Patents

Literature

58results about How to "Reduce inlet pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Absorption heat-transfer system

InactiveUS20050022963A1Reduce inlet pressureMechanical apparatusBoilers/analysersEngineeringRefrigerant

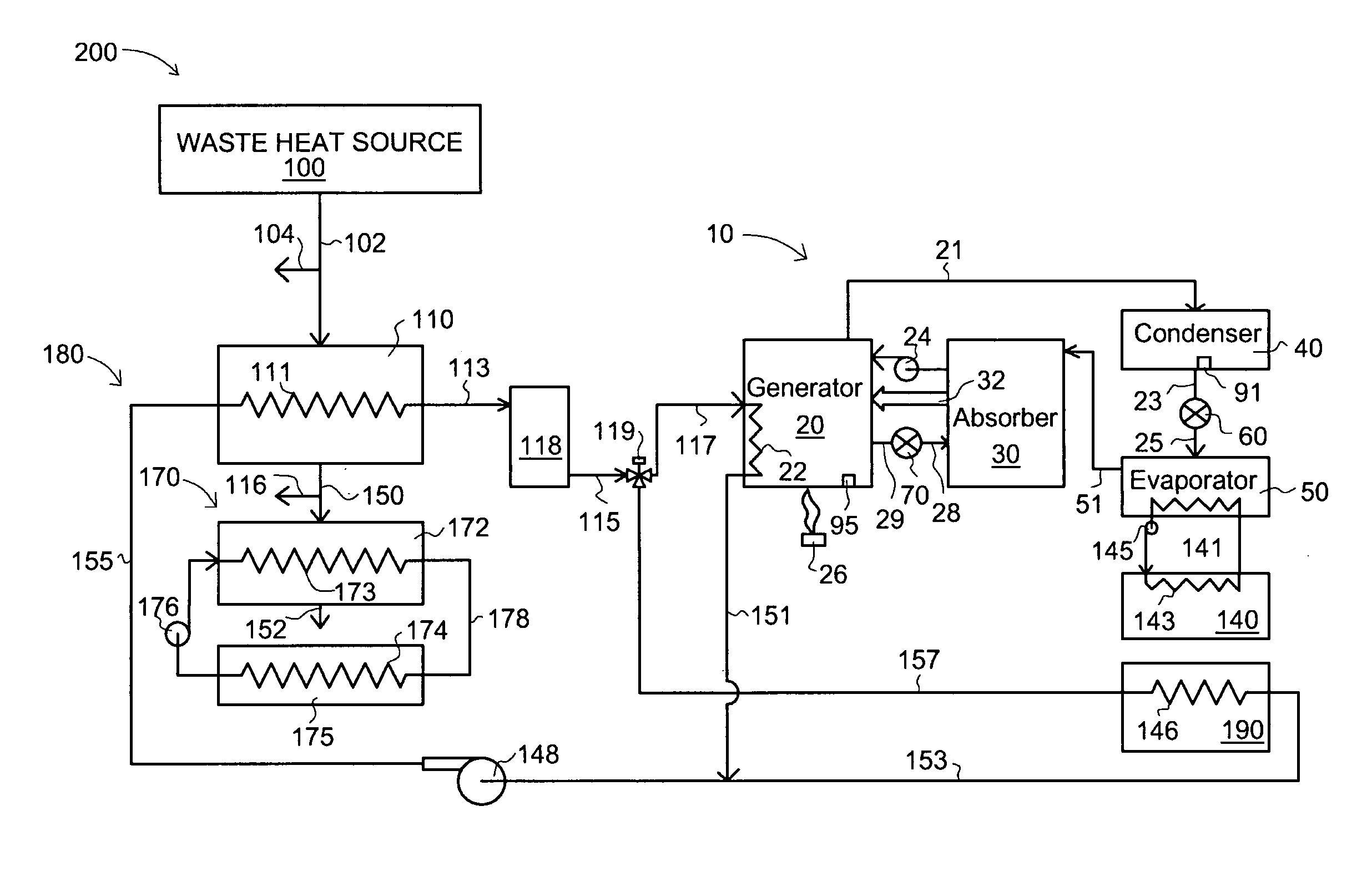

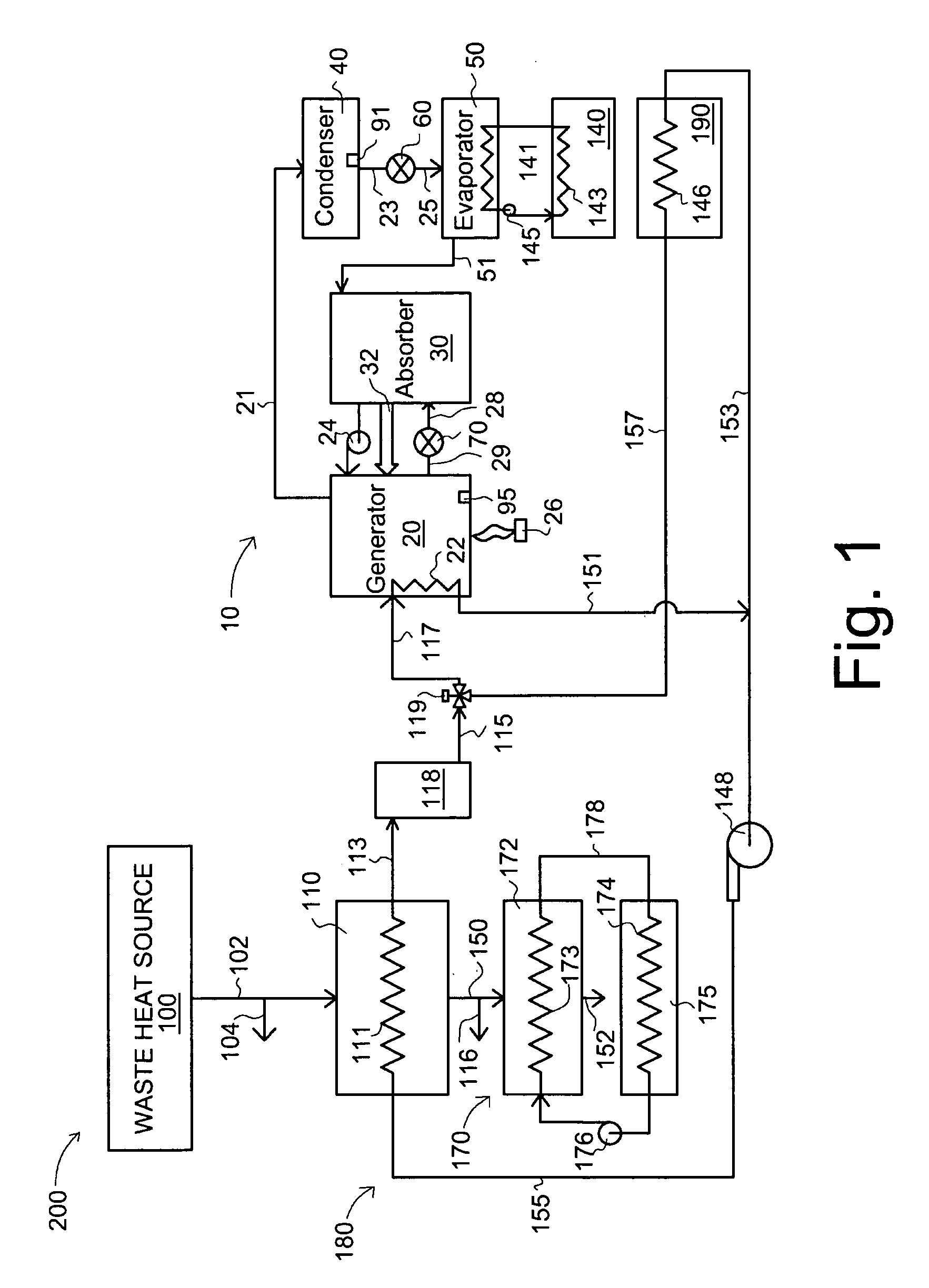

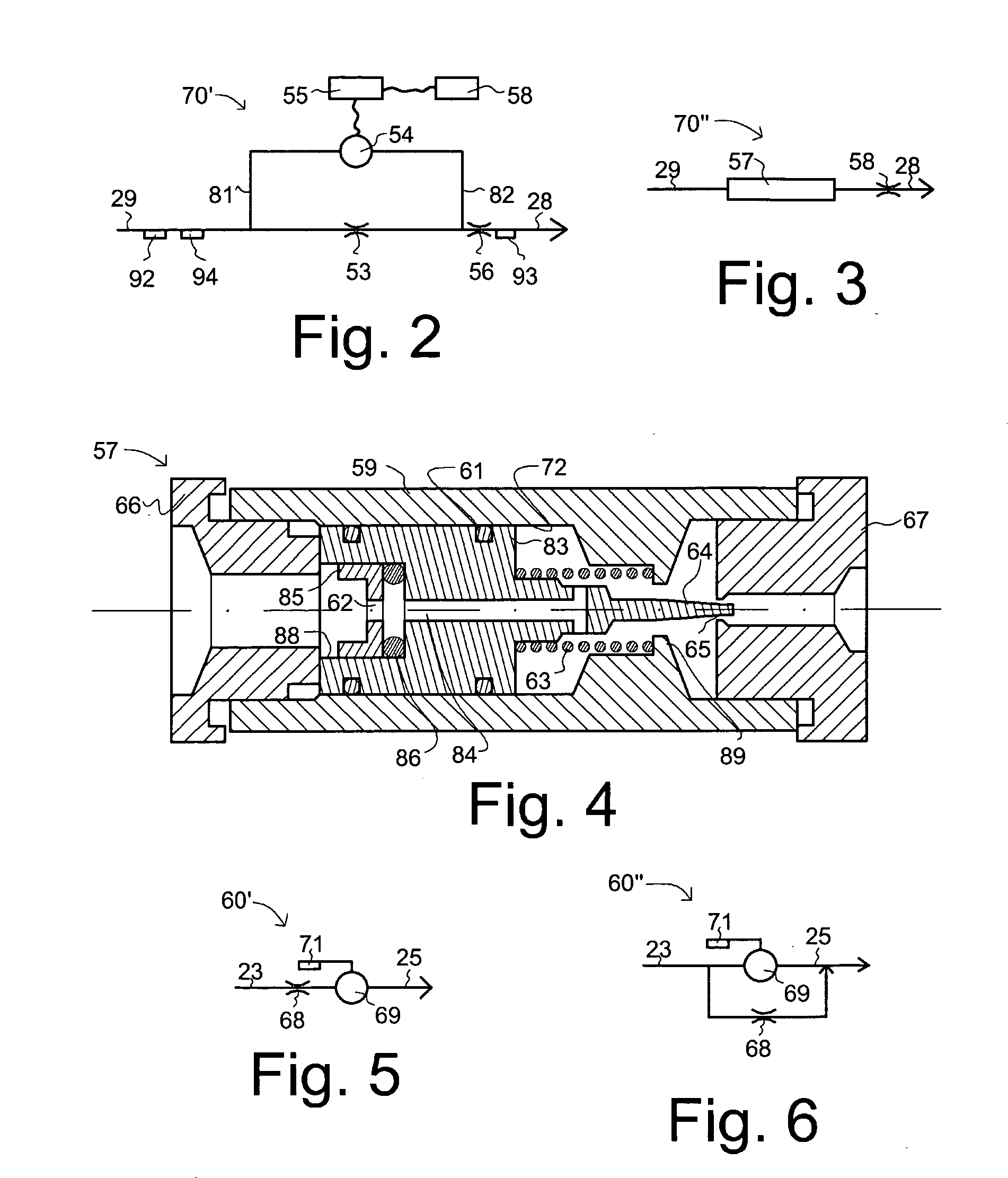

