Method for preparing polymyxin B sulfate for injection

A polymyxin and injection technology, applied in the field of medicine, can solve problems such as adverse reactions, unstable quality, complex components, etc., and achieve the effect of improving stability and reducing safety risks in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

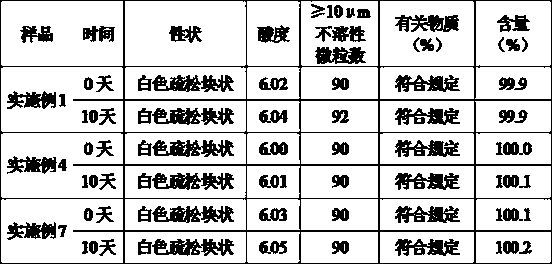

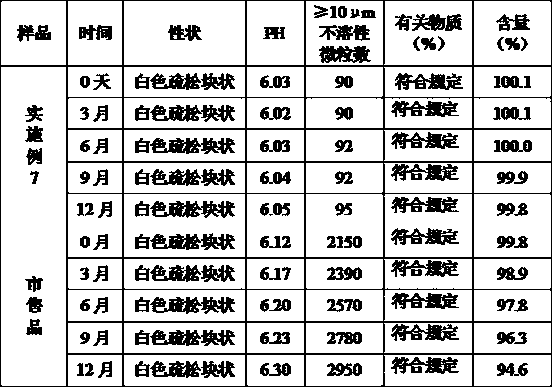

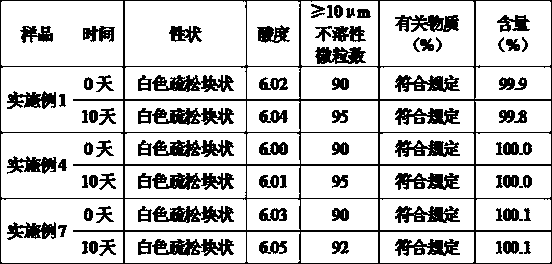

Examples

Embodiment 1

[0033] Example 1 Preparation of polymyxin B sulfate for injection (specification: 500,000 units)

[0034] (1) Add 62g of polymyxin B sulfate into 600ml of water for injection and stir to dissolve, add water for injection to 1000ml, and stir evenly;

[0035] (2) Filter the solution in step 1 through a 0.22 μm filter membrane, measure the pH value and content of the filtrate, determine the filling volume (about 1ml) according to the specifications, and divide into half-stoppered filling liquid;

[0036] (3) Freeze-drying:

[0037] ① Pre-freezing: put the aliquot in a freezer that has been cooled to -28°C in advance, and keep it for 3 hours;

[0038] ②Sublimation: Turn on the vacuum device, adjust the vacuum degree to 14Pa, raise the temperature at a constant speed (1.5°C / h) to -12°C, and keep at this temperature for 10 hours;

[0039] ③Drying: heat up to 38°C at a uniform speed, dry for 7 hours, pack and store after passing the test, and obtain polymyxin B sulfate for injectio...

Embodiment 2

[0040] Example 2 Preparation of polymyxin B sulfate for injection (specification: 500,000 units)

[0041] (1) Add 62g of polymyxin B sulfate into 600ml of water for injection and stir to dissolve, add water for injection to 1000ml, and stir evenly;

[0042] (2) Filter the solution in step 1 through a 0.22 μm filter membrane, measure the pH value and content of the filtrate, determine the filling volume (about 1ml) according to the specifications, and divide into half-stoppered filling liquid;

[0043] (3) Freeze-drying:

[0044] ① Pre-freezing: put the aliquot in a freezer that has been cooled to -23°C in advance, and keep it for 4 hours;

[0045] ②Sublimation: Turn on the vacuum device, adjust the vacuum degree to 14Pa, raise the temperature at a constant speed (2.0°C / h) to -7°C, and keep at this temperature for 10 hours;

[0046] ③Drying: heat up to 38°C at a uniform speed, dry for 7 hours, pack and store after passing the test, and obtain polymyxin B sulfate for injection...

Embodiment 3

[0047] Example 3 Preparation of polymyxin B sulfate for injection (specification: 500,000 units)

[0048] (1) Add 62g of polymyxin B sulfate into 600ml of water for injection and stir to dissolve, add water for injection to 1000ml, and stir evenly;

[0049] (2) Filter the solution in step 1 through a 0.22 μm filter membrane, measure the pH value and content of the filtrate, determine the filling volume (about 1ml) according to the specifications, and divide into half-stoppered filling liquid;

[0050] (3) Freeze-drying:

[0051] ① Pre-freezing: place the aliquot in a freezer that has been cooled to -25°C in advance, and keep it for 3.5 hours;

[0052] ②Sublimation: Turn on the vacuum device, adjust the vacuum degree to 14Pa, raise the temperature at a constant speed (1.8°C / h) to -10°C, and keep at this temperature for 10 hours;

[0053] ③Drying: heat up to 38°C at a uniform speed, dry for 7 hours, pack and store after passing the test, and obtain polymyxin B sulfate for inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com