Liquid-cooled battery module

A technology for liquid-cooled batteries and battery modules, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of reducing the safety of battery modules, unable to guarantee the protection level of battery module boxes, etc., and achieve major production practices Significance, reducing the risk of use safety, the effect of wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

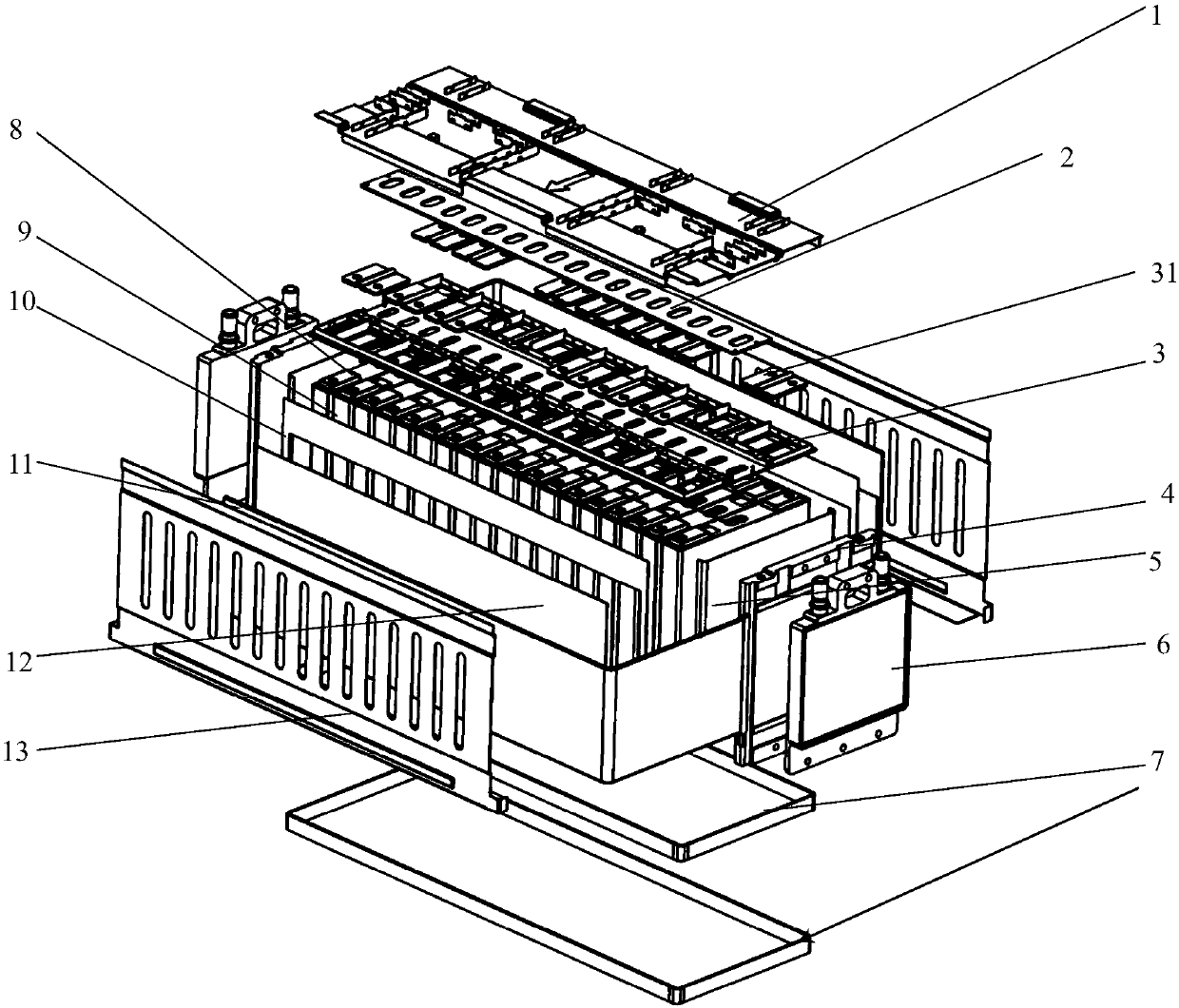

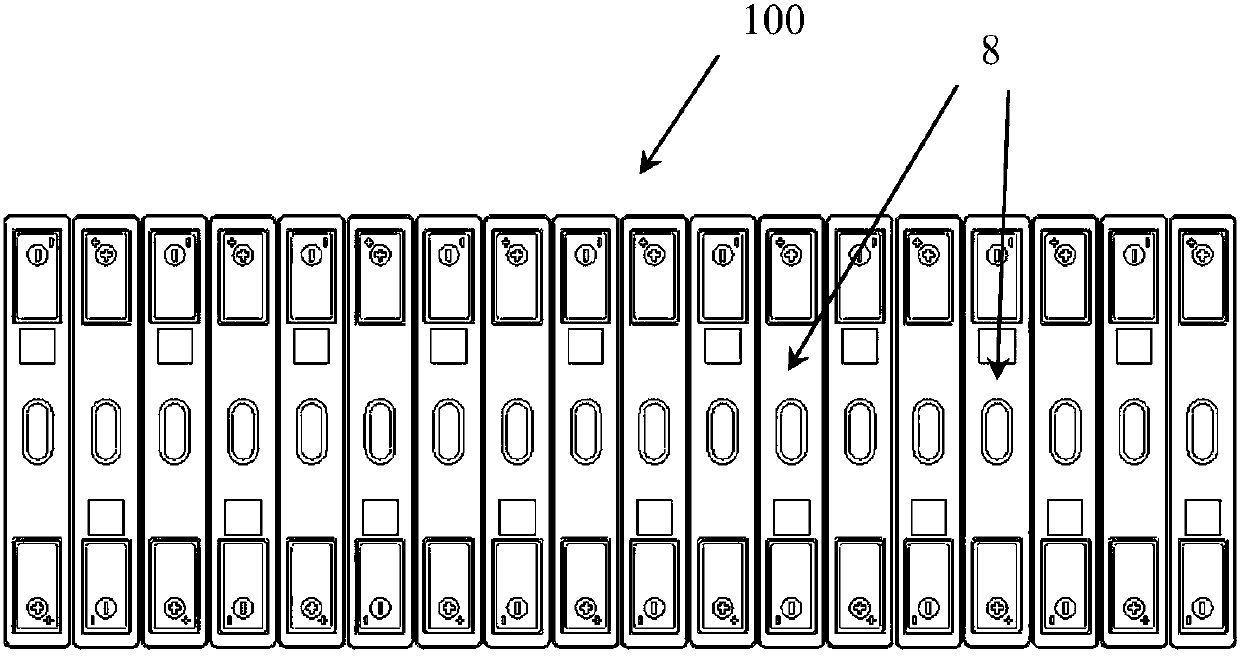

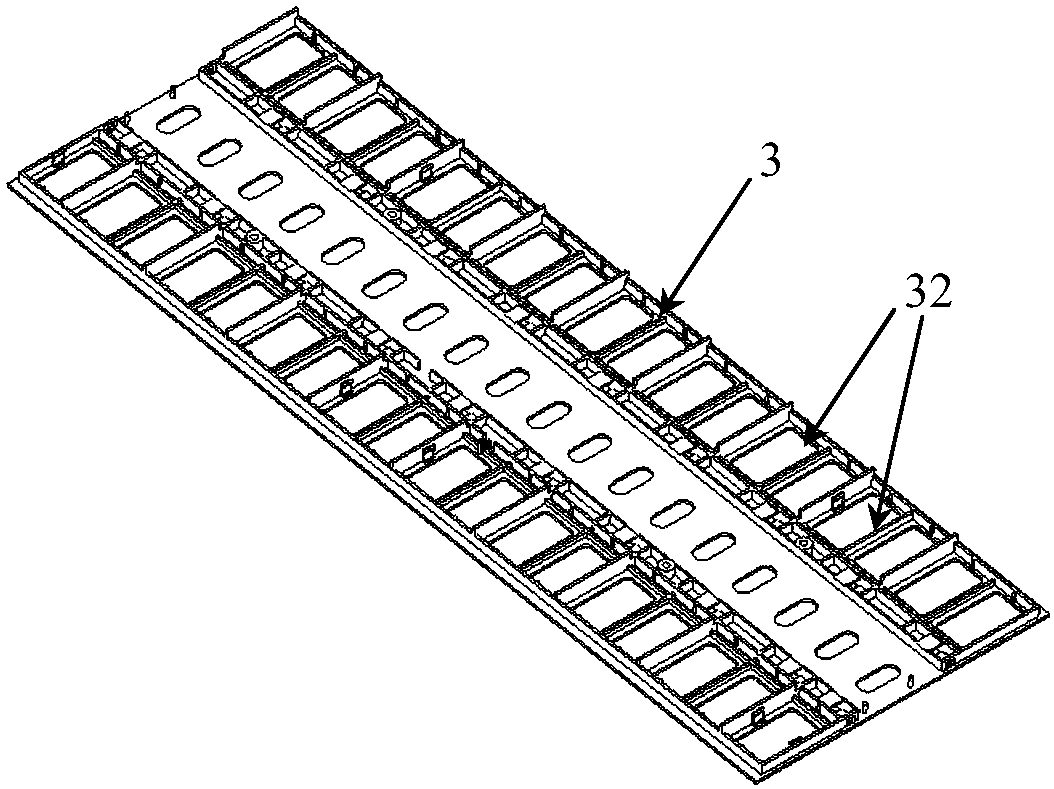

[0051] see Figure 1 to Figure 13 , the present invention provides a liquid-cooled battery module, including a battery module 100, and the battery module 100 includes a plurality of battery cells 8 arranged parallel and parallel in the longitudinal direction;

[0052] The cross section of each battery cell 8 is rectangular;

[0053] Two L-shaped heat pipes 11 are arranged on the outside of the battery module 100, and the two heat pipes 11 are distributed symmetrically about the center and have the same shape and size);

[0054] There is a structure capable of transferring heat between each of the heat pipes 11 and the battery module 100;

[0055] Each of the heat pipes 11 is in contact with a liquid cooling plate 6 , and each liquid coolin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com