Patents

Literature

35results about How to "Reduce the use of security risks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vehicle driver identity verification method and device and electronic device

InactiveCN109670436AReduce the use of security risksReduce the risk of not being the same personMatching and classificationSpoof detectionVehicle drivingMobile device

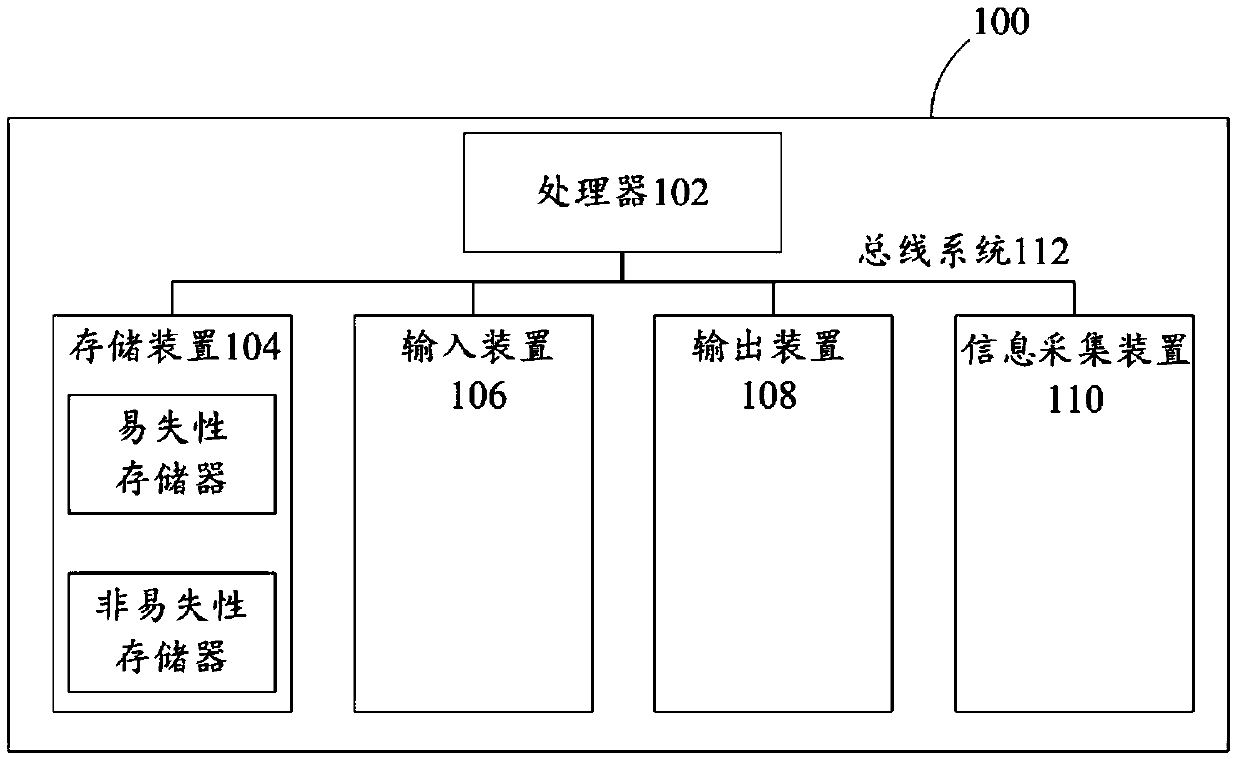

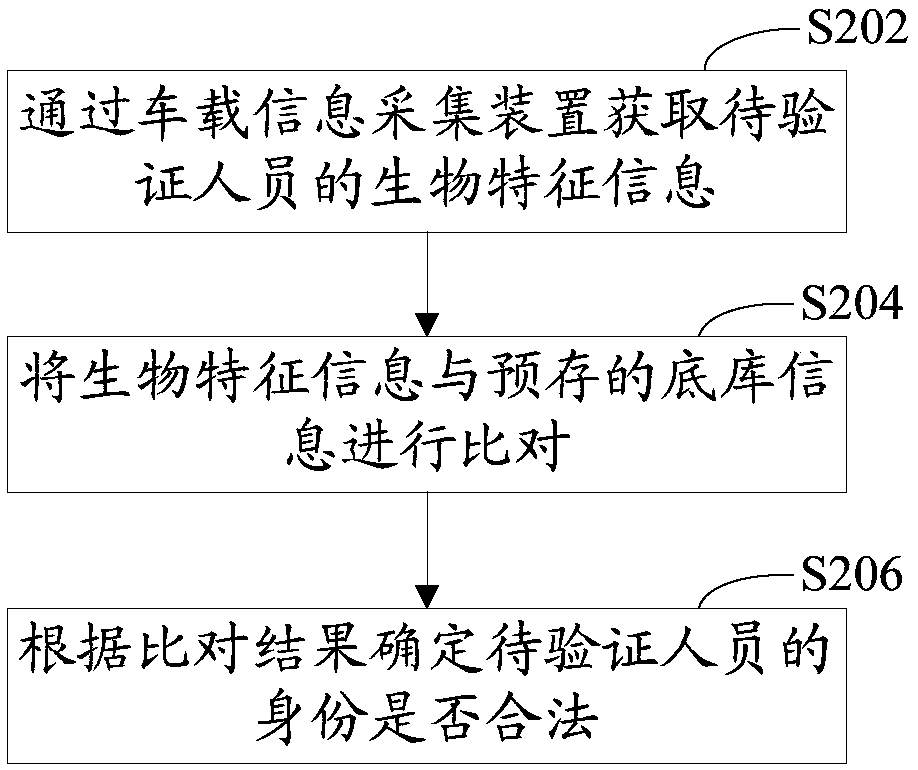

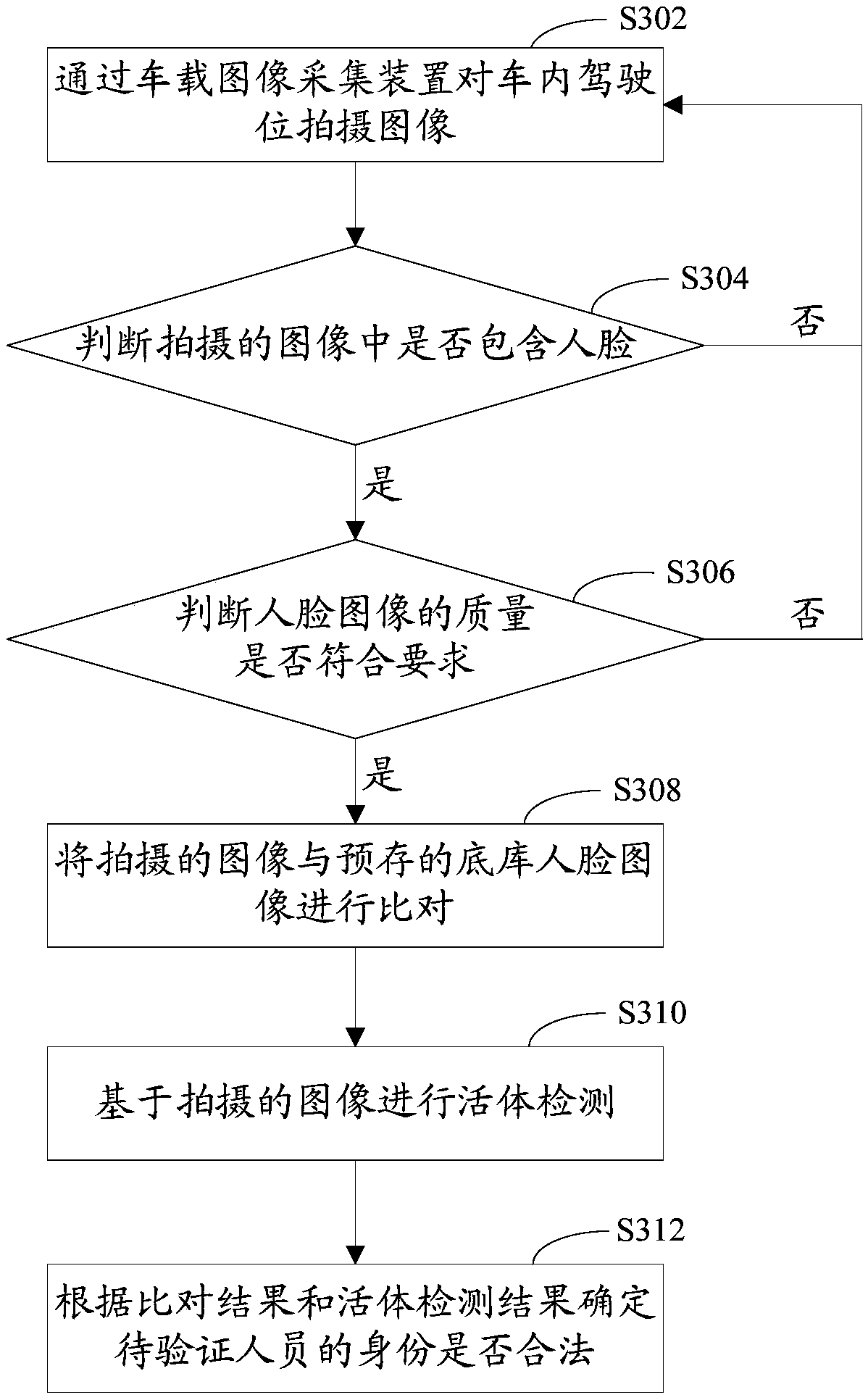

The invention provides a vehicle driver identity verification method and device and an electronic device, and relates to the technical field of identity verification. According to the vehicle driver identity verification method and device and the electronic device provided by the embodiment of the invention, the biological characteristic information of the to-be-verified person is acquired throughthe vehicle-mounted information acquisition device, and the acquired biological characteristic information is compared with the pre-stored base library information so as to determine whether the identity of the to-be-verified person is legal or not, wherein the base library information is the user biological characteristic information collected by the mobile device at the user registration stage.The biometric information of the to-be-verified person is acquired by adopting the vehicle-mounted information acquisition device, and then the identity of the to-be-verified person is verified, so that the risk that the verifier and the actual driver are not the same person can be reduced, and the use safety risk of the vehicle can be reduced.

Owner:BEIJING KUANGSHI TECH

Decommissioned battery cascade utilization method

ActiveCN111816938AAvoid inconsistenciesEliminate circulationSecondary cells charging/dischargingWaste accumulators reclaimingAutomotive engineeringWhole systems

The invention discloses a decommissioned battery cascade utilization method, which is characterized by comprising the following steps of: S1, sorting decommissioned batteries; S2, recombining the single decommissioned batteries again; and S3, constructing a flexible grouped energy storage system based on parallel connection of a multi-cluster battery system. The invention further discloses application of the decommissioned battery cascade utilization method in recycling of decommissioned batteries of new energy vehicles. According to the decommissioned battery cascade utilization method disclosed by the invention, the decommissioned batteries can be rapidly, safely and efficiently utilized in an cascade manner, the reuse cost is low, the battery capacity can be adjusted according to the current cascade cluster, the energy is automatically adjusted and output to a PCS and a charger, the parallel high-power output of various cascade battery clusters can be compatible in a diversified manner, the problem of circulation generated between different cascade battery clusters in differential parallel connection is eliminated, the inconsistency of cascade batteries is well avoided, the optimal stable operation of the whole system is realized, and the safety risk in use is reduced.

