Preparation method of doped graphene

A graphene and substrate technology, which is applied in the field of graphene preparation by chemical vapor deposition, can solve the problems of high oxygen content in the sample and increase the complexity of the process, and achieve simple process and equipment, easy control of nitrogen doping amount, simple and feasible operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

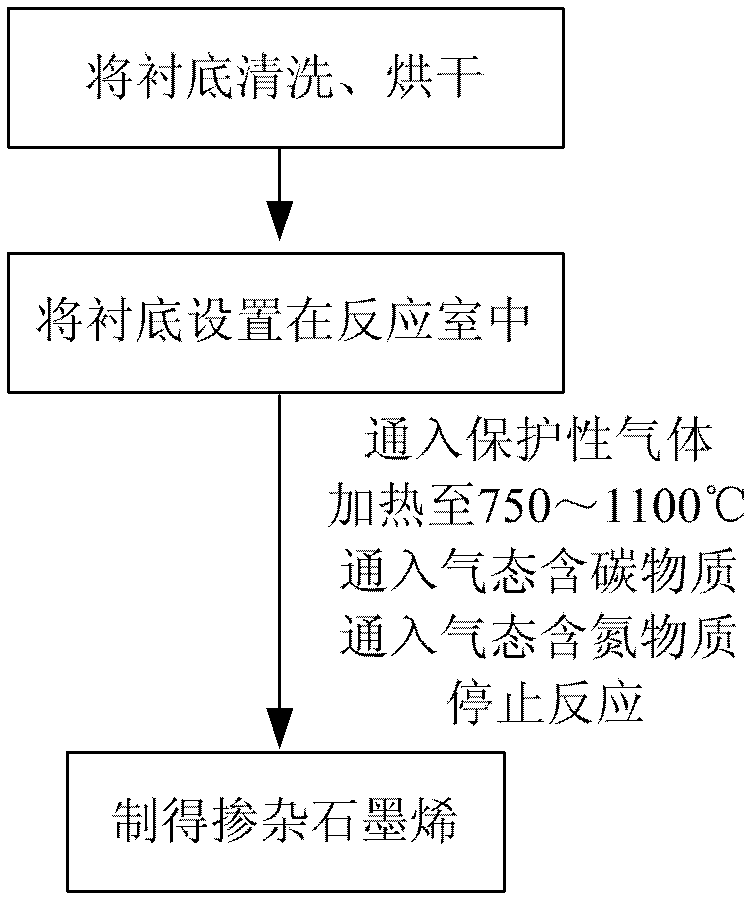

[0026] A kind of preparation method of doped graphene provided by the present embodiment, such as figure 1 shown, including the following steps:

[0027] (1) drying the metal substrate after cleaning;

[0028] (2) Place the dried substrate in the reaction chamber, and pass a protective gas with a flow rate of 10 to 1000 sccm into the reaction chamber, and keep it for 1 to 60 minutes;

[0029] (3) Subsequently, the reaction chamber is heated to 750-1100° C., and gaseous carbon-containing substances with an air flow rate of 20-1000 sccm and gaseous nitrogen-containing substances with an air flow rate of 10-200 sccm are introduced to react, and the C:N atomic ratio is 2 ~20:1, keep the reaction for 1~300 minutes;

[0030] (4) After the reaction is completed, stop feeding gaseous carbon-containing substances and gaseous nitrogen-containing substances, and stop heating the substrate, stop feeding protective gas after cooling to room temperature, and prepare doped graphene on the ...

Embodiment 1

[0044] A preparation method of doped graphene, comprising the following steps:

[0045] (1) Carry out ultrasonic cleaning to iron foil with deionized water, ethanol and acetone successively and dry;

[0046] (2) The iron foil after drying is arranged in the reaction chamber, and the hydrogen gas with a flow rate of 100ccm is introduced into the reaction chamber, and kept for 50 minutes;

[0047] (3) Subsequently, the reaction chamber was heated to 1100° C., and the methane gas flow rate of 20 sccm and the ammonia gas gas flow rate of 10 sccm were introduced to react, and the gas flow time was maintained for 60 minutes;

[0048] (4) After the reaction is completed, stop feeding methane and ammonia, and stop heating the iron foil, stop feeding hydrogen after cooling to room temperature, and prepare doped graphene on the surface of the iron foil.