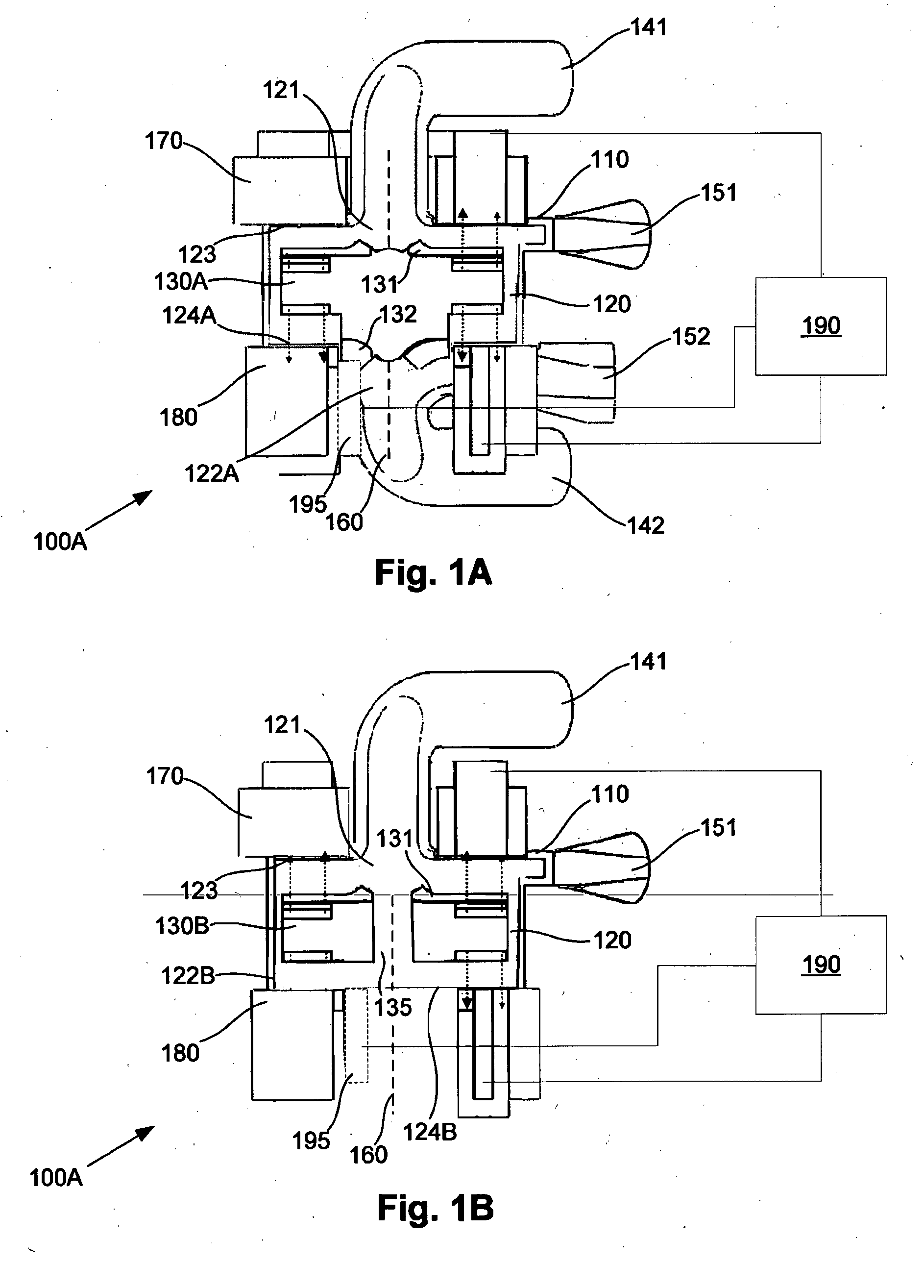

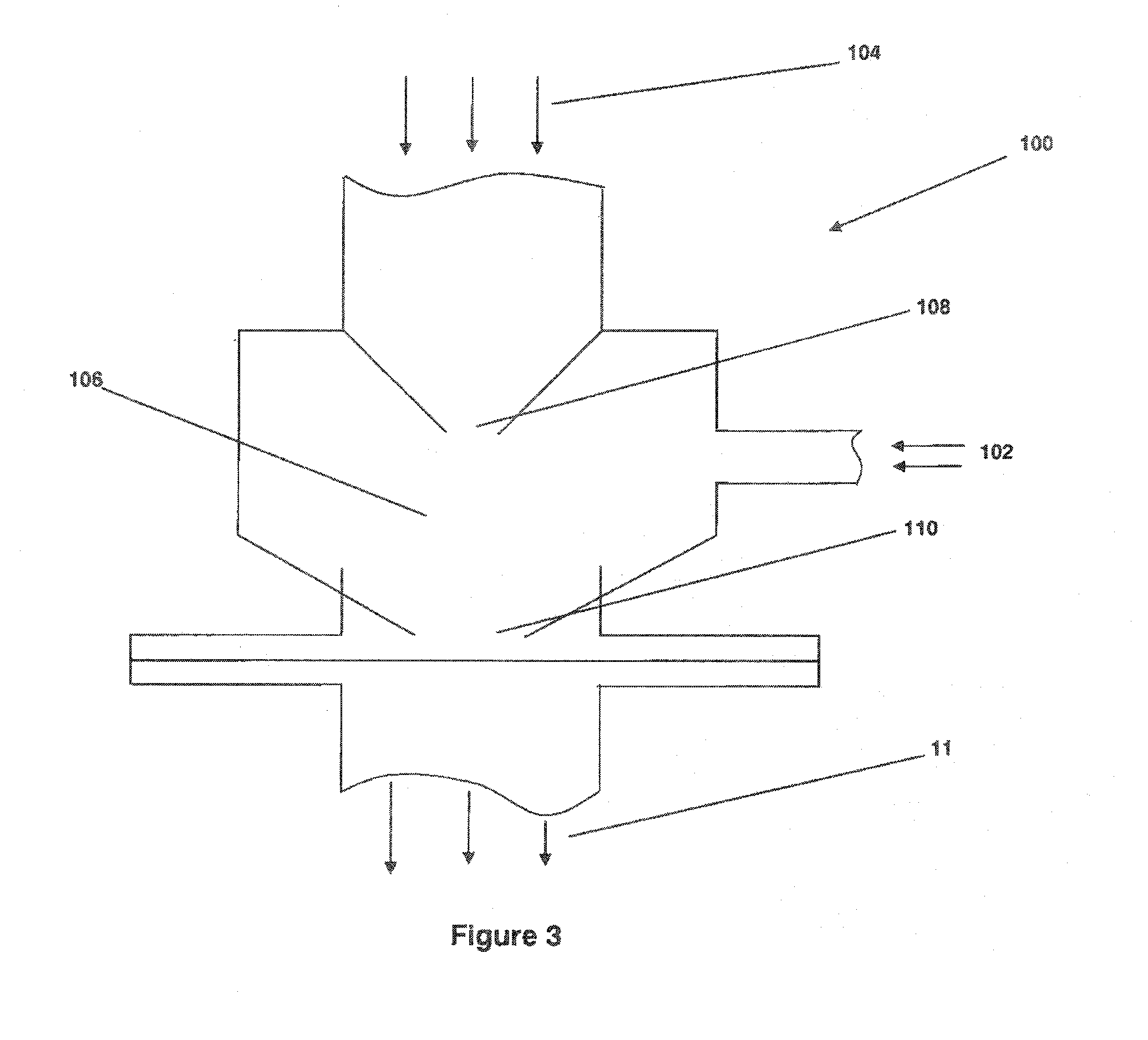

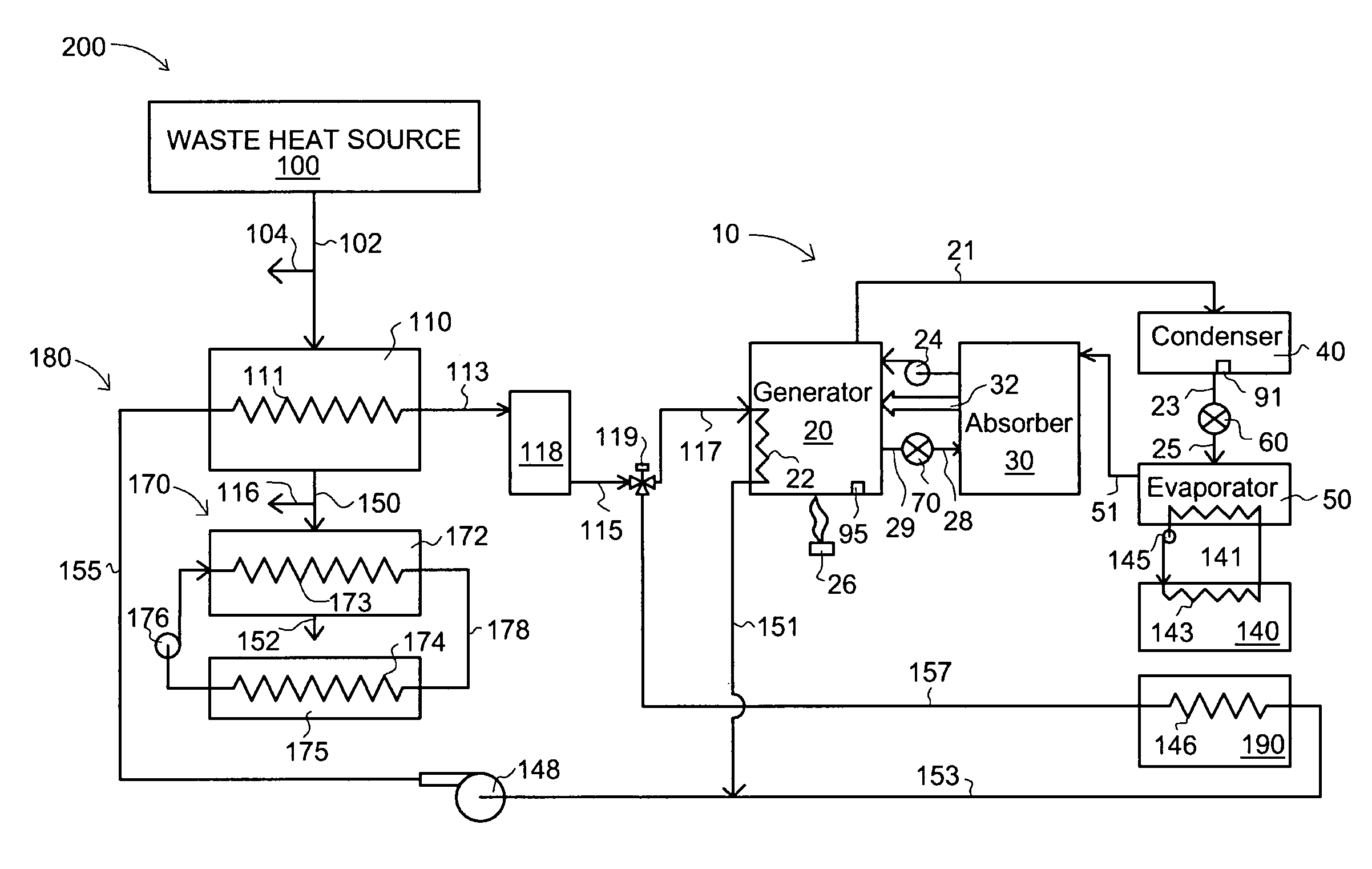

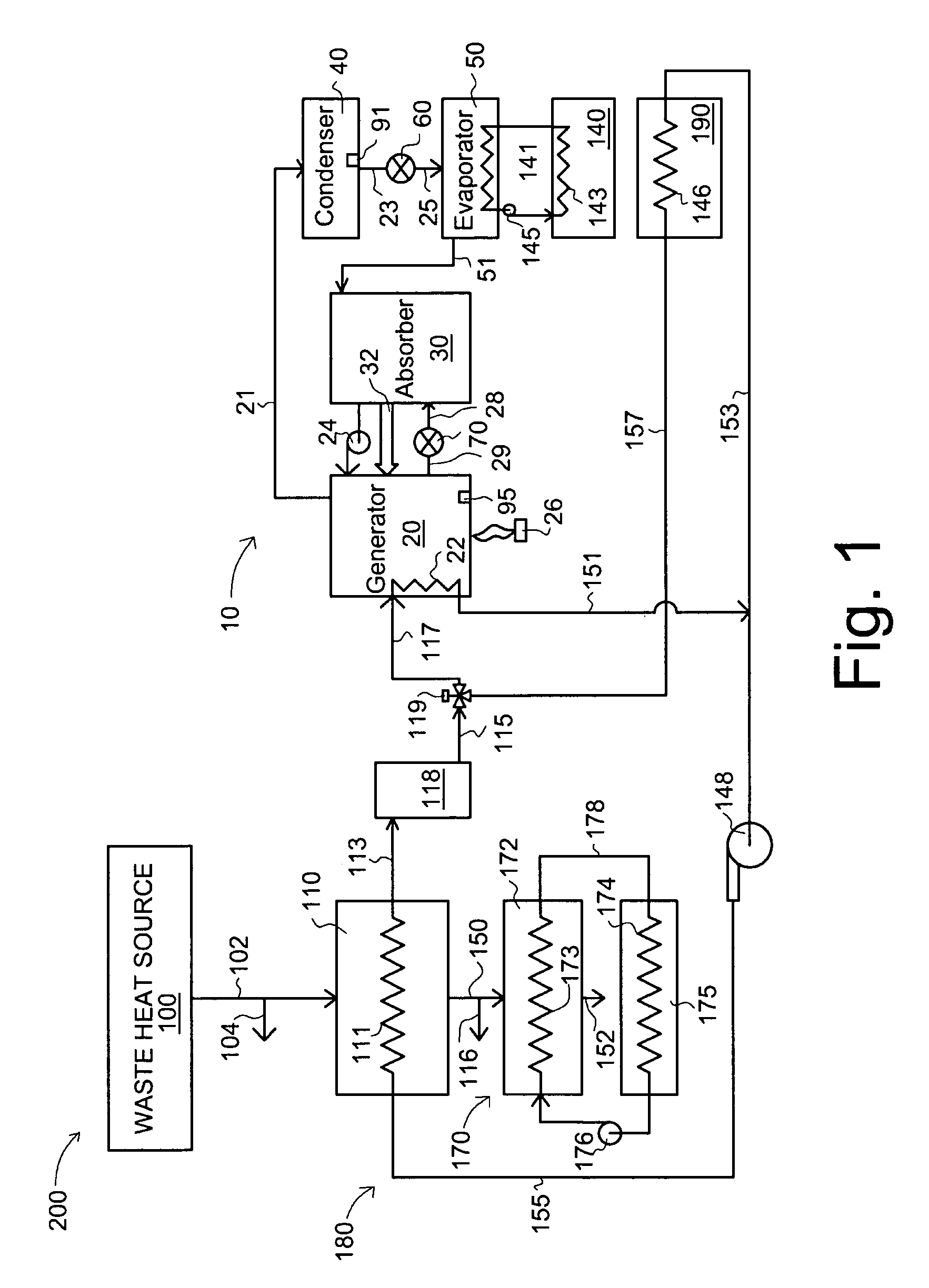

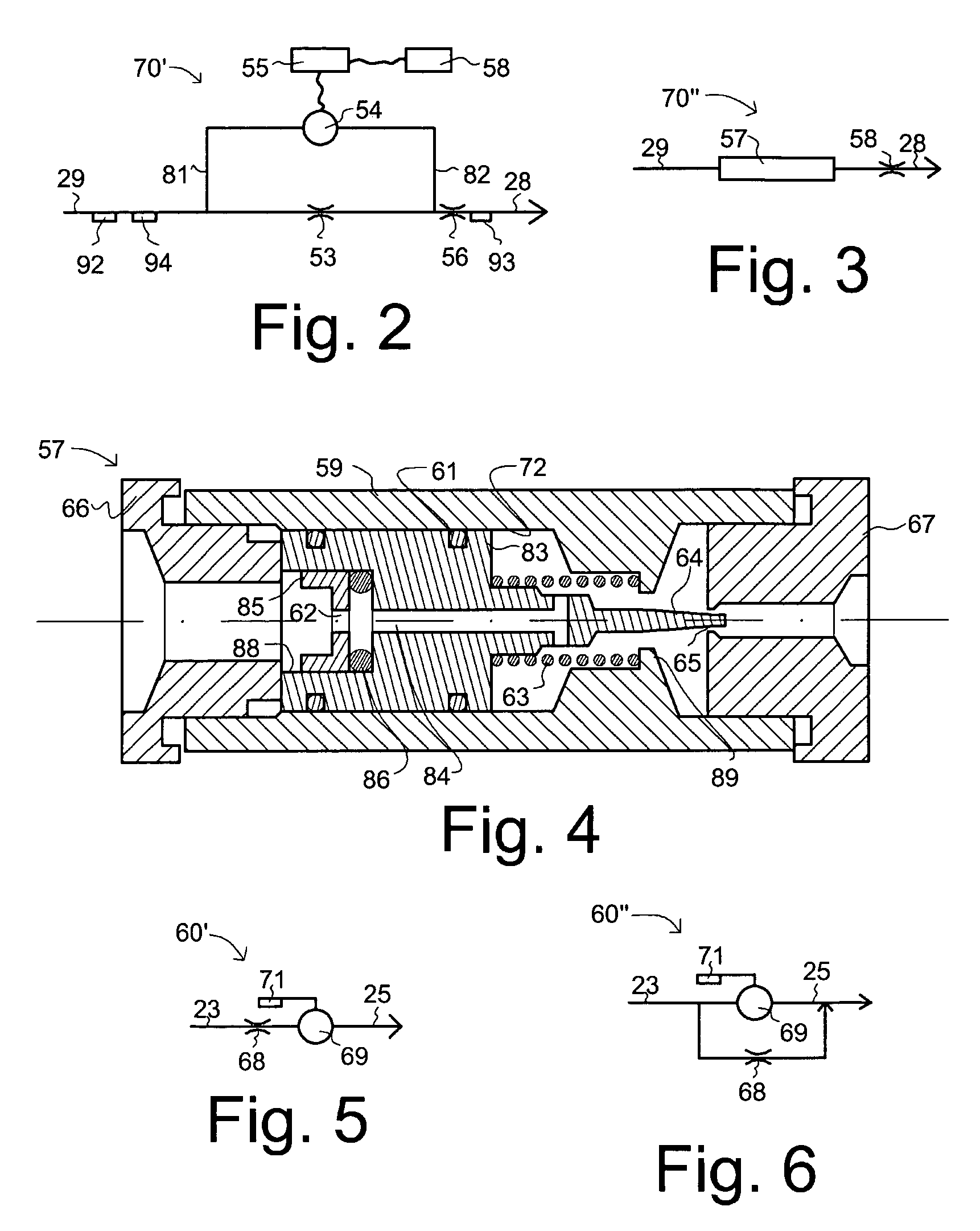

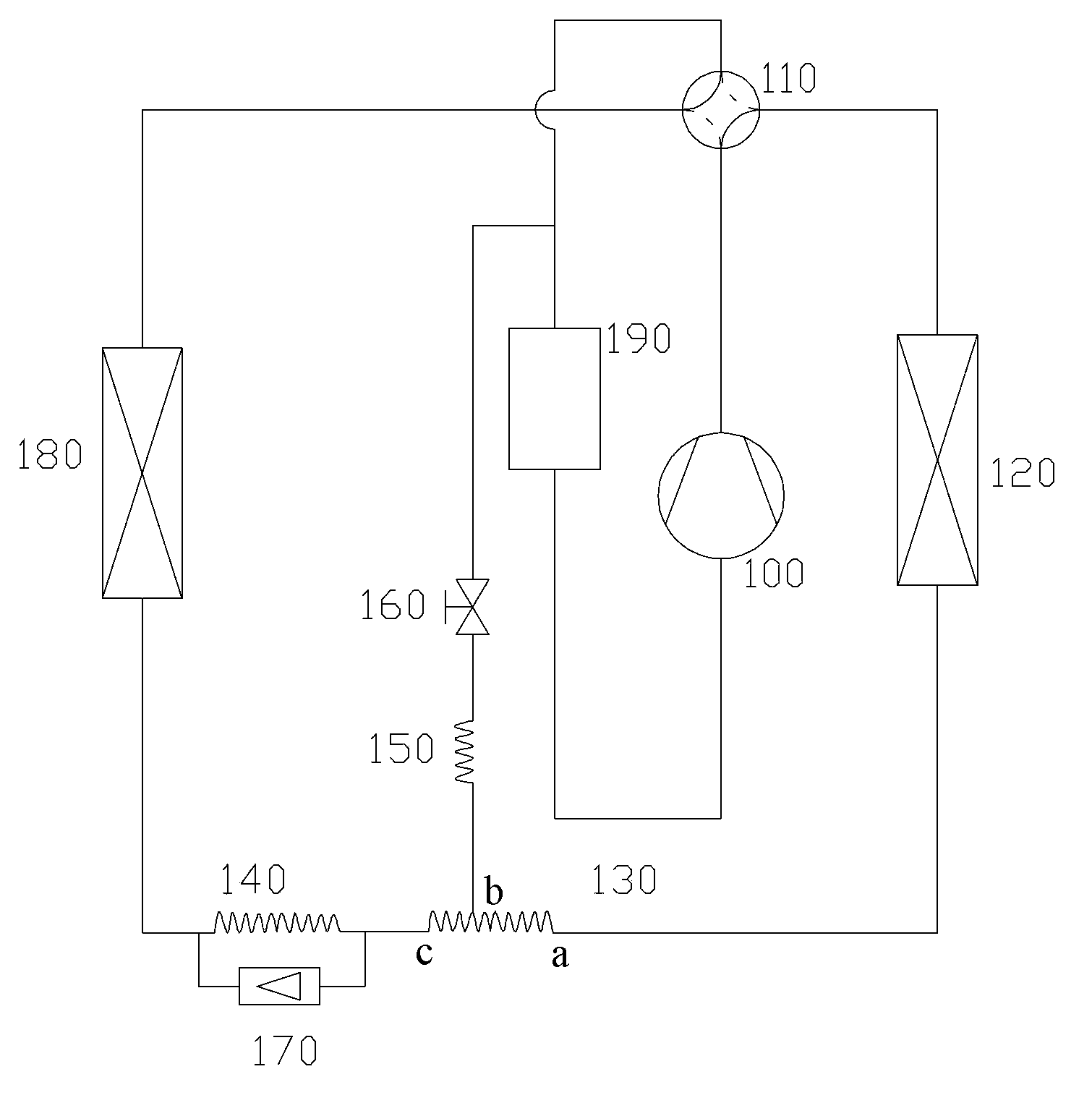

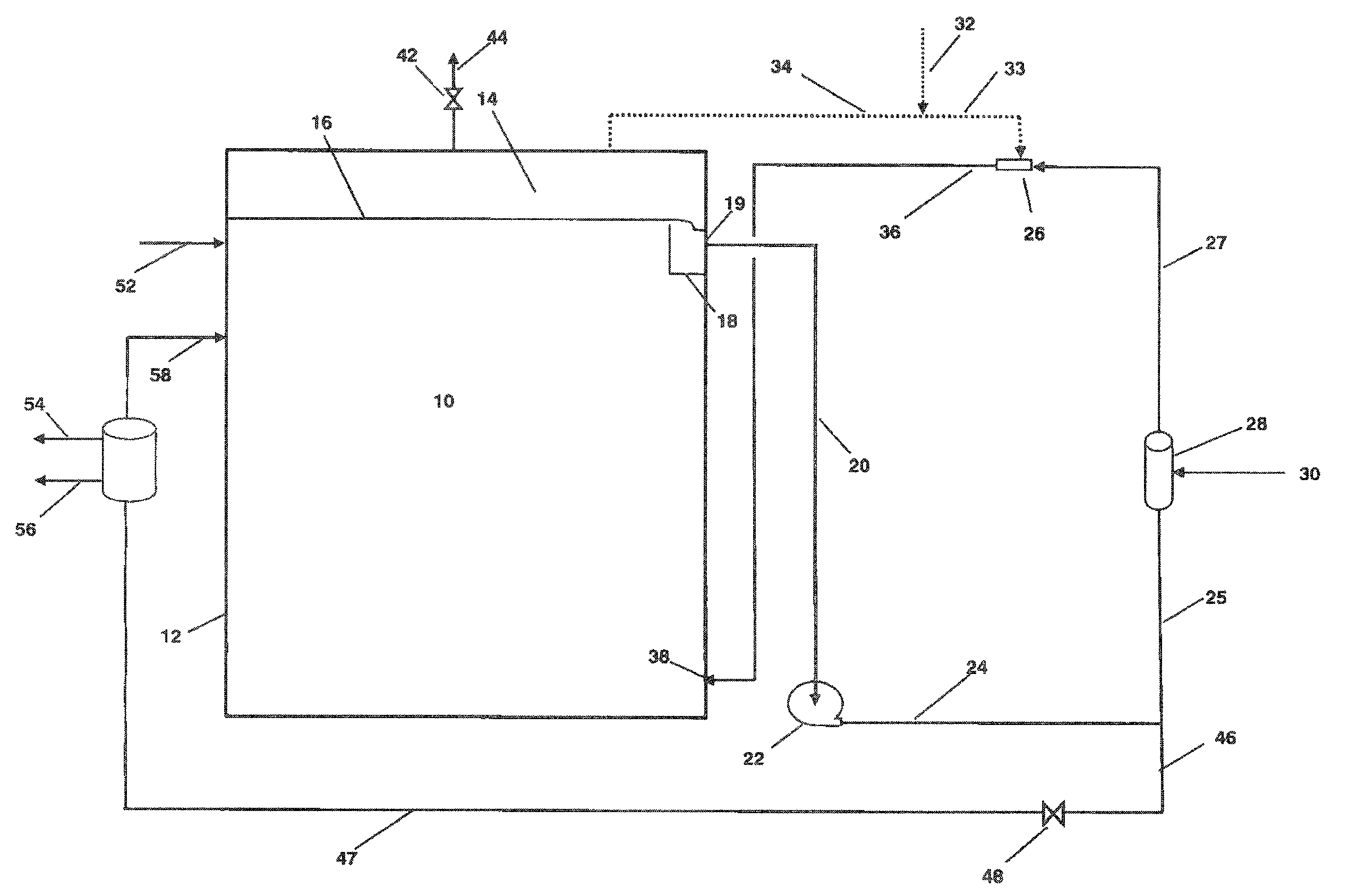

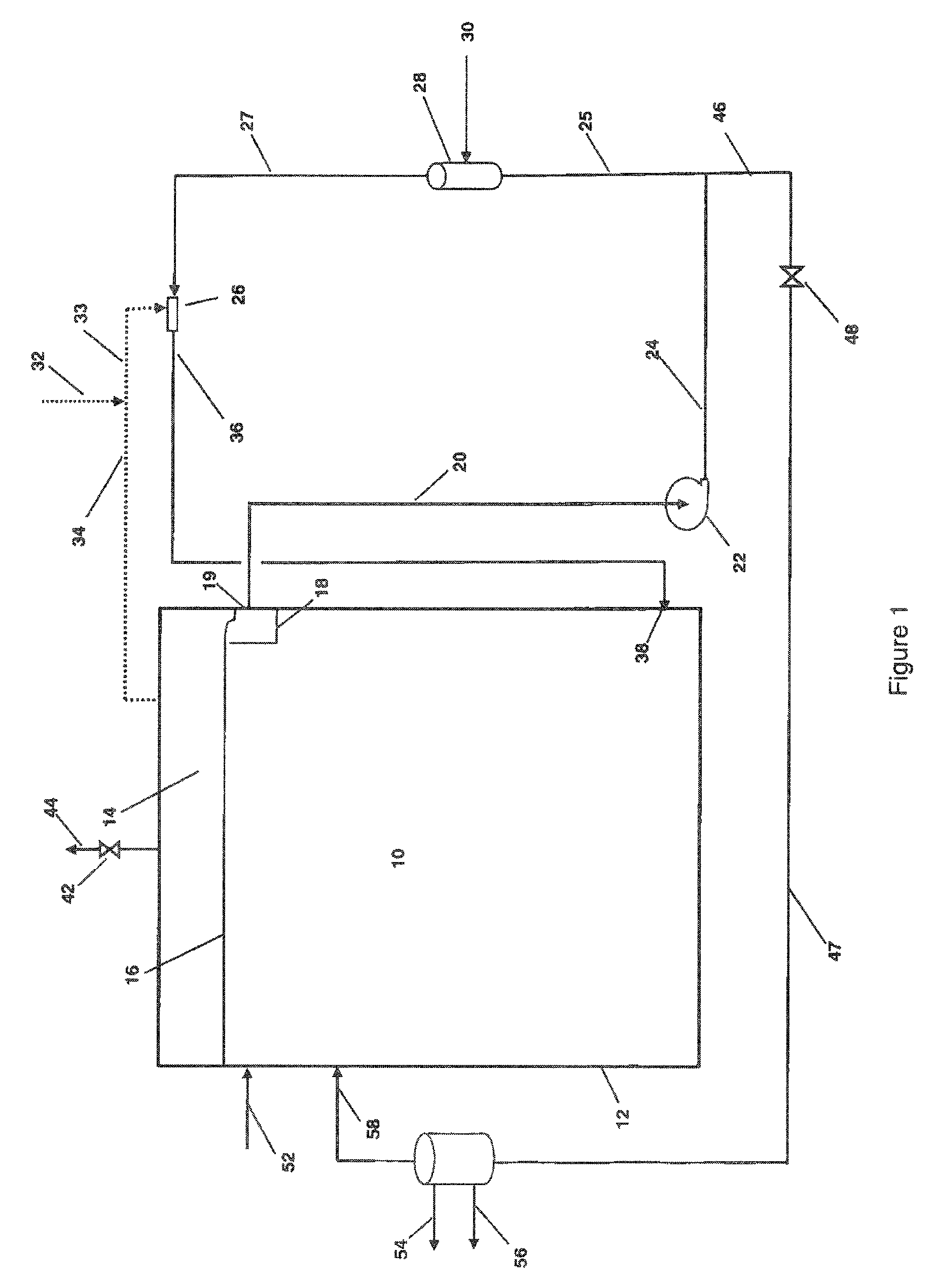

A waste heat source (100) is used to heat a high temperature heat transfer fluid which is used to heat an absorption heat transfer machine (10) having a generator (20), an absorber (30), a condenser (40), and an evaporator (50) operatively connected together. The high temperature heat transfer fluid can also be used to heat a load (190) such as a room space or a process. The waste heat source (100) can also be used to heat an intermediate heat transfer fluid, which can be used to heat a second load (175) such as a space, a process, or an absorption heat transfer machine. Novel flow control devices (70, 60) for controlling the flow of weak solution from generator (20) to absorber (30) or of refrigerant from condenser (40) to evaporator (50), respectively, are also described.

Owner:COOLING TECH

Fluid transport apparatus

InactiveUS20140288354A1Decreased blood flowIncrease blood flowControl devicesBlood pumpsFluid transportCombined use

Owner:TIMMS DANIEL +2

Method for Injecting a Feed Gas Stream into a Vertically Extended Column of Liquid

ActiveUS20120003707A1Reduce surface tensionProfound effect on gas transfer efficiencyBiochemistry apparatusBiofuelsSyngasLiquid product