Owner:ANHUI LVWO RECYCLING ENERGY TECHNOLOGY CO LTD

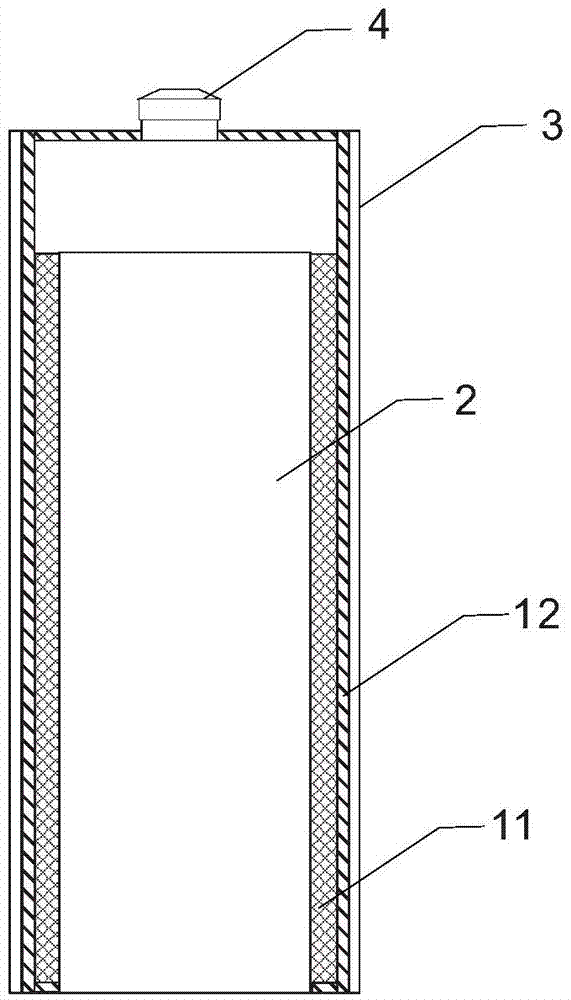

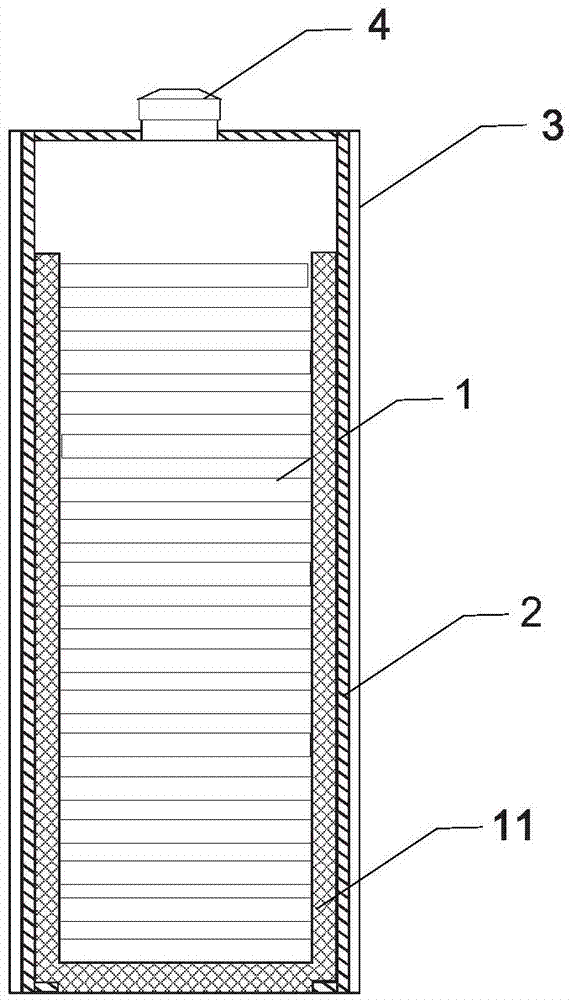

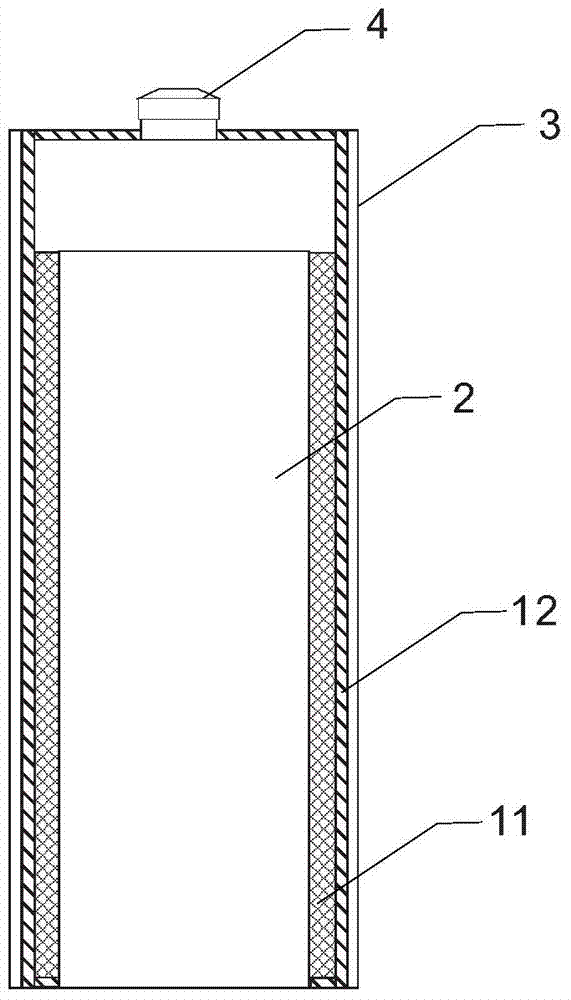

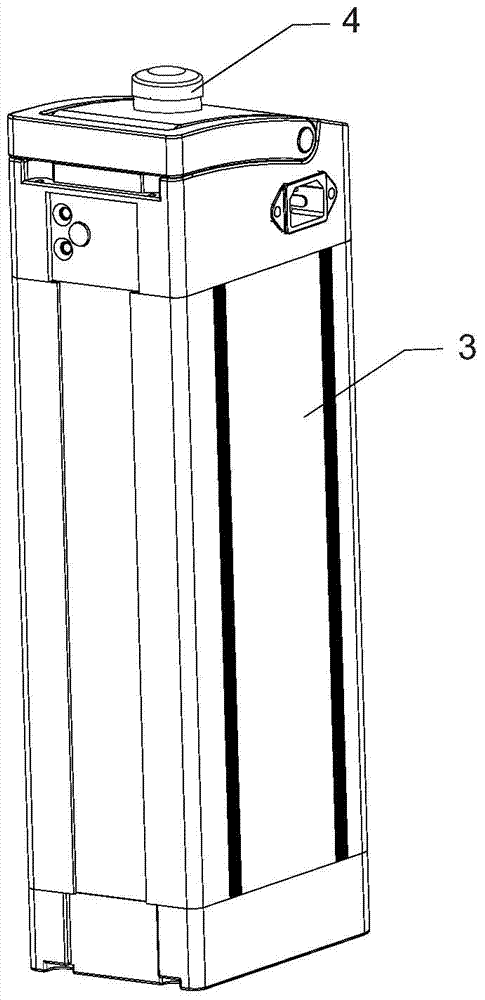

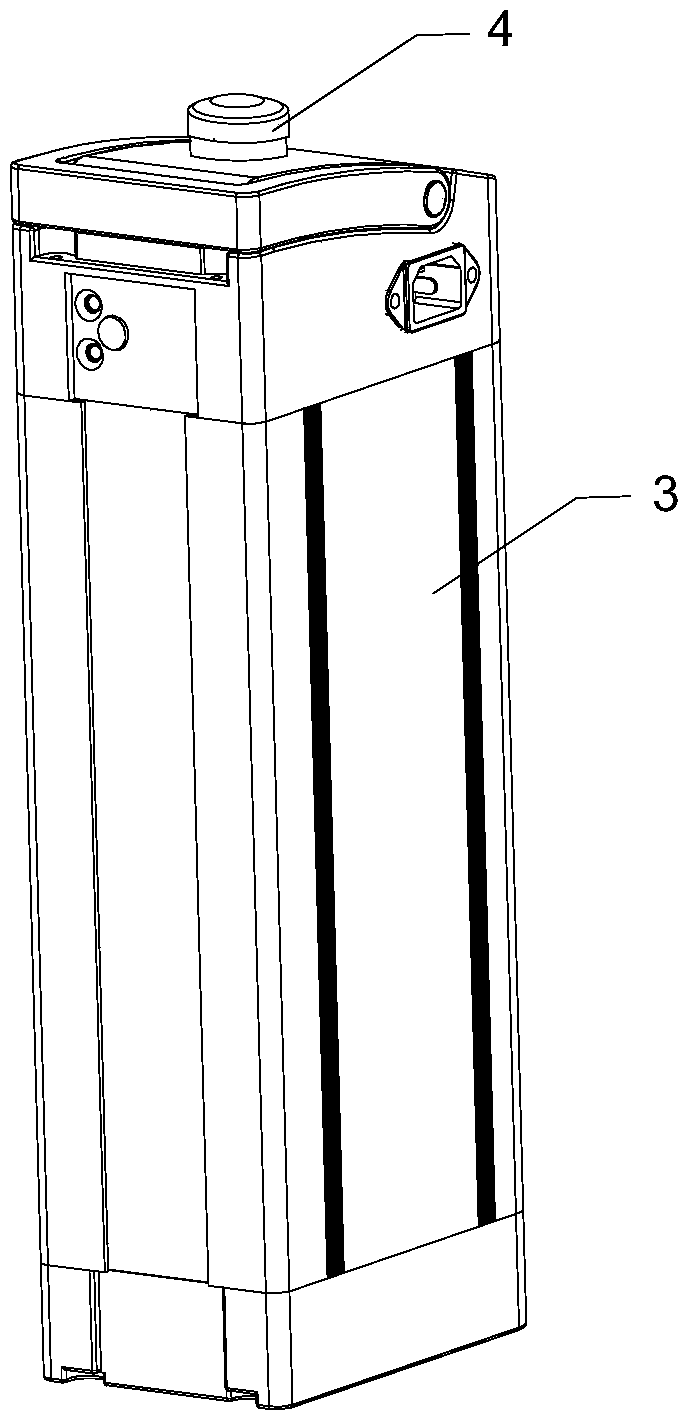

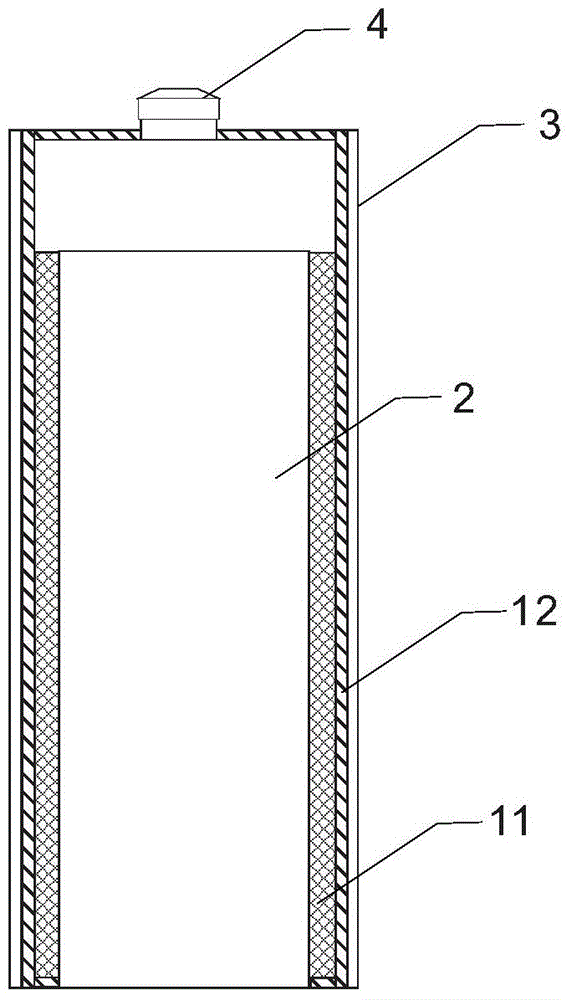

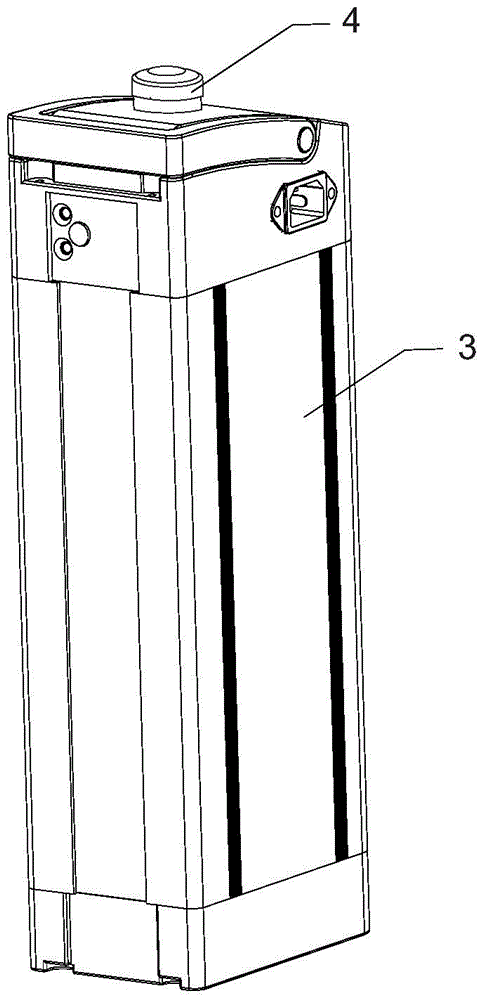

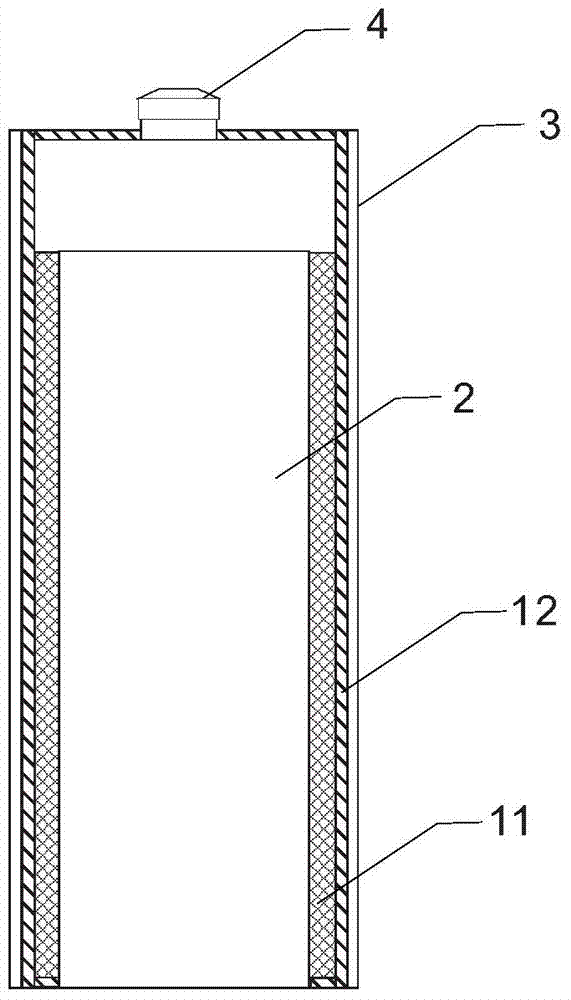

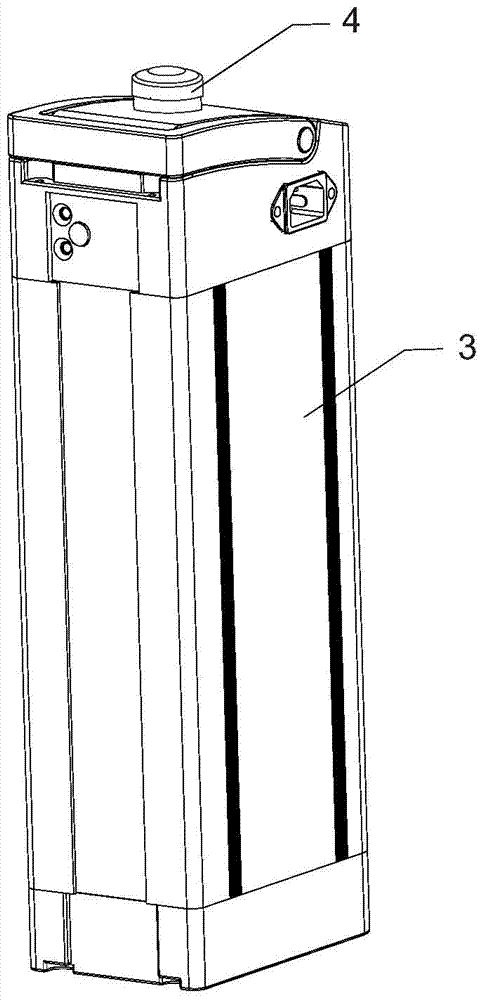

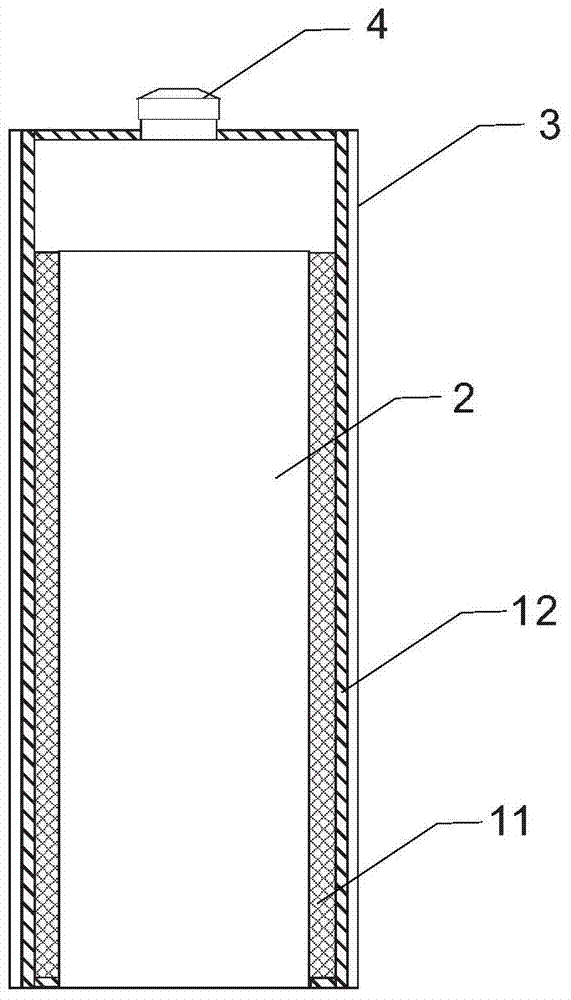

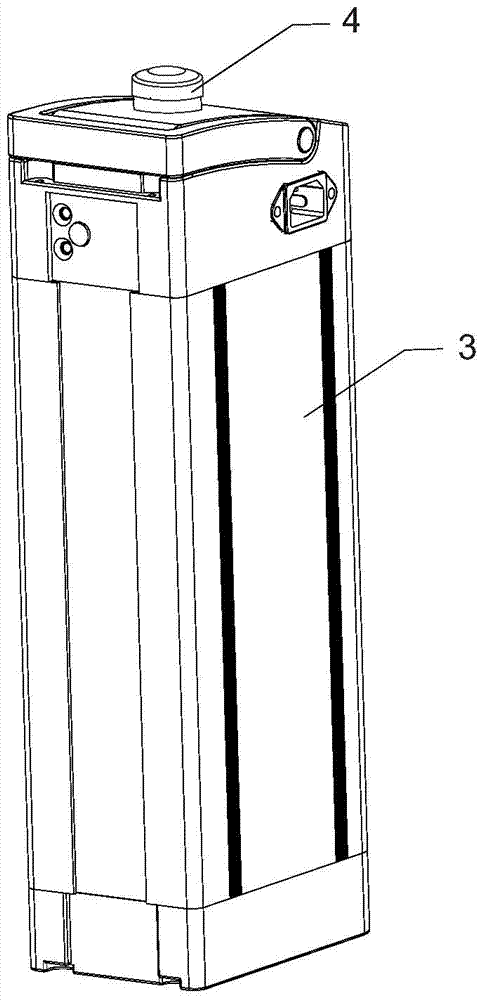

Lithium battery having fire-proof and explosion-proof device and electrical vehicle equipped with same

ActiveCN104218202AImprove security performanceReduce security risksFire rescueSecondary cell gas removalAutomotive engineeringElectric cars

The invention discloses a lithium battery having a fire-proof and explosion-proof device. The lithium battery includes a cell set, a cell protective sheath and an external shell. The cell set is arranged in the cell protective sheath and the cell protective sheath is disposed in the external shell. A thermal-insulation layer is disposed between an inner surface of the external shell and the cell protective sheath. A clearance between the cell protective sheath and the thermal-insulation layer is filled with a fire extinguish material. The external shell is provided with a discharging hole. In the device, during a use process of the lithium battery, the fire extinguish material, which can be subject to an endothermic reaction when being heated and generates carbon dioxide, is used as a working medium for performing heat absorption and oxygen insulation to the battery. In addition, an internal pressure of the battery can be regulated timely. By the comprehensive protective method above, accidents, such as ignition, explosion and the like, can be effectively prevented so that safe risk of the lithium battery can be greatly reduced.

