Mixed refrigerant circulation natural gas zone pressure liquefaction technology with sublimation removal of CO2

A technology for mixing refrigerant and natural gas, applied in the chemical and low temperature fields, can solve the problems of not involving the natural gas liquefaction process, unable to ensure that natural gas will not be precipitated, difficult to popularize and apply, etc., saving equipment investment, reducing floor space, and energy consumption. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

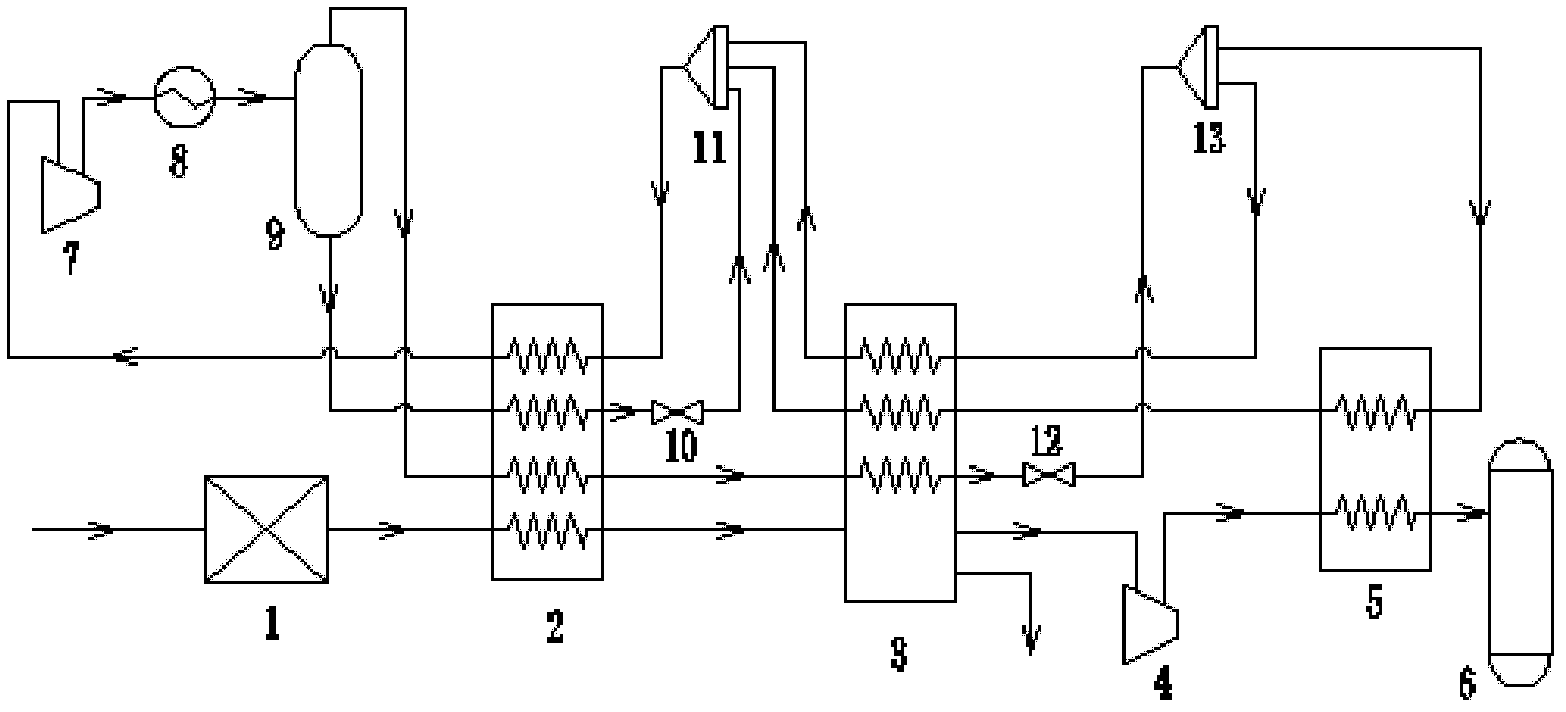

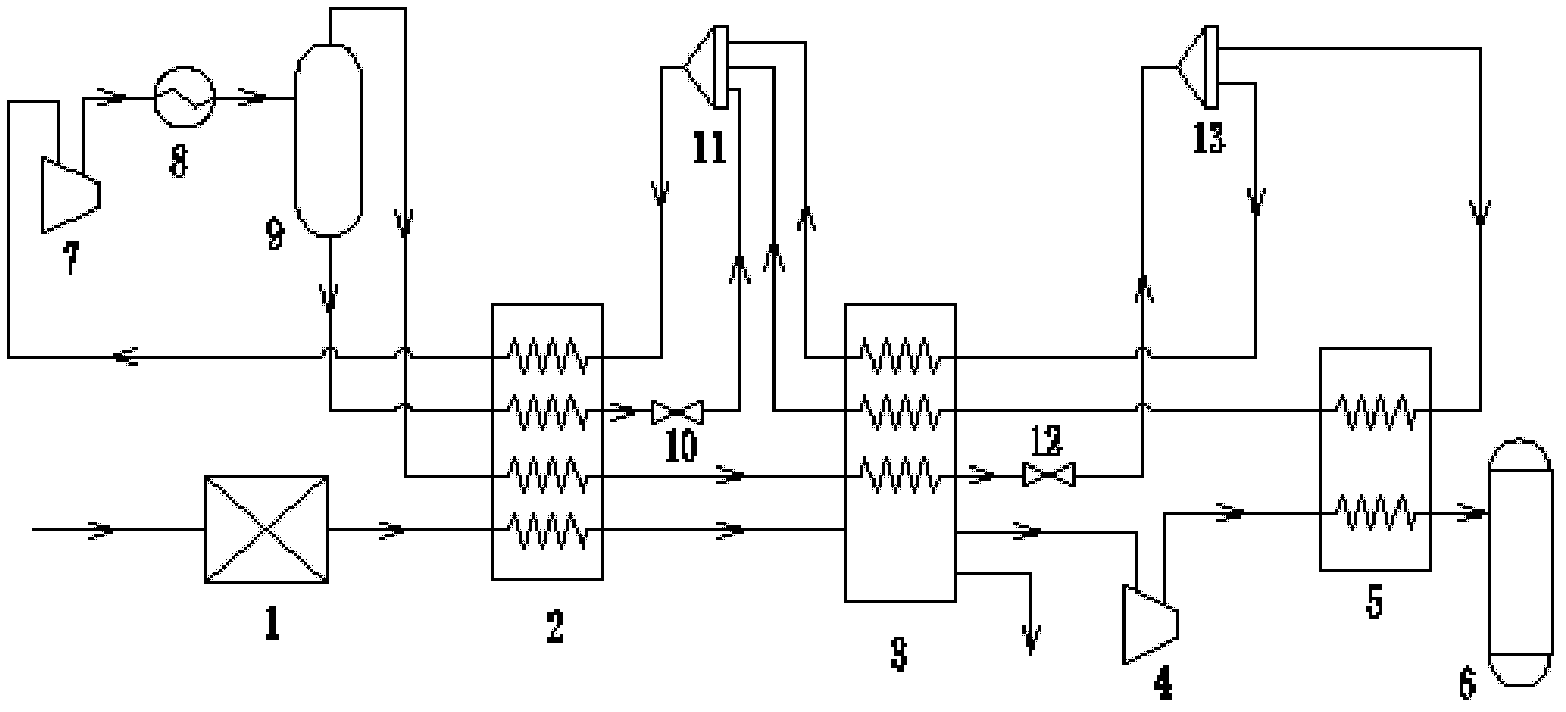

[0031] A CO removal with desublimation 2 The mixed refrigerant cycle natural gas liquefaction process under pressure, the implementation scheme is as follows figure 1 shown. Mixed refrigerant molar composition 37.03% CH 4 +35.63%C 2 h 6 +0.41%C 3 h 8 +12.44% i-C 4 h 10 +10.58% i-C 5 h 12 +3.92%N 2 , The flow rate is 4.5kmol / h, and the molar composition of raw natural gas is 0.5% CO 2 +99.5%CH 4 , pressure 1.5MPa, flow rate 1kmol / h, CO removal with desublimation 2 The specific steps of the mixed refrigerant cycle natural gas liquefaction process under pressure are as follows:

[0032] 1. Since the raw natural gas is within the pressure range of 1.4-1.6MPa, the pressure regulating device 1 is omitted. The raw material gas is introduced into the precooler 2, absorbs cooling energy from the mixed refrigerant, flows out of the precooler 2, and the temperature drops to -40°C;

[0033] 2. The natural gas pre-cooled in step 1 is introduced into the crystallizer 3, and t...

Embodiment 2

[0040] A CO removal with desublimation 2 The mixed refrigerant cycle natural gas liquefaction process under pressure, in the process of natural gas liquefaction to desublimate CO 2 , and then produce LNG products under pressure. The innovative design of the process cancels the CO 2 Pretreatment device, and ensure no CO in the subsequent liquefaction process 2 Crystals precipitated.

