Preparation method of amidoxime group uranium extraction sorbent

An amidoxime-based and adsorbent technology, applied in chemical instruments and methods, uranium compounds, inorganic chemistry, etc., can solve the problems of low mechanical properties, low adsorption capacity, and slow adsorption rate of adsorption materials, and achieve enhanced mechanical strength, The effect of high adsorption capacity and strong adsorption selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) TiO 2 Sol preparation

[0019] At room temperature, 20 mL of butyl titanate (Ti(OBu) 4 ) and 6ml of acetylacetone (acac) were dissolved in 50mL of absolute ethanol, after fully reacting, 80mL of H 2 A solution formed of O, 1mL HCl and 150ml ethanol was slowly added dropwise to the above solution under vigorous stirring. After reacting for about half an hour, a uniform, stable and transparent yellow sol was obtained.

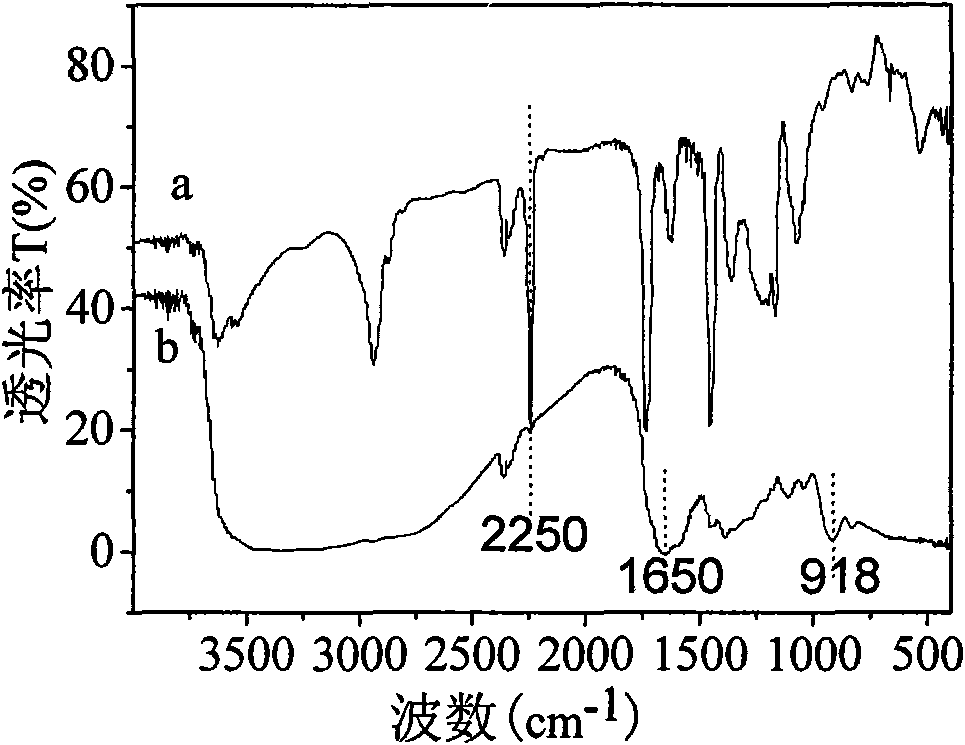

[0020] (2) Preparation of amidoxime-based adsorbent

[0021] Add 40ml of organic solvent dimethyl sulfoxide (DMSO) and 2.78g NH 2 OH·HCl was solid, slightly heated, stirred and dissolved, and 2.12 g of anhydrous sodium carbonate was added (the molar ratio to hydroxylamine hydrochloride was 1:0.5). After dissolving, add 2g of polyacrylonitrile powder, heat to 70°C and stir to dissolve, and pass through N 2 , react for 3h, then add TiO 2 The sol is stirred evenly, washed with water, washed with ethanol, and dried to prepare a hybrid amidoxime-based...

Embodiment 2-6

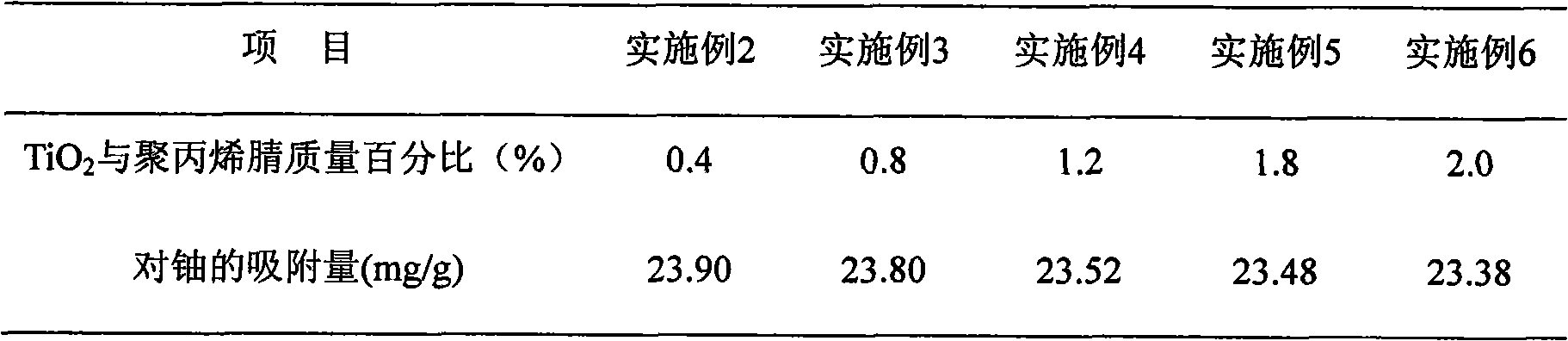

[0024] Using the same preparation steps as in Example 1, different amounts of TiO were added 2 sol, examine different TiO 2 The effect of content on the uranium adsorption capacity and mechanical strength of amidoxime-based adsorbent materials.

[0025] Table 1 Different TiO 2 Effect of content on uranium adsorption capacity of amidoxime-based uranium extraction adsorbent

[0026]

[0027] As can be seen from the table, with TiO 2 The more the amount of sol added, the adsorption amount of uranium on the adsorbent decreased slightly, but at the same time it was found that the addition of TiO 2 The higher the amount of sol, the better the mechanical properties of the adsorbent.

Embodiment 7

[0029] The amidoxime-based uranium-extracting adsorbent prepared in Example 2 was used to investigate its adsorption selectivity for uranium in the presence of calcium and magnesium ions. For UO in a ratio equivalent to 10 times the concentration of seawater concentration 2 2+ , Mg 2+ , Ca 2+ Three ions are adsorbed. The concentration of uranium in the solution before and after adsorption was determined by ultraviolet spectrophotometry, and the concentration of calcium and magnesium ions was determined by titration. The distribution coefficient D and the selectivity coefficient K are calculated by the following formulas respectively:

[0030] D = ( A 0 - A f ) V A f W ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com