Owner:ZHEJIANG CHAOWEI CHUANGYUAN INDUSTRAIAL

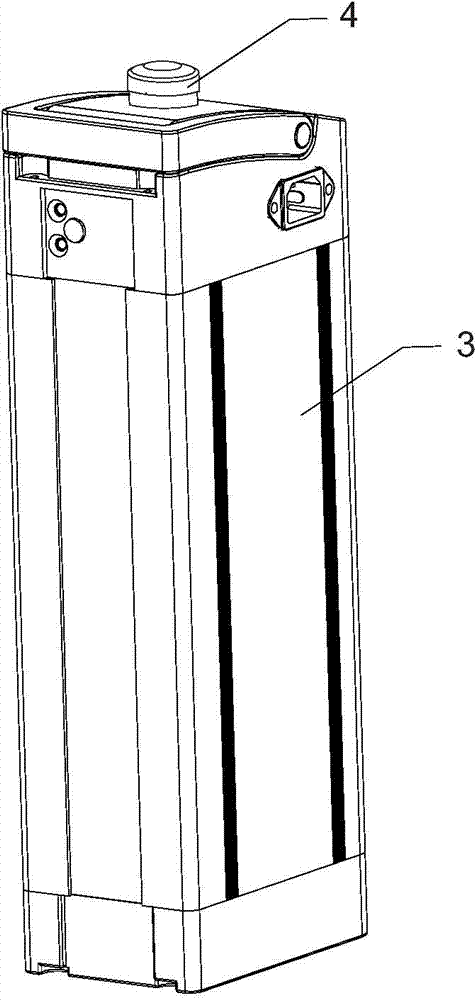

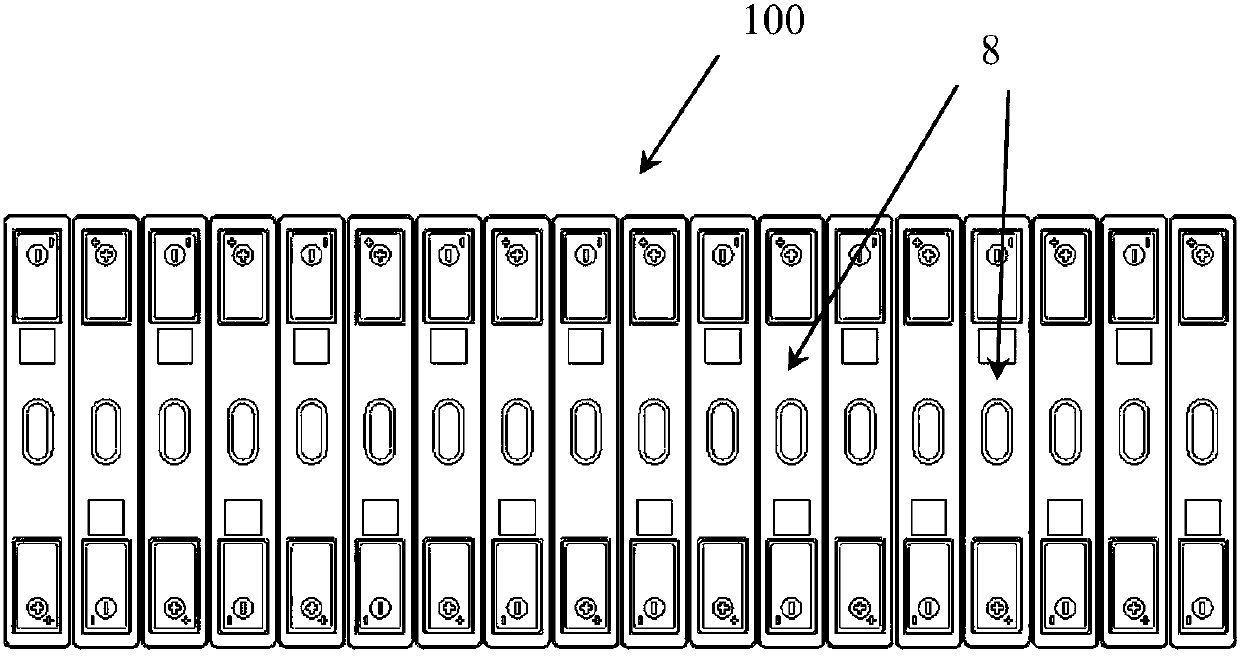

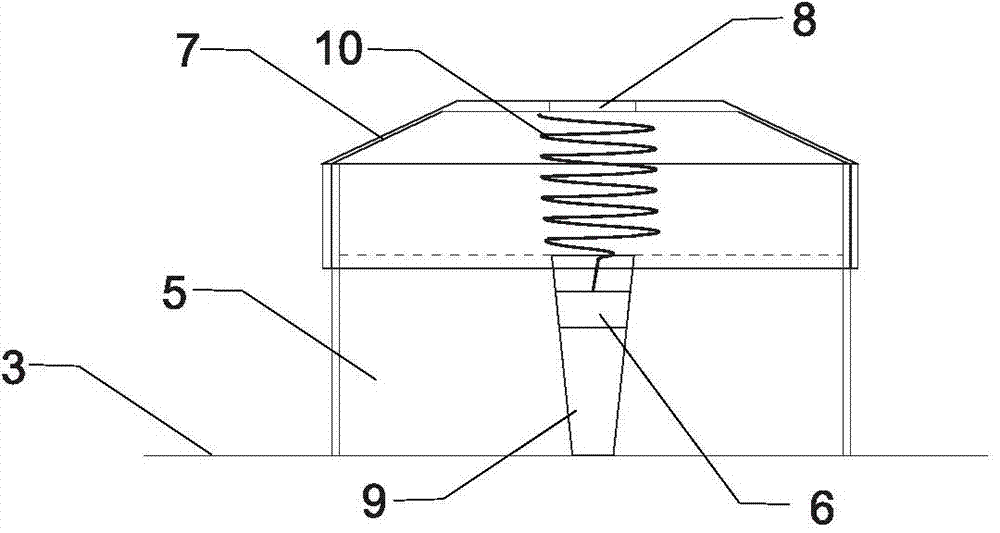

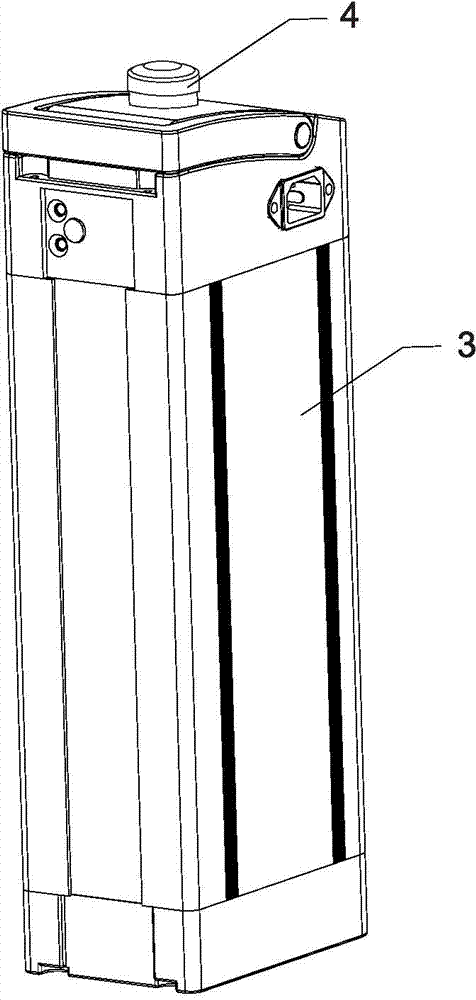

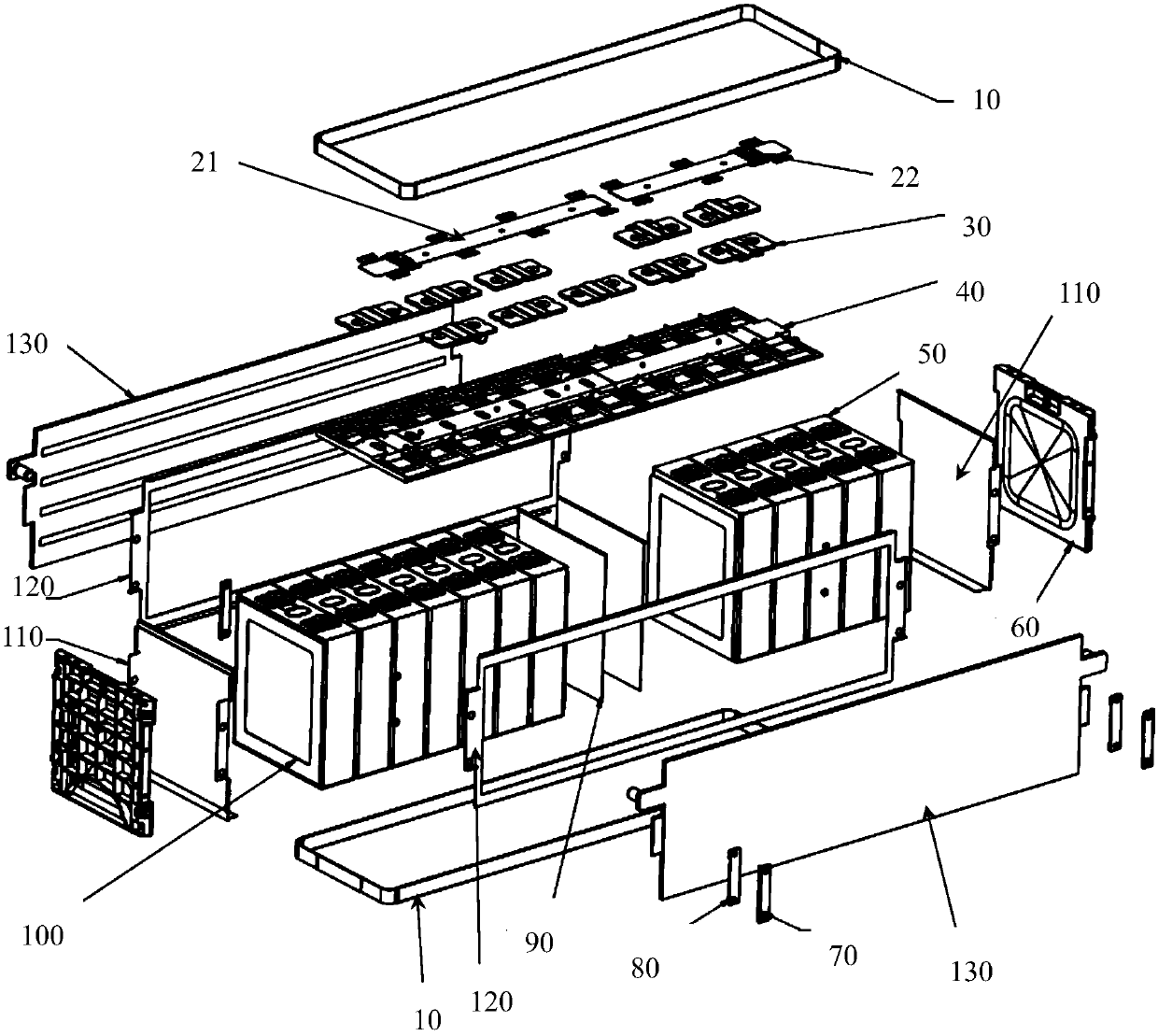

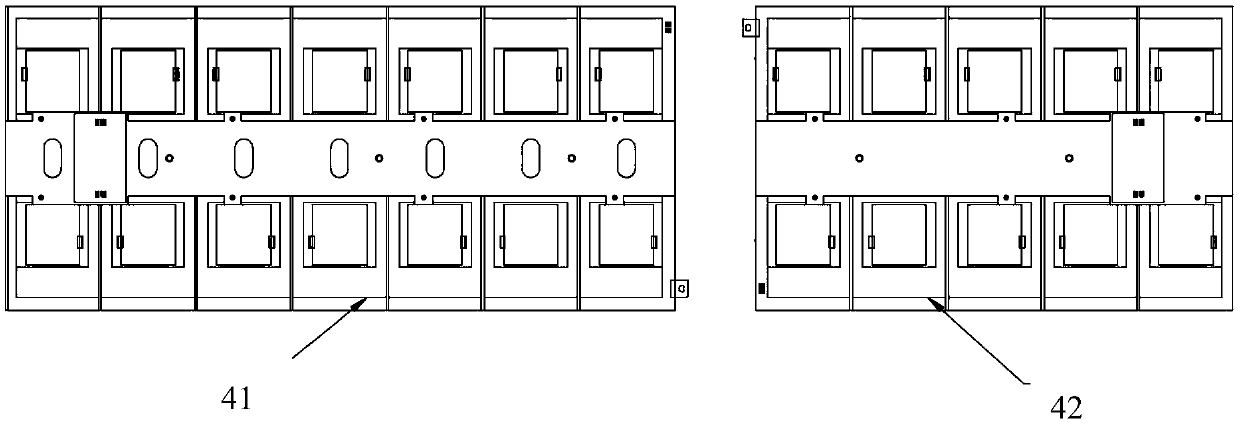

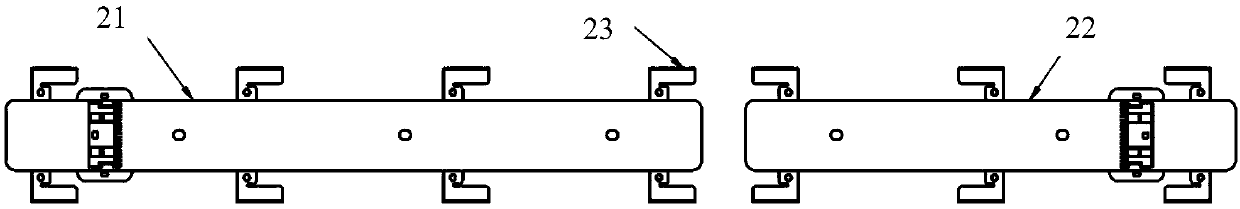

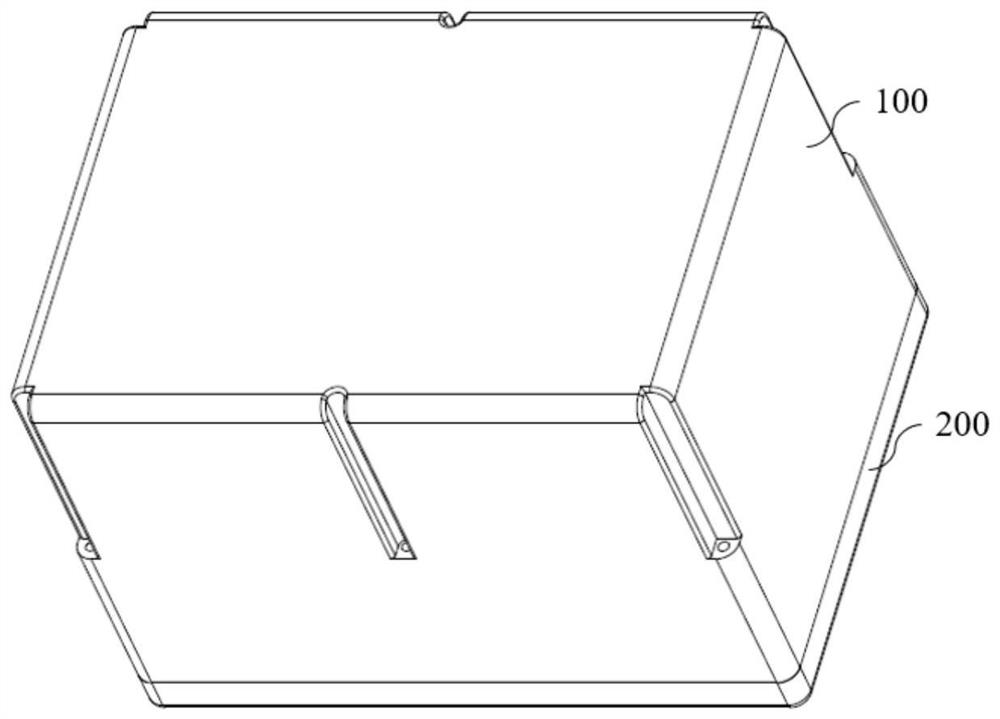

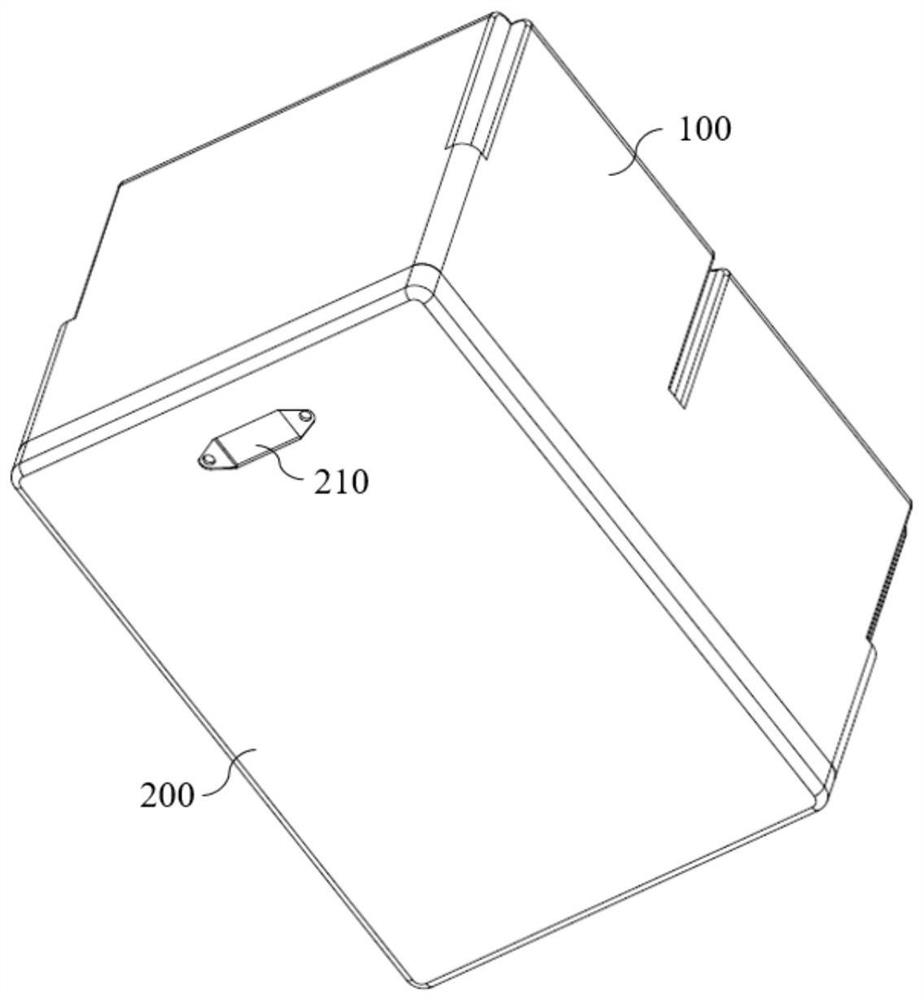

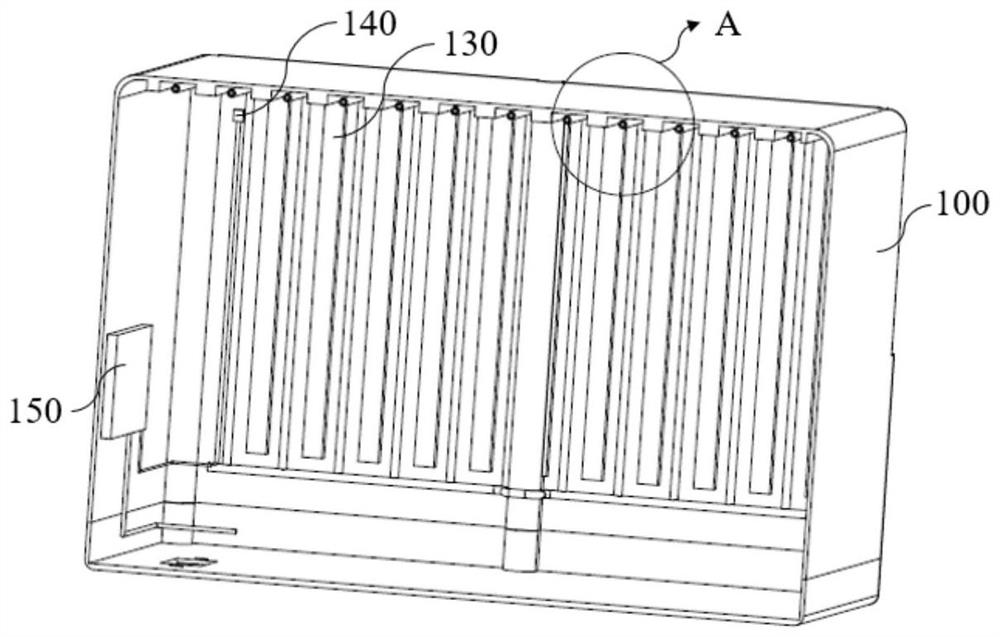

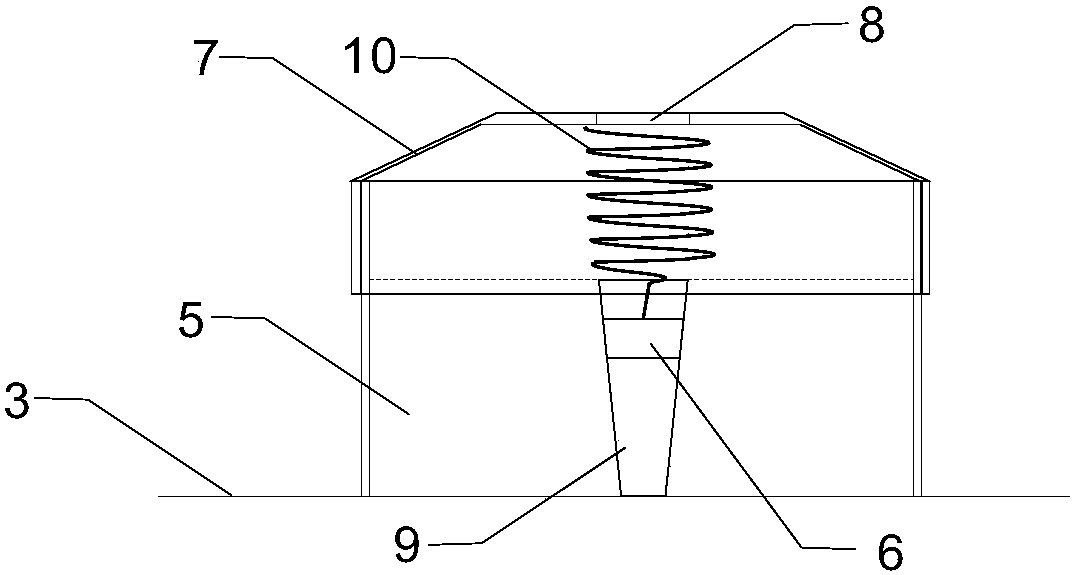

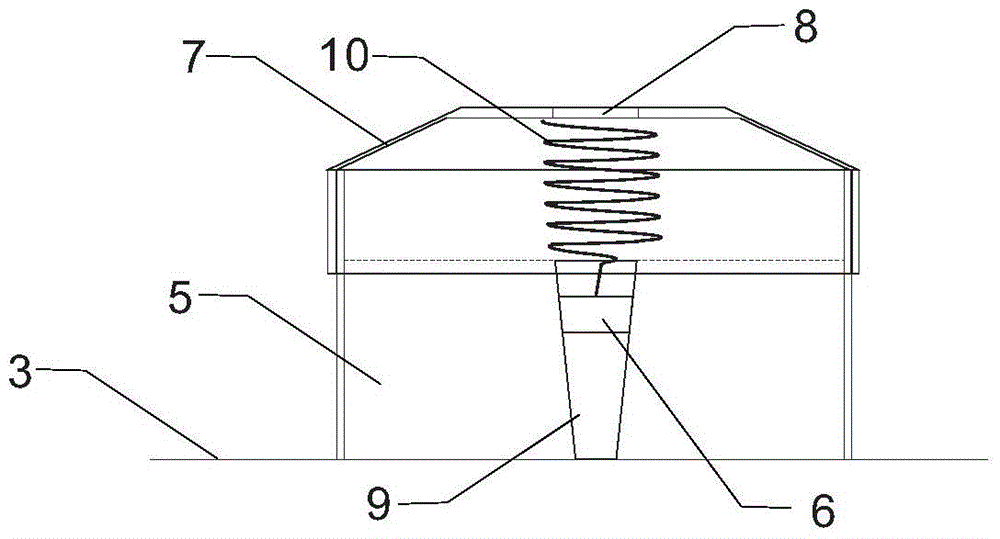

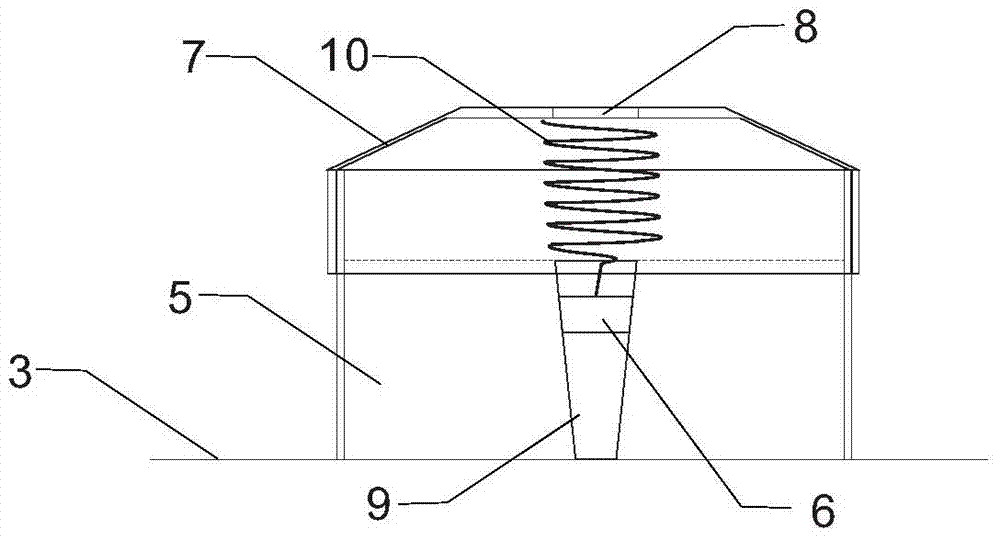

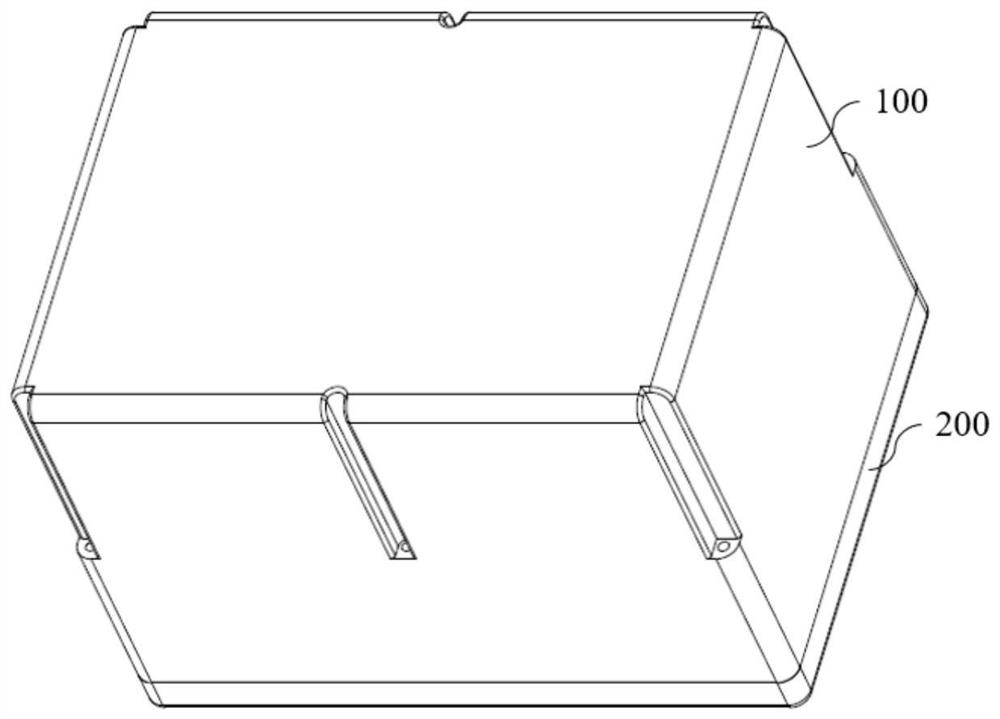

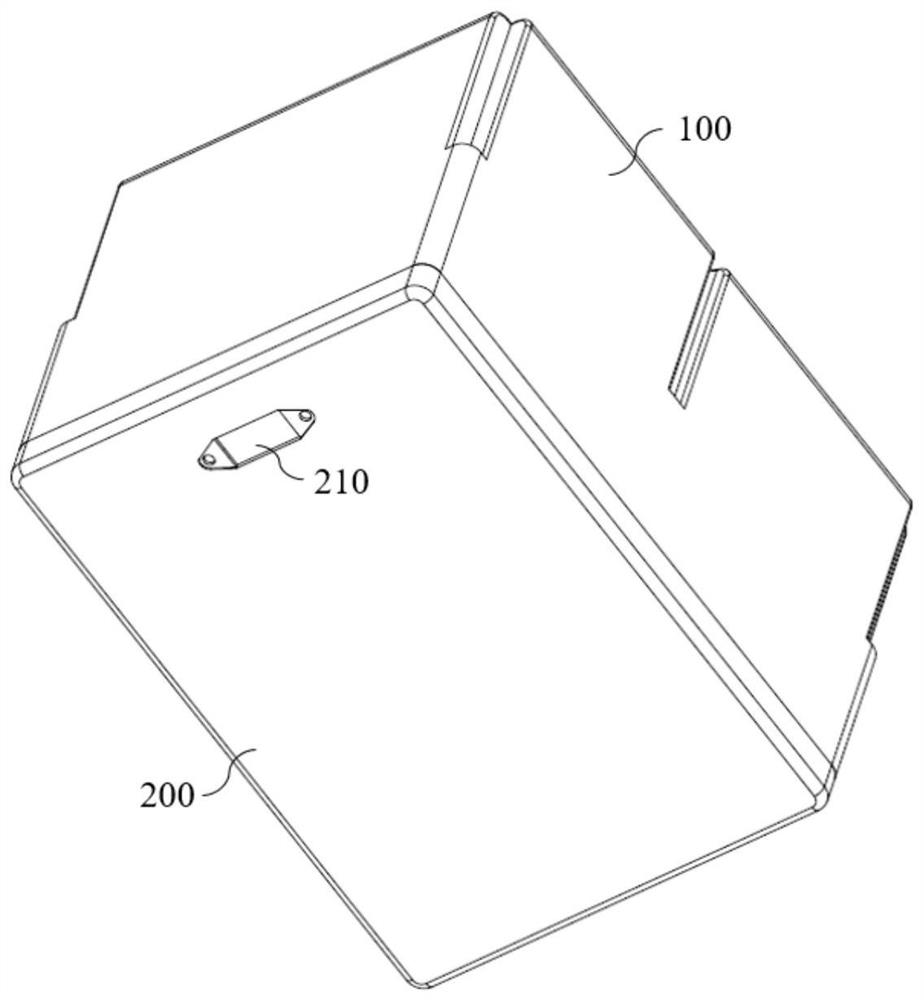

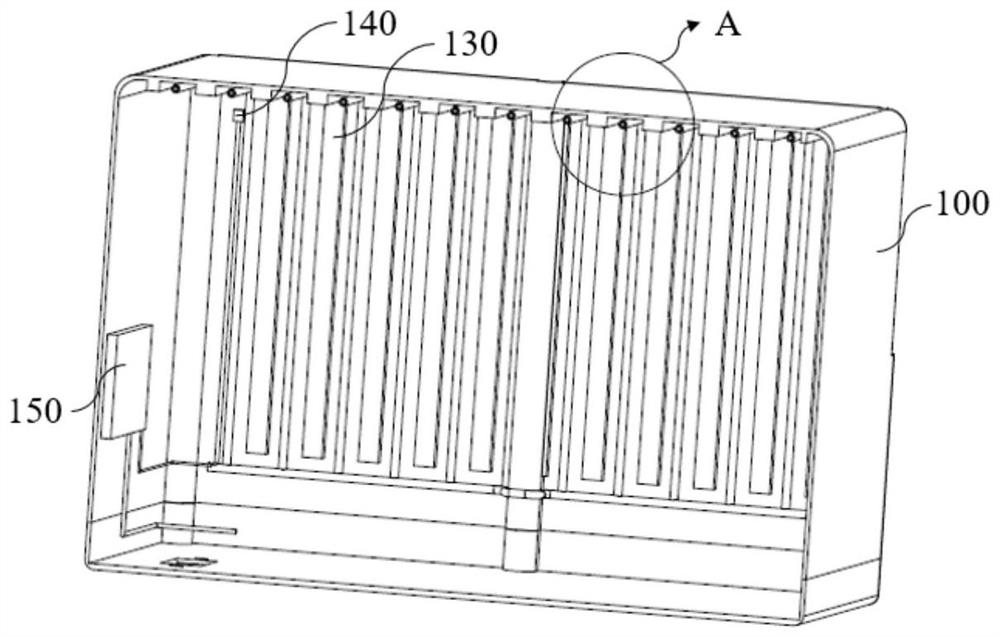

Liquid-cooled battery module

PendingCN107845845AImprove performanceReduce the use of security risksSecondary cellsHeat conductingBattery cell

The invention discloses a liquid-cooled battery module. The liquid-cooled battery module comprises a battery module (100), wherein the battery module (100) comprises a plurality of battery cells (8) which are longitudinally arranged in parallel; the cross section of each battery cell (8) is rectangular; two L-shaped heat conducting tubes (11) are arranged outside the battery module (100) and are distributed in a central symmetry manner; a structure capable of transferring heat is arranged between each heat conducting tube (11) and the battery module (100); each heat conducting tube (11) makescontact with one liquid-cooled plate (6). The liquid-cooled battery module disclosed by the invention has the advantages that the performance is excellent; the temperature in the battery module can bereduced; the problem of heat dissipation of the battery cells in the battery module is well solved; use safe risk of the battery module is remarkably reduced, industry scale can be formed, and wide application is facilitated; the liquid-cooled battery module has great production and practical significance.

