Flotation method of lead-zinic-sulphide ore with high oxygenation efficiency

A technology of oxidation rate and sulfide ore, which is applied in the field of flotation of lead-zinc sulfide ore with high oxidation rate, can solve the problems of low lead concentrate grade, low recovery rate, and large consumption of beneficiation agents, so as to improve recovery rate and recovery rate , Improve the effect of concentrate quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

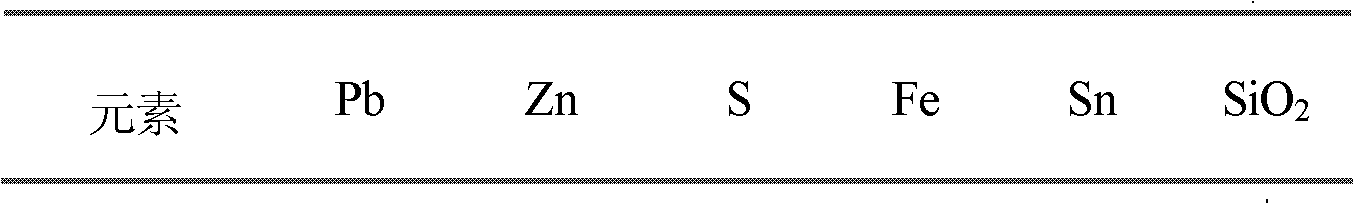

[0018] 1. A lead-zinc mine in Mengzi, Yunnan. The main metal minerals of the ore are galena, lead oxide, sphalerite and pyrite. The main gangue minerals are quartz, calcite and so on. The oxidation rate of lead in the ore is 15.87%, and the oxidation rate of zinc is 2.32%. The multi-element analysis results of the ore are shown in Table 1.

[0019] Table 1 Multi-element analysis of raw ore

[0020]

[0021]

