Lanthanum actinide group separation system and method based on oxidation, screening and extraction coupling

A separation method and component separation technology, which is applied in the field of nuclear fuel cycle and waste liquid treatment, can solve the problems of secondary waste generation, increased environmental protection pressure, difficult continuous operation, etc., and achieve the effect of avoiding contact reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

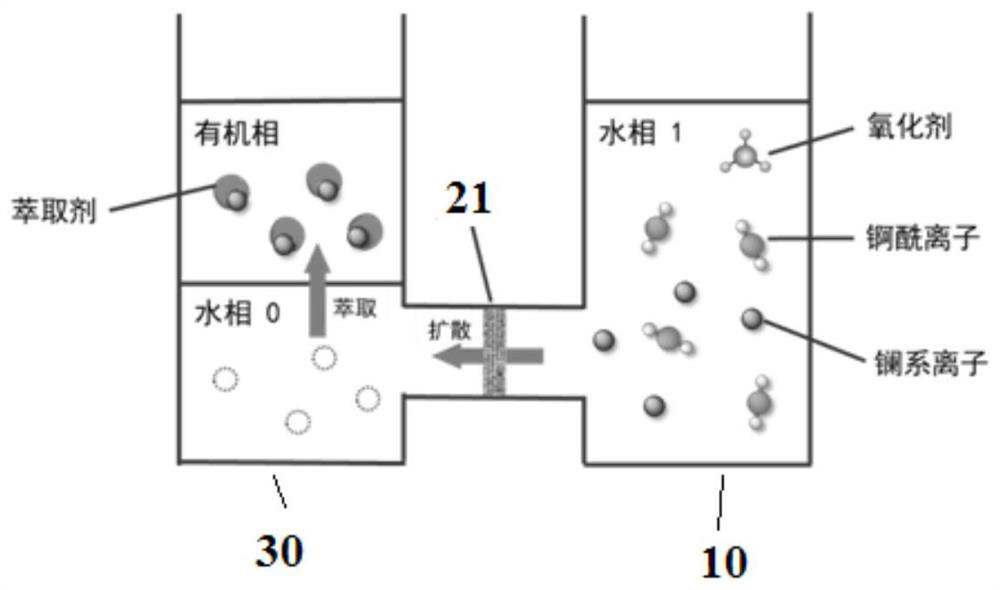

Method used

Image

Examples

Embodiment 1

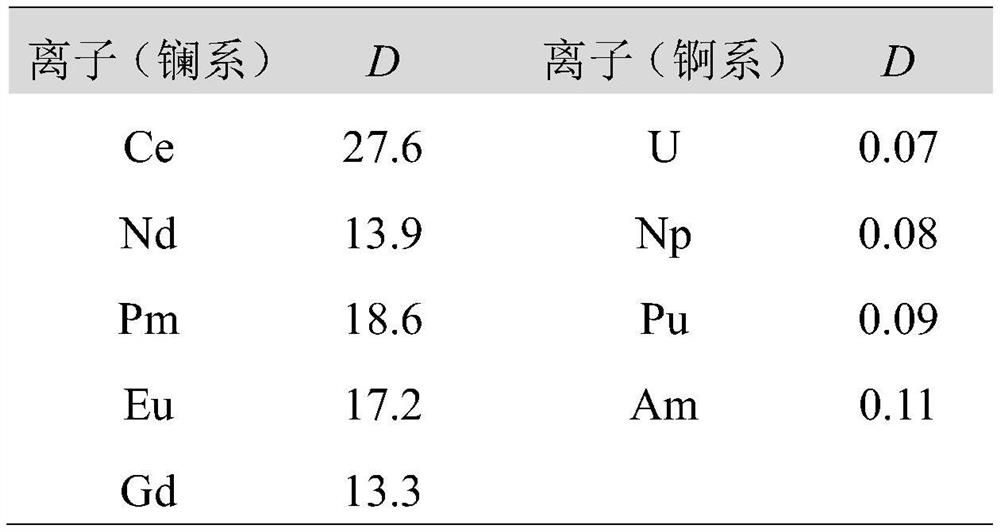

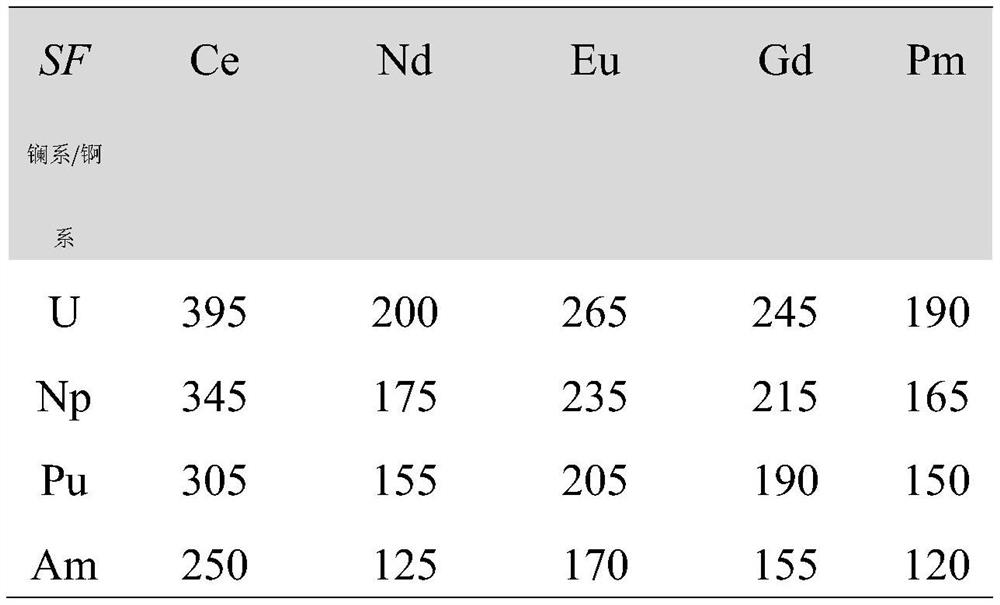

[0038] N,N,N',N'-tetraoctyl-3-oxoglutaramide (TODGA) / n-dodecane separated actinides (uranium (U), neptunium (Np), plutonium (Pu), americium (Am )) and lanthanides (cerium (Ce), neodymium (Nd), promethium (Pm), europium (Eu), gadolinium (Gd)). Feed liquid is 10mL containing 1×10 -7 mol / L Np, Pu, Am, 1×10 -3 mol / L U, Ce, Nd, Eu, Gd, 1×10 -2 3mol / L HNO of mol / L sodium bismuthate 3 solution. The separation membrane is a pretreated commercial sub-nanofiltration membrane (graphene oxide membrane). The water phase in the permeation zone is 5mL 3mol / L HNO 3 Solution, the organic phase is 5mL 0.1mol / L TODGA / n-dodecane solution. The ratio of the metal ion concentration in the permeation zone (organic phase + water phase) to the liquid zone is defined as the distribution ratio (distribution ratio, D), and the ratio of each ion distribution ratio is the separation factor (separation factor, SF). After 12 hours of stirring, the distribution ratio and separation factor of each ion ar...

Embodiment 2

