Gravity drive-in self-moving intensive warehouse rack allowing for convenient delivery

A self-moving and lightweight technology, applied in the directions of transportation, packaging, storage devices, etc., can solve the problems of depth limitation, difficulty in placing goods, and inability to assist in inbound and outbound shipments, so as to reduce unit energy consumption and reduce refrigeration. Cost and manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way. Any transformation or replacement based on the teaching of the present invention belongs to the protection scope of the present invention.

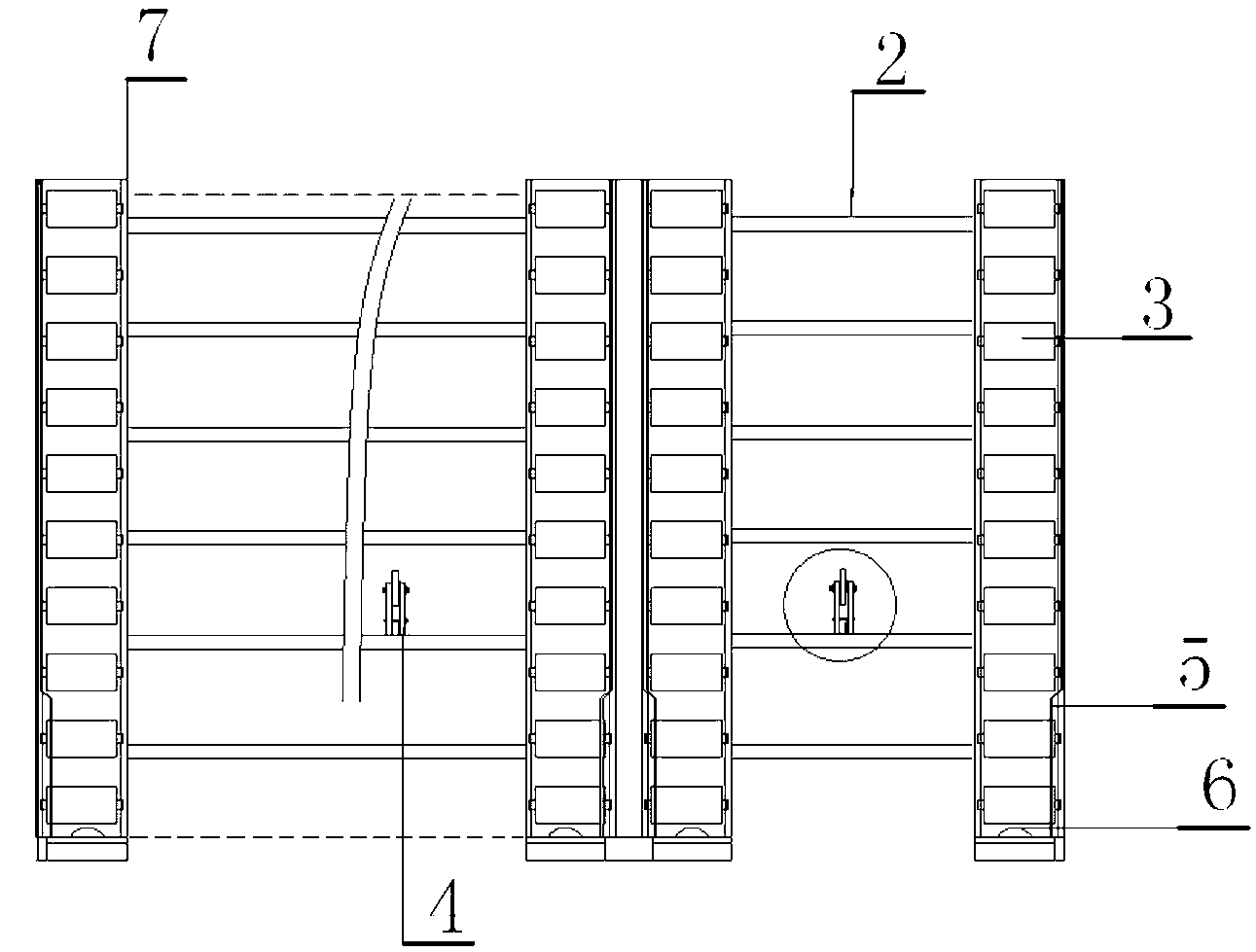

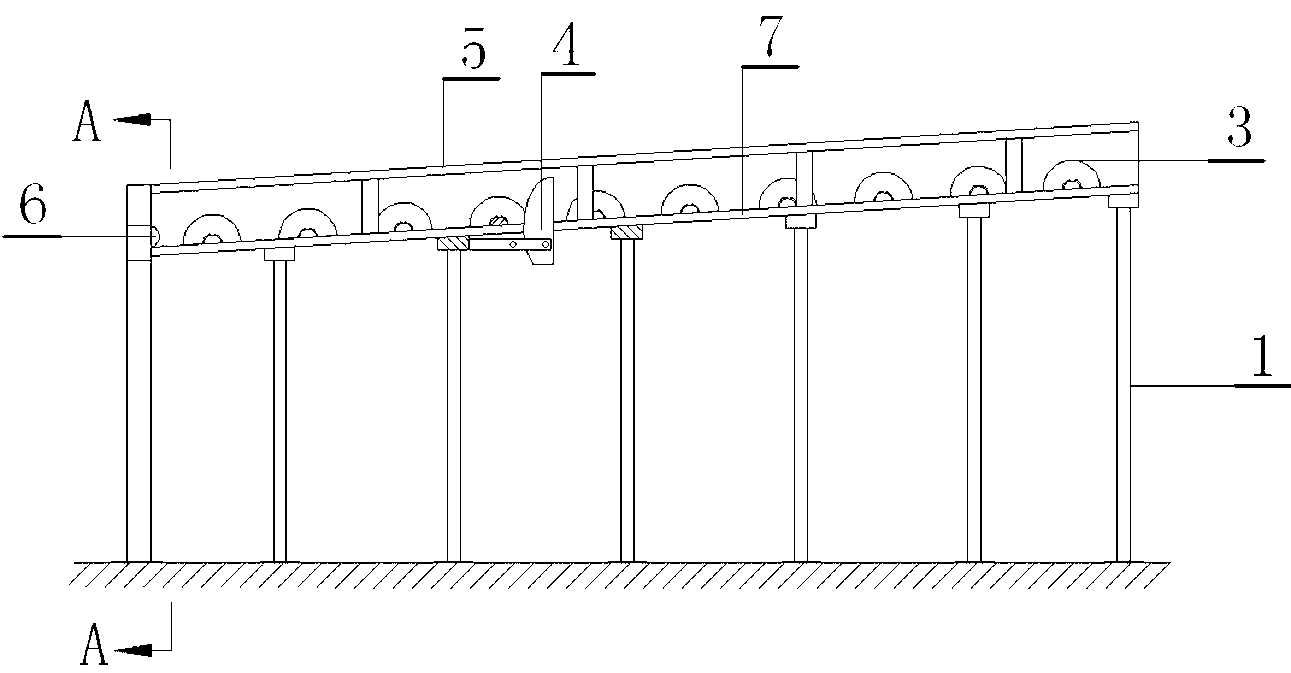

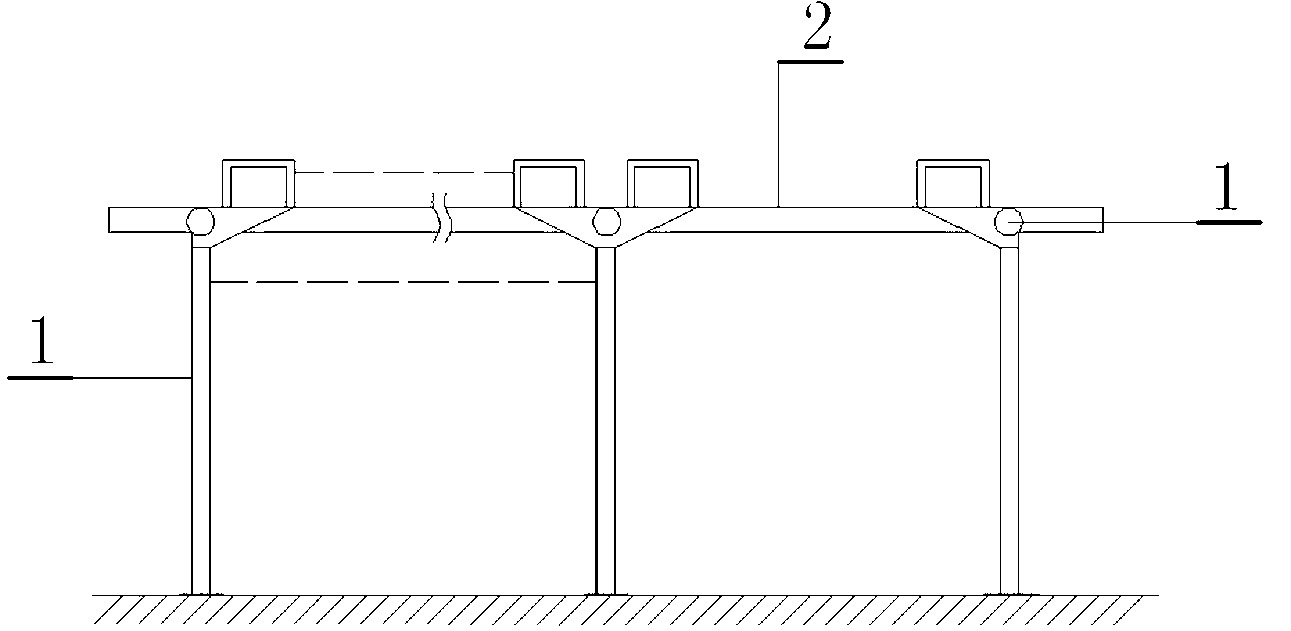

[0014] Such as Figure 1~Figure 5 As shown, the present invention includes a stand 1 and a crossbeam 2, the crossbeam 2 is arranged on the stand 1, and the two ends of the crossbeam 2 are correspondingly provided with a conveying track 7, and the conveying track 7 is inclined downward toward the inlet and outlet ends set up.

[0015] The downward inclination angle of the conveying track 7 is 5-30°.

[0016] The conveying tracks 7 are arranged symmetrically, and are respectively composed of rollers 3 arranged in the longitudinal beams. An automatic goods stop device 4 is arranged on the beam 2 , and the working end of the automatic goods stop device 4 is higher than the upper pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com