Turbojet injecting incineration device and incineration method

A technology of incineration device and turbojet, which is applied to combustion methods, jet propulsion devices, incinerators, etc., can solve the problems of many types of equipment used in incineration methods, low efficiency of neutralization treatment methods, and poor removal effect, etc., and achieves a small scale of equipment. , the equipment is tight, the treatment effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

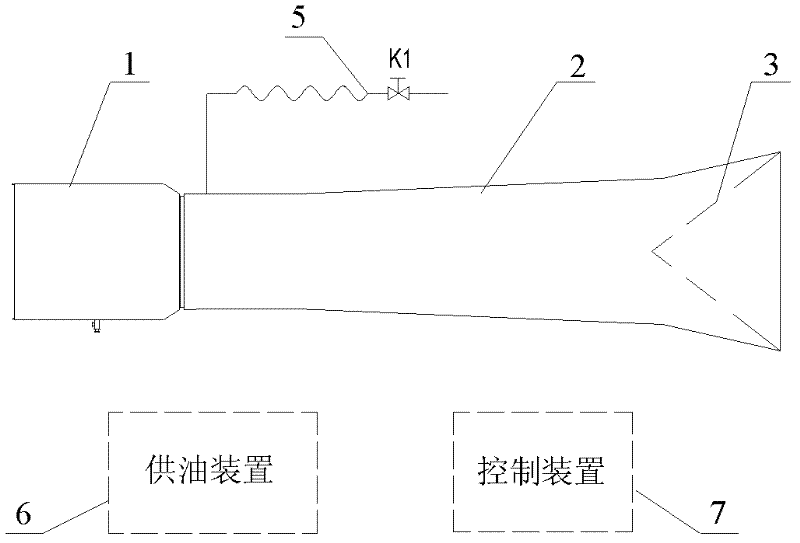

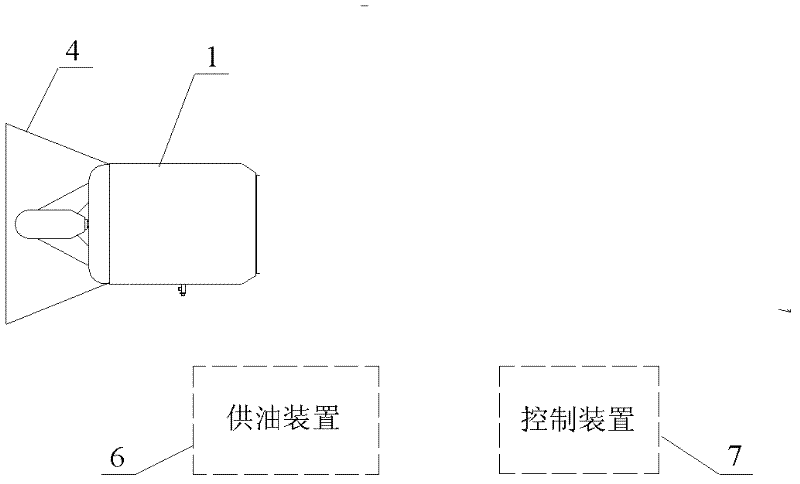

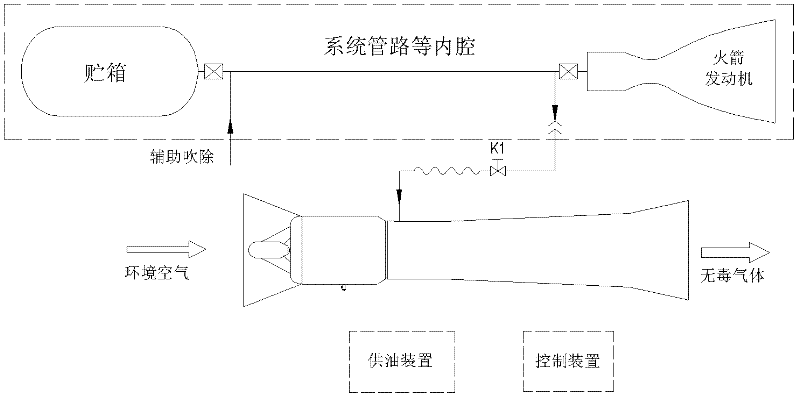

[0038] Such as figure 1 Shown, the present invention is made up of turbojet engine 1, injection incinerator 2, muffler grid 3, suction pipeline 5, and oil supply device 6 and control device 7, and oil supply device 6 supplies oil to turbojet engine 1, The control device 7 controls the work of the turbojet engine 1, the inlet of the injection incinerator 2 is connected with the outlet of the turbojet engine, the suction line is connected with the inlet of the injection incinerator 2, and the inlet of the turbojet engine 1 is connected to the polluted The gas source is connected, the outlet of the ejector incinerator 2 is emptied, and the vacuum is formed in the ejector incinerator 2 by suction pipeline 5, and the polluted gas is sucked into the ejector incinerator 2 through the turbojet engine 1, and the turbojet engine The high-temperature gas generated in 1 flows into the injection incineration cylinder 2, and in the injection incineration cylinder 2, the polluted gas is inci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com