Preparation method of multi-component slurry for production of synthesis gas and multi-component slurry obtained by said method

A multi-component slurry and synthesis gas technology, applied in the field of coal chemical industry, can solve problems such as weak energy demand, and achieve the effects of high degree of automation, stable quality and high concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

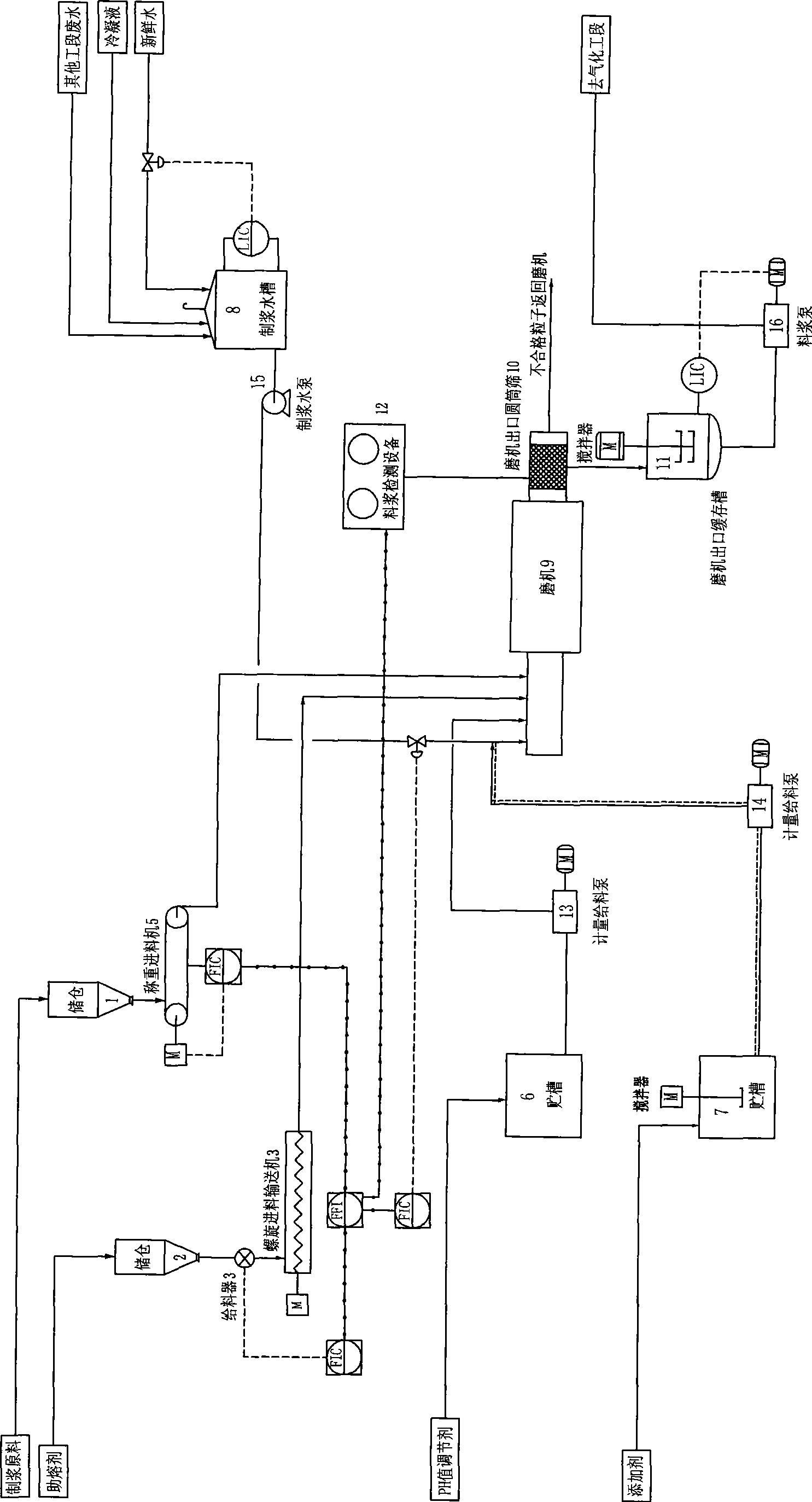

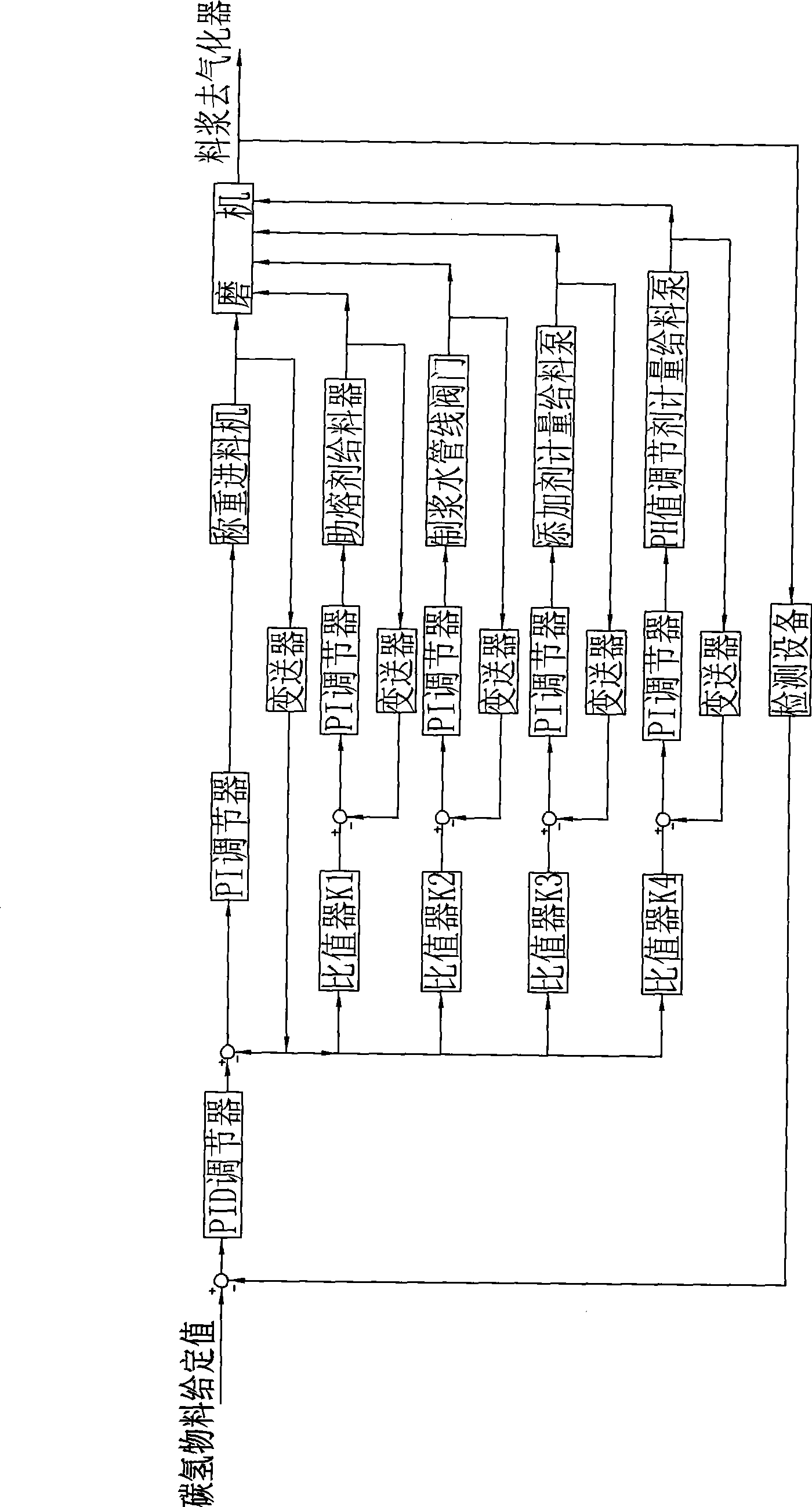

Method used

Image

Examples

Embodiment 1

[0129] Example 1: Using Xinjiang coal samples to prepare multi-component slurry for the production of syngas

[0130] The Xinjiang coal raw material pre-crushed to ≤20mm enters the storage bin 1 and then is sent to the mill 9 through the weighing feeder 5 .

[0131] The present embodiment selects ball mill parameter as follows:

[0132]Specification Φ3200×4700mm, speed 17.42r / min, power 650Kw, maximum steel ball loading capacity 44t, steel ball press Do the grading.

[0133] The additives used in this example are sodium polystyrene sulfonate produced and sold by Tianjin Dagang Hongli Dye Chemical Factory and nonylphenol polyoxyethylene ether produced and sold by Nanjing Nanda Surface and Interface Chemical Engineering Technology Research Center Co., Ltd. The mixture prepared in a weight ratio of 1:2 was prepared into a 25wt% aqueous solution with water. The prepared additive solution is sent into the storage tank 7, and the equipped agitator performs continuous stirring,...

Embodiment 2

[0147] Example 2: Preparation of multi-component slurry for producing syngas with Ningxia coal samples

[0148] Adopt the same mode as embodiment 1 to carry out, but difference is as follows:

[0149] The Xinjiang coal raw material pre-crushed to ≤15mm enters the storage bin 1 and then is sent to the mill 9 through the weighing feeder 5 .

[0150] The present embodiment selects ball mill parameter as follows:

[0151] Specification Φ2400×8000mm, speed 20.4r / min, power 570Kw, maximum loading capacity of steel balls 36t, steel balls by Do the grading.

[0152] The additives used in this embodiment are acrylic acid, methyl acrylate, and acrylamide produced and sold by Zibo Dongfang Polymer Co., Ltd., and a mixture prepared according to acrylic acid: methyl acrylate: acrylamide = 1:2:1, use water It is prepared as a solution with a concentration of 25 wt%.

[0153] The pH regulator used in this embodiment is 40wt% sodium hydroxide aqueous solution, and the configured pH re...

Embodiment 3

[0163] Example 3: Preparation of multi-component slurry for production of synthesis gas with Inner Mongolia coal blending coal samples

[0164] Adopt the same mode as embodiment 1 to carry out, but difference is as follows:

[0165] The present embodiment selects ball mill parameter as follows:

[0166] Specification Φ2700×4500mm, speed 20r / min, power 430Kw, maximum loading capacity of steel balls 50t, steel balls press Do the grading.

[0167] The additive used in this example is prepared by using polysodium p-styrene sulfonate produced and sold by Xinyi Jingwei Technology Co., Ltd. and nonylphenol polyoxyethylene ether produced and sold by Xuzhou Chengzheng Fine Chemical Co., Ltd. in a weight ratio of 4:5. The mixture is used in an amount of 0.5% by weight of dry coal, and is prepared into a solution with a concentration of 25% by weight.

[0168] The pH regulator used in this embodiment is 40wt% sodium hydroxide aqueous solution, and the configured pH regulator soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com