Method for directly detecting ammonia in wastewater by non-contact gas film diffusion-electric conductance

A gas film diffusion and non-contact technology, applied in the direction of material resistance, can solve the problems of environmental secondary pollution, long detection time of ammonia nitrogen in wastewater, harsh detection conditions, etc., and achieve long service life, convenient and reliable use, and wide detection range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

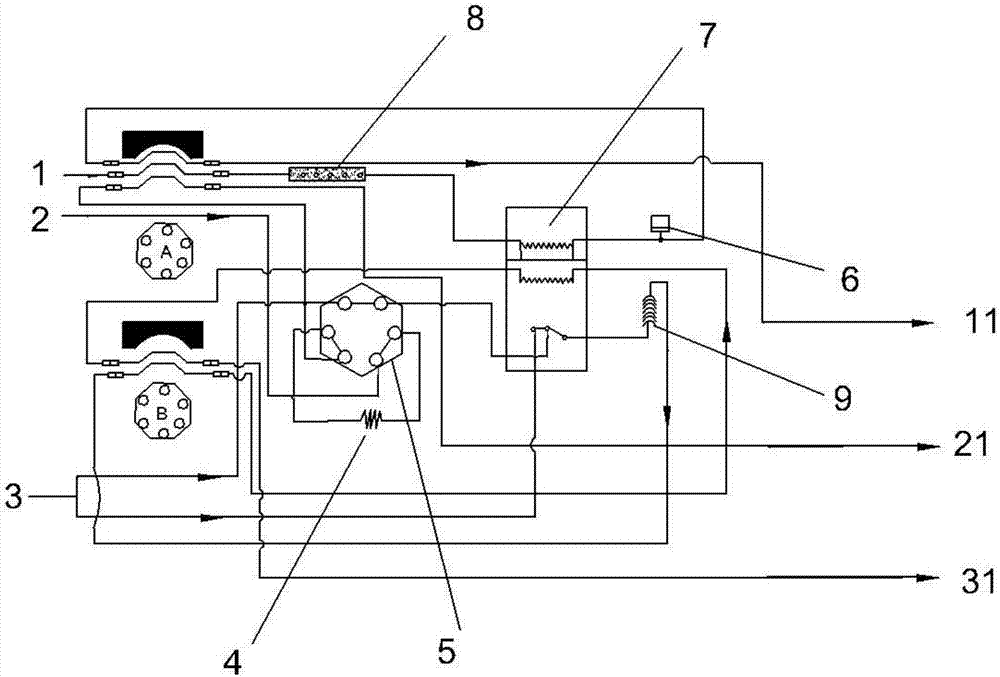

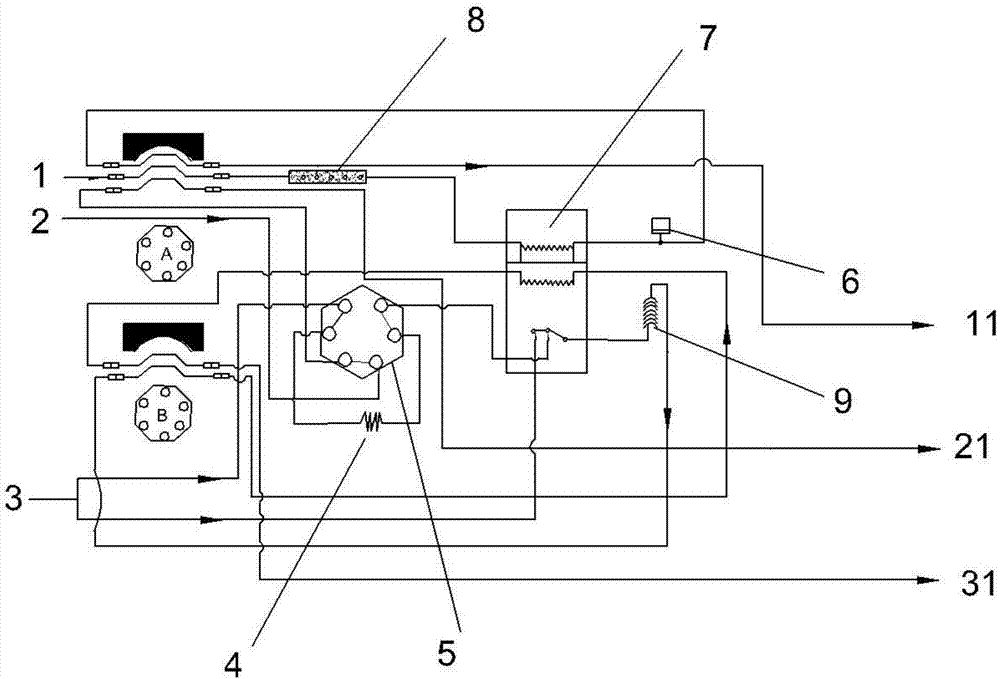

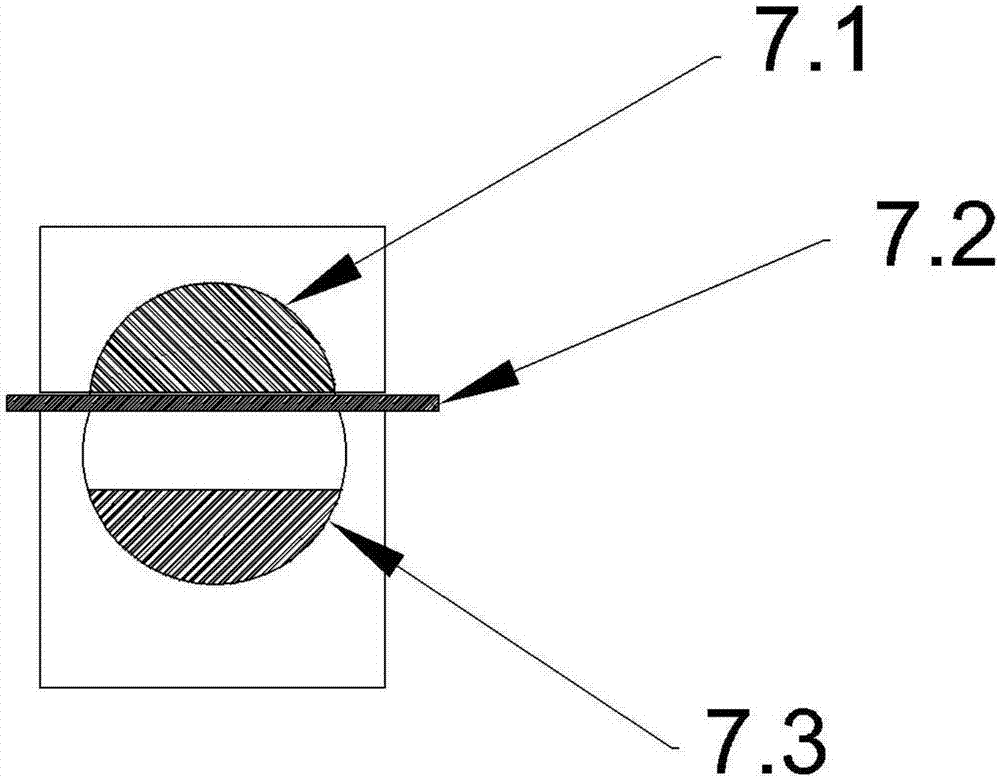

[0034] This embodiment discloses a method for non-contact gas film diffusion-conductivity detection of ammonia nitrogen in wastewater, using the "stop flow" dialysis mode, including the following steps: figure 1 , 3 As shown, 1) Turn on the peristaltic pump A, the sample solution 2 containing ammonia nitrogen is drawn into the quantitative loop 4 connected with the six-way valve 5 by the peristaltic pump A through the sample pipeline, and the excess sample solution 2 flows into the sample waste after filling the quantitative loop. In the liquid bottle 21; at the same time, the hydrochloric acid solution 1 with a concentration of 0.005mol / L is driven and sucked by the peristaltic pump A, and flows through the purifier 8, the receiving liquid channel 7.1 and the conductance channel in the membrane diffusion unit 7 successively through the receiving liquid pipeline. Detector device 6, the hydrochloric acid receiving liquid after coming out from the conductivity detecting device 6...

Embodiment 2

