Biomass straw granulator

A technology of biomass straw and granulator, which is applied in the direction of mold extrusion granulation, press, material forming press, etc., which can solve the problems of inability to guarantee the normal operation rate of the machine, difficulty in ensuring the yield rate, and surrounding environmental pollution. Achieve high machine normal operation rate, improve the environment of the workplace, and protect the surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

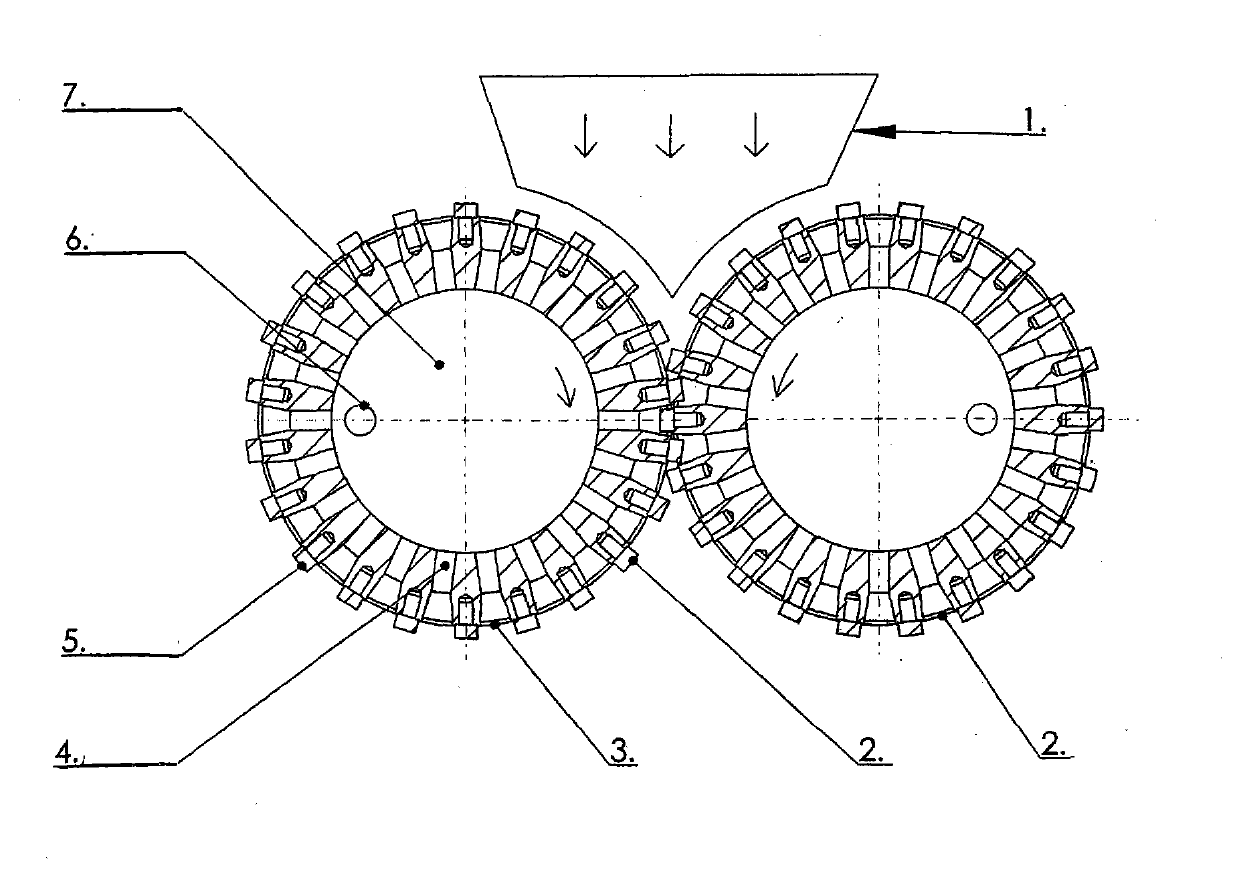

