Method for extracting potassium chloride from high-silt-content high-grade feldspar salt mine

A technology of potassium halite and potassium chloride, applied in the direction of alkali metal chloride, etc., can solve problems such as difficulty in potassium chloride, achieve the effects of less investment in equipment, full use of resources, and improvement of concentrate quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following is a preferred embodiment of the present invention, which is only used as an explanation of the application rather than a limitation.

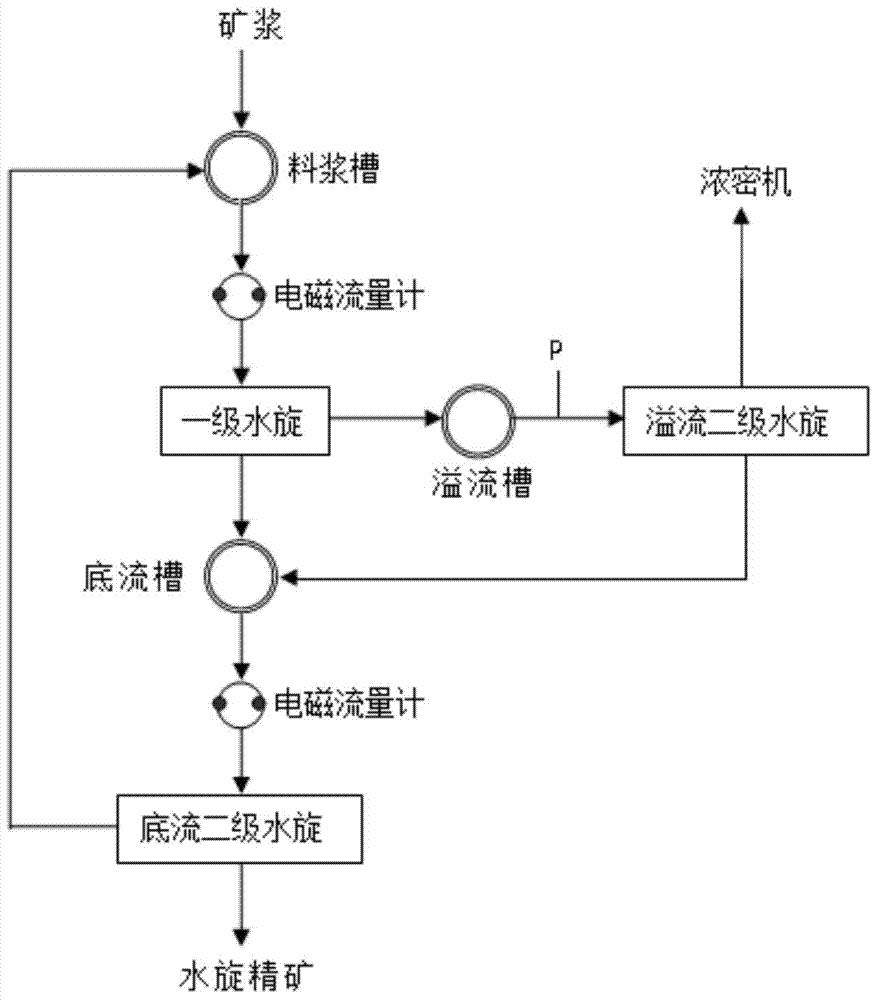

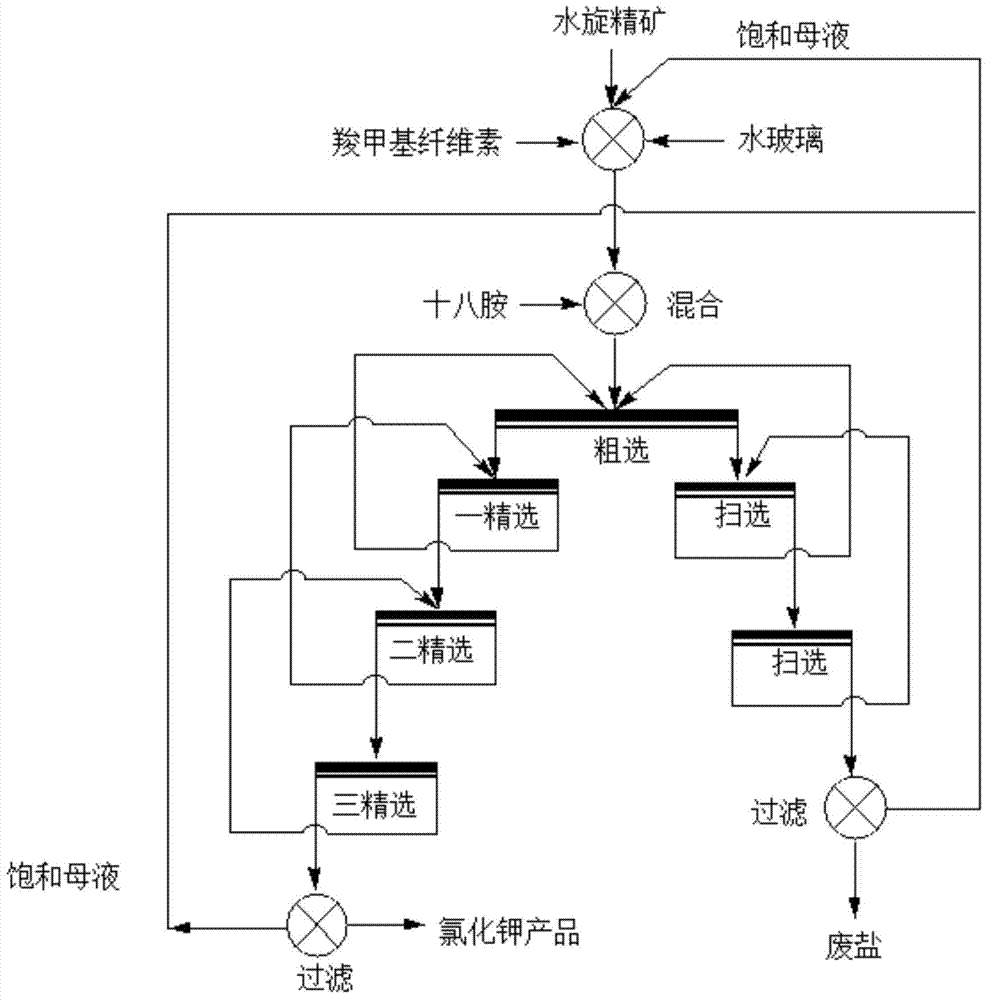

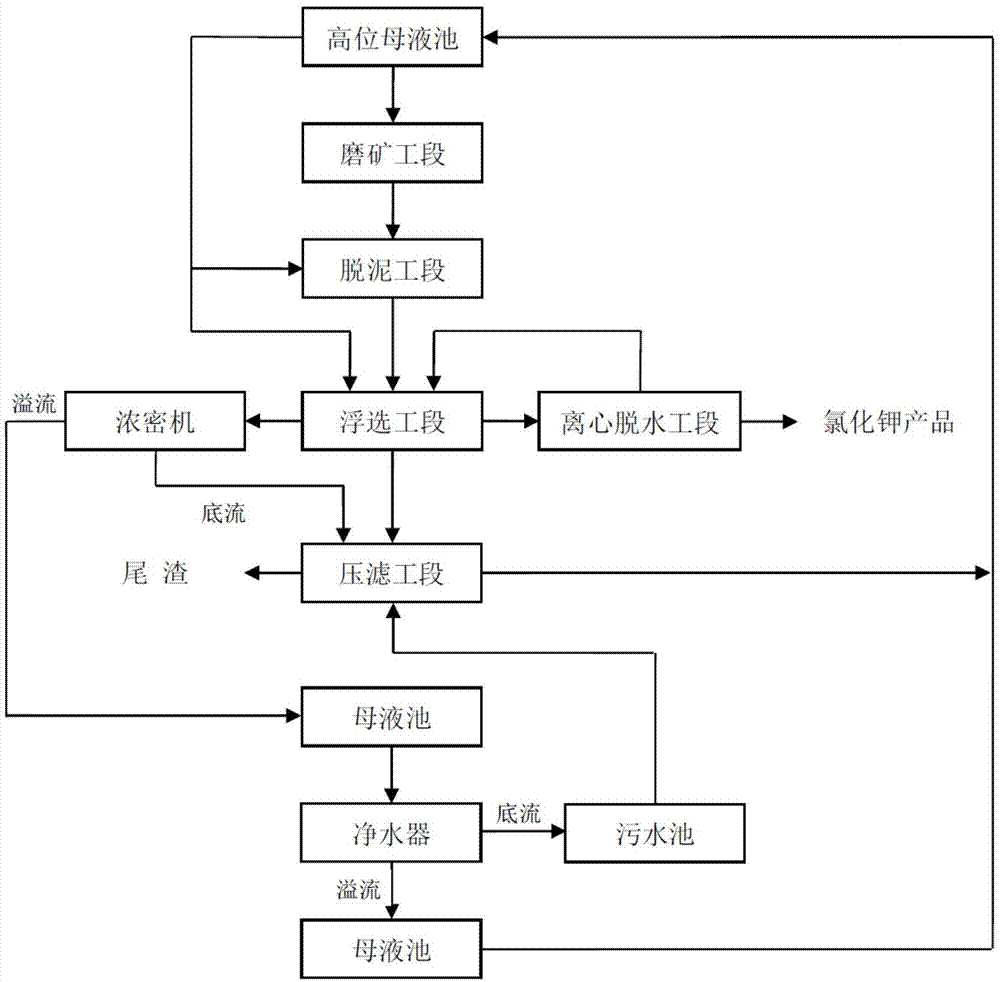

[0044] Use a crusher to crush the gray-green potassium halite raw ore with a mud content of 20%-40% and a potassium chloride content of 10%-19% or its mixed ore with a blue-gray potassium halite ore to obtain a particle size of less than 40 mm ore. The crushed ore enters the rod mill or ball mill through the pendulum feeder and the belt scale. At the same time, the saturated mother liquor of potassium chloride and sodium chloride flowing down from the high level tank is added to the entrance of the mill, and the slurry at the outlet of the mill passes through the water The rotary classifier or spiral classifier screens the particle size of the minerals, so that the minerals with a particle size of less than 1 mm enter the next process, and the minerals with a particle size larger than 1 mm return to the rod mill or ball mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com