A production system and method for comprehensively utilizing salt lake resources to realize metal magnesium integration

A technology for salt lake resources and production systems, applied in the directions of alkali metal compounds, chemical instruments and methods, alkali metal carbonates, etc., can solve the problems of small development scale and the inability to complete the construction of the circular economy industrial chain, and achieve the degree of equipment automation High, reduce dry spot and crystallization, avoid troublesome maintenance and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

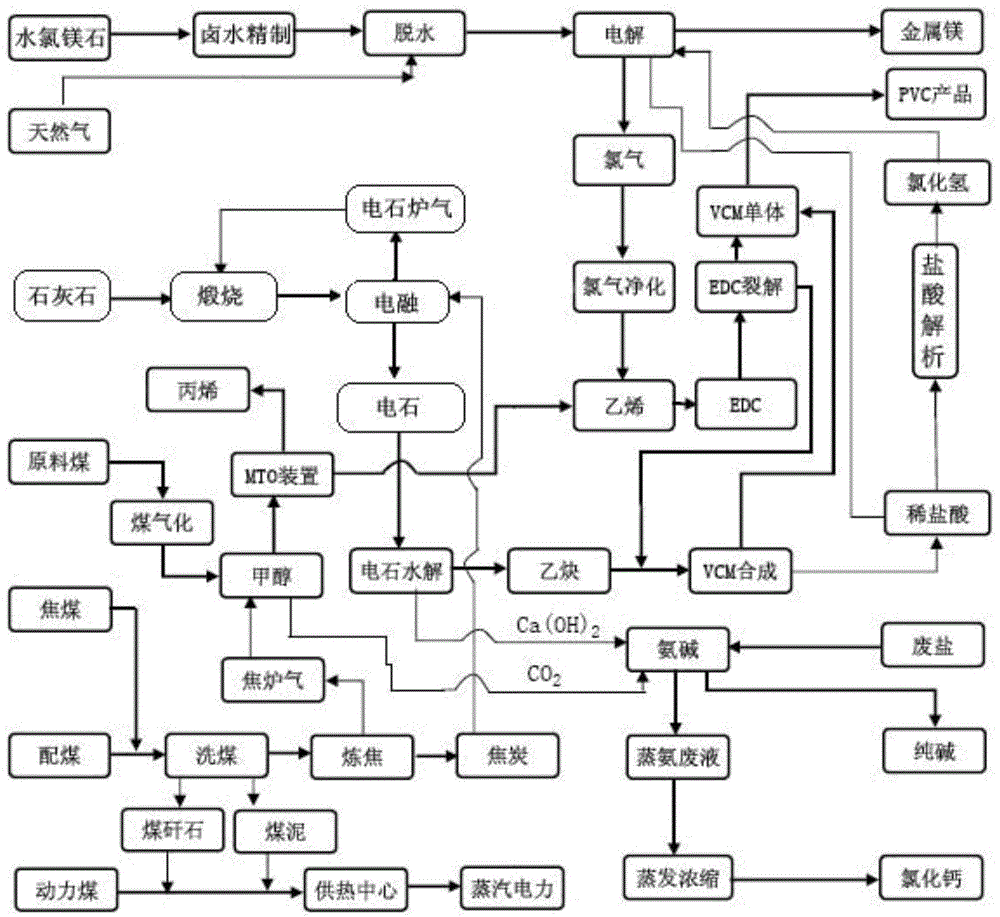

[0040] Such as figure 1 Shown is a schematic diagram of the production process of the integrated production system of magnesium metal by comprehensive utilization of salt lake resources in the present invention.

[0041] A comprehensive utilization of salt lake resources to realize the integration of metal magnesium production system, including metal magnesium production equipment, direct chlorinated methanol cracking ethylene (MTO) production PVC equipment, calcium carbide method production equipment, soda ash production equipment, calcium chloride production Device, the devices are connected in sequence, and the product or by-product of the previous device is the raw material of the next device;

[0042] In the metal magnesium production device, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com