Iso-floatable separation process of siliceous-calcareous collophanite

A technology of collophosite and silicon-calcium, which is applied in the field of flotation separation technology, can solve the problems of large flotation capacity, high consumption and large alkali consumption in flotation, and achieve the reduction of collector and acid consumption, The effect of excellent process index and high concentrate quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

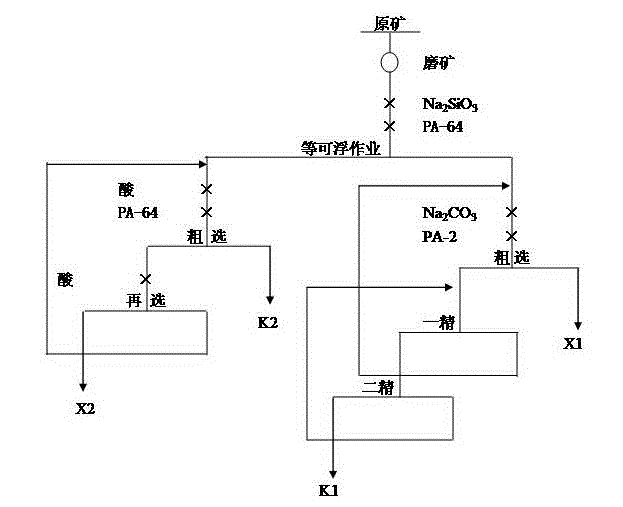

Image

Examples

Embodiment 1

[0021] Embodiment 1, a kind of flotation separation process such as siliceous calcareous colloidal phosphate rock, its steps are as follows:

[0022] The siliceous-calcium colloidal phosphate ore is crushed and ground to dissociate the mineral monomers, add water to adjust the slurry to a mass concentration of 20%, and then flow into the stirring tank, and then add 3kg / t to the slurry. Raw ore adjuster sodium silicate and reverse flotation collector PA-64 with an amount of 0.5 kg / t raw ore are used for pulping, and the materials after pulping are put into other flotation operations for minerals and other flotation flotation, containing carbonate Gangue minerals and a part of phosphorus minerals enter the flotation froth;

[0023] The flotation foam flows into the reverse flotation stirring tank, and the reverse flotation regulator inorganic acid with the dosage of 3 kg / t raw ore and the reverse flotation collector PA-64 with the dosage of 0.5 kg / t raw ore are added to it for a...

Embodiment 2

[0025] Embodiment 2, a kind of flotation separation process such as siliceous calcareous collophosphine, its steps are as follows:

[0026] The siliceous-calcium colloid ore is crushed and ground to dissociate the constituent mineral monomers, and water is added to adjust the slurry to a mass concentration of 40%, and then flowed into the stirring tank, and then added to the slurry in an amount of 10 kg / The adjustment agent water glass of t raw ore and the reverse flotation collector PA-64 with an amount of 2.0 kg / t raw ore are used for pulping. Gangue minerals and a part of phosphorus minerals enter the flotation froth;

[0027] The flotation foam flows into the reverse flotation stirring tank, and the reverse flotation regulator inorganic acid with the dosage of 10 kg / t raw ore and the reverse flotation collector PA-64 with the dosage of 2.0 kg / t raw ore are added to it for adjustment. Slurry, the inorganic acid sulfuric acid, phosphoric acid or the mixed acid of the two, ...

Embodiment 3

[0029] Embodiment 3, a kind of flotation separation process such as siliceous calcareous collophosphine, its steps are as follows:

[0030]The siliceous-calcium colloidal phosphate ore is crushed and ground to dissociate the mineral monomers, add water to adjust the pulp to a mass concentration of 30%, and then flow into the stirring tank, and then add 6kg / t to the pulp respectively Raw ore adjuster sodium silicate and reverse flotation collector PA-64 with an amount of 1.0 kg / t raw ore are used for pulping, and the materials after pulping are put into other flotation operations for minerals and other flotation flotation, containing carbonates Gangue minerals and a part of phosphorus minerals enter the flotation froth;

[0031] The flotation foam flows into the reverse flotation stirring tank, and the reverse flotation regulator inorganic acid with the dosage of 6 kg / t raw ore and the reverse flotation collector PA-64 with the dosage of 1.0 kg / t raw ore are added to it for adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com