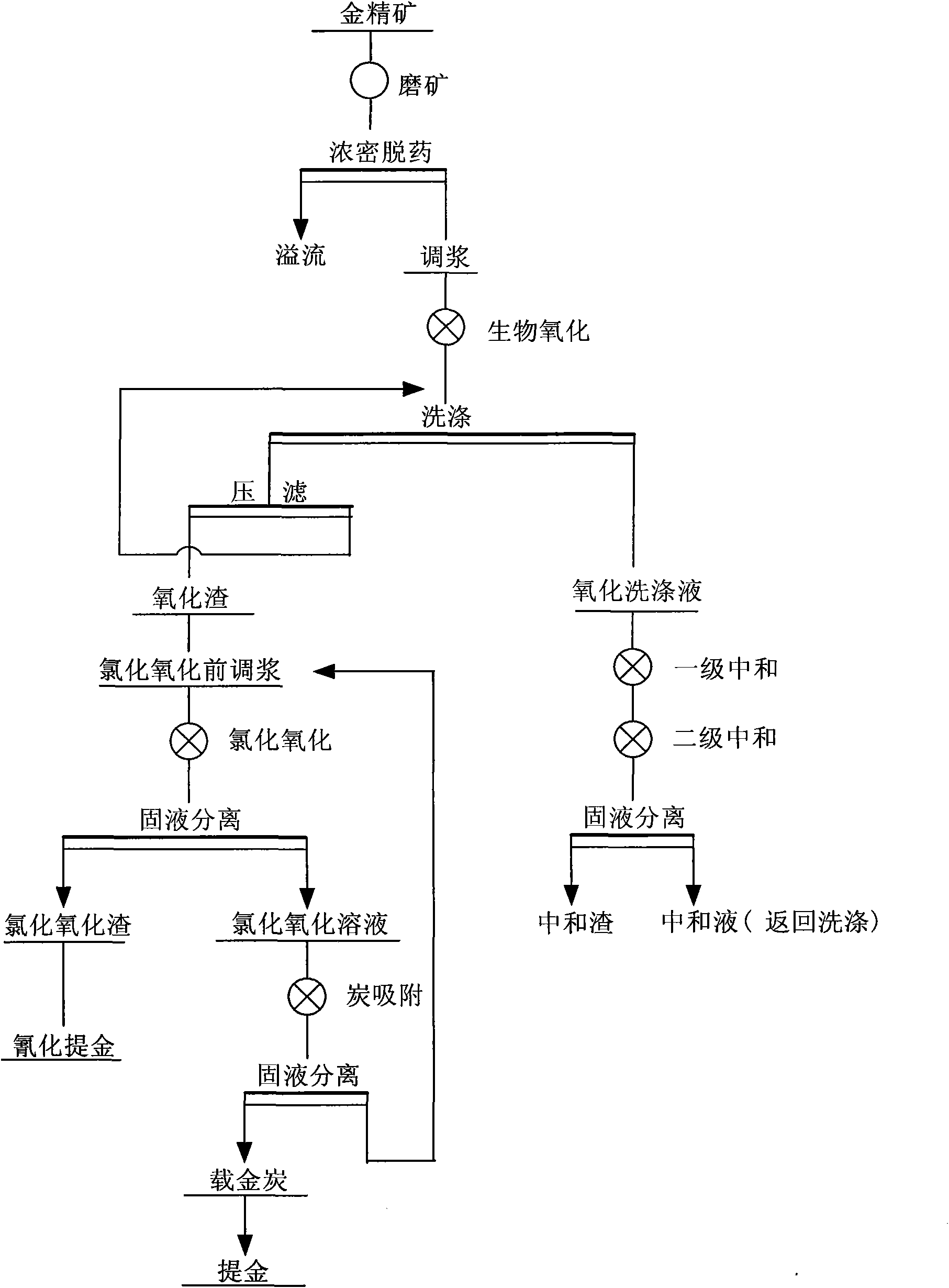

Secondary oxidation pretreatment process for arsenic, sulphur and carbon-containing difficultly treated gold concentrate

A technology of refractory gold and secondary oxidation, which is applied in the direction of improving process efficiency, can solve the problems of robbery carbon substances affecting cyanidation and gold extraction, etc., to achieve strong adaptability of ore, strengthen gold leaching effect, and expand the application of ore. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0030] A refractory gold concentrate, the multi-element analysis of the ore is shown in Table 1.

[0031] Table 1 Multi-element analysis results

[0032] element

Au(g / t)

Ag(g / t)

Cu

Pb

Zn

Fe

S

content(%)

33.08

8.80

0.063

0.046

0.12

15.72

12.99

element

Sb

As

C

CaO

MgO

SiO 2

Al 2 o 3

content(%)

0.05

4.82

2.86

6.31

2.09

37.18

6.32

[0033] The metal minerals in the mine are mainly pyrite and arsenopyrite, the contents of which are 22.04% and 10.79% respectively. The carbonate content in the concentrate is 17.33%. The gold particle size is relatively fine, the gold smaller than 0.01mm accounts for 96.98%, and the gold smaller than 0.005mm accounts for 49.56%. Gold is very closely related to metal sulfides, and mostly occurs in sulfides, accounting for 74.46% of the gold content. The concentrate contains 0.61% org...

Embodiment 1

[0036] Step 1: Concentrate regrinding and drug removal:

[0037] The flotation concentrate is finely ground, and the grinding fineness is less than 0.045mm, and the particle size content is 95%, and the concentration of the pulp is 30% after dense chemical removal, so as to reduce the residual flotation agent in the concentrate;

[0038] Step 2: Biooxidation:

[0039] (1) Concentrate pulping: add biological culture medium 3kg / t and water to the gold concentrate after regrinding and drug removal, and adjust the pulp concentration to 20%;

[0040] (2) Biological oxidation: After the concentrate is mixed, it is fed into the biological oxidation tank. The oxidation system is inoculated with chemoautotrophic bacteria such as Thiobacillus ferrooxidans and Thiobacillus thiooxidans. 1~2, inflating and stirring, dissolved oxygen 3~5mg / l, the concentrated ore is oxidized under the action of microorganisms for 4 days, the secondary oxidation is 2 days, and the total oxidation time is 6 ...

Embodiment 2

[0052] Example 1 was repeated according to the same steps described above, but the difference was that the pH value of the slurry prepared by oxidation slag in the chlorination and oxidation operation was 1.5, which was close to the conditions for performing biological oxidation.

[0053] In Example 2, the removal rate of arsenic after biological oxidation was 77.24%, the removal rate of iron was 67.54%, the removal rate of sulfur was 91.09%, the gold grade in the oxidation residue was 37.76g / t, and the carbon leaching rate was 88.58%, the total gold leaching rate is 91.46% after the biological oxidation slag is chlorinated and oxidized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com