Owner:LISHEN (QINGDAO) NEW ENERGY CO LTD

Lithium battery having fire-proof and explosion-proof device and electrical vehicle equipped with same

ActiveCN104218203AImprove security performanceReduce security risksFire rescueSecondary cell gas removalAutomotive engineeringElectrical battery

The invention discloses a lithium battery having a fire-proof and explosion-proof device. The lithium battery includes a cell set and an external shell. The cell set is arranged in the external shell. A clearance between the cell set and the external shell is filled with a fire extinguish material which can be subject to an endothermic reaction and generates carbon dioxide. The external shell is provided with a discharging hole. In the device, during a use process of the lithium battery, the fire extinguish material, which can be subject to an endothermic reaction when being heated and generates carbon dioxide, is used as a working medium for performing heat absorption and oxygen insulation to the battery. In addition, an internal pressure of the battery can be regulated timely. By the comprehensive protective method above, accidents, such as ignition, explosion and the like, can be effectively prevented so that safe risk of the lithium battery can be greatly reduced.

Owner:ZHEJIANG CHAOWEI CHUANGYUAN INDUSTRAIAL

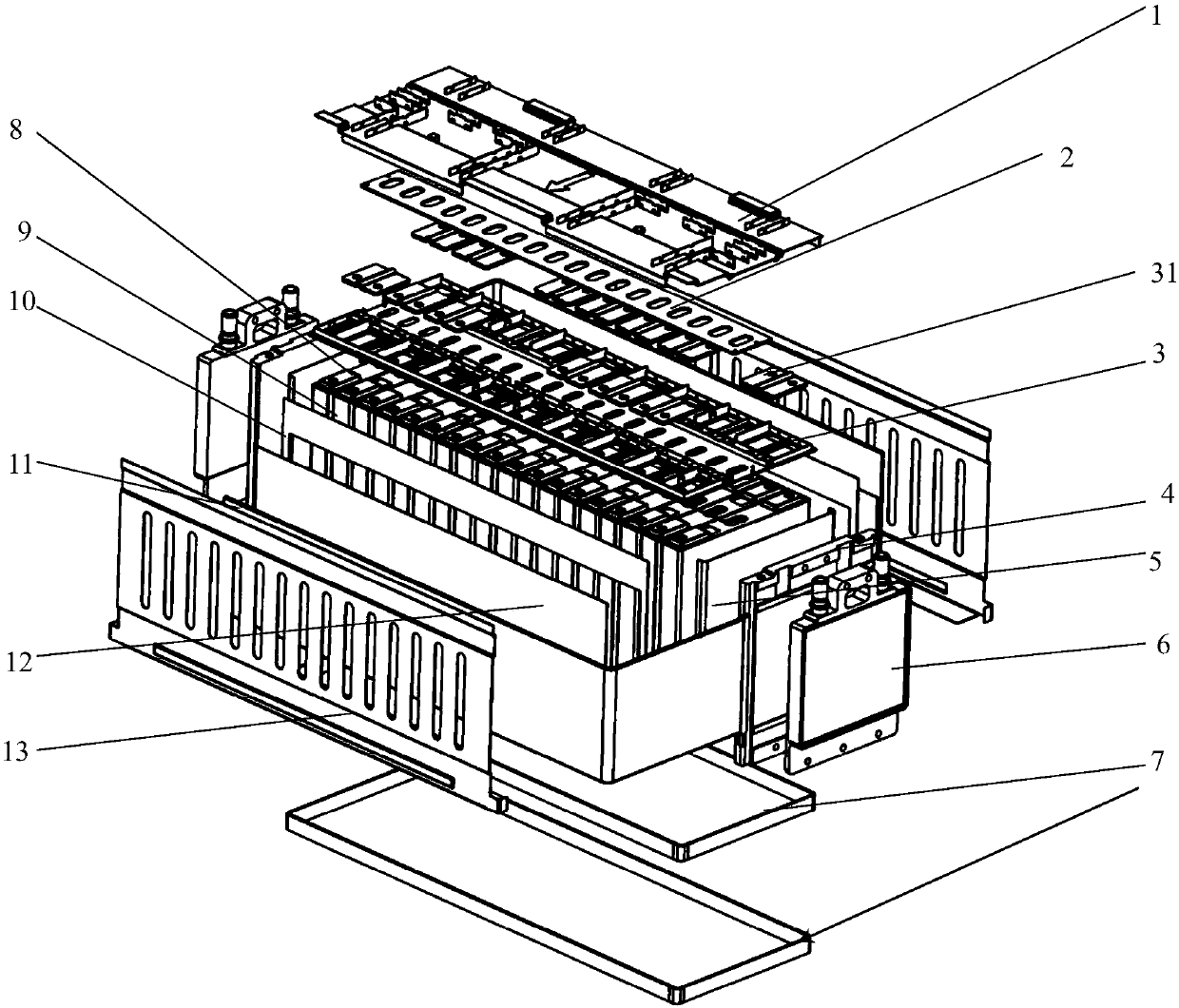

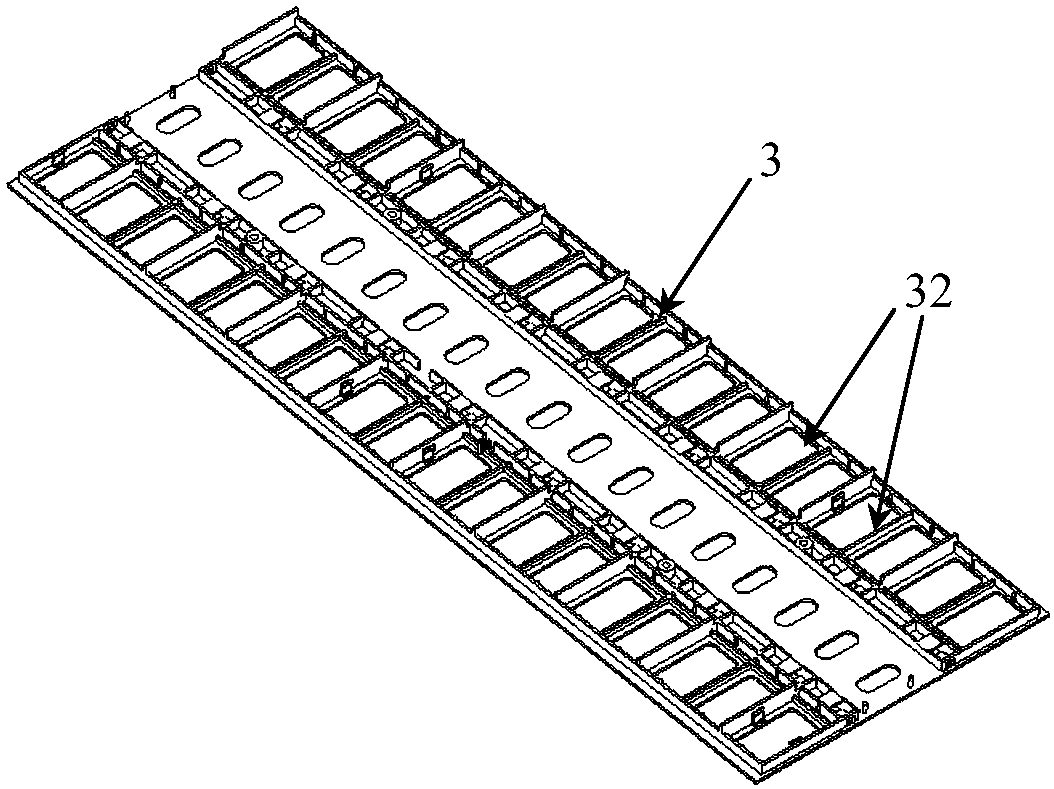

Modularized liquid cooling battery module

PendingCN109524588AScientific and reasonable structure designReduce the use of security risksBatteries circuit arrangementsCell component detailsHigh rateElectrical battery

The invention discloses a modularized liquid cooling battery module, comprising a battery module main body, wherein the battery module main body comprises a plurality of parallelly arranged monomer battery cells; the tab of each monomer battery cell is located on the top surface; the left and the right of the battery module main body are respectively vertically provided with an aluminium materialprotective plate; the front side and the back side of the battery module main body are respectively vertically provided with a liquid cooling plate; the left end and the right end of the liquid cooling plate are respectively fixedly connected with the two aluminium material protective plates; the outer surface of each monomer battery cell is wrapped with a polyimide film; a first insulating plateis arranged between any two adjacent monomer battery cells, and the first insulating plate is adhered with the monomer battery cells by a heat conducting structural adhesive. The modularized liquid cooling battery module disclosed by the invention is scientific and reasonable in structure design, can effectively control the problem of temperature rise of the lithium battery, ensures that a batterycell in a battery module performs high-rate charging and discharging operation, and further ensures the safety performance of the battery cell.

Owner:LISHEN (QINGDAO) NEW ENERGY CO LTD

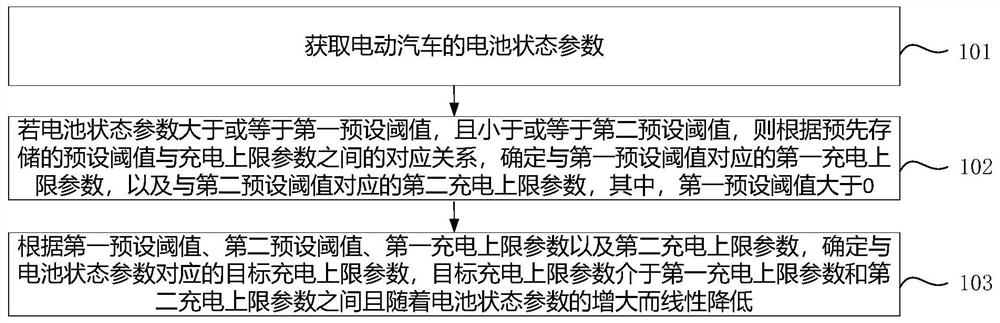

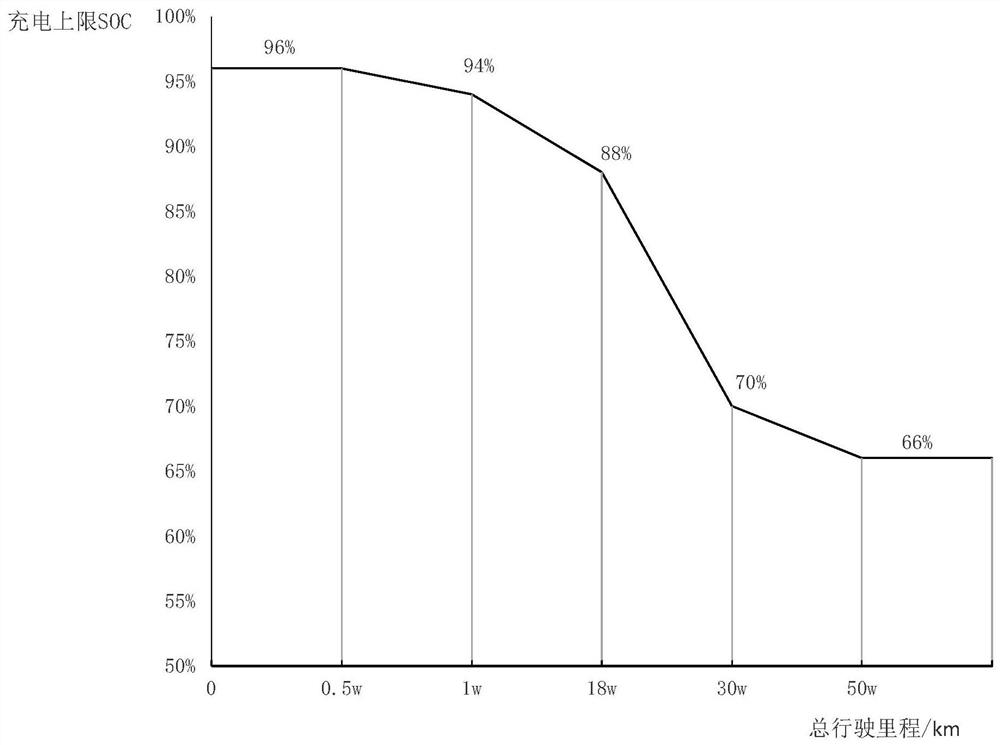

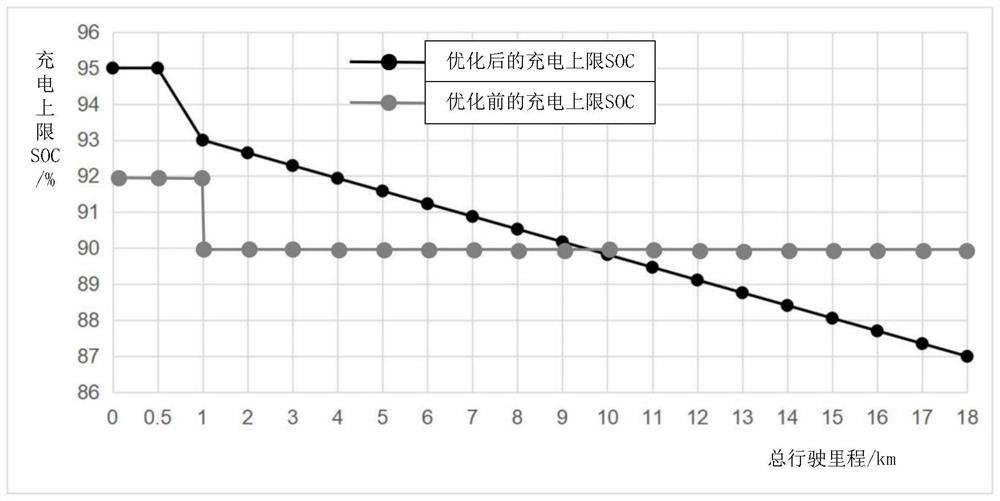

Battery management method and device and vehicle

ActiveCN112572233AImprove operating conditionsReduce lifespan decay rateCharging stationsElectric vehicle charging technologyElectrical batterySimulation

The embodiment of the invention provides a battery management method and device and a vehicle. The battery management method comprises the steps of obtaining a battery state parameter of the electricvehicle; if the battery state parameter is between a first preset threshold value and a second preset threshold value, determining a first charging upper limit parameter corresponding to the first preset threshold value and a second charging upper limit parameter corresponding to the second preset threshold value; and determining a target charging upper limit parameter according to the first preset threshold value, the second preset threshold value, the first charging upper limit parameter and the second charging upper limit parameter. According to the technical scheme, the interval range where the target charging upper limit parameter is located is determined according to the interval range where the battery state parameter is located, and the target charging upper limit parameter is linearly reduced along with the increase of the battery state parameter in the corresponding interval range, so that a user does not perceive the endurance change of the whole vehicle; and different charging upper limit parameters can be set in each stage of the battery, so that the attenuation speed of the service life of the battery is reduced, and the safety risk is reduced.

Owner:GUANGZHOU CHENGXING ZHIDONG AUTOMOTIVE TECH CO LTD +1

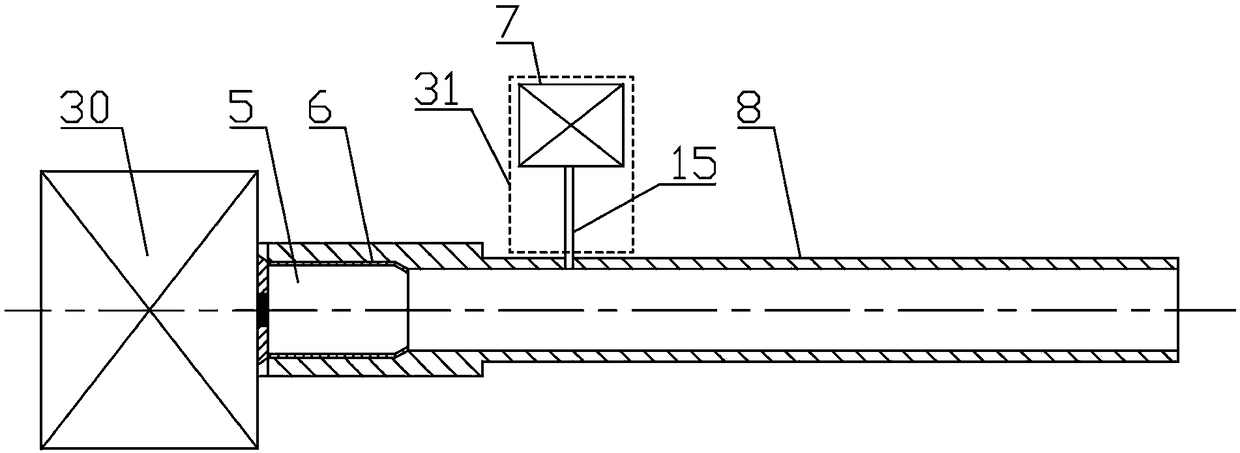

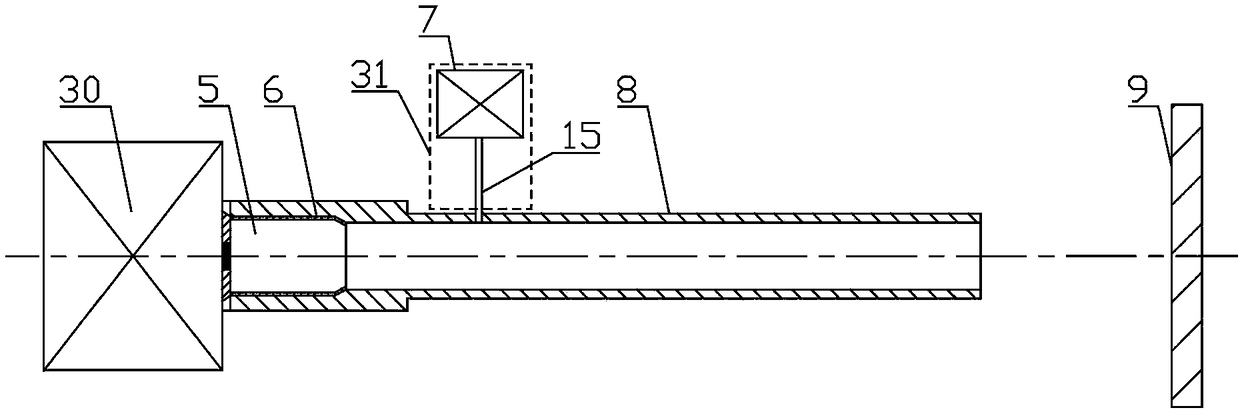

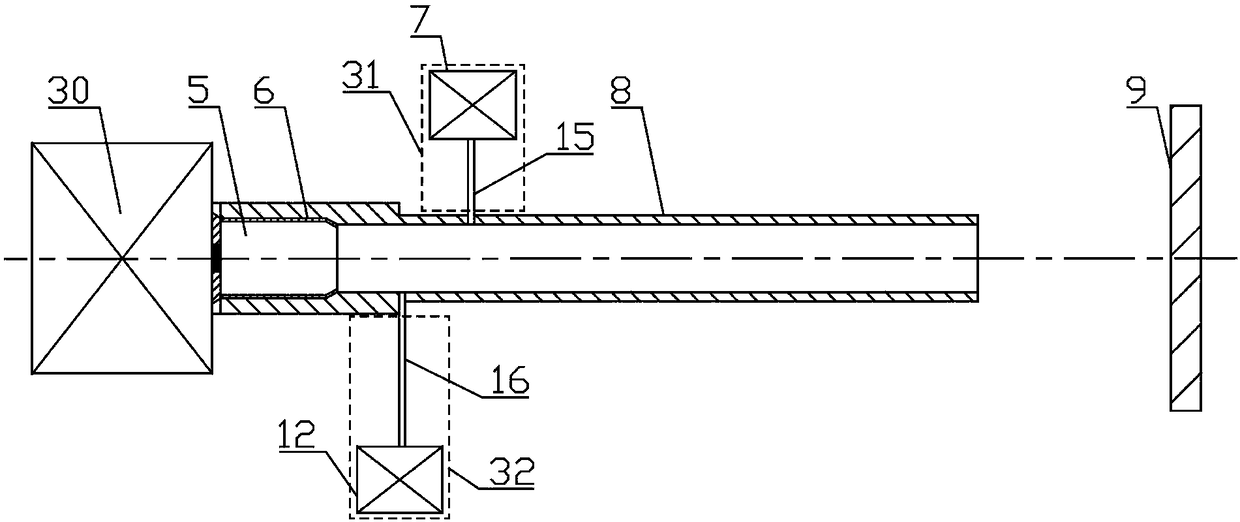

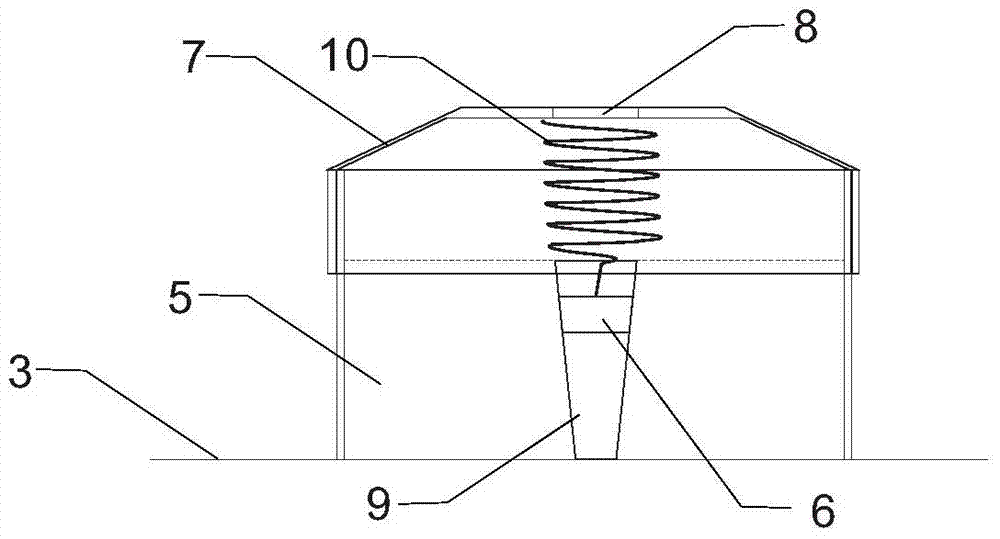

Detonation gun spraying device and detonation gun spraying technology

The invention relates to a detonation gun spraying device and a detonation gun spraying technology. The detonation gun spraying device comprises a launching unit, a jet pipe and a projectile body; thejet pipe is connected to the launching unit; a power supply unit is connected to the jet pipe and is used for conveying spraying powder into the jet pipe; the launching unit is used for detonating the projectile body; and a blast wave generated by detonation of the projectile body pushes and heats the spraying powder to jet toward a workpiece to form a coating in the jet pipe. The detonation gunspraying device provided by the invention is simple in structure, can utilize detonation of a solid propellant or a propellant in a powder load or a bullet to push and heat a powder material, replacesthe traditional technological device for pushing and heating the powder material with detonation of hybrid gas, is more light, handy and portable and can realize filed construction operation to ultra-large type parts. The detonation gun spraying technology provided by the invention does not involve combustible gas and detonation gas, is high in safety, is suitable for spraying technological needsfor various heat spraying powders and realizes accurate control on the detonation gun spraying process.