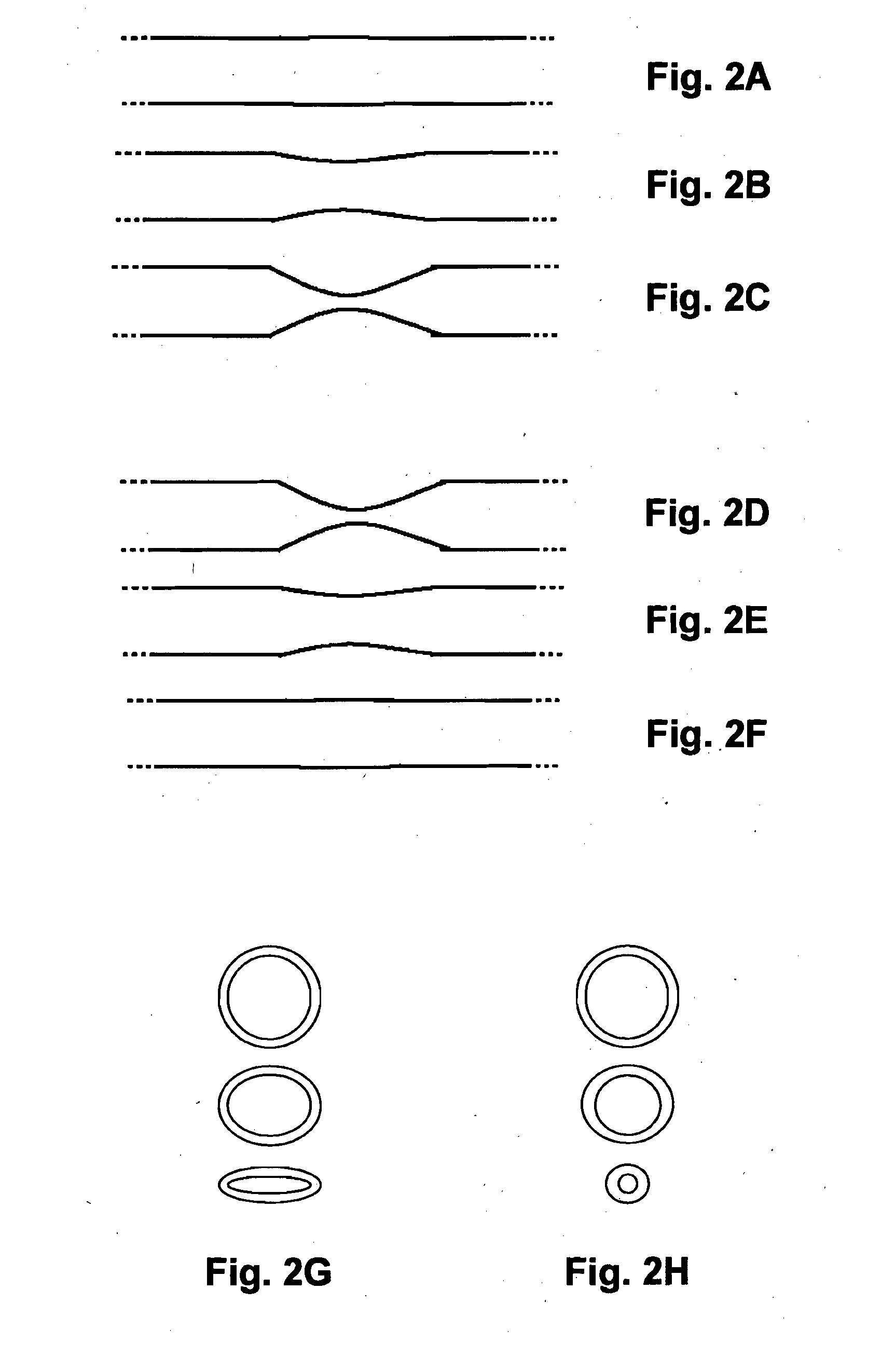

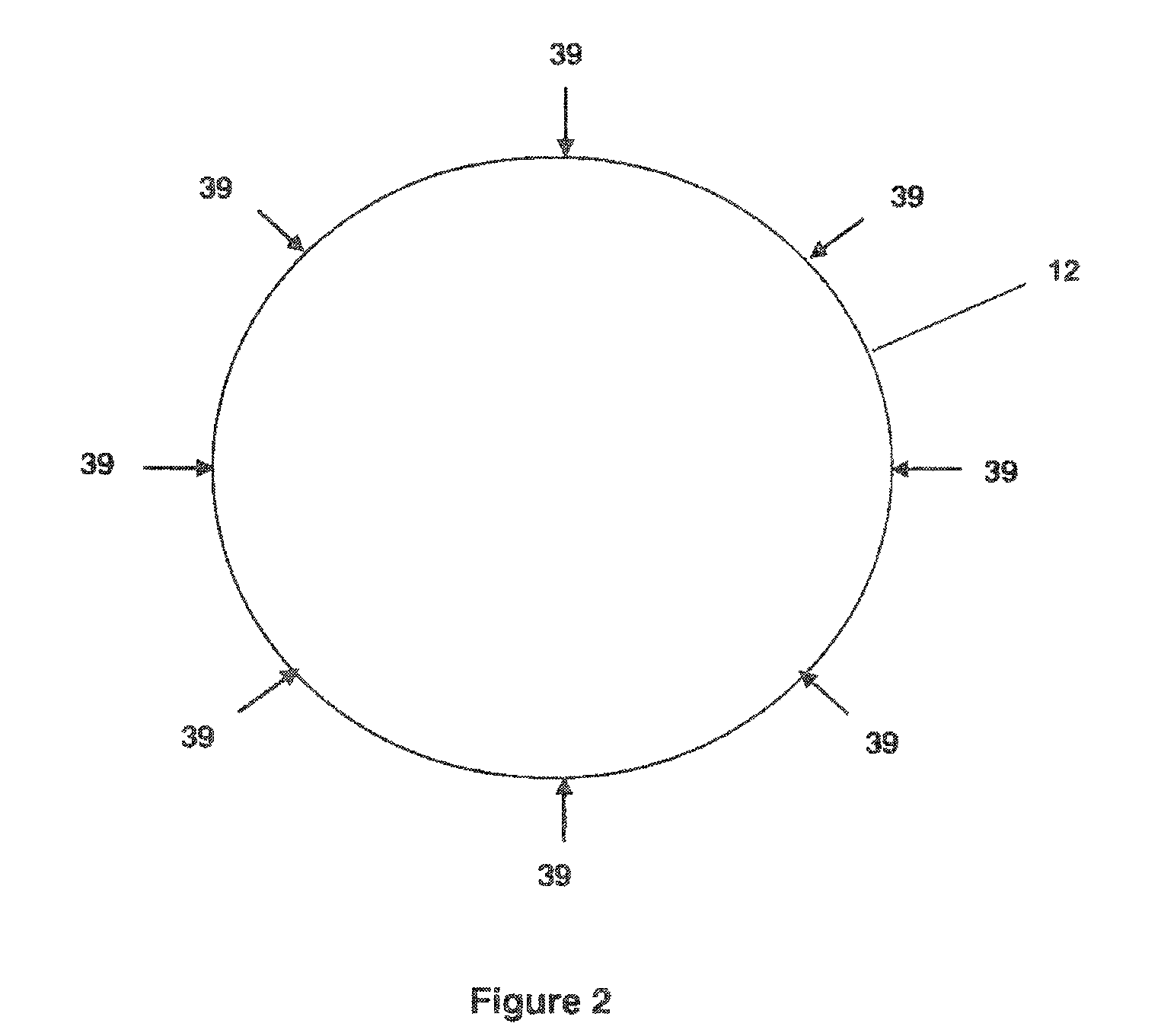

A process for conversion of syngas to liquid products that serve as surface acting agents uses the gas stream at a relatively low pressure to eliminate the use of a compressor. The process uses a liquid stream as the primary energy input to a gas injector that intensely mixes gas and the liquid with reduced compression costs while the presence of the liquid product maintains the gas-liquid dispersion as it flows downward to build a static pressure head. The process lowers the required gas pressure by adjusting the elevation of the gas injector such that a conduit receives the gas-liquid dispersion from the outlet of the injector and confines it as it travels downward to enter the bottom of a column of liquid. The liquid product provides a surface acting agent that prolongs the creation and duration of microbubbles in the gas-liquid dispersion.

