Preparation method of monodisperse micron-sized uranium oxide particle

A uranium oxide and monodisperse technology, which is applied in the field of particle preparation, can solve the problems of not disclosing particle morphology information, not satisfying monodispersity, cumbersome preparation methods, etc., and achieves the effects of ensuring safety, easy operation, and simple technical solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

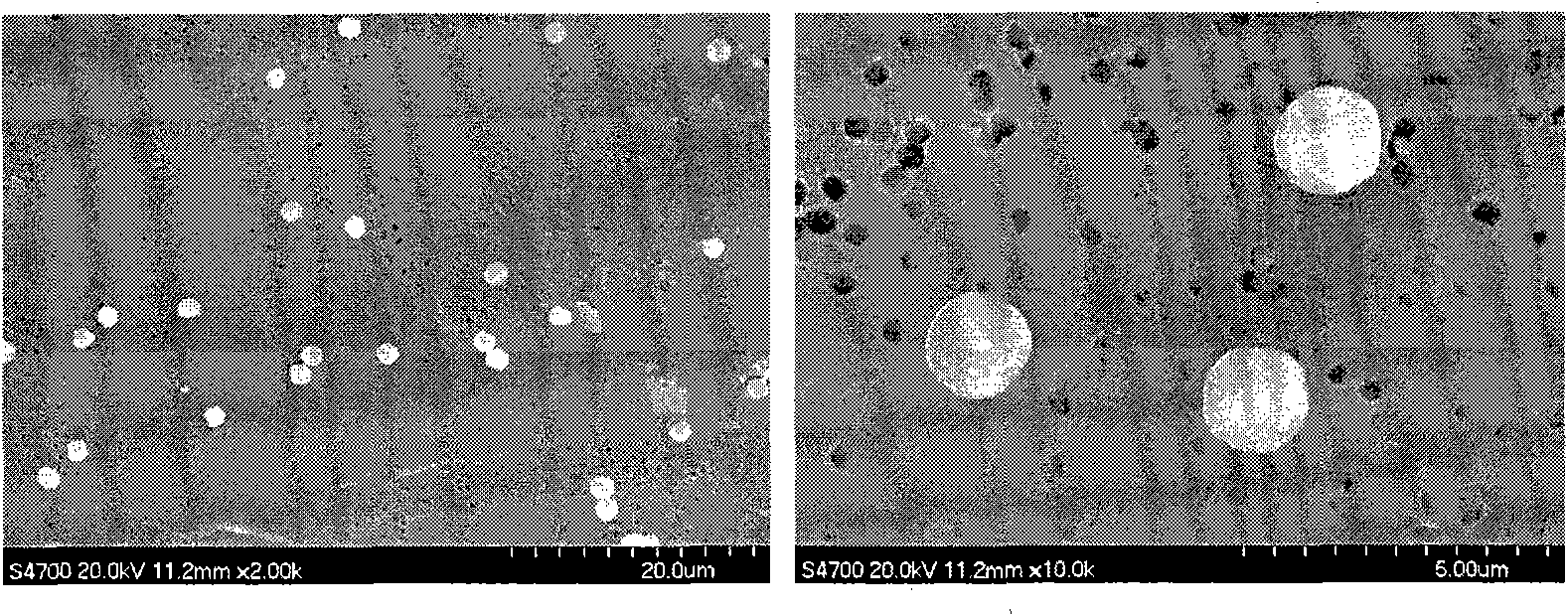

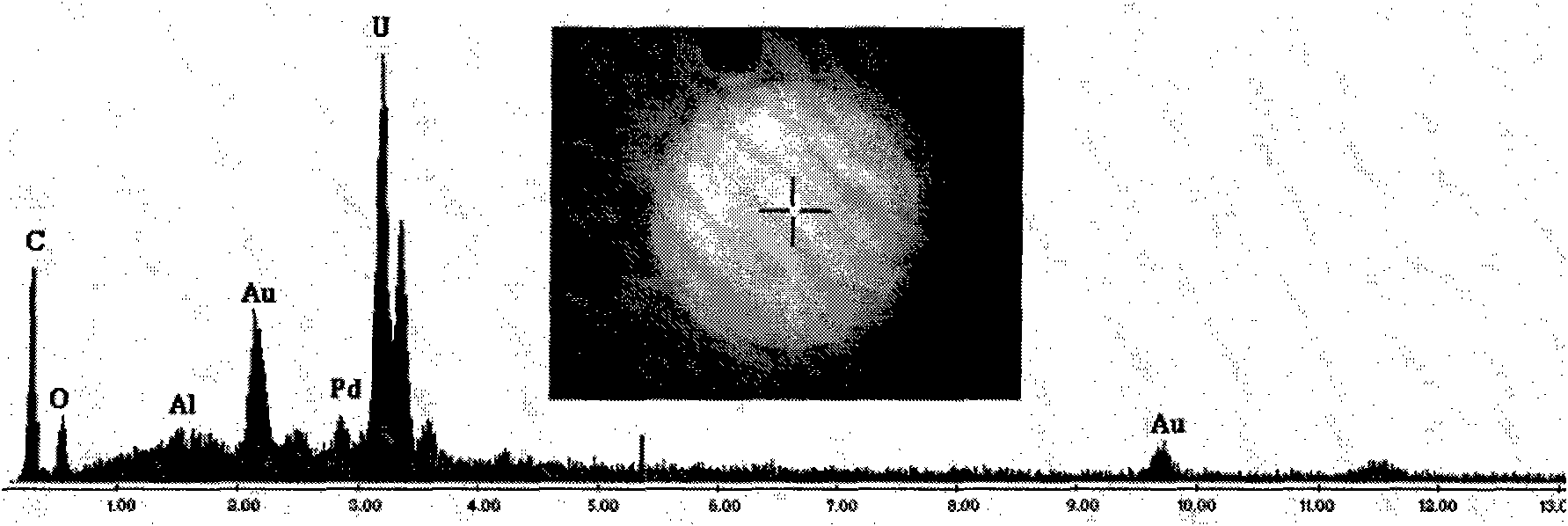

[0026] This embodiment takes the preparation of 2 μm monodisperse uranium oxide particles as an example. Using the VOAG-3450 vibrating hole aerosol generator produced by TSI Company of the United States, the vibrating orifice plate was redesigned to be made of stainless steel. U3O8 reference reagent 235 U / 238 U nominal value is 7.25×10 -3 .

[0027]The uranyl nitrate solution solution needs to be prepared before preparation. The configuration method is to weigh about 0.098g of U3O8 powder, put it into a polytetrafluoroethylene beaker, add about 15ml of 1mol / L nitric acid, then evaporate the solvent to about 2ml left, and finally add deionized water to make up the volume to 25ml, the