Owner:王东曦

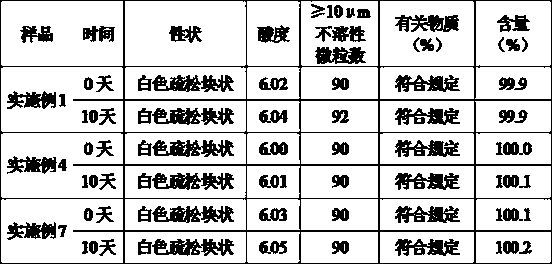

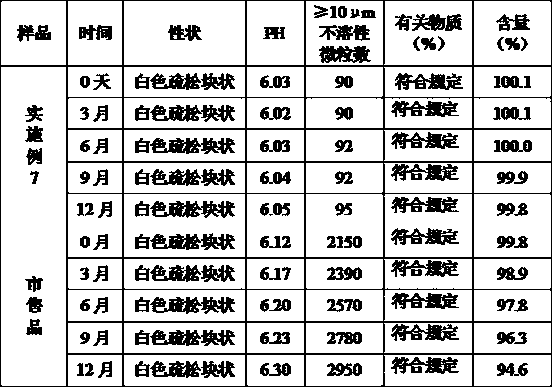

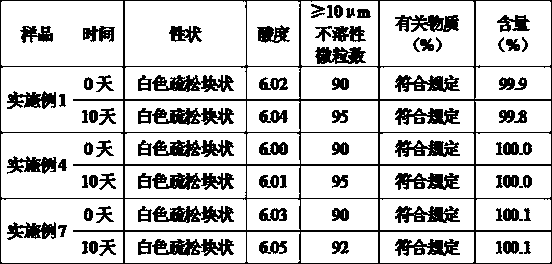

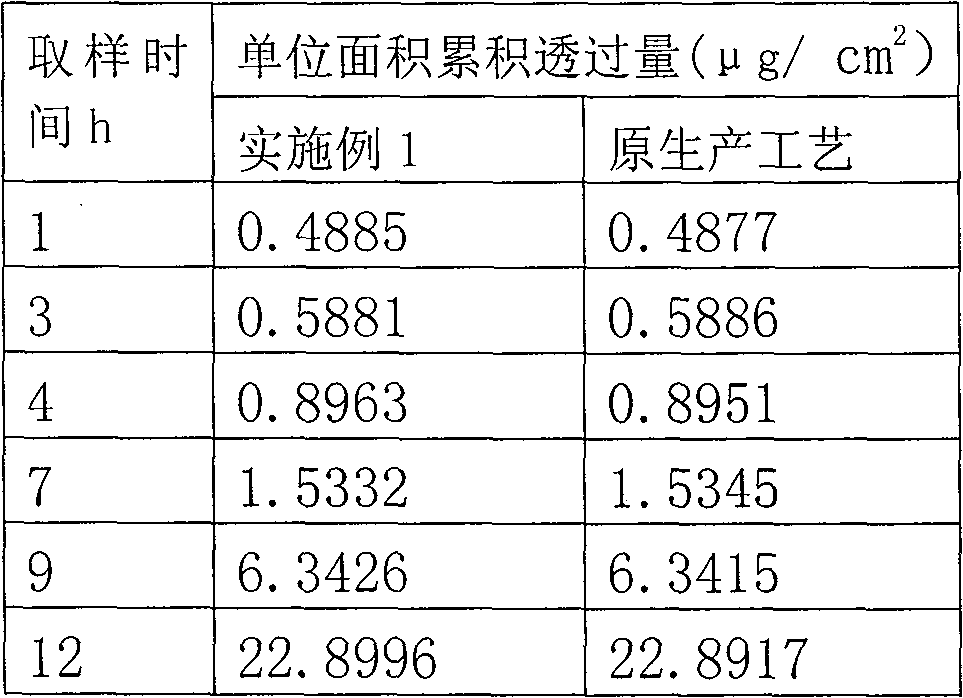

Method for preparing polymyxin B sulfate for injection

ActiveCN108309945AReduce the use of security risksImprove stabilityAntibacterial agentsPowder deliveryMillion UnitsInjections water

The invention relates to a method for preparing polymyxin B sulfate for injection. The auxiliary material of the prepared polymyxin B sulfate for injection is injection water only, and the specification of the polymyxin B sulfate for injection is 0.5 million units. The polymyxin B sulfate for injection, prepared through the method, has significantly improved quality and stability, and has significantly reduced insoluble particle quantity.

Owner:湖北美林药业有限公司

Power battery safety detection method and system and storage medium

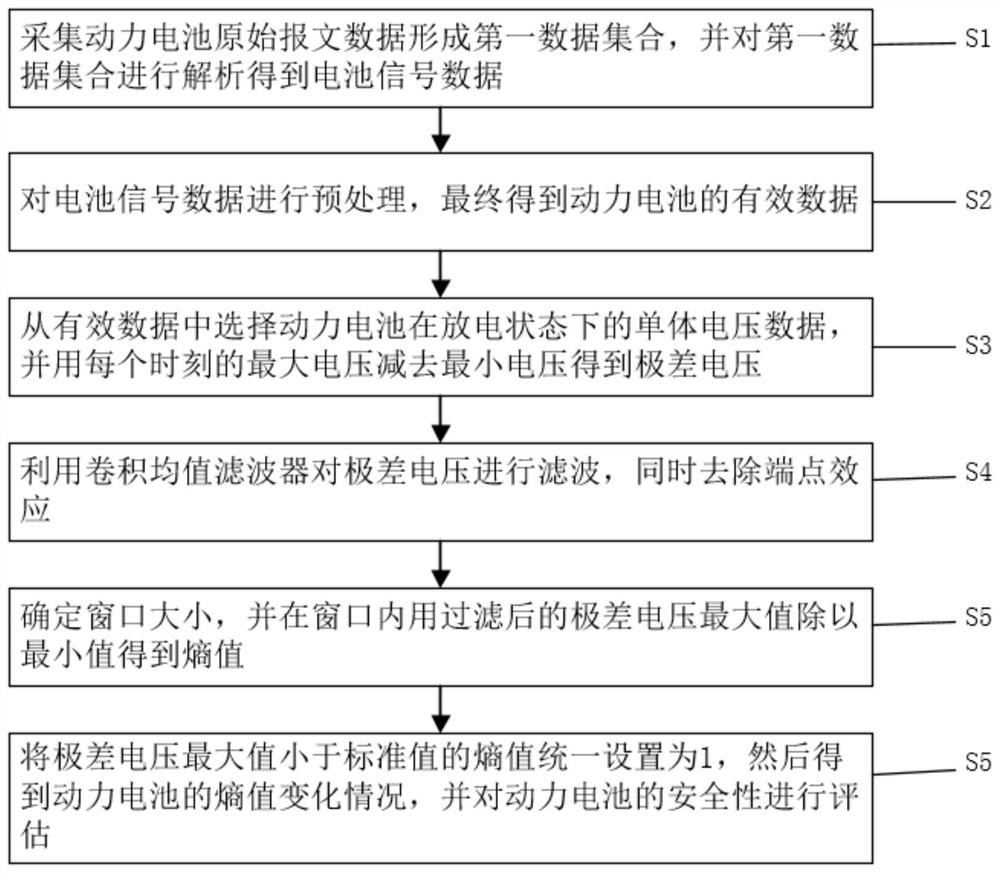

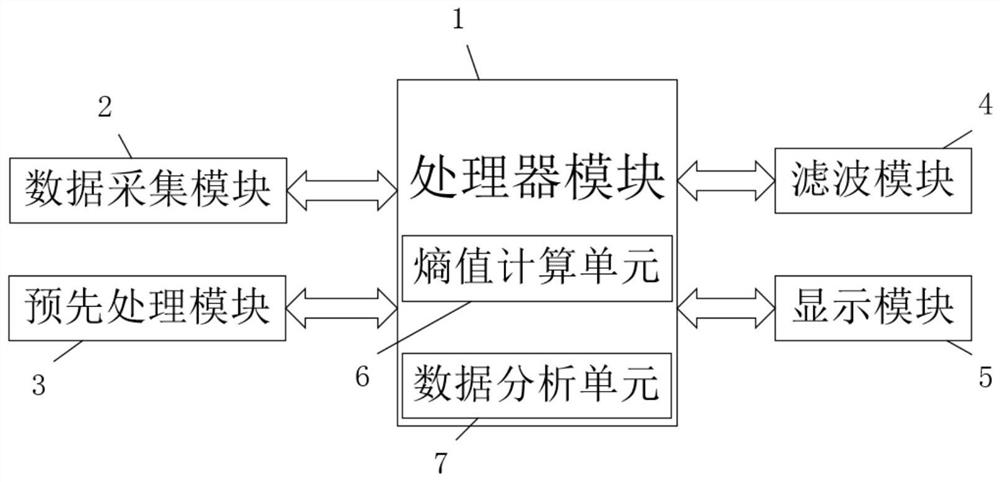

InactiveCN114415032AKnow your health statusReal-time understanding of health statusElectrical testingVehicular energy storagePower batteryData acquisition module

The invention relates to the technical field of power battery safety detection, and discloses a power battery safety detection method and system and a storage medium, and the system comprises a processor module, and a data collection module, a preprocessing module, a filtering module and a display module which are connected with the processor module. Historical operation data of the power battery are collected, single voltage data in a discharging state are adopted to calculate range voltage, and then the change condition of entropy is calculated, so that the safety of the power battery is evaluated accurately and quickly. The method has the beneficial effects of quickly and accurately detecting the health state of the power battery, ensuring the use safety of the power battery and improving the driving safety of the electric automobile.

Owner:CHINA AUTOMOTIVE ENG RES INST

Seedling growing and planting method for Banqiao codonopsis pilosula

ActiveCN112772332AImprove cultivation efficiencyIncrease productionMagnesium fertilisersGrowth substratesMedicinal herbsCodonopsis pilosula

The invention discloses a seedling growing and planting method for Banqiao codonopsis pilosula, and belongs to the technical field of cultivation of traditional Chinese medicinal materials. A nutrient solution special for Banqiao codonopsis pilosula seedling growing is prepared and used for Banqiao codonopsis pilosula seedling growing, and the method comprises the steps of 1), seedling growing including (1) matrix preparation, (2) seed treatment, (3) sowing, (4) water and fertilizer management, (5) temperature and humidity control and (6) illumination management; 2) transplanting and 3) field management including (1) final singling, (2) frame building, (3) bud picking and the like. The problems that the yield and quality of medicinal materials are unstable due to serious weed damage and the like in the seedling stage of direct seeding cultivation of the Banqiao codonopsis pilosula are solved, and the yield of dry medicinal materials per mu reaches 200 kg or above.

Owner:湖北省农业科学院中药材研究所

Lithium battery with fire-proof and explosion-proof device and electric vehicle using the battery

ActiveCN104218193BImprove the protective effectReduce the use of security risksSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsElectrical batteryElectric vehicle

The invention discloses a lithium battery having a fire-proof and explosion-proof device. The lithium battery includes a cell set, a cell protective sheath and an external shell. The cell set is arranged in the cell protective sheath and the cell protective sheath is disposed in the external shell. A clearance between the cell protective sheath and the external shell is filled with bicarbonate powder which can be subject to an endothermic reaction and generates carbon dioxide. Silicon dioxide is arranged between an internal surface of the external shell and the bicarbonate powder. The external shell is provided with a discharging hole. In the device, during a use process of the lithium battery, the bicarbonate powder, which can be subject to an endothermic reaction when being heated and generates carbon dioxide, is used as a working medium for performing heat absorption and oxygen insulation to the battery. In addition, an internal pressure of the battery can be regulated timely. By the comprehensive protective method above, accidents, such as ignition, explosion and the like, can be effectively prevented so that safe risk of the lithium battery can be greatly reduced.

Owner:浙江超恒动力科技有限公司

Method for extracting Olibanum and Myrrha in Fengtongling medicament

The invention relates to a method for extracting Olibanum and Myrrha in Fengtongling medicament, which replaces the methods for extracting Olibanum and Myrrha in Fengtongling medicament in the prior art. The invention is characterized in that methylene chloride is used as an extraction solvent during the extraction process; the consumption of methylene chloride is 0.1 to 2 times the total weight of Olibanum and Myrrha; the extraction method is one available in solvent extraction methods of traditional Chinese medicines and comprises the steps of mixing, ultrasonic treatment and refluxing; during the preparation process of Fengtongling medicament, the procedure of extracting Olibanum and Myrrha with methylene chloride is performed after first-time extraction with methyl salicylate or after second-time or third-time extraction with methyl salicylate; and the application of methylene chloride as extraction solvent of Olibanum and Myrrha in Fengtongling medicament can improve safety of production and application of Fengtongling medicament.

Owner:ZHEJIANG JINGYUETANG PHARMA

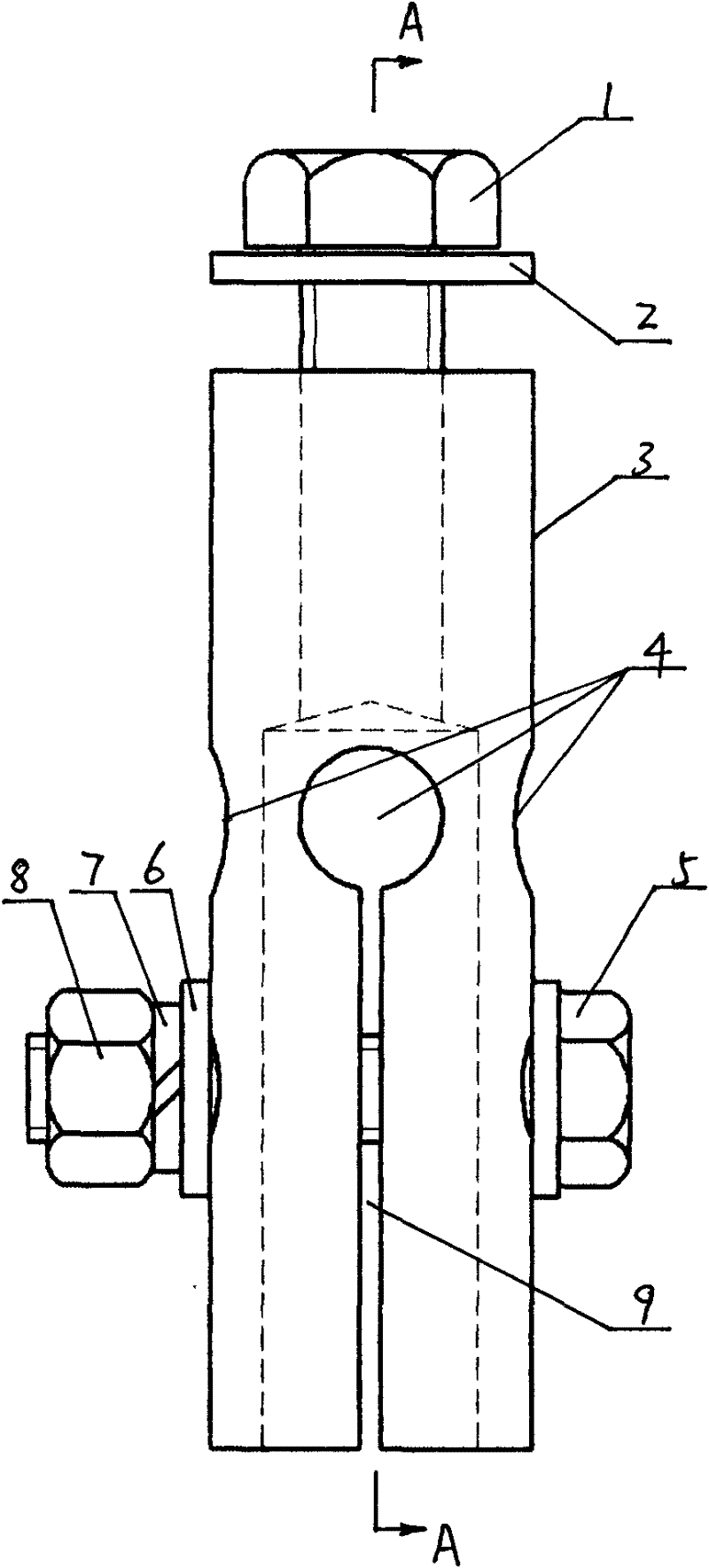

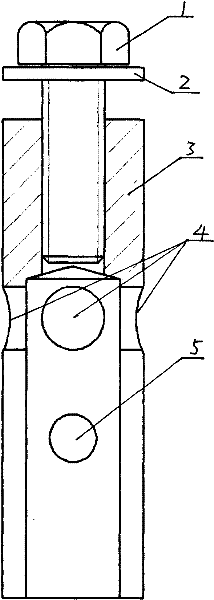

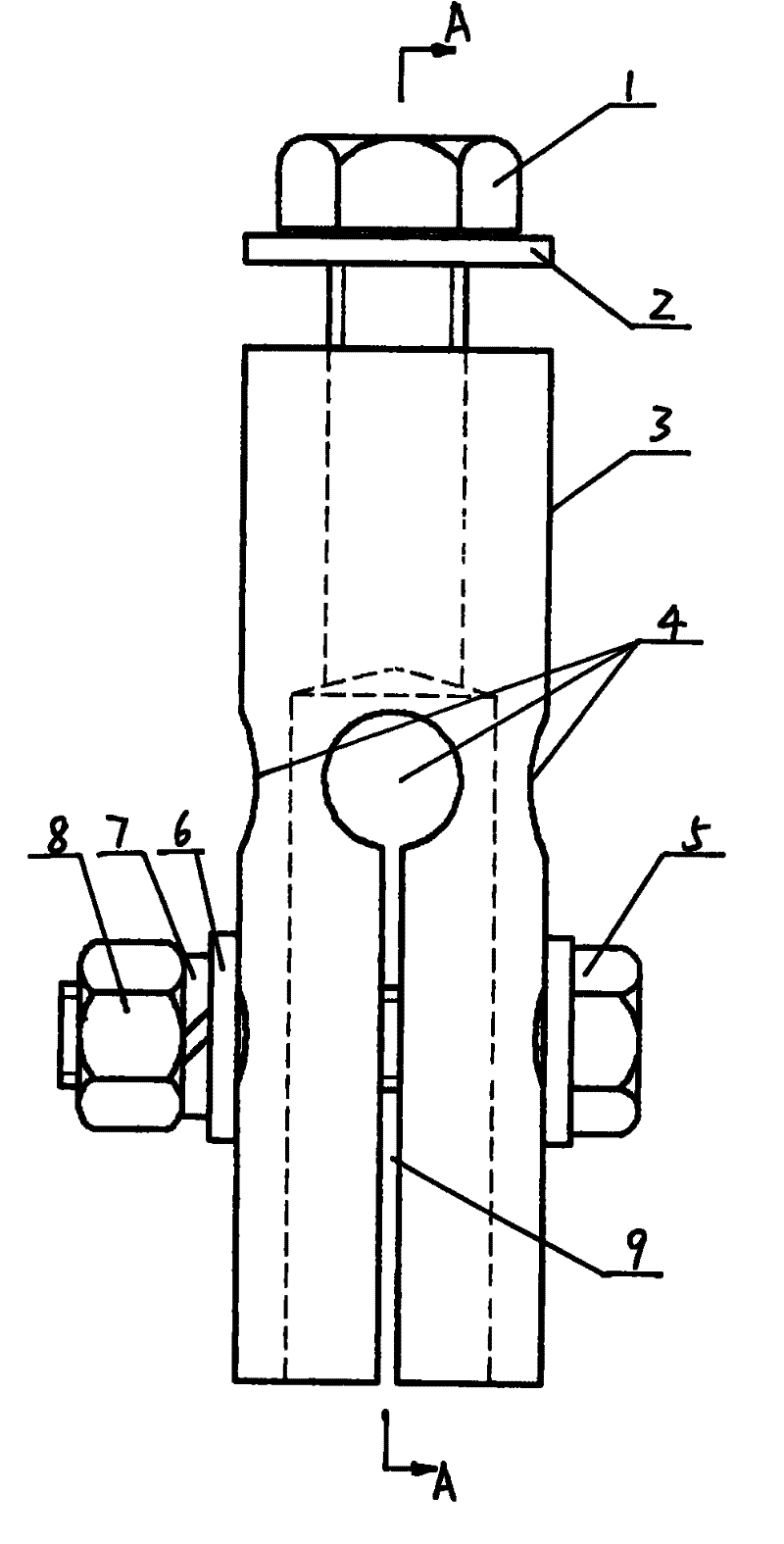

Leading-out connector of anode and cathode terminals of valve-control storage battery

InactiveCN101714711BImprove reliabilityNot easy to slipClamped/spring connectionsMultiple conductors connectorEngineeringUltimate tensile strength

The invention discloses a leading-out connector of anode and cathode terminals of a valve-control storage battery. A screw hole is arranged at the upper end of a high-cap nut, symmetrical expansion seams are vertically arranged on the middle and lower walls of the high-cap nut, four holes are evenly arranged on the same circumference on the wall at the upper end of the expansion seams, the diameter of the inner wall at the lower end of the expansion seam is slightly larger than that of a terminal of the storage battery, and penetrating holes are arranged on the same diameter of the same circumference on the wall of the lower end part of the expansion seam; when the leading-out connector is used, a wire-pressing bolt penetrates into the screw hole, and a wire is tightly pressed at the upper end of the high-cap nut directly or through a spacer; the lower end of the high-cap nut is sleeved on the anode terminal or the cathode terminal of the storage battery, and a long screw rod penetrates into the penetrating hole on the wall of the lower end part of the high-cap nut, locked and fixed by a nut, a spring spacer and a spacer. The leading-out connector can connect wires firmly, can notslide off easily, and is convenient to use when used to replace the lag storage battery. The invention greatly shortens the replacing time, reduces the workload, the labor intensity and the using safety risks, improves the working efficiency and the direct-current system operation, and is light in weight and portable in carrying.

