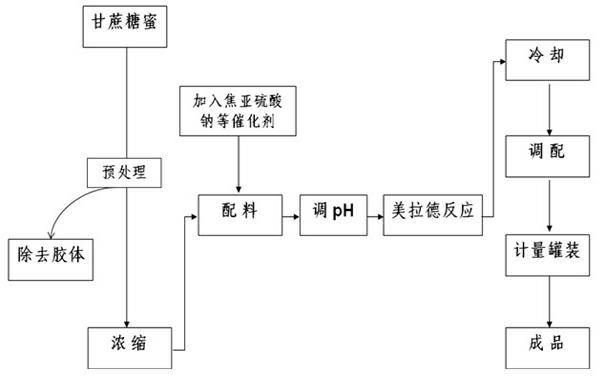

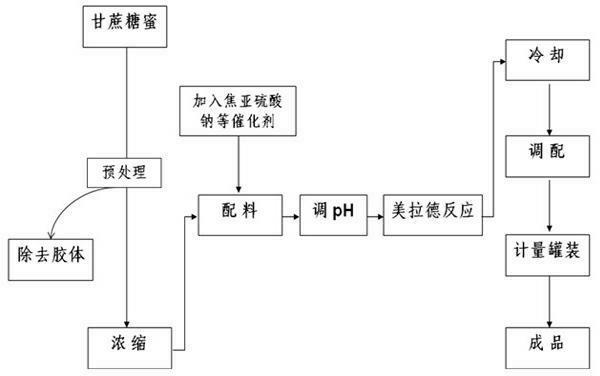

Method for producing high color ratio double-strength caramel using cane molasses

A sugarcane molasses, double caramel technology, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problems of difficult to improve product color rate, increased unsafe factors, large unit energy consumption, etc., to prevent Effects of coking and resinization, cost reduction of main raw materials, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Adjust 50kg of sugarcane molasses with water, the mass percentage of water accounts for 78% of the total solution, and the dry basis of sugarcane molasses reaches 40%, then add phosphoric acid with a concentration of 85%, adjust the pH to 2.7, heat up to 98°C, maintain for 30 minutes, and cool to 50°C, use 98% sodium hydroxide to adjust the pH value, and adjust the pH value to 4.0.

[0035]Use perlite as a filter aid and filter through a filter press to obtain clarified molasses liquid. At this time, the mass percentage of molasses on a dry basis is 45%, a total of 78kg. The filtered clear liquid is centrifuged under 3500R / M centrifugal action After 20 minutes, the centrifuged sediment content was less than 0.1%; the pretreated molasses was concentrated by three effects to 75% by mass percentage on a dry basis, 46.8kg; the dry basis content in the total solids of the accurately measured molasses was 35.1kg , and add the catalyst in proportion to the total amount of sol...

Embodiment 2

[0039] Adjust 50kg of sugarcane molasses with water, the mass percentage of water accounts for 78% of the total solution, and the dry basis of sugarcane molasses reaches 40%, then add phosphoric acid with a concentration of 85%, adjust the pH to 3, heat up to 98°C, maintain for 30 minutes, and cool To 50°C, use 98% sodium hydroxide to adjust the pH value, and adjust the pH value to 4.5.

[0040] Use perlite as a filter aid and filter through a filter press to obtain clarified molasses liquid. At this time, the mass percentage of molasses on a dry basis is 45%, a total of 78kg. The filtered clear liquid is centrifuged under 3500R / M centrifugal action After 20 minutes, the centrifuged sediment content was less than 0.1%; the pretreated molasses was concentrated by three effects to 75% by mass percentage on a dry basis, 46.8kg; the dry basis content in the total solids of the accurately measured molasses was 35.1kg , and add the catalyst in proportion to the total amount of solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com