Owner:KLA SYST +1

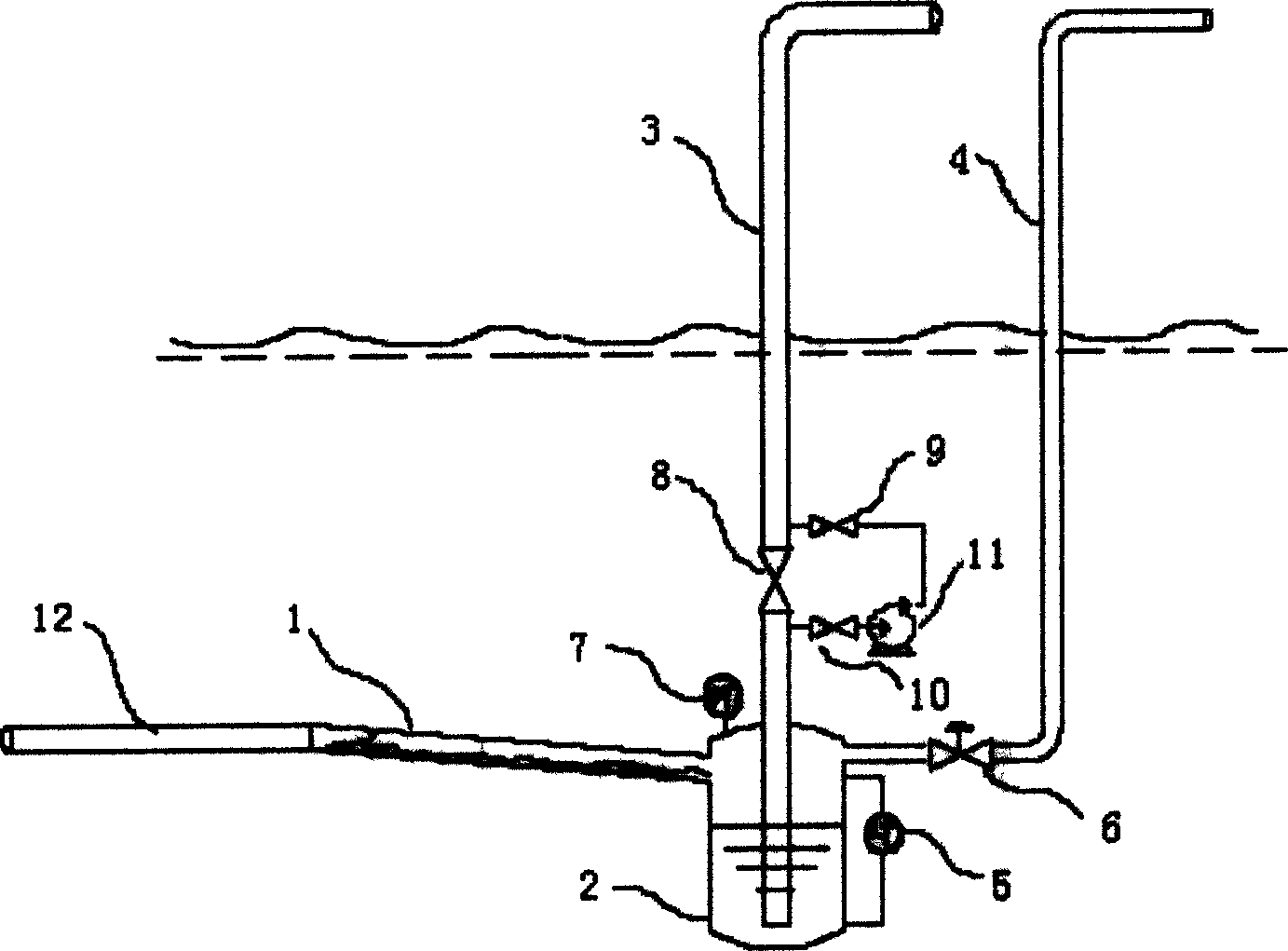

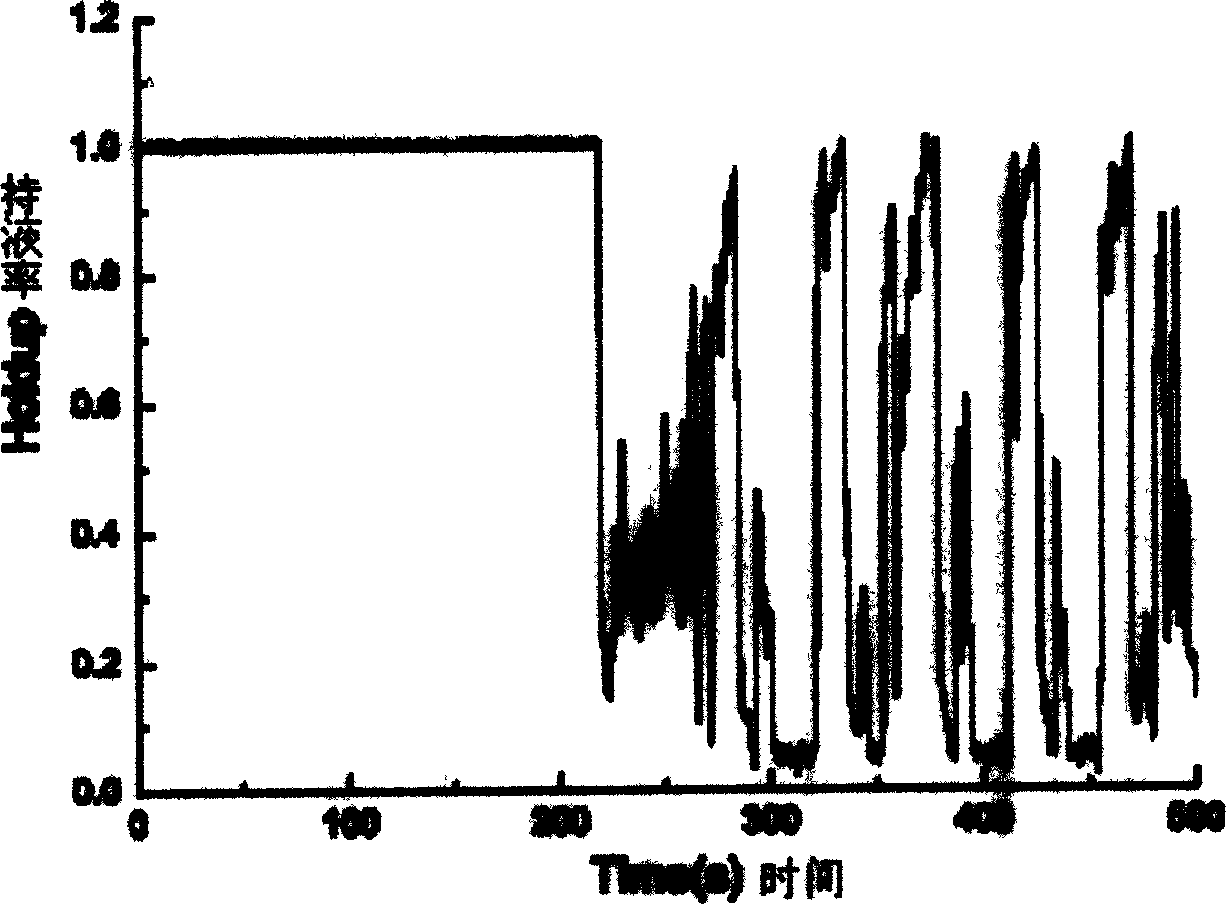