[0045] Trialkylphosphine (TRPO) / toluene separation of actinides (uranium (U), neptunium (Np), plutonium (Pu), americium (Am)) and lanthanides (lanthanum (La), samarium (Sm), dysprosium ( Dy), thulium (Tm), lutetium (Lu)). Feed liquid is 12mL containing 1×10 -7 mol / L Np, Pu, Am, 1×10 - 3 mol / L U, La, Sm, Dy, Tm, Lu, 1×10 -3 1mol / L HNO in mol / L potassium permanganate 3 solution. The separation membrane is a pretreated commercial reverse osmosis membrane. The water phase in the permeation zone is 2mL 1mol / L HNO 3 Solution, the organic phase is 10mL 1mol / L TRPO / toluene solution. After stirring for 18 hours, the distribution ratio and separation factor of each ion are shown in Table 3 and Table 4. Obviously, the separation factors of the selected lanthanides to actinides are all higher than 100, thus realizing comprehensive, efficient and stable separation of lanthanides and actinides.

[0046] Table 3. Distribution ratio of each ion extracted by TRPO

[0047]

[0048]...

Embodiment 3

[0051]Di-(2-ethylhexyl) phosphoric acid (HDEHP) / n-octanol separation of actinides (uranium (U), neptunium (Np), plutonium (Pu), americium (Am)) and lanthanides (praseodymium (Pr), Terbium (Tb), Holmium (Ho), Erbium (Er), Ytterbium (Yb)). Feed liquid is 12mL containing 1×10 -7 mol / L Np, Pu, Am, 1×10 -3 mol / L U, Pr, Tb, Ho, Er, Yb, 0.1mol / L potassium dichromate in 0.001mol / L HNO 3 solution. The separation membrane is a pretreated commercial nanofiltration membrane. The water phase in the permeation zone is 10mL 0.01mol / L HNO 3 Solution, the organic phase is 2mL 0.01mol / L HDEHP / n-octanol solution. After stirring for 24 hours, the distribution ratio and separation factor of each ion are shown in Table 5 and Table 6. Obviously, the separation factors of the selected lanthanides to actinides are all higher than 100, thus realizing comprehensive, efficient and stable separation of lanthanides and actinides.

[0052] Table 5. Distribution ratio of each ion extracted by HDEHP

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com