Disposal method for iron and steel pickling waste water containing hydrochloric acids

A steel pickling and disposal method technology, applied in metallurgical wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve environmental pollution and other problems, achieve reduced emissions, low production costs, and disposal process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

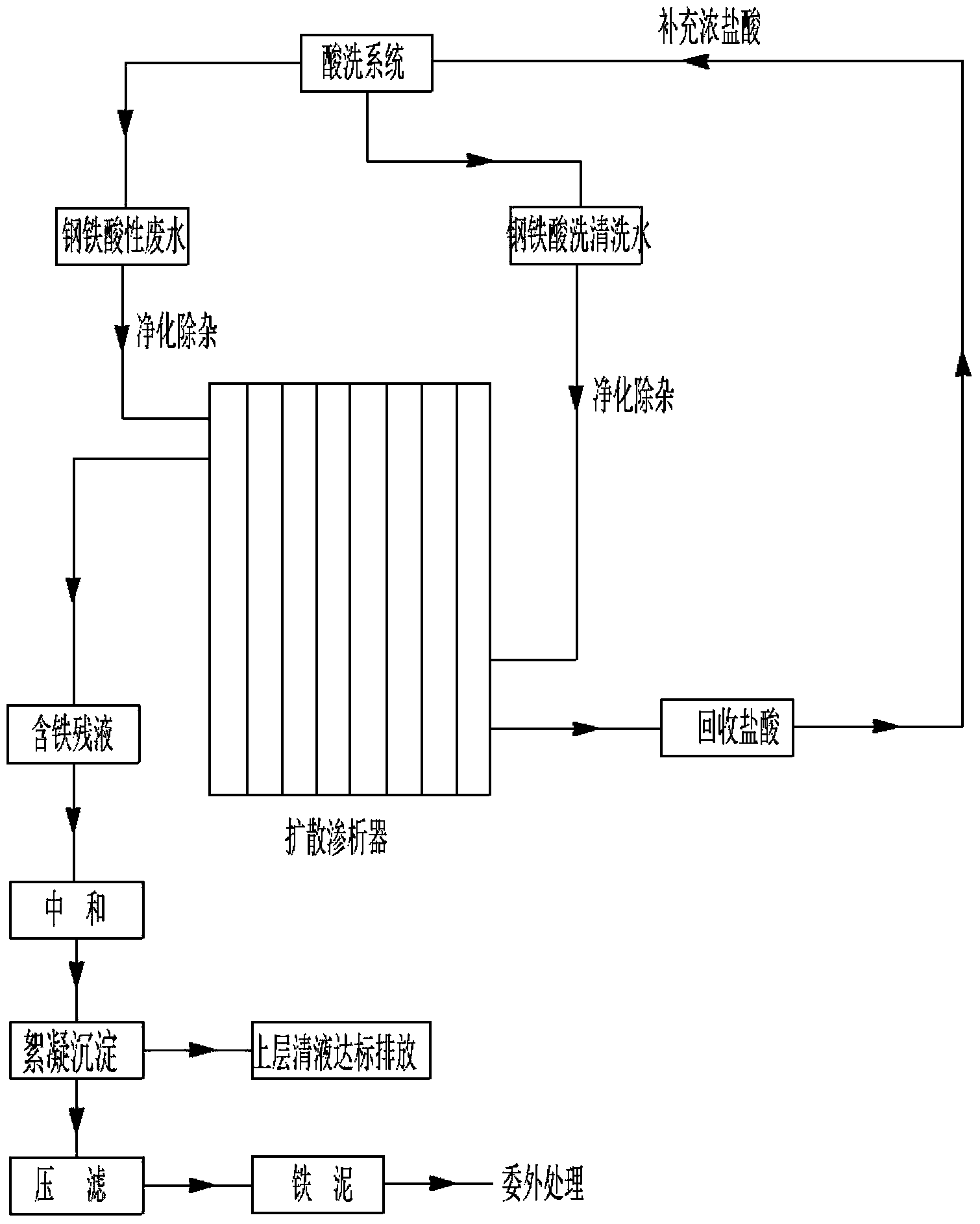

Image

Examples

specific Embodiment 1

[0028] Specific embodiment one: (1) carry out mechanical filtration respectively to the waste acid liquid and pickling cleaning water that produce in steel pickling production process, purify impurity removal, and mechanical filtration is specifically to filter by the filter core of precision filter, purify and remove impurity , wherein the hydrochloric acid concentration of the waste acid solution after mechanical filtration is 8.5%, and the iron content is 4.5%;

[0029] (2) The waste acid solution after purification and removal of impurities and pickling cleaning water flow through the inside of the anion exchange membrane diffusion dialyzer at the same time, specifically, the waste acid solution fills the stock solution chamber of the anion exchange membrane diffusion dialyzer from the stock solution inlet, At the same time, pickling cleaning water fills the diffusion liquid chamber of the anion exchange membrane diffusion dialyzer from the diffusion liquid inlet, leaves st...

specific Embodiment 2

[0032] Specific embodiment two: (1) waste acid liquid and pickling cleaning water produced in the iron and steel pickling production process are mechanically filtered respectively to purify and remove impurities, and mechanical filtration is specifically filtered by a filter element of a precision filter, and purified and removed , wherein the hydrochloric acid concentration of the waste acid liquid after mechanical filtration is 13.3%, and the iron content is 7.8%;

[0033] (2) The waste acid solution after purification and removal of impurities and pickling cleaning water flow through the inside of the anion exchange membrane diffusion dialyzer at the same time, specifically, the waste acid solution fills the stock solution chamber of the anion exchange membrane diffusion dialyzer from the stock solution inlet, At the same time, pickling cleaning water is filled with the diffusion liquid chamber of the anion exchange membrane diffusion dialyzer from the diffusion liquid inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com