[0041] Mixed refrigerant molar composition 36.79% CH 4 +36.19% C 2 h 6 +12.86% i-C 4 h 10 +11.14% i-C 5 h 12 +3.02%N 2 , the flow rate is 4.512kmol / h, and the molar composition of raw natural gas is 10% CO 2 +90%CH 4 , pressure 1.5MPa, flow rate 1kmol / h, CO removal with desublimation 2 The specific steps of the mixed refrigerant cycle natural gas liquefaction process under pressure are as follows:

[0042] 1. Since the raw natural gas is within the pressure range of 1.4-1.6MPa, the pressure regulating device 1 is omitted. The raw material gas is introduced into the precooler 2, absor...

Embodiment 3

[0050] A CO removal with desublimation 2 The mixed refrigerant cycle natural gas liquefaction process under pressure, in the process of natural gas liquefaction to desublimate CO 2 , and then produce LNG products under pressure. The innovative design of the process cancels the CO 2 Pretreatment device, and ensure no CO in the subsequent liquefaction process 2 Crystals precipitated.

[0051] Mixed refrigerant molar composition 26.29% CH 4 +40.08% C 2 h 6 +17.12% i-C 4 h 10 +14.03% i-C 5 h 12 +2.49%N 2 , The flow rate is 4.512kmol / h, and the molar composition of raw natural gas is 30%CO 2 +70%CH 4 , pressure 1.5MPa, flow rate 1kmol / h, CO removal with desublimation 2 The specific steps of the mixed refrigerant cycle natural gas liquefaction process under pressure are as follows:

[0052] 1. Since the raw natural gas is within the pressure range of 1.4-1.6MPa, the pressure regulating device 1 is omitted. The raw material gas is introduced into the precooler 2, absorb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com