Production equipment and method for synthesizing 3-aminopropanol through continuous hydrogenation

An aminopropanol and production equipment technology, applied in the field of chemical organic synthesis, can solve the problems of solvent recovery, many side reactions, low production capacity, etc., and achieve the effects of reducing recovery costs, high flexibility in equipment operation, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

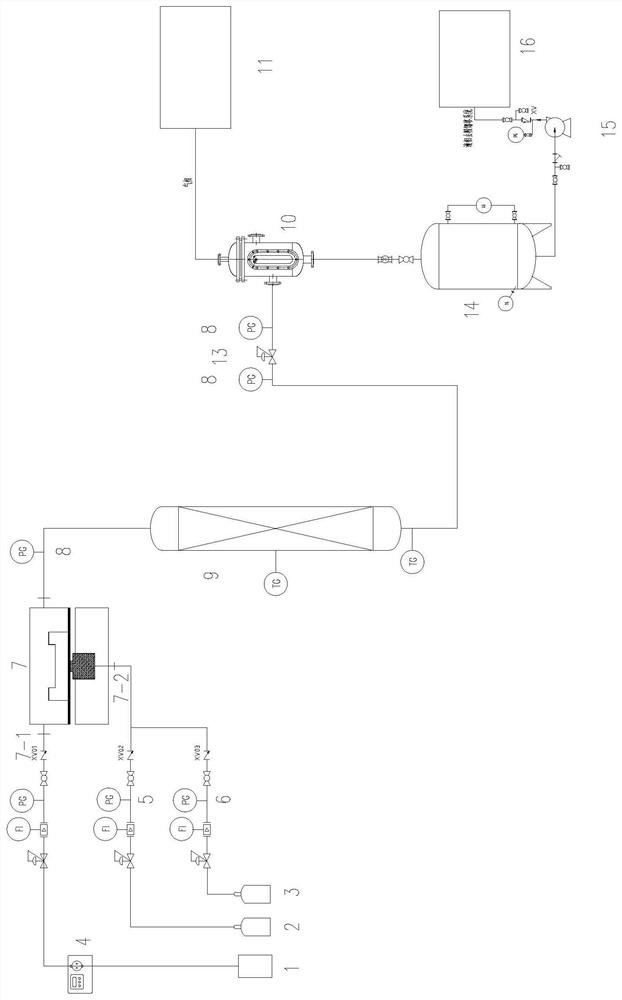

[0037] Another core of the present invention is to provide a kind of method of continuous hydrogenation synthesis 3-amino propanol, claim it as specific embodiment two, and this method comprises the following steps:

[0038] ① Load the loaded nickel-based catalyst into the packed bed reactor and raise the temperature to a reaction temperature of 80-110°C;

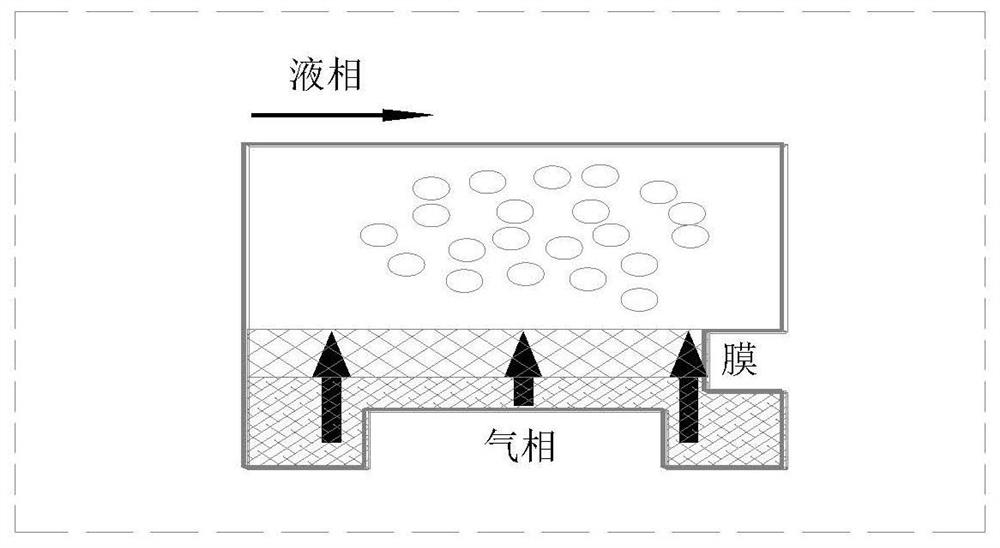

[0039] ② After the membrane diffuses, the pressure gauge 8 reaches a certain pressure and the packed bed reaches a certain temperature, feed the three streams of 3-hydroxypropionitrile, hydrogen and ammonia into the membrane diffusion module and mix them thoroughly;

[0040] ③ The hydrogenation synthesis reaction of the reaction materials occurs in the packed bed reactor, and the pumping speed of 3-hydroxypropionitrile and the output pressure of hydrogen and amino groups are continuously maintained;

[0041] ④The reaction liquid obtained after the reaction in the packed bed reactor is separated into a gas phase (ammonia) an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com