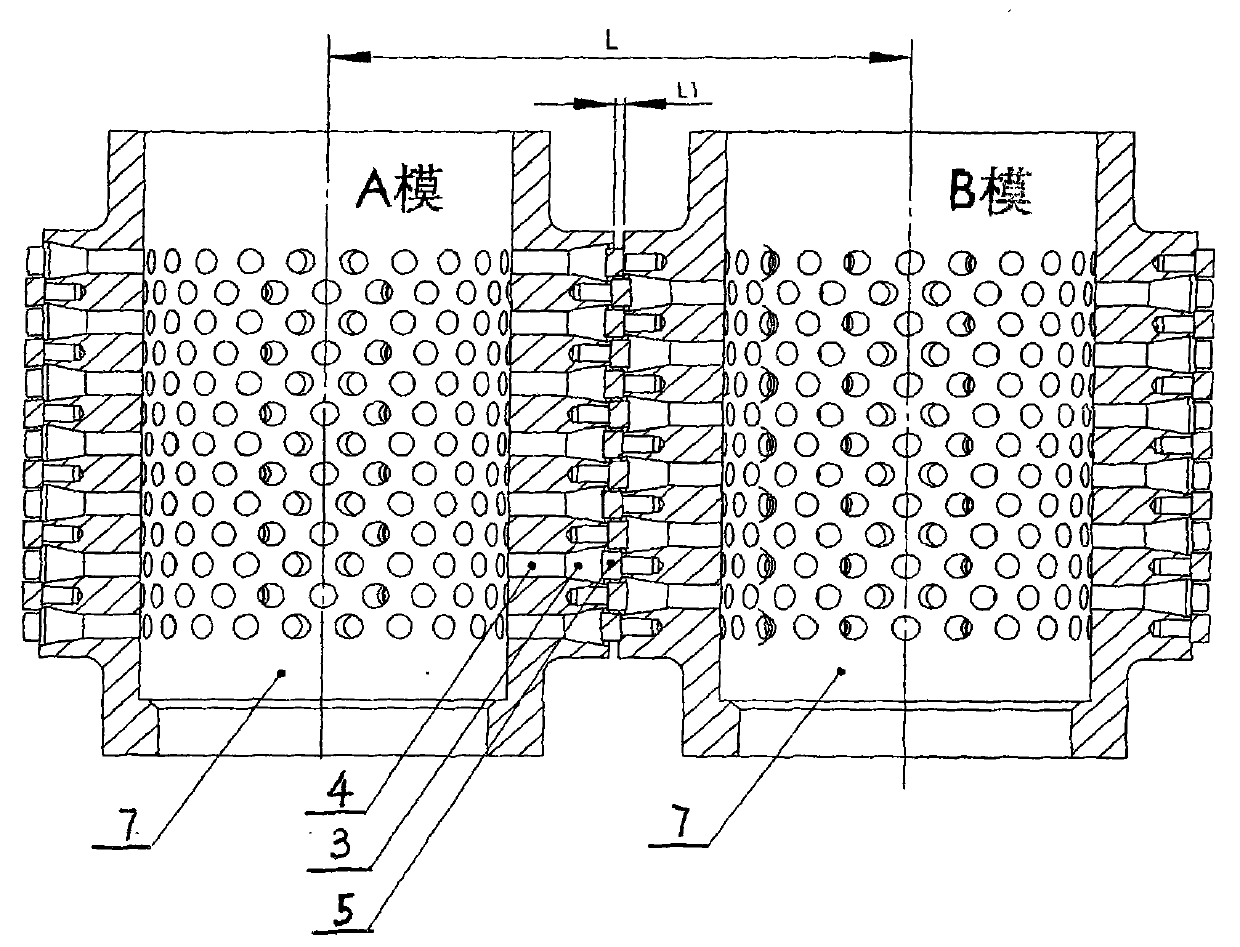

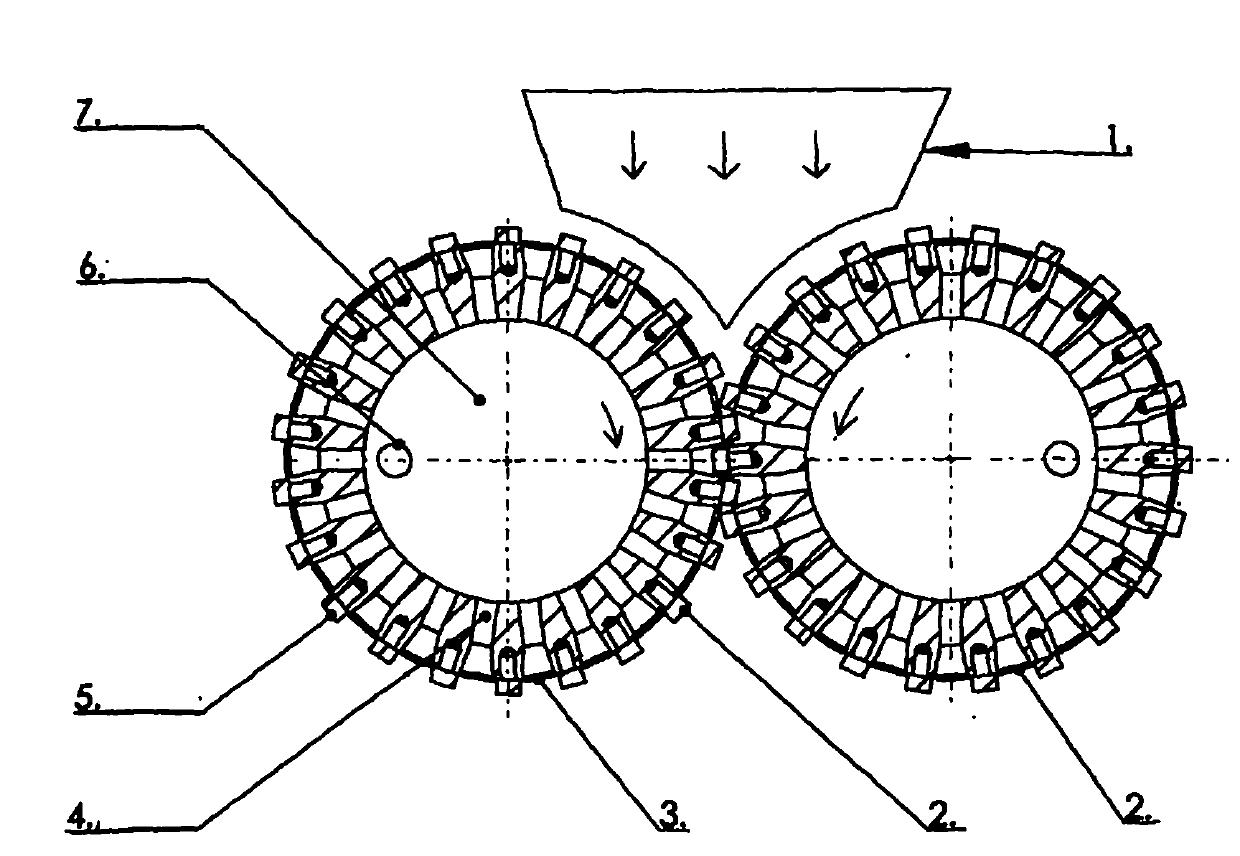

[0015] As shown in the figure: a biomass straw granulator, which consists of two rolling dies 2, A and B. Forming holes 4 and extrusion heads 5 are evenly arranged on each rolling die, and the extrusion heads and forming holes are arranged alternately. The heads of the forming holes are provided with compression holes 3, and the middle part of the rolling die is a discharge chamber 7. The cavity is equipped with a cutter 6; the extrusion head of one rolling roller extends into the forming hole of the other rolling roller, and the extrusion head of the other rolling roller extends back into the forming hole of this rolling roller Inside. The above-mentioned extrusion head and the number of forming holes are equal. The diameter of the extrusion head is smaller than the diameter of the compression hole.

[0016] The working process of the present invention is: the reducer is driven by the motor, and the reducer drives the rolling dies A and B to move relative to each other, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com