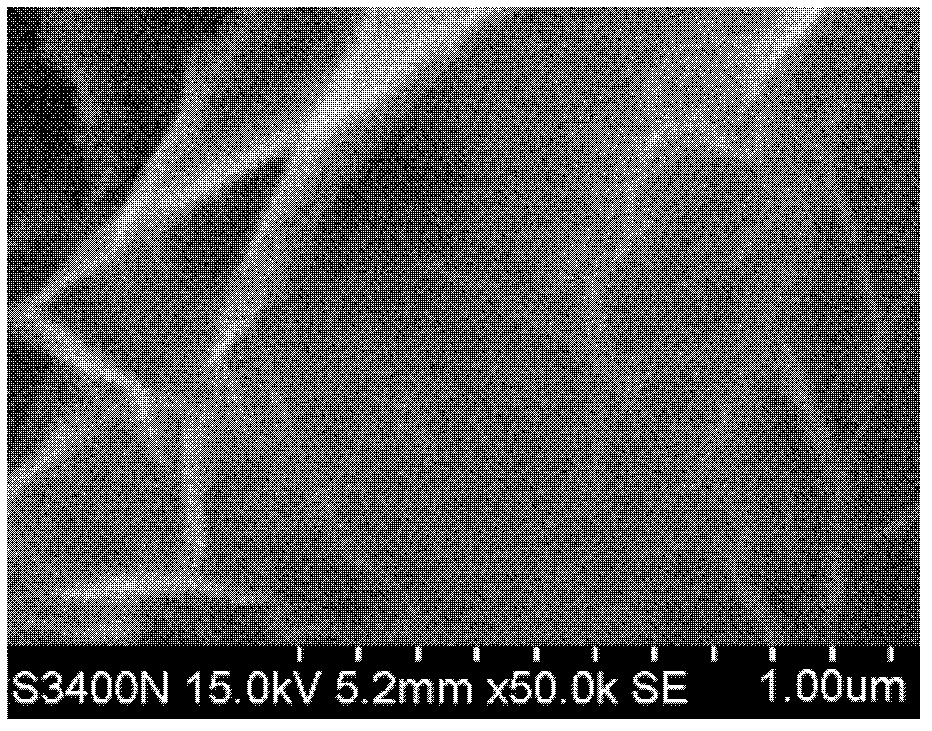

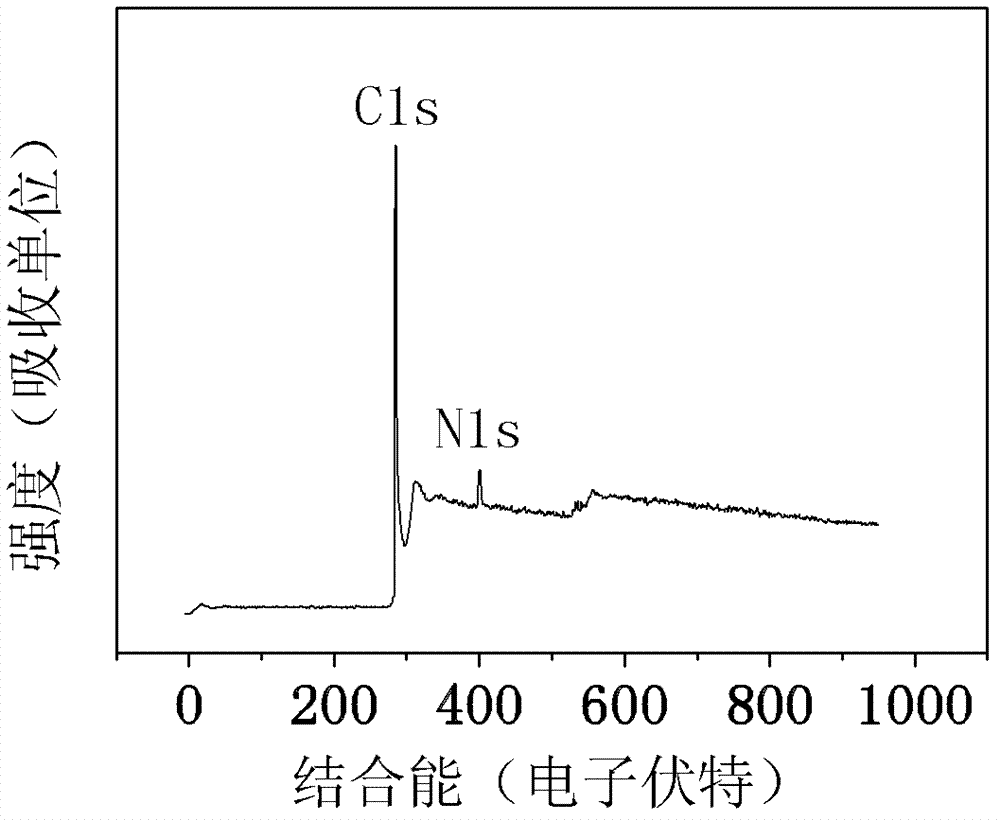

[0049] figure 2 For the SEM picture of the nitrogen-doped graphene prepared in embodiment 1, from figure 2 It can be clearly see...

Embodiment 2

[0052] A preparation method of doped graphene, comprising the following steps:

[0053] (1) Ultrasonic cleaning of cobalt foil with deionized water, ethanol and acetone followed by drying;

[0054] (2) The dried cobalt foil is arranged in the reaction chamber, and the argon gas with a gas flow rate of 1000 sccm is introduced into the reaction chamber and kept for 1 minute;

[0055](3) Subsequently, the reaction chamber is heated to 900° C., and the acetylene with an air flow rate of 200 sccm and the methylamine with an air flow rate of 40 sccm are introduced to react, and the aeration time is kept for 30 minutes;

[0056] (4) After the reaction is completed, stop feeding acetylene and methylamine, and stop heating the cobalt foil, stop feeding argon after cooling to room temperature, and prepare doped graphene on the surface of the cobalt foil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com