Owner:STATE GRID BAODING ELECTRIC POWER SUPPLY CO +2

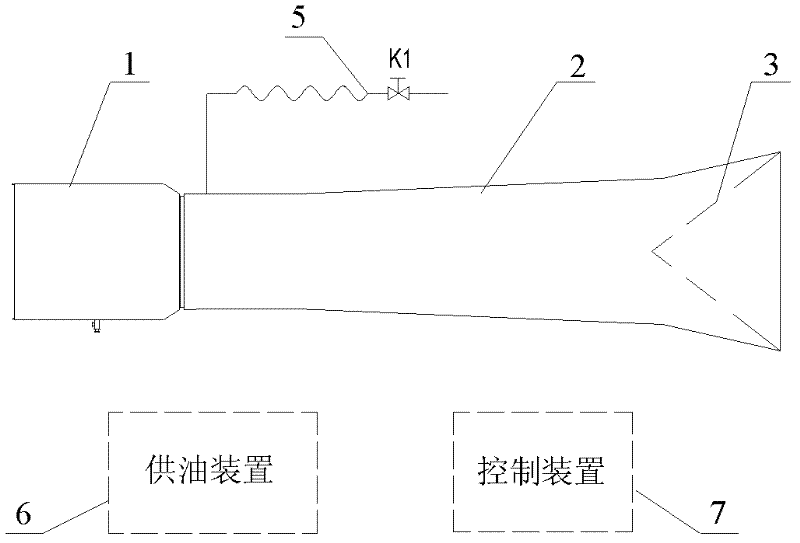

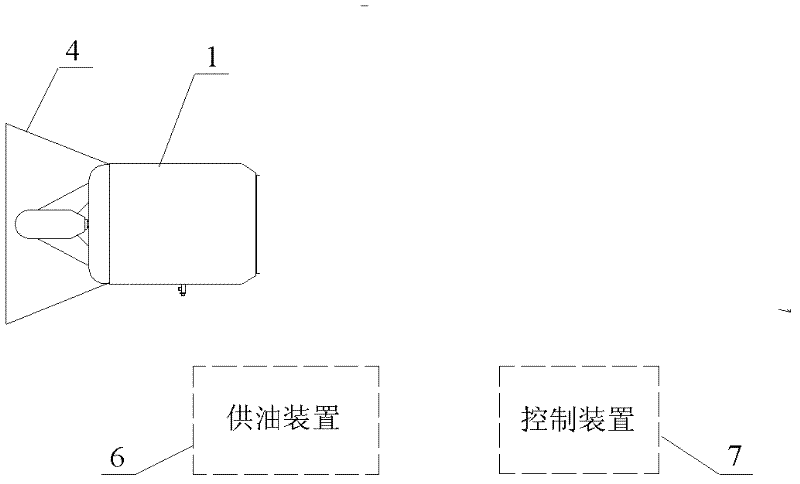

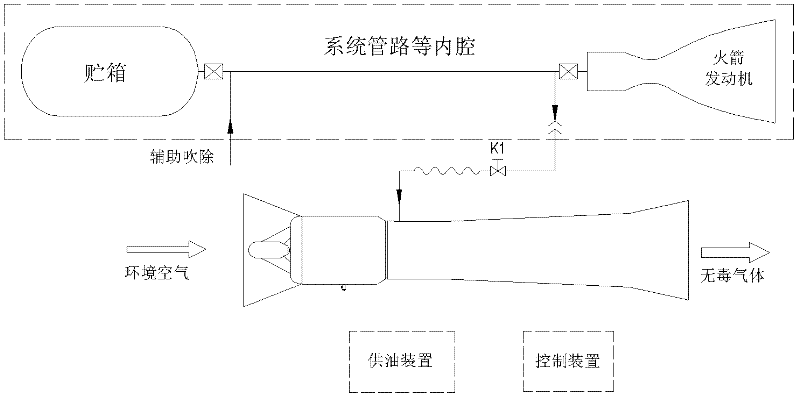

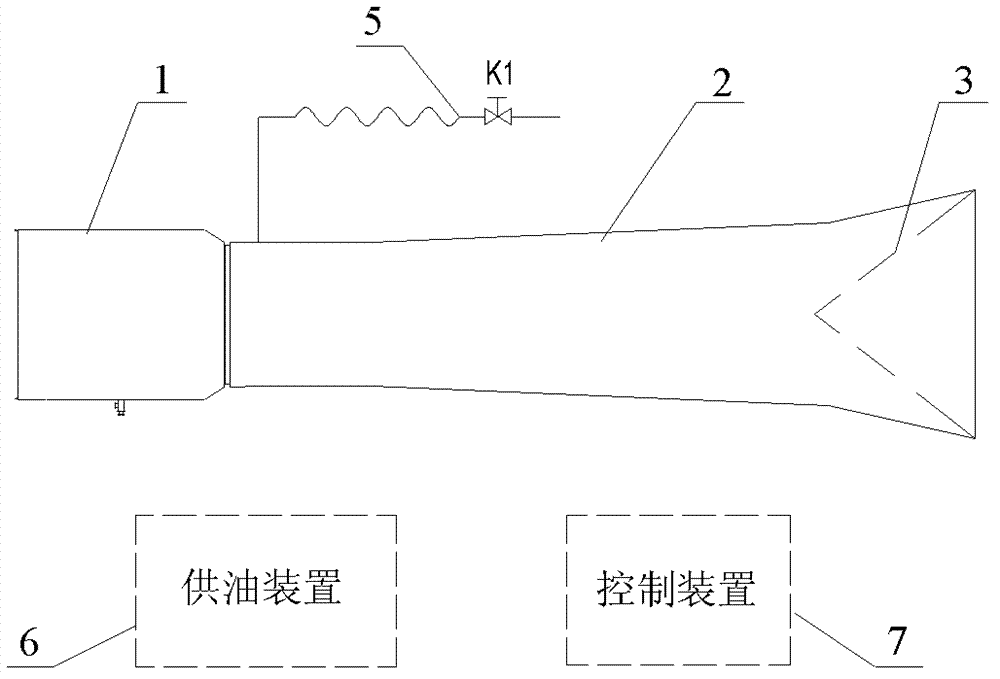

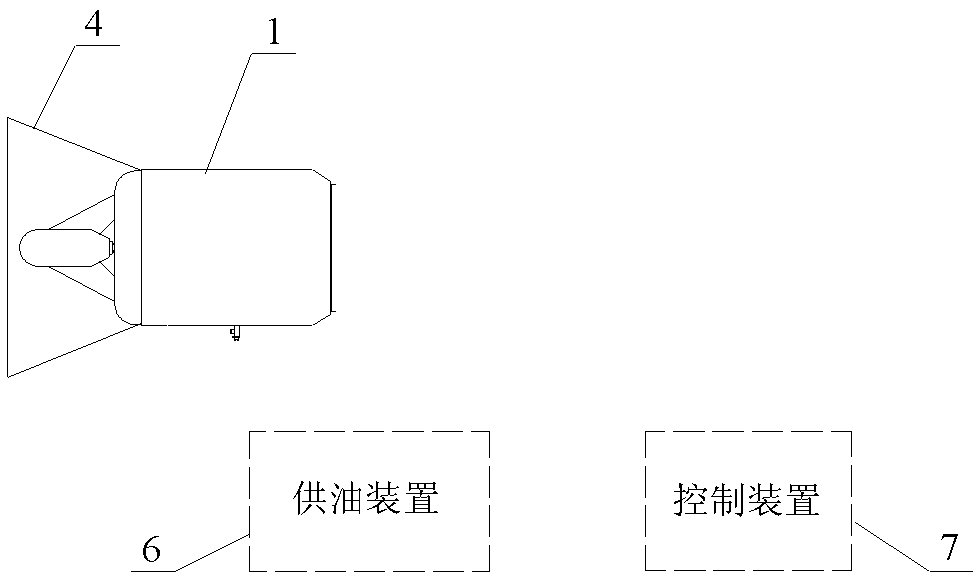

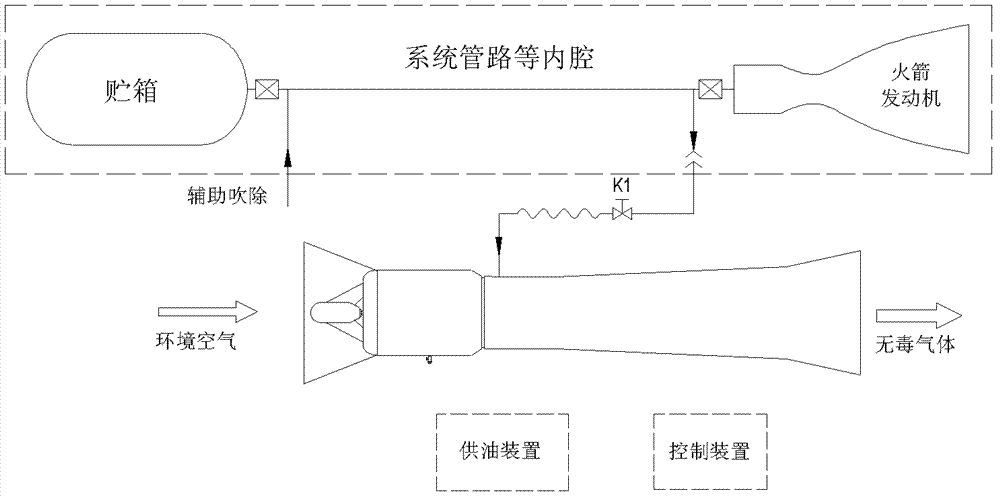

Turbojet injecting incineration device and incineration method

ActiveCN102563667AEfficient removalEasy to handleIncinerator apparatusJet propulsion plantsTurbineIncineration

The invention relates to a turbojet injecting incineration device and an incineration method. The incineration device comprises a turbojet engine, a suction component used for sucking polluted gas, an oil supply device and a control device, wherein the oil supply device supplies oil to the turbojet engine; the control device controls the turbojet engine to work; and the suction component is communicated with the turbojet engine. The incineration method comprises the steps of: generating high-temperature fuel gas, absorbing the polluted gas, incinerating the polluted gas and discharging the polluted gas. According to the turbojet injecting incineration device and the incineration method, disclosed by the invention, the technical problems of poorer cleaning effect of the traditional blowing method, low efficiency of the traditional neutralization processing method and various types of used devices of the traditional incineration method are solved, the equipment scale is small, high processing efficiency is obtained, and cleaning and detoxifying treatment on toxic propellants remained in a propelling system can be carried out.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

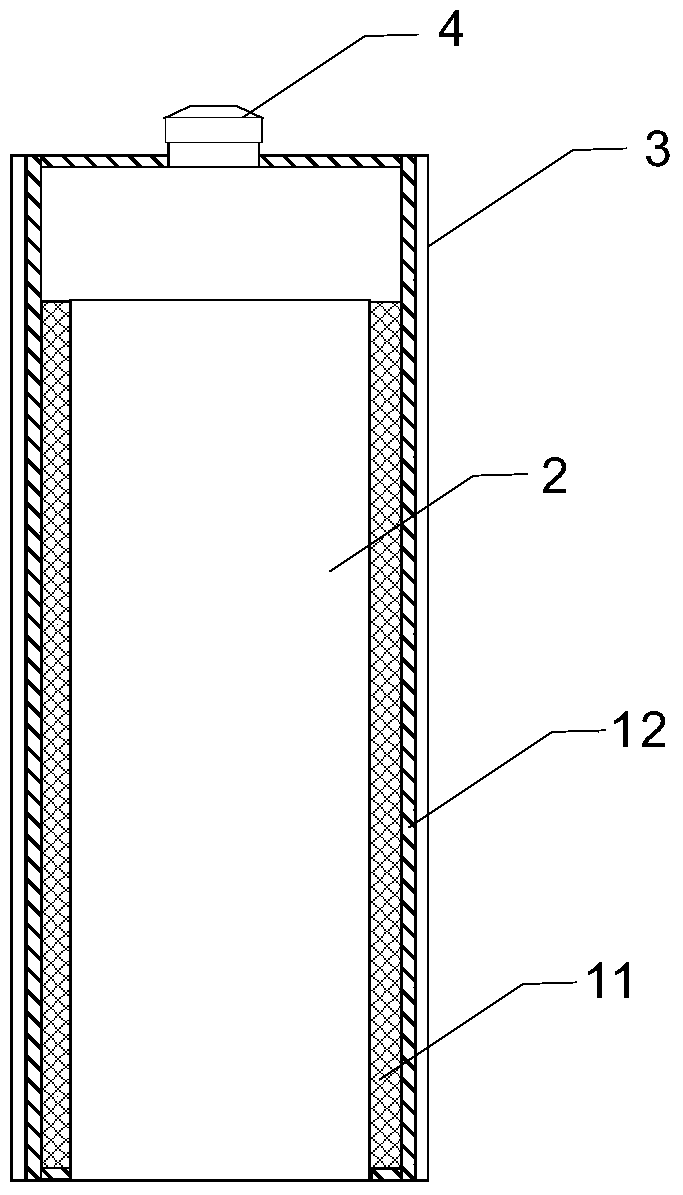

Lithium battery box, lithium battery pack and application thereof

ActiveCN111697290BAvoid damageAvoid translocationSecondary cellsHeating element shapesThermodynamicsEngineering

The invention discloses a lithium battery box, a lithium battery pack and applications thereof, belonging to the technical field of lithium batteries. It includes a box body and a base. The box body and the base are detachably connected. The inner wall is also provided with several insulating partitions, and the installation space of the insulating layer is formed between two adjacent insulating partitions, wherein the thickness of the insulating partition is greater than the diameter of the insulating layer, and the two ends of the heating wire are respectively electrically connected to the positive electrode of the heating wire and heating wire negative. The lithium battery box of the present invention is based on the existing battery box, and is provided with a heating wire inside, which can heat the lithium battery as a whole in the severe cold winter, and can make the internal temperature of the battery box like spring in the severe cold winter. Solve the existing lithium battery electric bicycles, the battery life is weakened in winter, and the lifespan is shortened.

Owner:SVOLT ENERGY TECH (MAANSHAN) CO LTD

Lithium battery with fire-proof and explosion-proof device and electric vehicle using the battery

ActiveCN104218201BImprove the protective effectReduce the use of security risksSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsInternal pressureElectrical battery

The invention discloses a lithium battery having a fire-proof and explosion-proof device. The lithium battery includes a cell set, a cell protective sheath and an external shell. The cell set is arranged in the cell protective sheath and the cell protective sheath is disposed in the external shell. A clearance between the cell protective sheath and the external shell is filled with a fire extinguish material which can be subject to an endothermic reaction and generates carbon dioxide. The external shell is provided with a discharging hole. In the device, during a use process of the lithium battery, the fire extinguish material, which can be subject to an endothermic reaction when being heated and generates carbon dioxide, is used as a working medium for performing heat absorption and oxygen insulation to the battery. In addition, an internal pressure of the battery can be regulated timely. By the comprehensive protective method above, accidents, such as ignition, explosion and the like, can be effectively prevented so that safe risk of the lithium battery can be greatly reduced.

Owner:ZHEJIANG CHAOWEI CHUANGYUAN INDUSTRAIAL

Lithium battery with fire-proof and explosion-proof device and electric vehicle using the battery

ActiveCN104218202BImprove the protective effectReduce the use of security risksFire rescueSecondary cell gas removalElectrical batteryElectric cars

Owner:ZHEJIANG CHAOWEI CHUANGYUAN INDUSTRAIAL

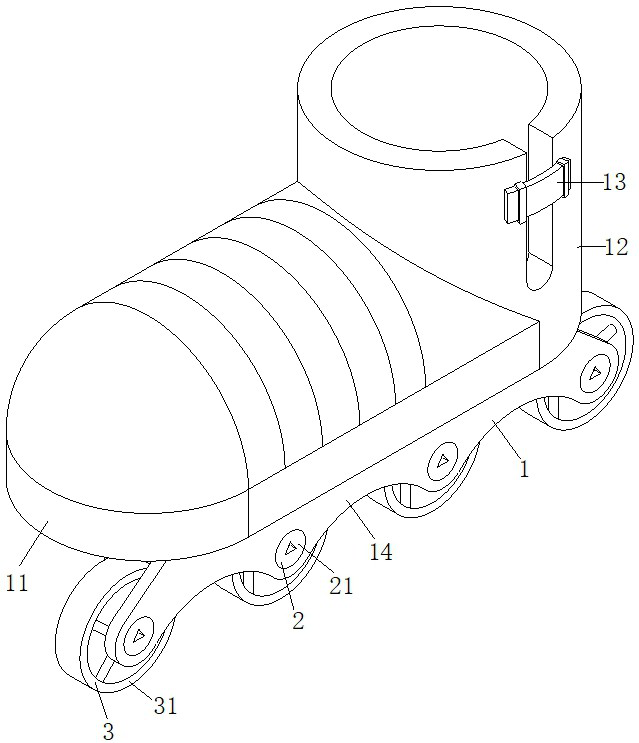

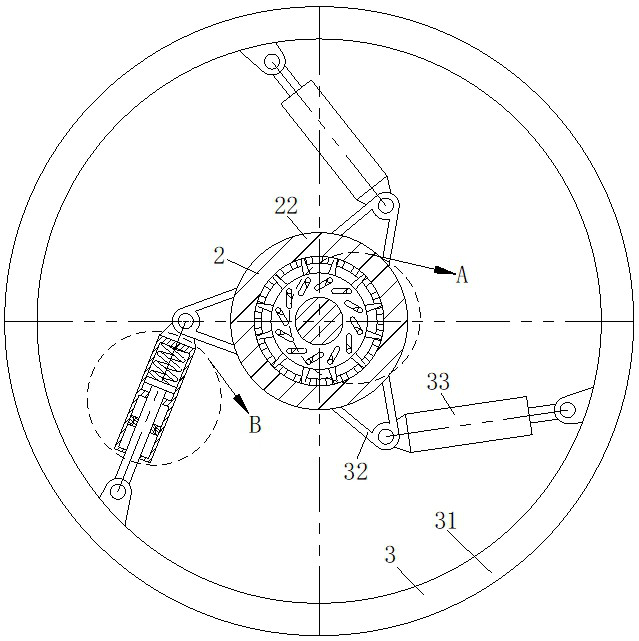

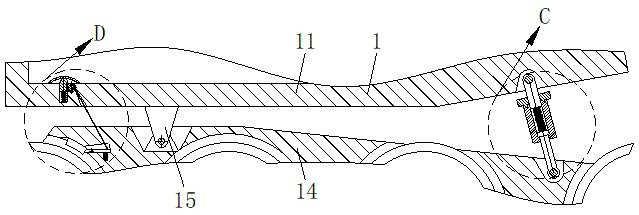

Skating shoes

InactiveCN112044051APrevent accidental fall offImprove maintainabilitySkate-boardsRoller skatesBering skateEngineering

The invention relates to the field of skating shoes, and particularly relates to skating shoes. The skating shoes comprise supporting mechanisms, quick-change mechanisms, damping mechanisms, angle mechanisms and speed reducing mechanisms. By arranging the supporting mechanisms, space is conveniently provided for subsequent placement of the damping mechanisms and the angle mechanisms; by arrangingthe quick-change mechanisms, easily-worn rotating parts are conveniently and quickly replaced, time and manpower are saved, and the maintenance effect of the skating shoes is improved; by arranging the damping mechanisms, jolt caused when the skating shoes roll on the ground is conveniently relieved, the adaptability of beginners is improved, and leg muscle fatigue caused after long-time use is avoided; by arranging the angle mechanisms, the pitching angle of the soles of a user is conveniently adapted, the buffering amplitude can be manually adjusted, and jolt in the using process is furtherrelieved; and by arranging the speed reducing mechanisms, the skating shoes are conveniently braked emergently for dealing with emergencies, and therefore the using safety risk is reduced.

