Producing method of lead frame cuprum alloy strip with high strength and conductivity

A technology of copper alloy strip and high lead wire is applied in the field of electronic semiconductors, which can solve the problems of long project construction period, low product yield and high operating cost, and achieve small footprint, high product yield and operating cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The production method of the high-strength, high-guide wireframe copper alloy strip material that the present invention relates to, described method is to adopt upward drawing copper rod-continuous extrusion method, and its main process step is as follows:

[0027] Step 1. Ingredients

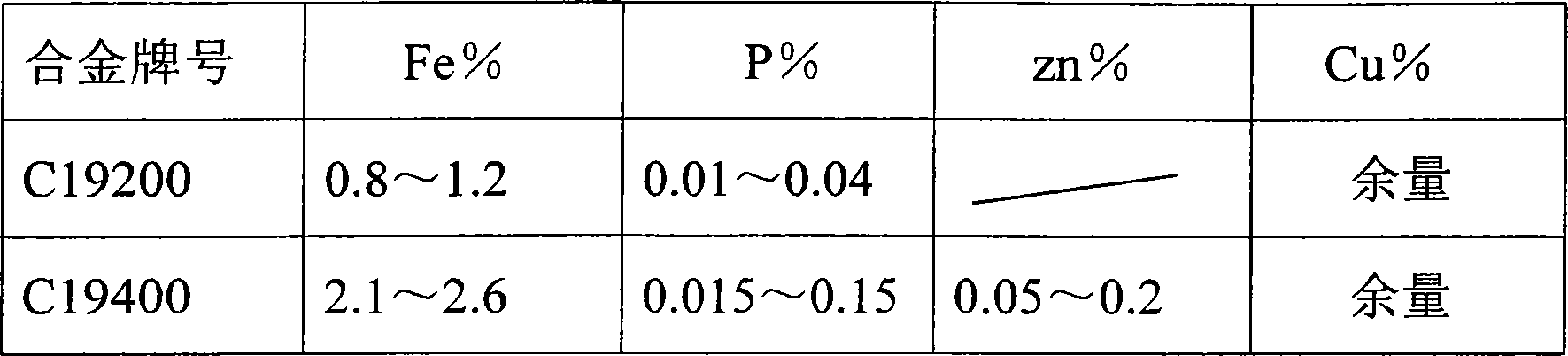

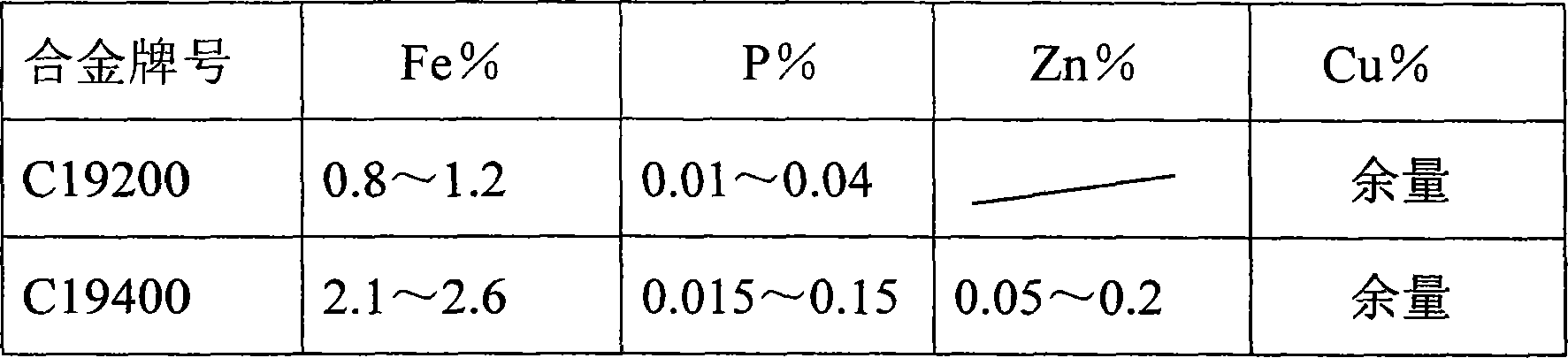

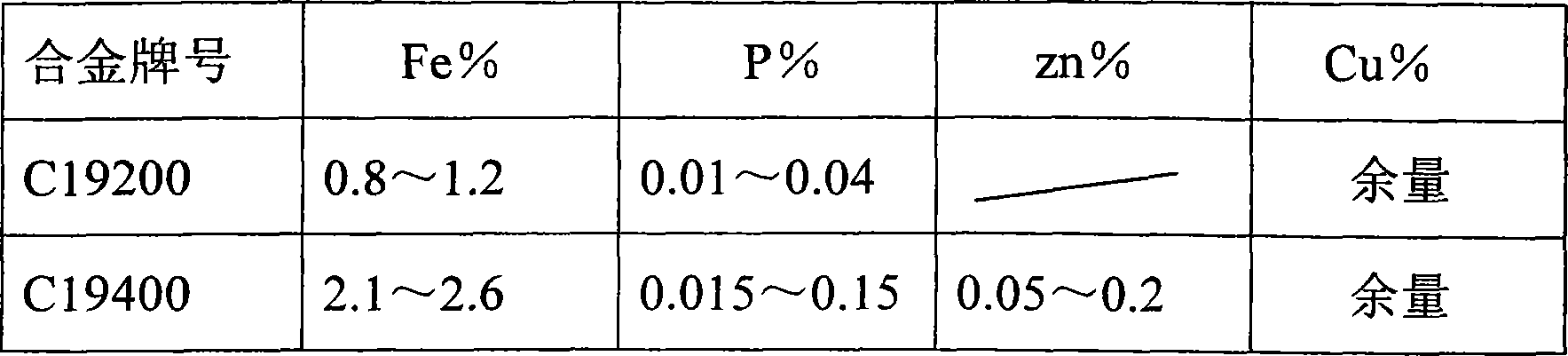

[0028] Chemical composition of two lead frame materials

[0029]

[0030] Among them, the content of pb and sn in C19400 shall not be greater than 0.03%,

[0031] The cathode copper, one of the raw materials required for C19400 or C19200 copper alloy materials, is fully inspected, the four sides and the particles on the four sides of the cathode copper are removed, and then dried for later use, and then the rest of the raw materials are formulated according to the chemical composition requirements, strictly To achieve the production method of one furnace and one frame,

[0032] Step 2. Upward melting and casting

[0033] Add the material described in step 1 into the submerged one-p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com