[0039] This embodiment discloses a method for non-contact gas film diffusion-conductivity detection of ammonia nitrogen in wastewater, using the "flow" dialysis mode, including the following operating steps: 1) Turn on the peristaltic pump A, and the sample solution 2 containing ammonia nitrogen passes through the sample pipeline from the peristaltic The pump A sucks into the quantitative loop 4 connected with the six-way valve 5, and the excess sample solution 2 flows into the sample waste liquid bottle 21 after the quantitative loop is filled; Drive and pull suction, through the receiving liquid pipeline, flow through the purifier 8, the receiving liquid channel 7.1 in the membrane diffusion unit 7 and the conductivity detector device 6 in sequence, and the hydrochloric acid receiving solution after coming out of the conductivity detection device 6 flows into the receiving liquid waste liquid In the bottle 11; after running continuously for 1 minute, the peristaltic pump A dr...

Embodiment 3

[0044] Spinning recovery sewage treatment: Quantitative loop is 100μL, sample solution flow rate is 1.5mL / min; receiving solution - 0.005mol / L hydrochloric acid, flow rate is 0.8mL / min, alkali solution - 0.5mol / L sodium hydroxide, flow rate is 1.0mL / min, the purifier is a cation exchange resin column. 38°C constant temperature, air film diffusion unit (serpentine diffusion cell with upper and lower symmetrical flow channels, hydrophobic membrane φ35mm, diffusion path about 25mm), the inlet of the sample solution is slightly higher than the outlet, and the inclination is 15°. The control program is started, the analysis is carried out automatically, and the automatic calculation shows that the measured ammonia nitrogen in the spinning recycled sewage is 13.82mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com