Owner:王苏姣

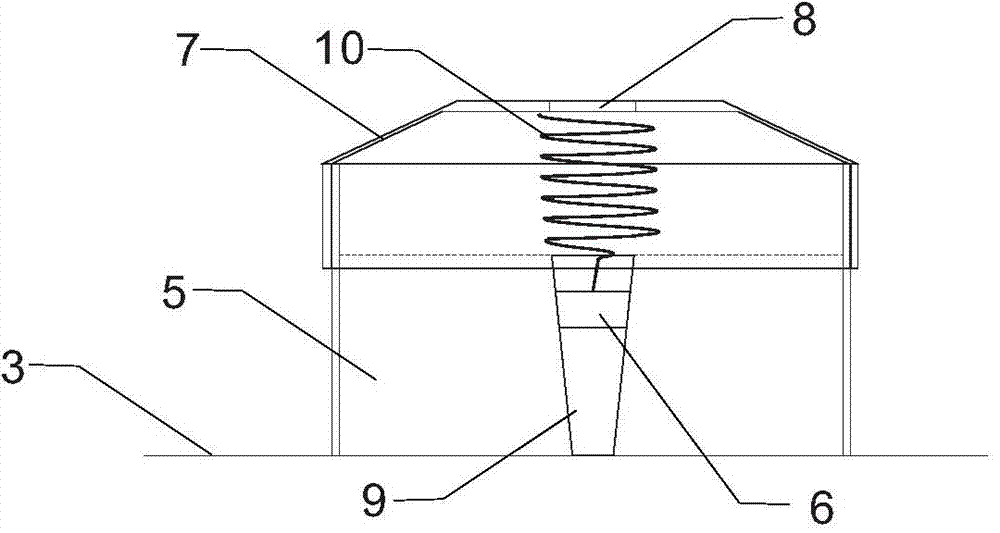

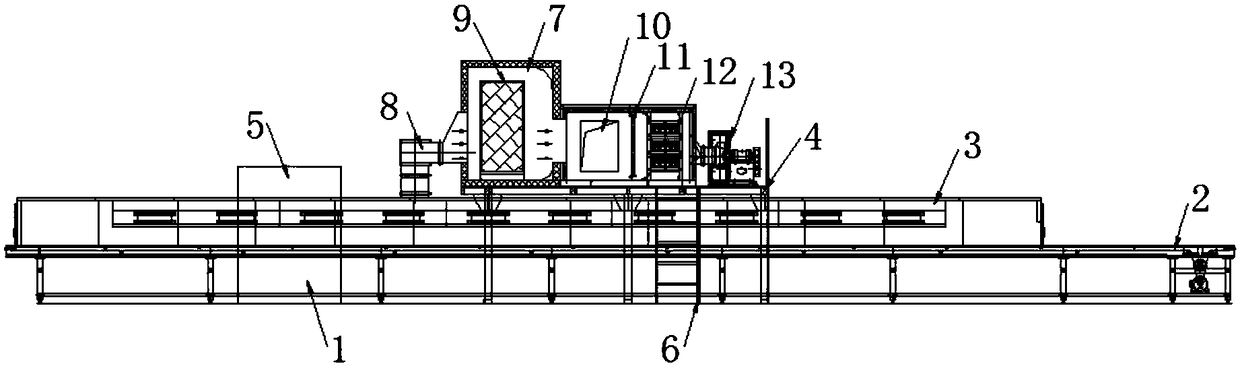

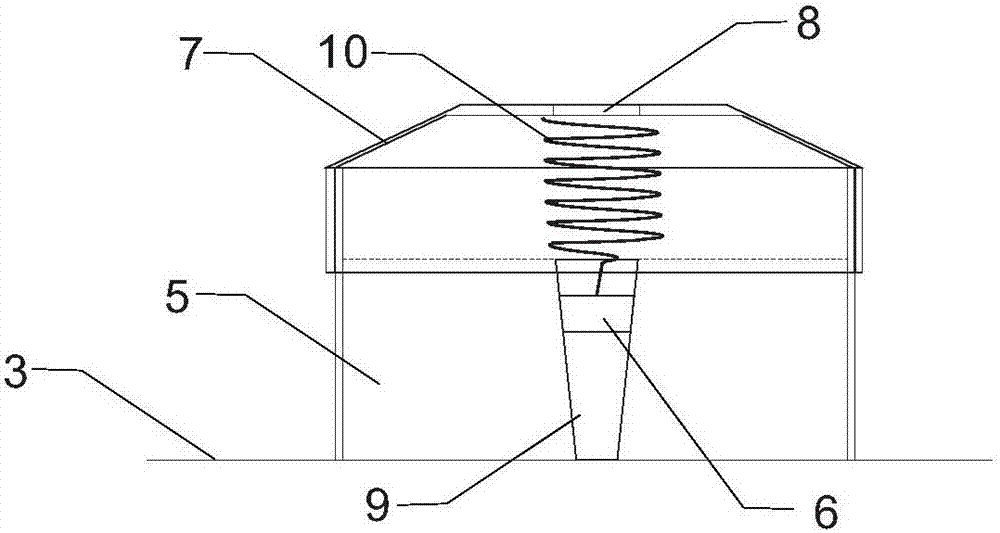

Plastic wire roaster hot air heating energy utilization device

PendingCN108592542AImprove cleanlinessReduce the use of security risksDrying gas arrangementsDrying chambers/containersSurface mountingProcess engineering

The invention discloses a plastic wire roaster hot air heating energy utilization device. The plastic wire roaster hot air heating energy utilization device comprises a device body, the bottom of thedevice body is provided with an installation bracket, the top surface of the installation bracket is provided with a drying oven body, one side of the drying oven body is provided with an air energy main engine, the top surface of the drying oven body is fixedly provided with a heating chamber body, and an air inlet in one side of the heating chamber body is provided with an air return pipe. The air energy main engine performs cooling on an upper-lower piece operation area, while the heat generated by an evaporator is collected an d introduced into the heating chamber body of the drying oven body to serve as a heat source for heating the drying oven body, the energy resources are utilized fully, roaster constant temperature treatment is performed through an electric heat spreader, energy is lowered, and consumption is saved; meanwhile, the use safety risks are lowered compared with natural gas heating, and potential safety hazards are eliminated; and the heat generated by the evaporator is clean and effective, the hot air cleanliness is guaranteed, product quality is effectively improved, and the plastic wire roaster hot air heating energy utilization device is simple in structureand high in practicability.

Owner:KUNSHAN RUI PU XIN COATING MACHINERY

Lithium battery with fire-proof and explosion-proof device and electric vehicle using the battery

ActiveCN104218194BImprove the protective effectReduce the use of security risksSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsThermodynamicsEngineering

The invention discloses a lithium battery with a fireproof and explosion-proof device. The lithium battery includes a cell group, a cell sheath and a casing. The cell group is placed in the cell sheath, and the cell sheath is placed in the casing. The gap between the cell sheath and the shell is filled with fire extinguishing materials that can undergo endothermic reactions and generate carbon dioxide. The gap between the cell sheath and the cell pack is filled with shock-absorbing and flame-retardant materials, and the shell is provided with dredging holes. . During the use of lithium batteries, this device uses fire extinguishing materials that can undergo endothermic reactions and generate carbon dioxide when heated as the working medium to absorb heat and isolate oxygen for the batteries, and can adjust the internal pressure of the batteries in time. By adopting the above comprehensive protection methods, It can effectively prevent accidents such as fire and explosion, and greatly reduce the safety risk of battery use.

Owner:ZHEJIANG CHAOWEI CHUANGYUAN INDUSTRAIAL

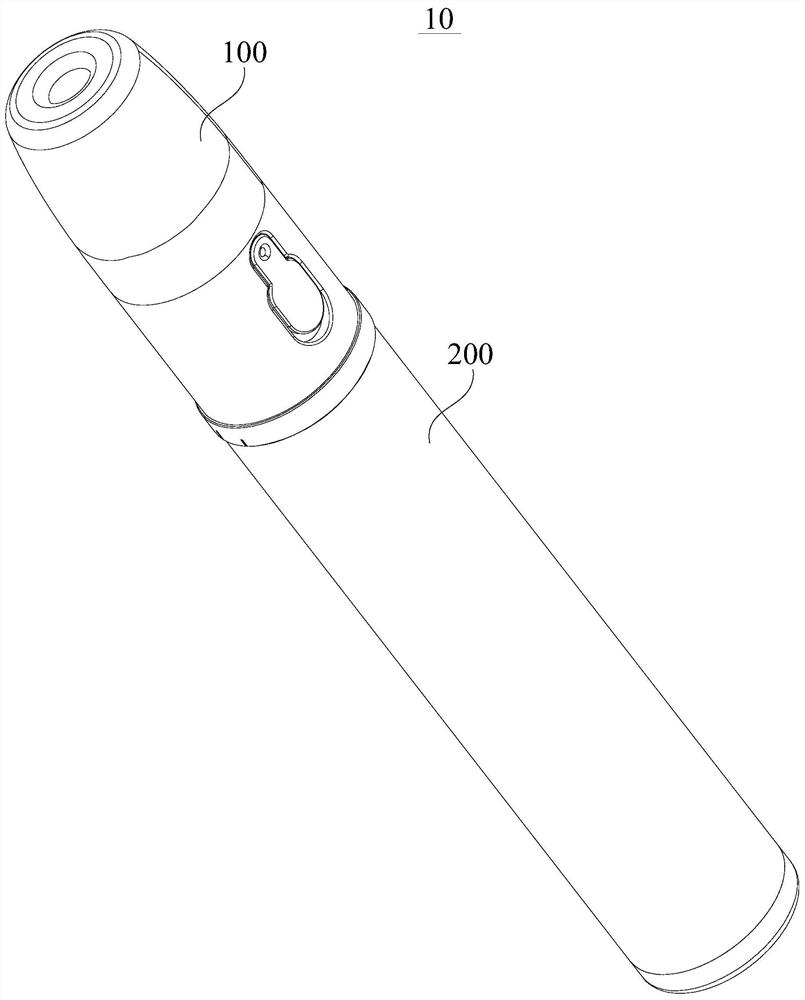

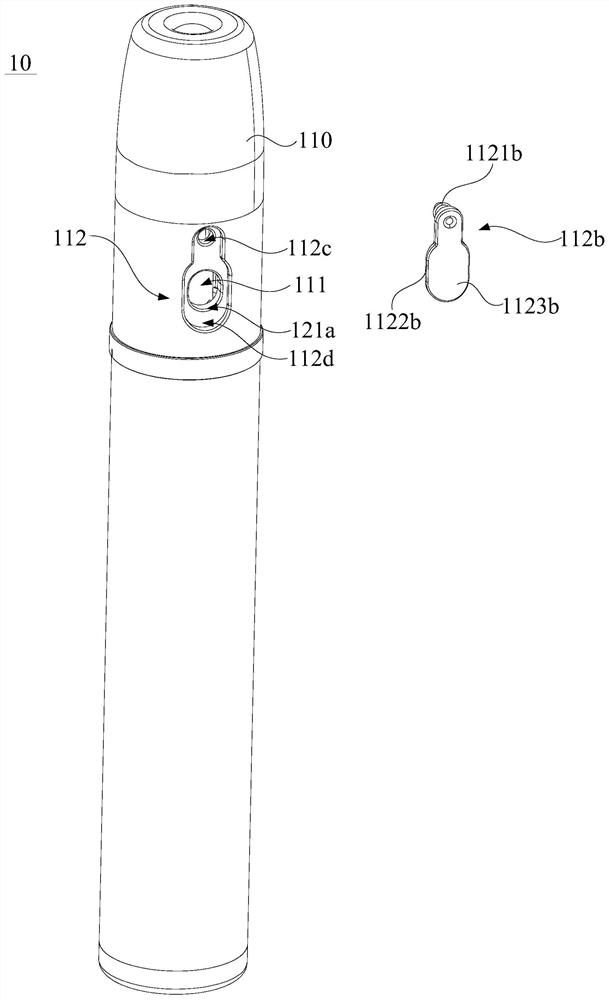

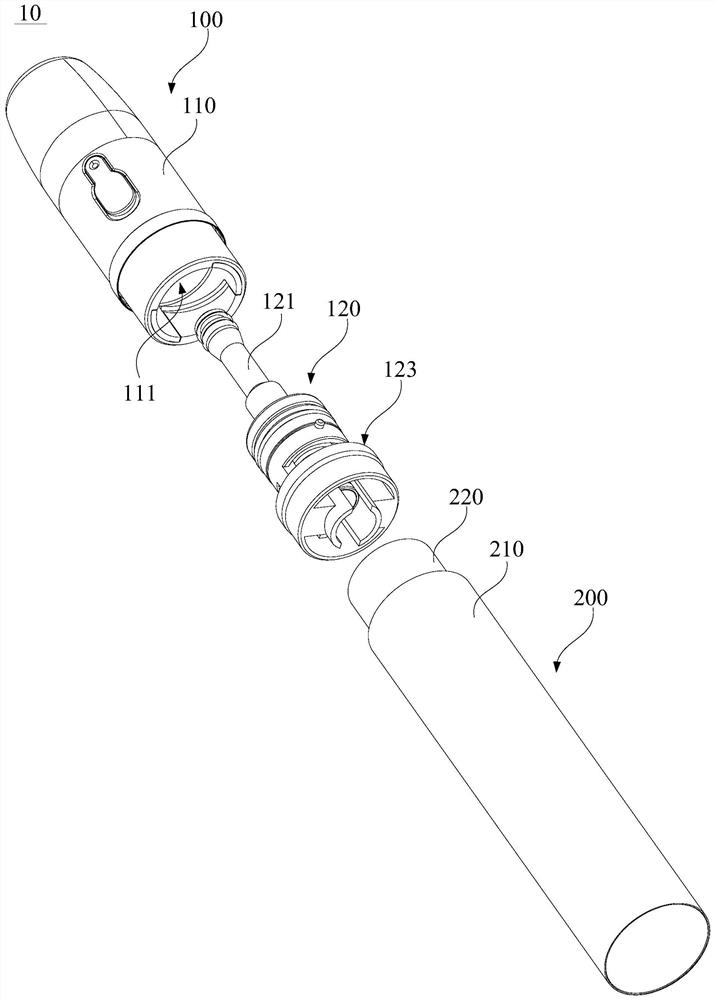

Electronic atomization equipment

PendingCN112806621AReduce interaction timeGood antibacterial effectTobaccoThermodynamicsProcess engineering

The invention provides electronic atomization equipment. The electronic atomization equipment comprises an atomization mechanism and a power source mechanism connected with the atomization mechanism. The atomization mechanism comprises a shell and an atomization assembly. The shell is provided with an oil storage cavity and an oil injection area communicated with the oil storage cavity, and an oil way cutting-off structure is arranged at the communicating position of the atomization assembly and the oil storage cavity. A fresh atomizing medium can be repeatedly injected into the oil storage cavity through the oil injection area, and the fresh atomizing medium which is repeatedly injected is contained in the oil storage cavity which is in a clean state for a long time, so that the quality-guaranteeing, anti-oxidation and anti-pollution effects of the electronic atomization equipment are better. On the premise of the same atomizing medium and on the premise of ensuring that the environment in the oil storage cavity and the atomizing medium reach the industrial quality safety standard, the number of times of continuously injecting the atomizing medium for the electronic atomization equipment is at least ten times that for the traditional electronic atomization equipment, so that the repeated utilization rate of parts can be greatly improved, the use safety risk problem can be remarkably reduced, and the equipment is more economical and environment-friendly.

Owner:SHENZHEN AEROSOL TECH RES CO LTD

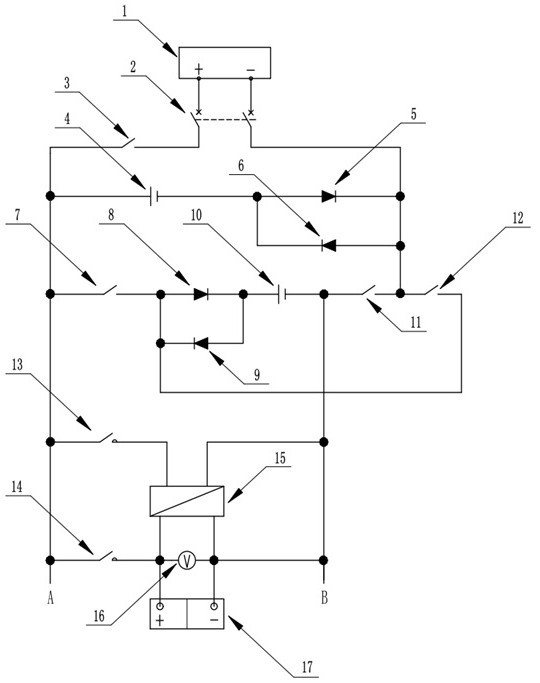

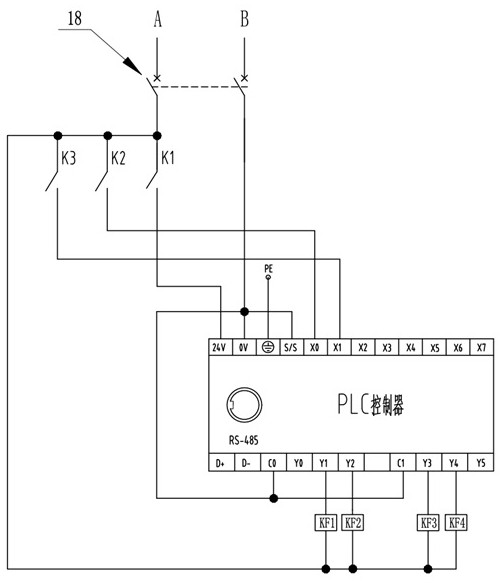

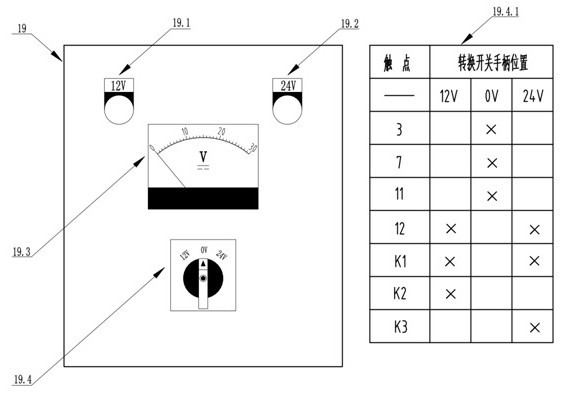

Mobile parallel charging and series power supply electric appliance detection system and control method

PendingCN114844163AExtension of timeImprove overload capacityElectric powerBattery overcharge protectionInternal resistanceControl theory

According to the mobile parallel charging and series power supply electric appliance detection system and the control method, under the condition that two storage batteries are connected in series, stable output of 12V voltage and 24V voltage can be achieved, excessive electric quantity loss caused by output of a single storage battery is avoided, the power supply time of the storage batteries is prolonged, and the overload capacity of the storage batteries is improved. And when the system is not used, the conversion handle is rotated to a 0V voltage gear, and at the moment, all electric appliance components of the system are powered off, so that the utilization rate of the electric quantity of the storage battery is improved. If the storage batteries need to be charged due to low electric quantity, the two storage batteries are converted into a parallel charging mode from an original series power supply mode, so that the storage batteries can reach the optimal charging state under the condition that the internal resistance and the loss electric quantity of the storage batteries are different, and the charger is automatically powered off after the storage batteries are fully charged; therefore, the service life of the storage battery is prolonged, the overload capacity of the system is improved, the use safety risk is reduced, the control method is simple and easy to operate, and an ideal technical effect is achieved.

Owner:YTO LUOYANG FLAG AUTO BODY

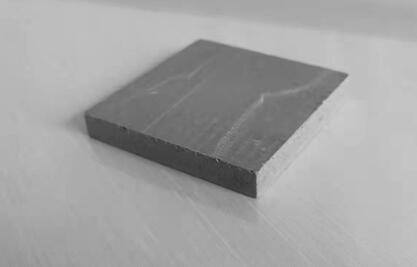

Multi-resin composite material and preparation method thereof

ActiveCN113755004AImprove flame retardant performanceReduce manufacturing costSolid waste managementPolymer sciencePolymer chemistry

The invention relates to a preparation method of a multi-resin composite material. The preparation method comprises the steps of 1, preparing an inorganic powder component according to parts by weight; 2, selecting an isocyanate liquid material and a first inorganic powder component to be mixed and pre-impregnated to serve as a material A; 3, selecting a polyether polyol and polyester polyol combined liquid material, bisphenol A unsaturated polyester resin, bisphenol A epoxy resin, styrene, a second inorganic powder component and a titanate coupling agent, mixing and pre-impregnating to serve as a material B; and 4, mixing the material A and the material B obtained in the step 2 and the step 3, dispersing at a high speed, injecting into a mold, closing the mold, standing, and demolding to obtain the product. According to the multi-resin composite material, the adding amount of the inorganic powder component is greatly increased on the basis of improving the flame retardant property, a brand new and effective flame retardant system is constructed in a reaction system through the compounded inorganic powder component, and the preparation method is simple, so that the cost is greatly reduced, the pollution is reduced, and the application market of the multi-resin composite material is widened.

