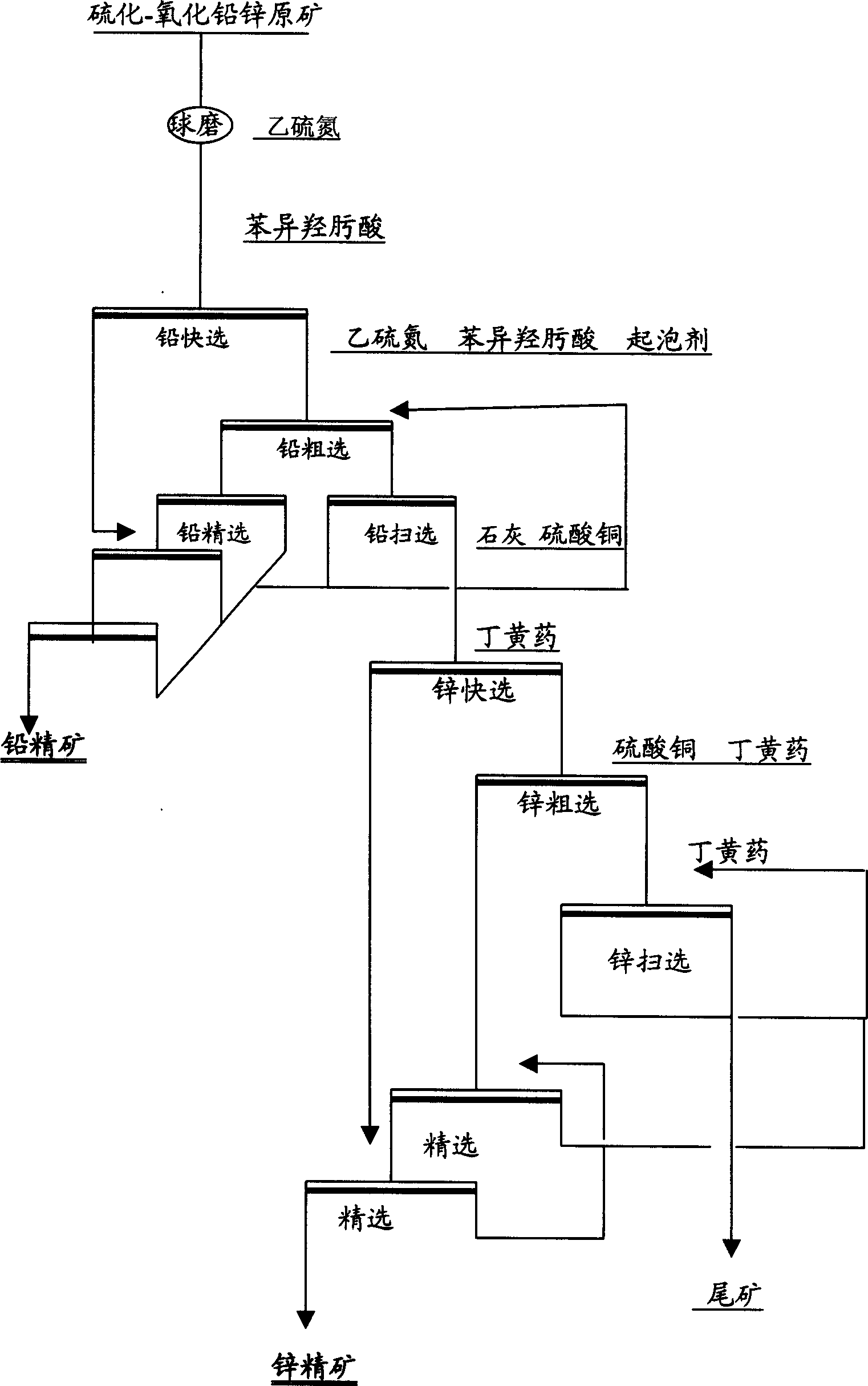

Flotation method for sulfidization-oxidization mixed lead-zinc ore

A lead-zinc ore and flotation technology, which is applied in flotation, solid separation, grain processing, etc., can solve the problems of large consumption of mineral dressing reagents, complex composition, and low recovery rate of lead and zinc, so as to improve recovery rate and concentrate quality , reduce flotation equipment and energy consumption, and improve flotation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Using a lead-zinc mine in Yunnan that contains Pb4.11% and Zn4.65% in the raw ore, the oxidation rate of lead-zinc minerals is 34%. The pH is controlled at a pH greater than 11.5, and the pH of the flotation system is controlled at a pH greater than 11; with ethyl dithiazide (amount of 40g / t) and phenylhydroxamic acid (amount of 20g / t) as collectors, flotation can Obtain lead concentrate, its grade Pb is 55%, recovery rate is 80%; Zinc concentrate grade Zn is 48% (sphalerite concentrate); Recovery rate is 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com