Multi-disc concentration equipment of papermaking system

The technology of an equipment and a thickening device is applied in the field of multi-disc thickening equipment in a papermaking system, which can solve the problems that the pulp can not meet the thickening requirements, the utilization rate of the receiving box is poor, the pulp is inconvenient to clean, etc. The effect of cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

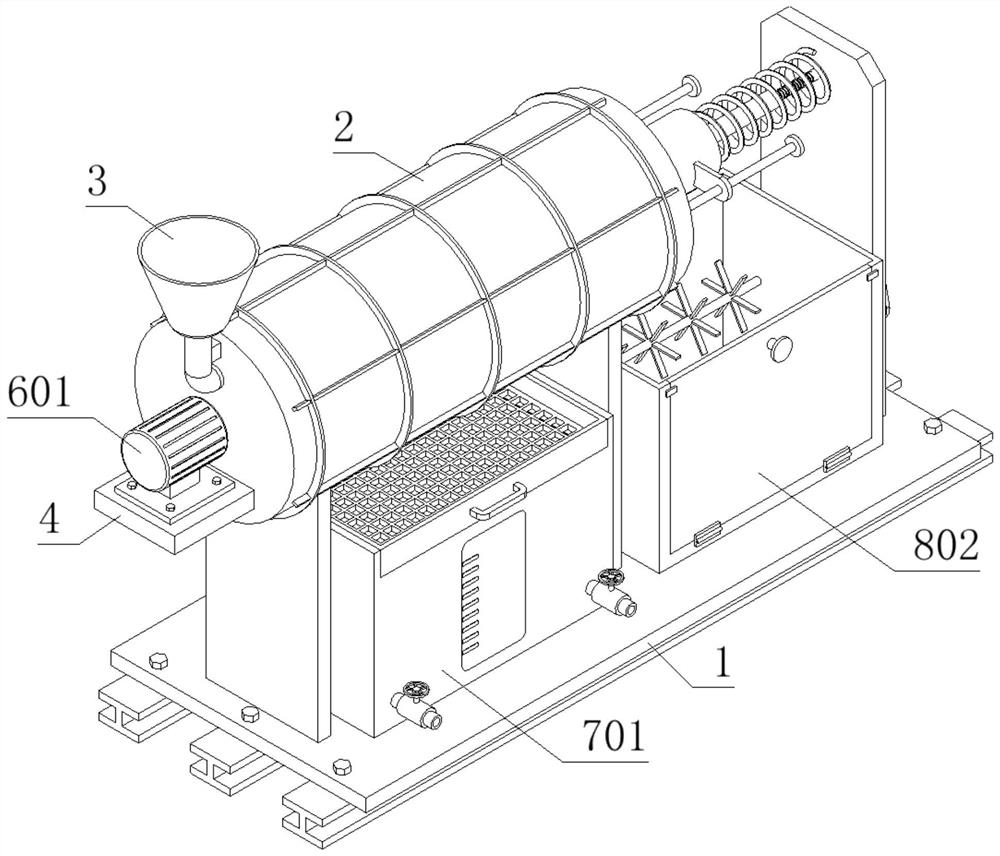

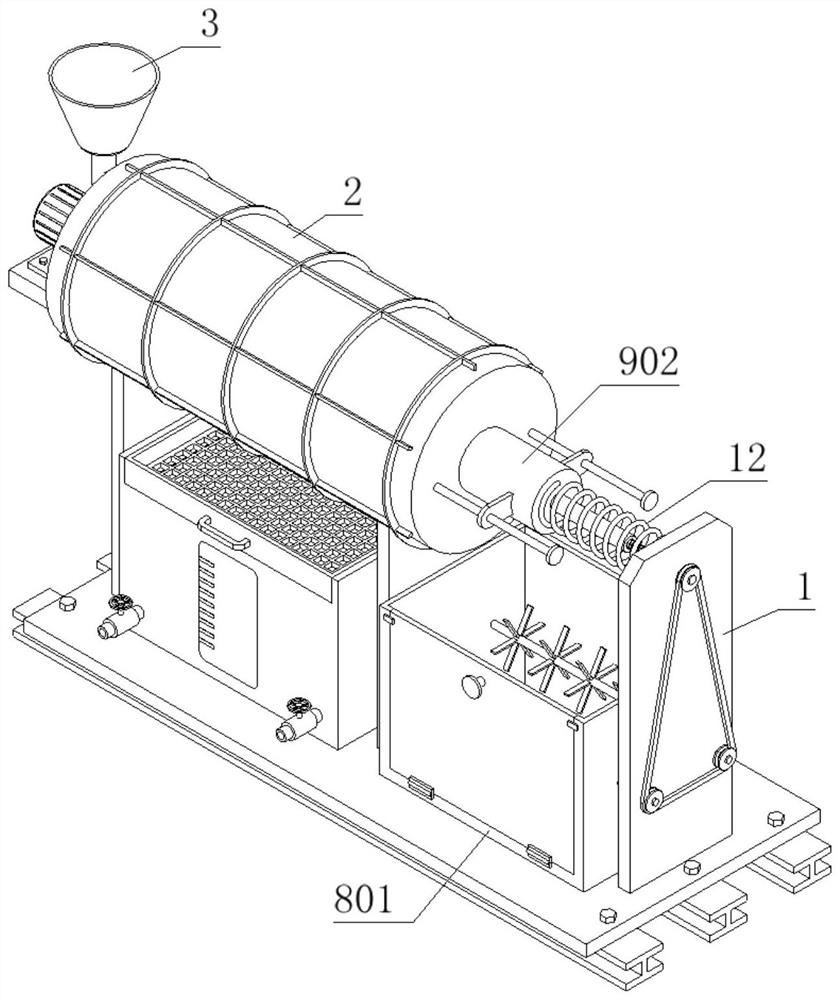

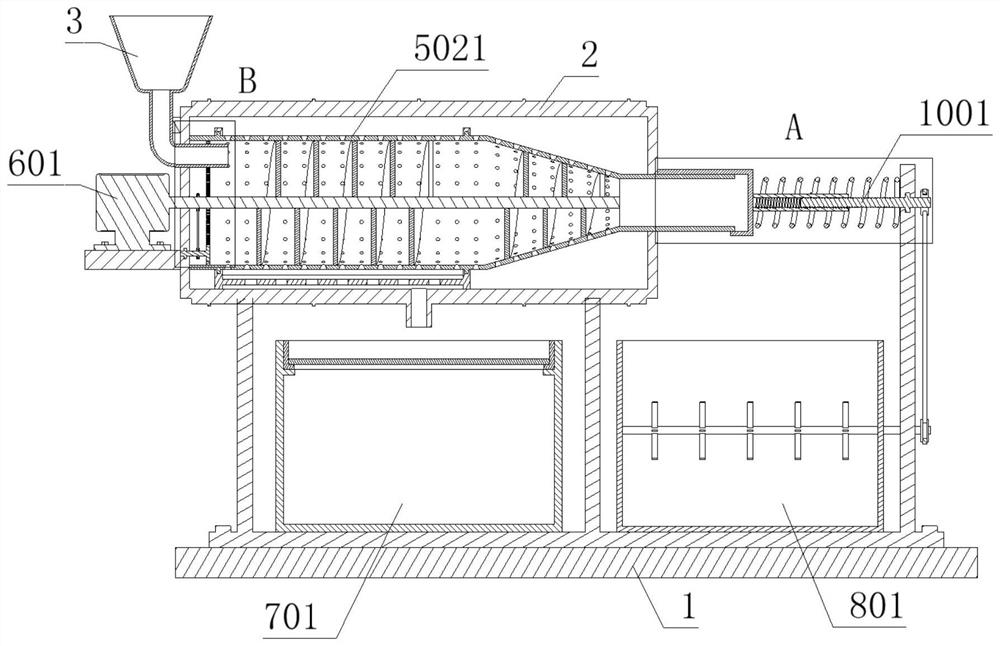

[0084] as attached figure 1 to attach Figure 12 Shown:

[0085] The present invention provides a papermaking system multi-disk thickening equipment, including a base 1;

[0086] A cylinder 2 is fixedly installed on the top of the base 1, and a mounting plate 4 is fixedly installed on the left side of the base 1; a feed port 3 is fixedly mounted on the left side of the base 1, and the feed port 3 is located above the mounting plate 4;

[0087] Concentration device 5, the concentration device 5 is installed inside the cylinder 2;

[0088] A deflector 6, the deflector 6 is installed on the top of the mounting plate 4, and the right side of the deflector 6 is located inside the enrichment device 5;

[0089] A collection device 7, the collection device 7 is installed on the top left side of the base 1, and a material receiving device 8 is installed on the top right side of the base 1;

[0090] A stopper device 9, the stopper device 9 is installed on the right side of the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com