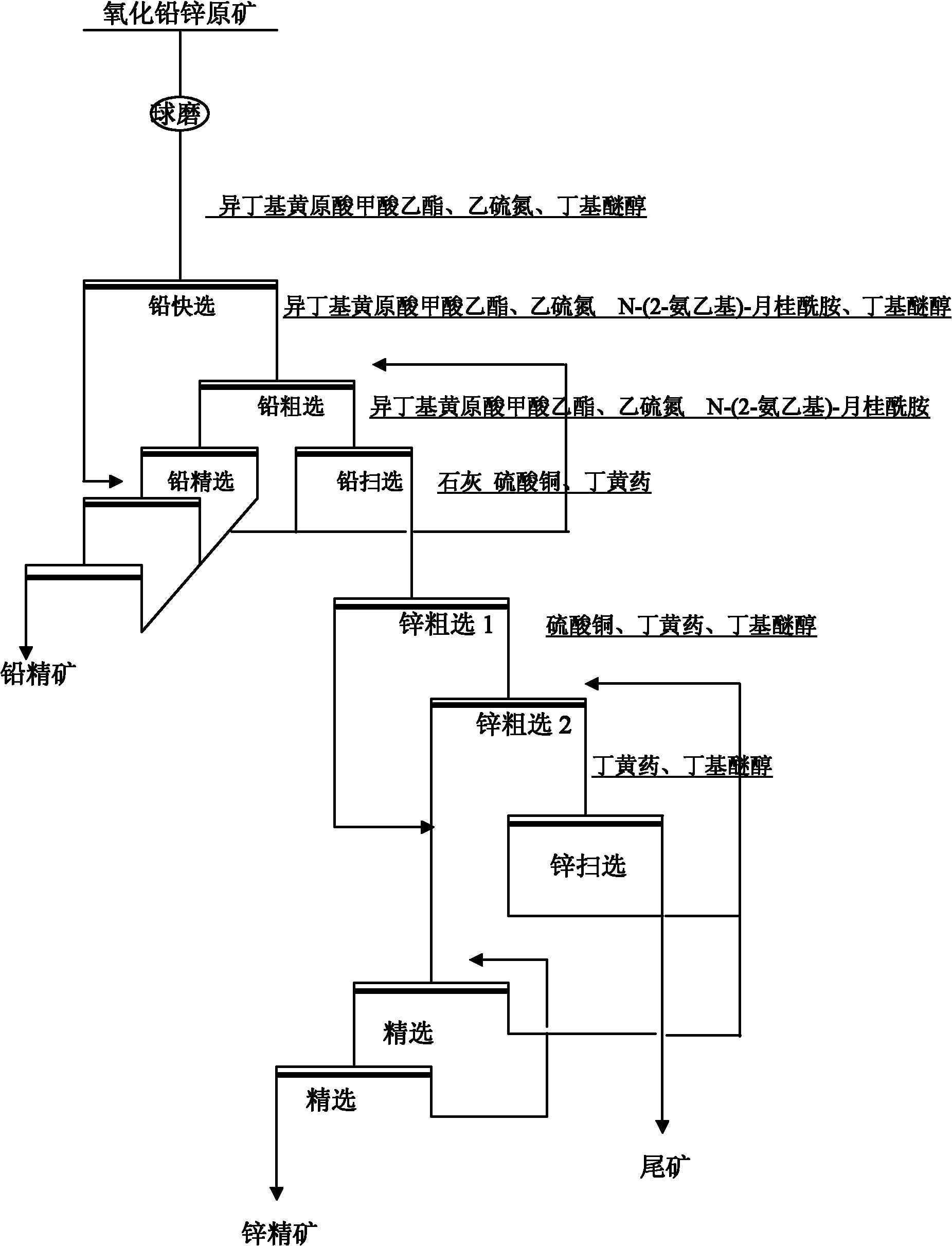

[0022] use as figure 1 The process flow is shown, and the specific process parameters are;

[0023] ① Grinding process: The lime consumption is 3000g / t, so that the pH of the slurry is 11.3, and the particle size of the grinding overflow product is -0.074mm, accounting for 60%; the grinding overflow product enters the flotation through the mixing tank.

[0024] ②The first flotation of lead: the flotation concentration is 30%, adding isobutyl xanthate ethyl formate 10g / t raw ore, ethyl disulfide [(C 2 h 5 ) 2 NCSSK] 20g / t raw ore, the foaming agent added is 30g...

Embodiment 2

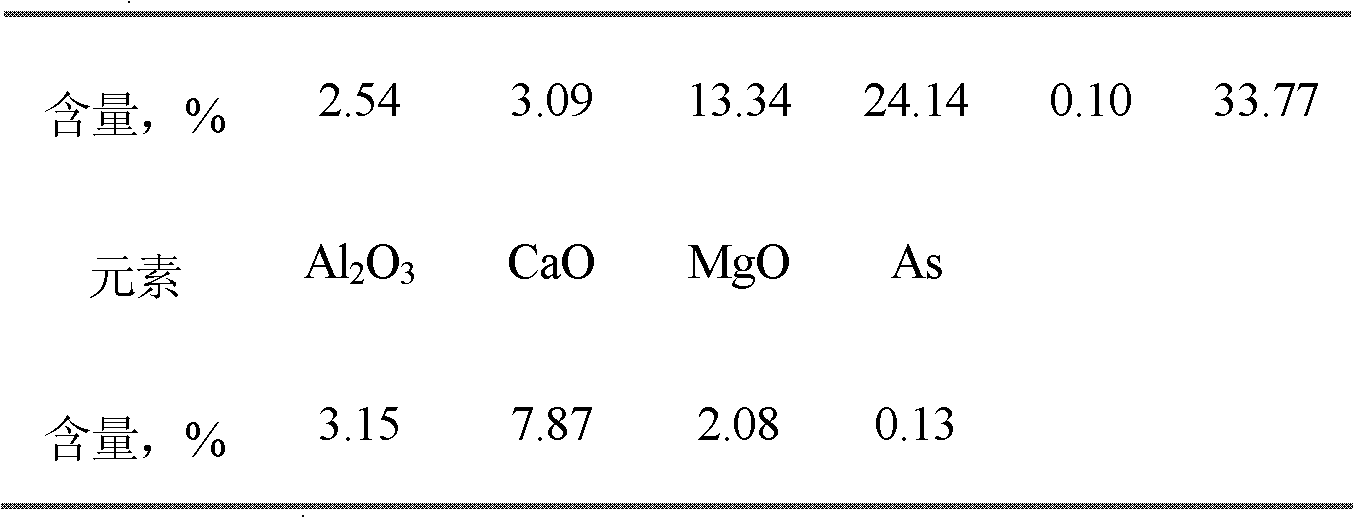

[0029] 1. A lead-zinc mine in Wenshan, Yunnan. The main metal minerals of the ore are galena, lead oxide, sphalerite and pyrite. The main gangue minerals are hematite, quartz, calcite and so on. The oxidation rate of lead in the ore is 20.45%, and the oxidation rate of zinc is 3.13%. The results of multi-element analysis of the ore are shown in Table 2.

[0030] Table 2 Multi-element analysis of raw ore

[0031]

[0032] use as figure 1 The process flow is shown, and the specific process parameters are;

[0033] ① Grinding process: The lime consumption is 3500g / t, so that the pH of the slurry is 11.5, and the particle size of the grinding overflow product is -0.074mm, accounting for 70%; the grinding overflow product enters the flotation through the mixing tank.

[0034] ②The first flotation of lead: the flotation concentration is 30%, adding isobutyl xanthate ethyl formate 120g / t raw ore, ethyl disulfide [(C 2 h 5 ) 2 NCSSK] 40g / t raw ore, butyl ether alcohol 30g / t raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com