Leading-out connector of anode and cathode terminals of valve-control storage battery

A valve-controlled battery, positive and negative technology, applied in multi-conductor connectors, clamping/spring connections, etc., can solve the problems of inconvenient loading, unloading and transportation of backup battery packs, easy to generate circulating currents in battery packs, poor reliability of DC systems, etc. , to achieve the effect of light weight, reduce use safety risks, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

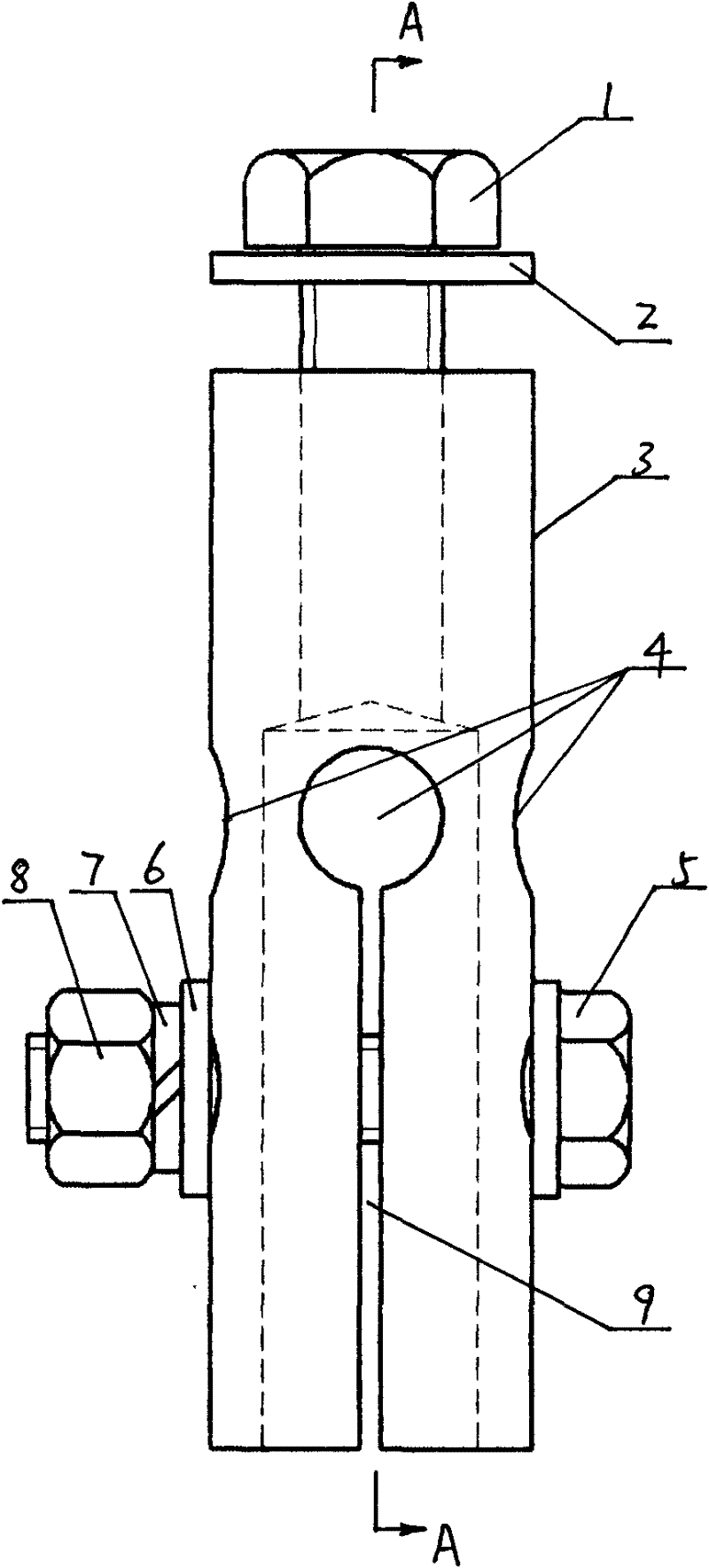

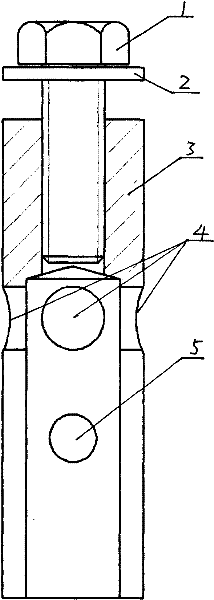

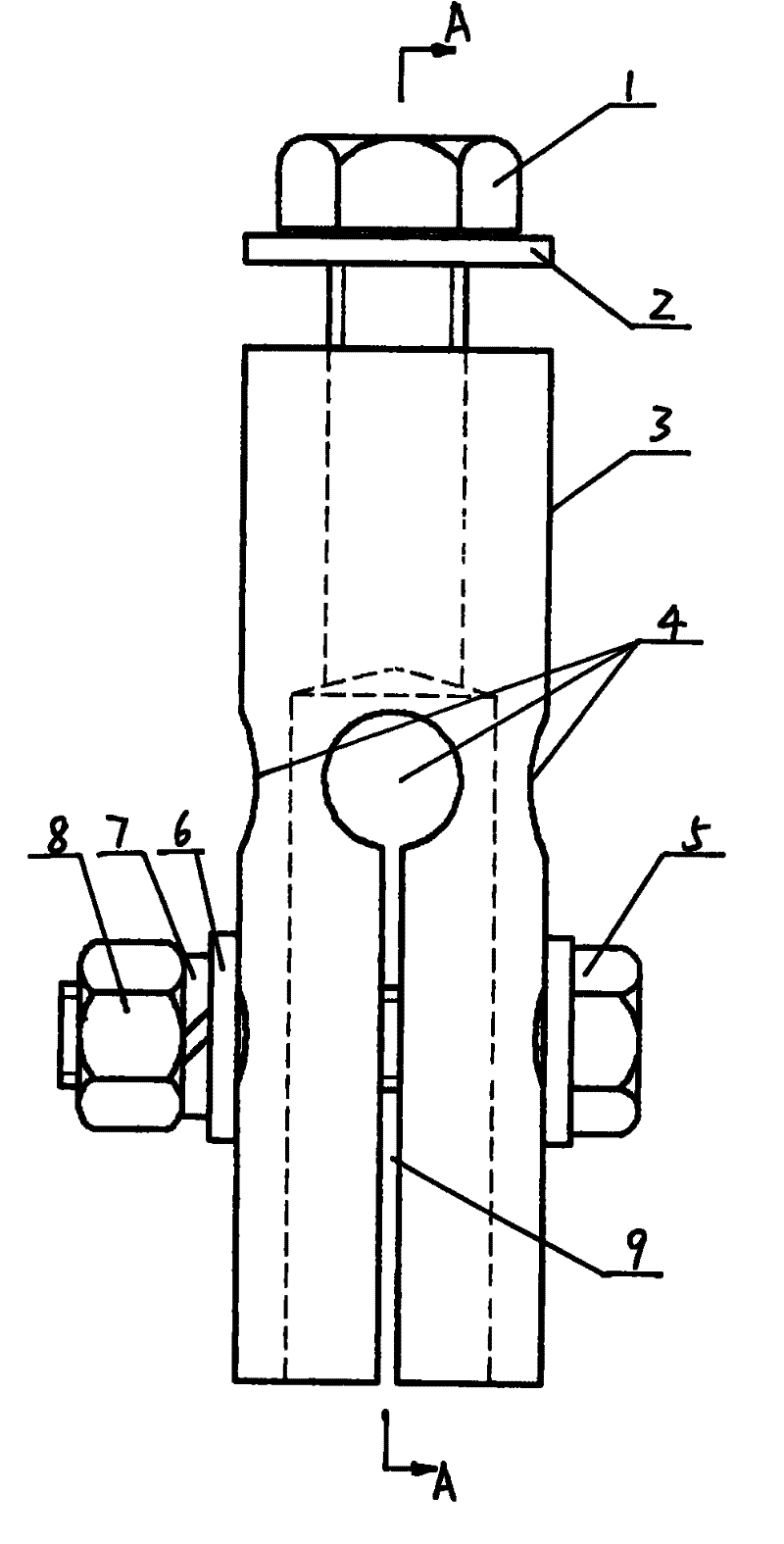

[0012] Such as figure 1 and figure 2 As shown, this embodiment includes a round top hat nut 3 with electrical conductivity, a crimping bolt 1 and a long screw rod 5 . There are threaded holes at the upper end of the top nut 3, symmetrical expansion joints 9 are vertically opened on the middle and lower wall, four holes 4 are evenly opened on the same circumference on the wall at the upper end of the expansion joint 9, and the inner wall diameter of the lower end is slightly larger than the terminal of the battery. Diameter, the lower end wall has a pair of perforations on the same diameter of the same circumference. When in use, the crimping bolt 1 penetrates the threaded hole, and the wire is pressed on the upper end of the high hat nut 3 through the gasket 2; the lower end of the high hat nut 3 is set on the positive or negative terminal of the battery, and the long sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com