Owner:张磊

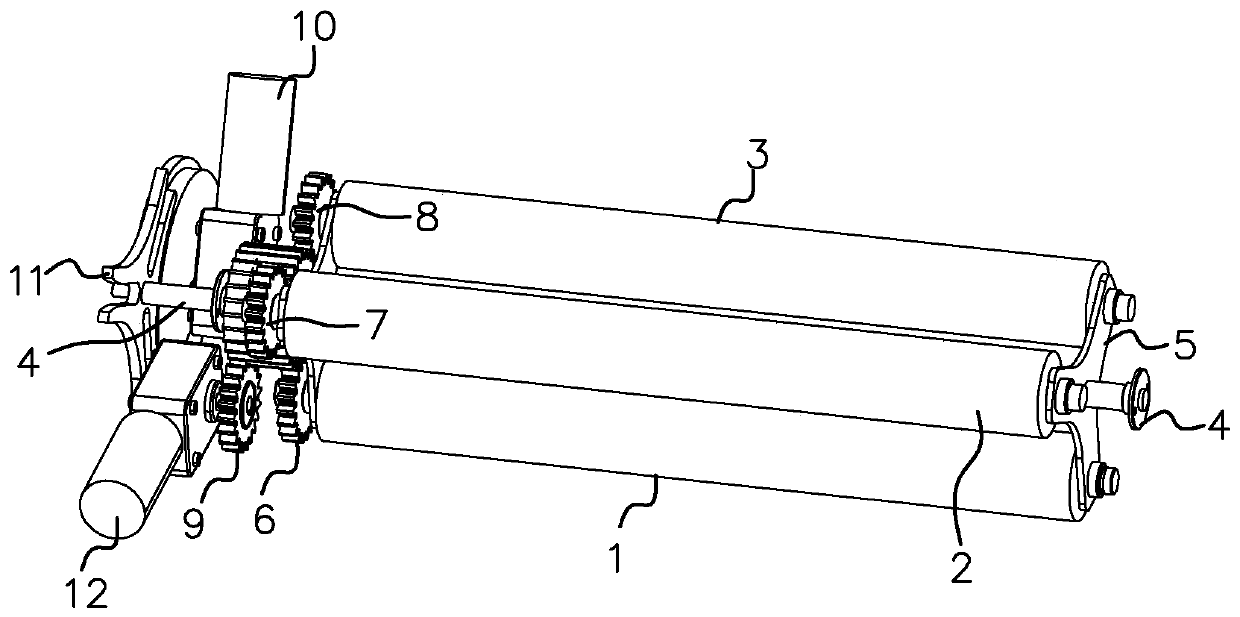

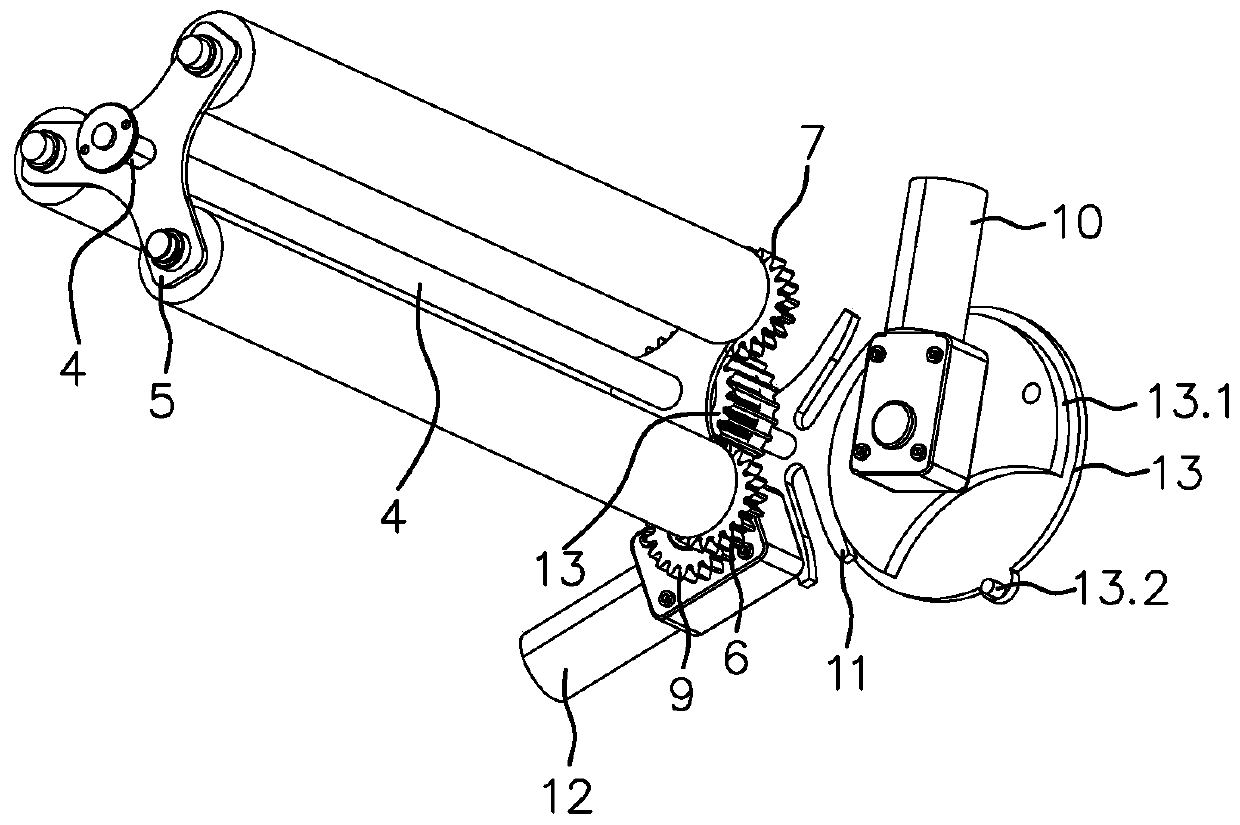

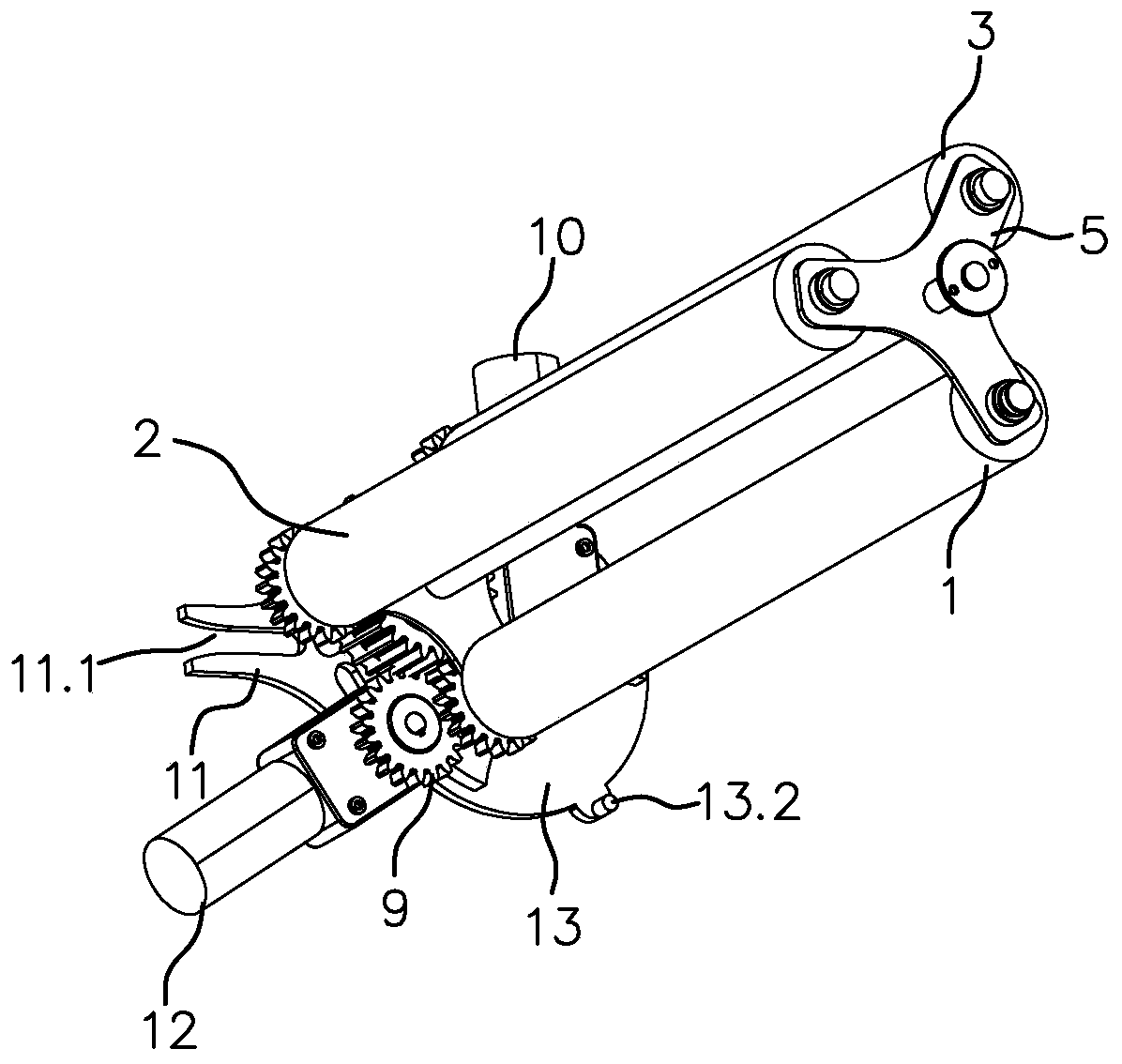

Bottle-shaped garbage recycling mechanism and recycling method thereof

PendingCN110626673AReduce the use of security risksAchieve rotationRefuse receptaclesEngineeringRecovery method

The invention discloses a bottle-shaped garbage recycling mechanism. The bottle-shaped garbage recycling mechanism comprises a first driving device, a second driving device and a rotating component, wherein the rotating component comprises at least two guide rods arranged in parallel, the first driving device drives the guide rods to autorotate, and the second driving device drives the rotating component to rotate integrally. The bottle-shaped garbage recycling mechanism has the beneficial effects that (1), 360-degree rotation of a bottle-shaped garbage in the space can be realized, so that abarcode can be captured by a code scanning gun while once delivery is completed; and (2), by controlling the rotation direction of the auto-rotated guide rods to control the entrance and exit of the bottle-shaped garbage in a feeding port, a user does not need to extend a hand into the mechanism, so that the use safety risk is reduced.

Owner:成都锐阳伟业科技有限公司

Lithium battery with fire-proof and explosion-proof device and electric vehicle using the battery

ActiveCN104218200BImprove the protective effectReduce the use of security risksBattery isolationFire rescueElectrical batteryElectric cars

Owner:浙江超恒动力科技有限公司

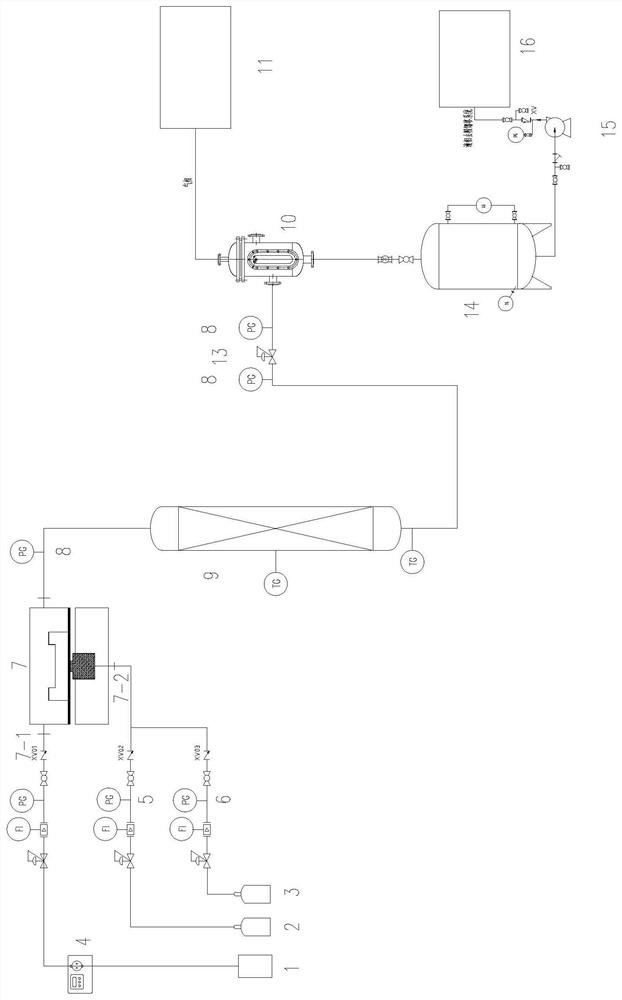

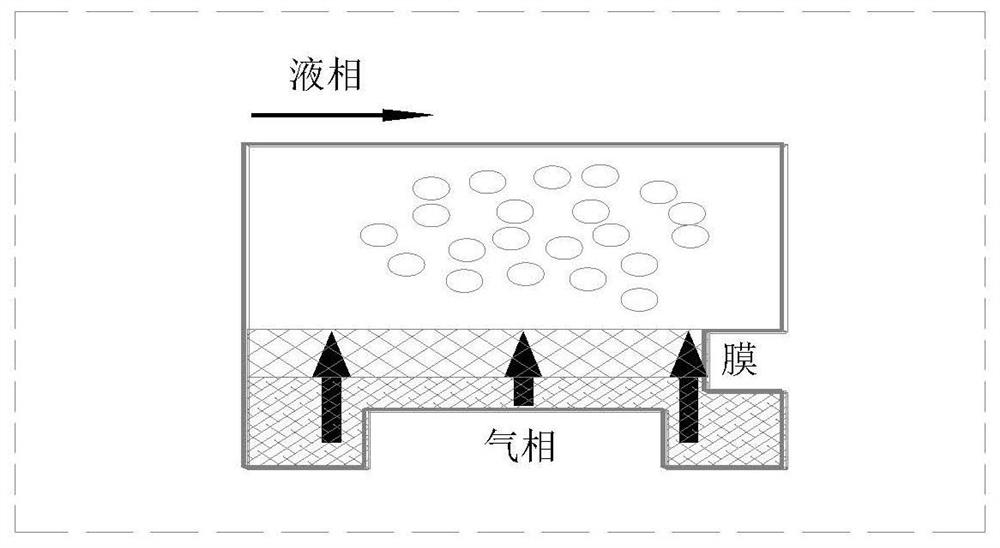

Production equipment and method for synthesizing 3-aminopropanol through continuous hydrogenation

PendingCN111991827ALow reaction temperatureRelieve pressureOrganic compound preparationDistillation separationPropanolPtru catalyst

The invention relates to a synthetic method of 3-aminopropanol, in particular to production equipment and method for synthesizing 3-aminopropanol through continuous hydrogenation, and belongs to the technical field of chemical organic synthesis. The equipment mainly comprises a membrane diffusion module, a packed bed reactor and a gas-liquid separation device which are connected in sequence; the top end of the gas-liquid separation device is connected with an ammonia gas absorption device; a bottom outlet of the gas-liquid separation device is connected with a liquid phase collection device, and the liquid phase collection device is connected with a rectifying tower pipeline; the membrane diffusion module is provided with a liquid phase inlet and a gas phase inlet; a 3-hydroxypropionitrilestorage tank is connected with the liquid phase inlet; and a hydrogen steel cylinder and an ammonia gas steel cylinder are connected with a gas phase inlet through branch pipelines respectively. Themethod and the device disclosed by the invention are low in cost, high in total yield, good in safety and environment-friendly. In the absence of a solvent, a supported nickel-based catalyst and ammonia gas are used as co-catalysts, and hydrogen is introduced to reduce cyano groups, so that the defects of temperature runaway and low productivity of a kettle type reaction device are avoided, and the process route is economic, safe, green and environment-friendly,.

Owner:BROTHER ENTERPRISES HLDG CO LTD

Lithium battery box, lithium battery pack and application thereof

ActiveCN111697290AAvoid translocationAvoid damageSecondary cellsHeating element shapesChemistryComposite material

The invention discloses a lithium battery box, a lithium battery pack and an application thereof, and belongs to the technical field of lithium batteries. The box comprises a box body and a base, wherein the box body is detachably connected with the base; the box body and the base are connected to form a battery cell position; a plurality of heating wires are uniformly arranged on the inner wall of the box body; each heating wire is wrapped with an insulating layer, a plurality of insulating partition plates are further arranged on the inner wall of the box body, and an insulating layer installation space is formed between every two adjacent insulating partition plates, wherein the thickness of each insulating partition plate is greater than the diameter of the corresponding insulating layer, and the two ends of each heating wire are electrically connected with the heating wire positive electrode and the heating wire negative electrode respectively. According to the lithium battery box, on the basis of an existing battery box, the heating wire is arranged in the lithium battery box, the whole lithium battery can be heated in severe cold winter, the temperature in the battery box can be as high as spring in severe cold winter, and the problems that an existing lithium battery electric bicycle is weakened in cruising ability in winter, shortened in service life and the like are solved.

Owner:蜂巢能源科技(马鞍山)有限公司

Turbojet injecting incineration device and incineration method

ActiveCN102563667BEfficient removalEasy to handleIncinerator apparatusJet propulsion plantsEngineeringProcess engineering

The invention relates to a turbojet injecting incineration device and an incineration method. The incineration device comprises a turbojet engine, a suction component used for sucking polluted gas, an oil supply device and a control device, wherein the oil supply device supplies oil to the turbojet engine; the control device controls the turbojet engine to work; and the suction component is communicated with the turbojet engine. The incineration method comprises the steps of: generating high-temperature fuel gas, absorbing the polluted gas, incinerating the polluted gas and discharging the polluted gas. According to the turbojet injecting incineration device and the incineration method, disclosed by the invention, the technical problems of poorer cleaning effect of the traditional blowing method, low efficiency of the traditional neutralization processing method and various types of used devices of the traditional incineration method are solved, the equipment scale is small, high processing efficiency is obtained, and cleaning and detoxifying treatment on toxic propellants remained in a propelling system can be carried out.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

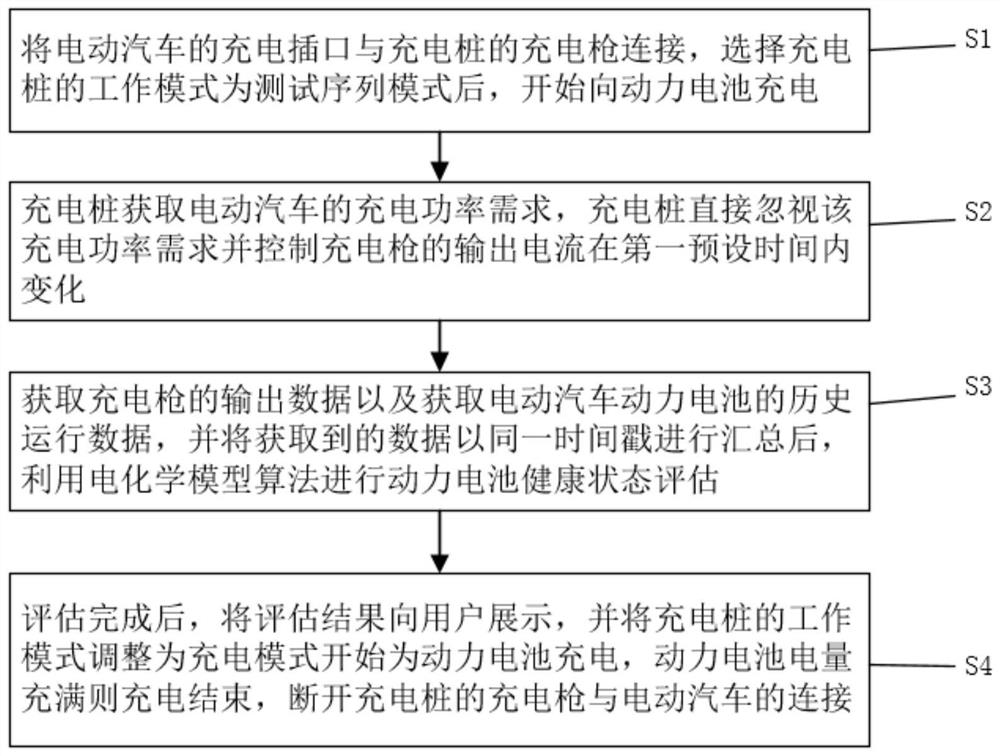

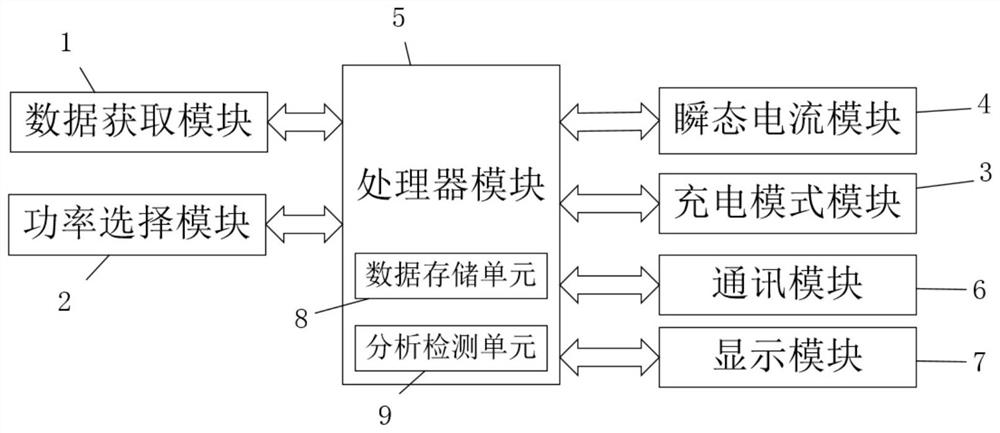

Electric vehicle power battery detection method and system and storage medium

PendingCN113917341AReduce the use of security risksAccurate assessmentElectrical testingAutomotive engineeringElectric vehicle

The invention relates to the technical field of electric vehicles, and discloses an electric vehicle power battery detection method and system and a storage medium, the system comprises a processor module, and a data acquisition module, a power selection module, a charging mode module, a transient current module, a communication module and a display module which are respectively connected with the processor module; the output current of the charging pile is rapidly changed through pulse current to generate transient current, meanwhile, BMS message data of the power battery are obtained, calculation and analysis are conducted through an electrochemical model algorithm, and finally accurate evaluation of the health state of the power battery is achieved. The method has the beneficial effects of high detection efficiency, accurate evaluation result of the health state of the power battery and improvement of the use safety of the electric vehicle.

Owner:CHINA AUTOMOTIVE ENG RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com