concentration of uranyl nitrate is 5.5×10 -3 g / ml solution, using 1:1 (volume ratio) mixed isopropanol and deionized water as a solvent to carry out gradual dilution of the above concentrated solution to obtain 3.2 × 10 -4 g / ml of uranyl nitrate solution.

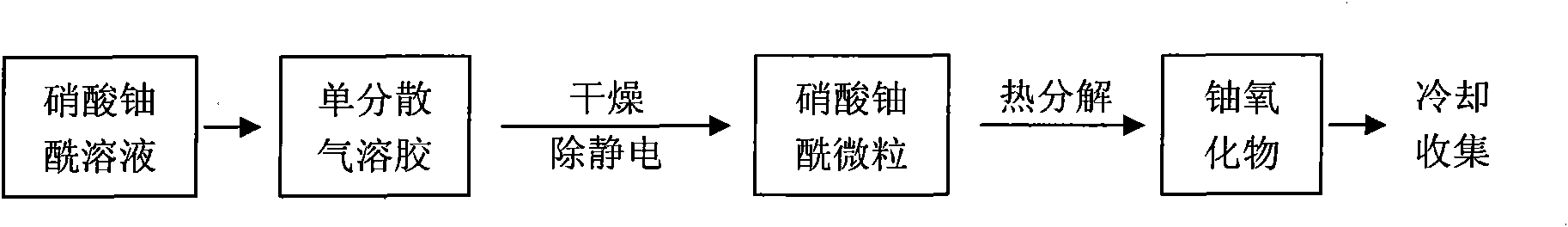

[0028] The preparation process of...

Embodiment 2

[0035] The operation steps are the same as in Example 1, except that in step 1, the vibration frequency of the vibrating hole aerosol generator is set to 57.2kHz, and the flow rate of the carrier gas is 45L / min; in step 2, the temperature of the heating zone is set to 115°C, The temperature of the carrier gas is raised to about 75-77°C; in step 3, the solid particles of uranyl nitrate are thermally decomposed through a muffle furnace, and the heating temperature of the muffle furnace is 740-750°C.

Embodiment 3

[0037] The operation steps are the same as in Example 1, the difference is that: in step 1, the flow rate of the carrier gas is 35L / min; , The solid particles of uranyl nitrate are thermally decomposed by a muffle furnace at a high temperature, and the heating temperature of the muffle furnace is 650-670°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com