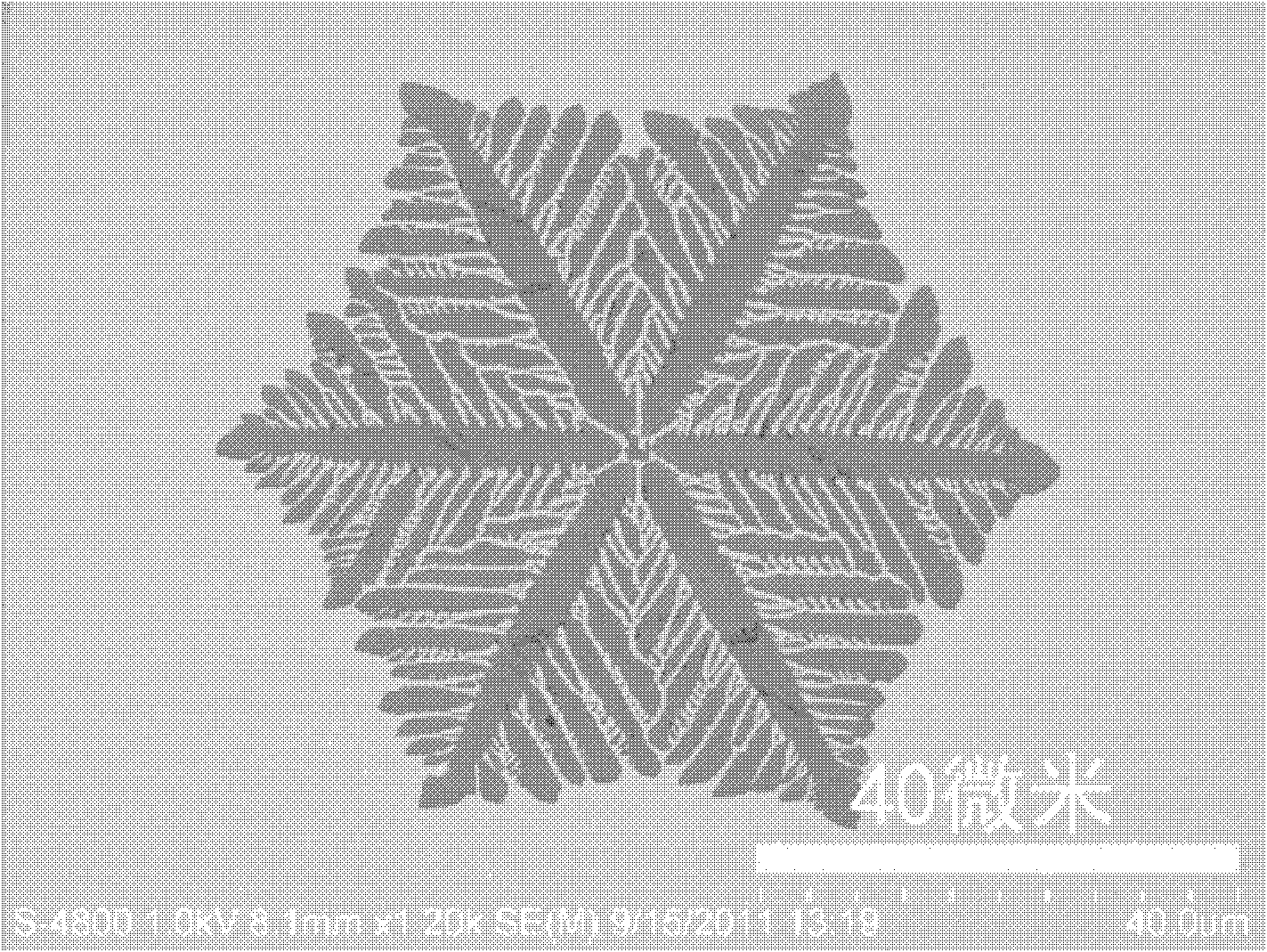

[0030] Embodiment 1, the preparation of the graphene of dendritic morphology

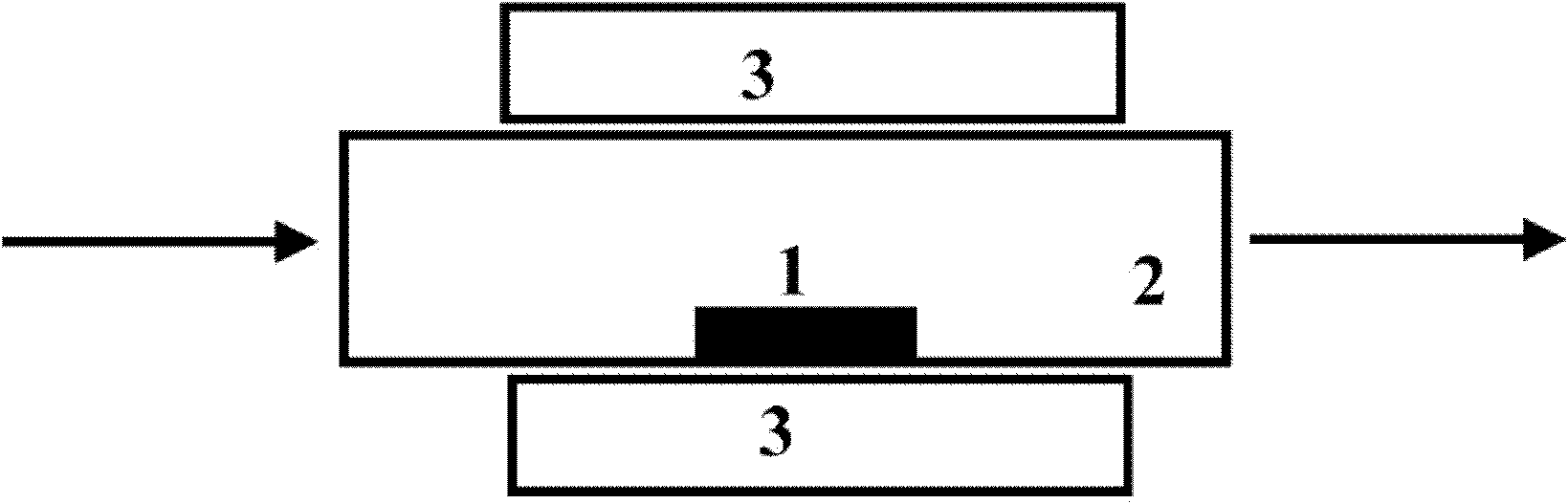

[0031] Commercial 25um thick copper foil (purity 99.8%) was ultrasonically cleaned with deionized water, ethanol and acetone and dried in an oven. The tungsten substrate loaded with the above copper foil was placed in the middle of a clean quartz tube, and the quartz tube was placed Put it into the electric furnace, make the middle part of the quartz tube located in the central area of the electric furnace, then pass 120 sccm of argon gas into the quartz tube, and stop feeding the argon gas after 5-10 minutes. Turn on the vacuum pump to start vacuuming. When the pressure in the reaction chamber is 3 to 10 Pa, turn off the vacuum pump, and then feed the mixed gas of 100 sccm of argon and 300 sccm of hydrogen until the pressure in the reaction chamber is consistent with the external atmospheric pressure, and then stop feeding the argon. Only use 300sccm hydrogen as the carrier gas. After 10 minutes ...

Embodiment 2

[0033] Embodiment 2, the preparation of petal-shaped graphene

[0034] According to the same preparation method as in Example 1, only the following changes were made: the tungsten substrate was replaced by a molybdenum substrate, and when the temperature in the central area of the electric furnace reached 1080°C, the amount of methane and argon gas introduced remained unchanged, and the hydrogen flow rate was adjusted to 20 sccm. The time is 7 minutes.

[0035] The scanning electron micrograph of the obtained product is as Figure 6 As shown, it can be seen from the figure that a petal-shaped substance is uniformly distributed on the copper surface, and the substance is graphene.

Embodiment 3

[0036] Embodiment 3, the preparation of gear-shaped graphene

[0037] According to the same preparation method as in Example 1, only the following changes were made: the hydrogen flow rate was adjusted to 60 sccm during growth, and the reaction time was 15 min.

[0038] The scanning electron micrograph of the obtained product is as Figure 7 As shown, it can be seen from the figure that the gear-like substance is uniformly distributed on the copper surface, and the substance is graphene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com