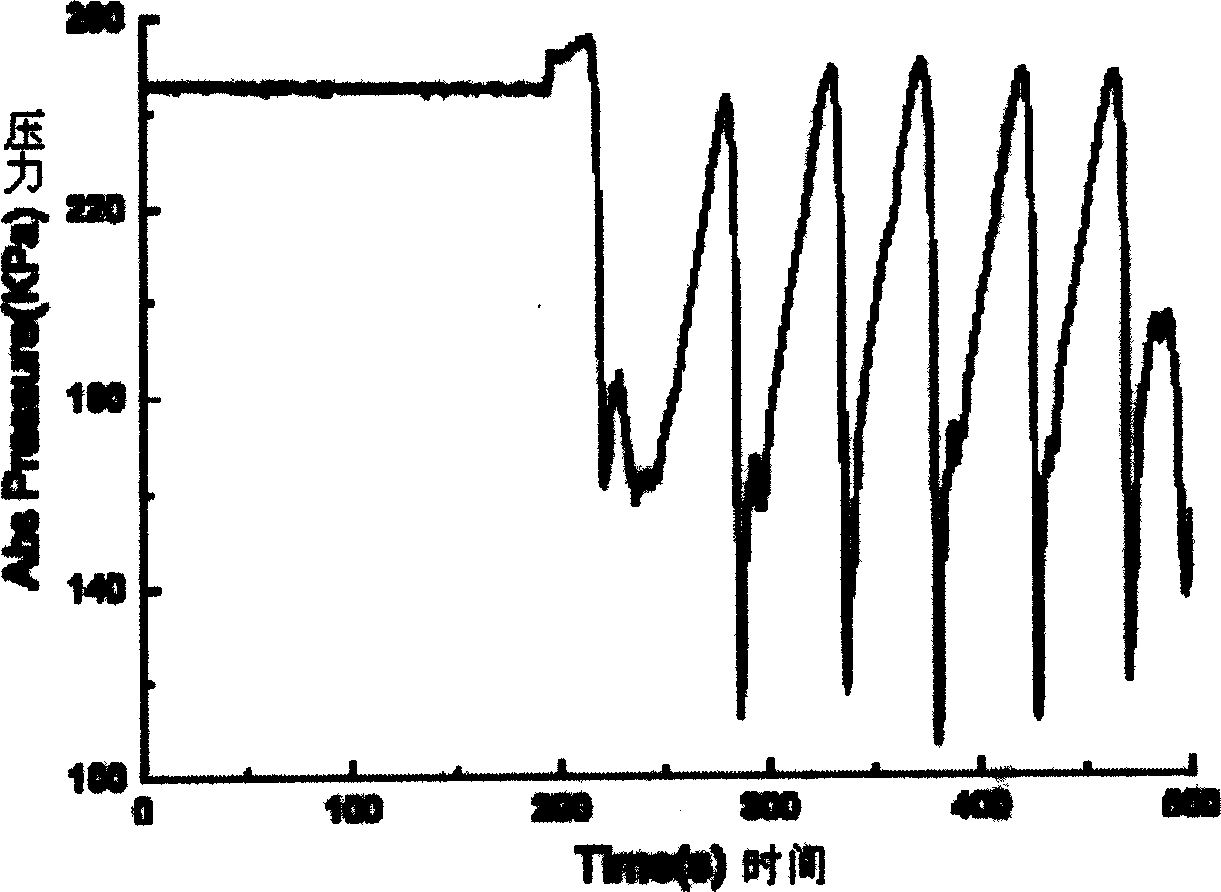

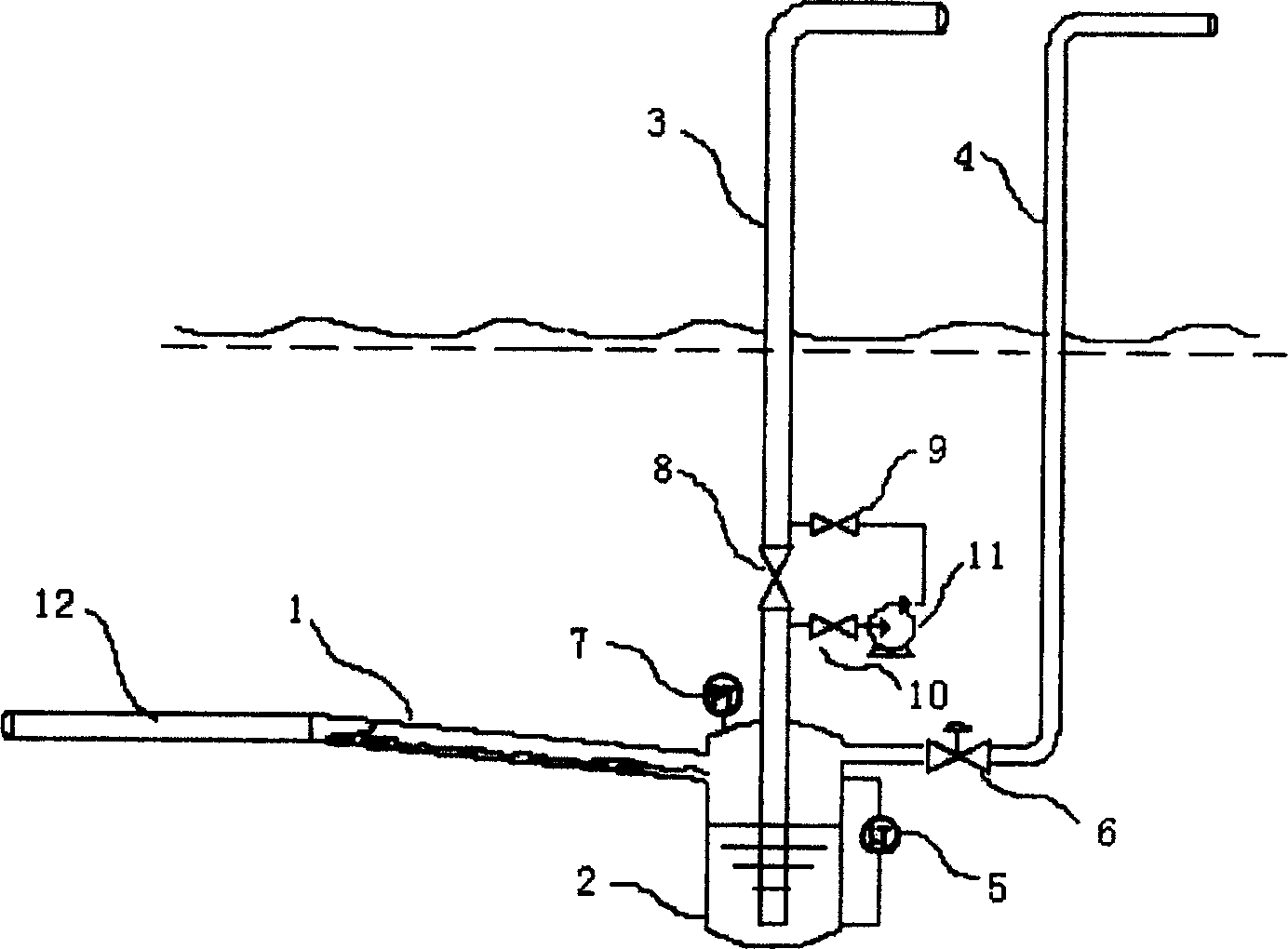

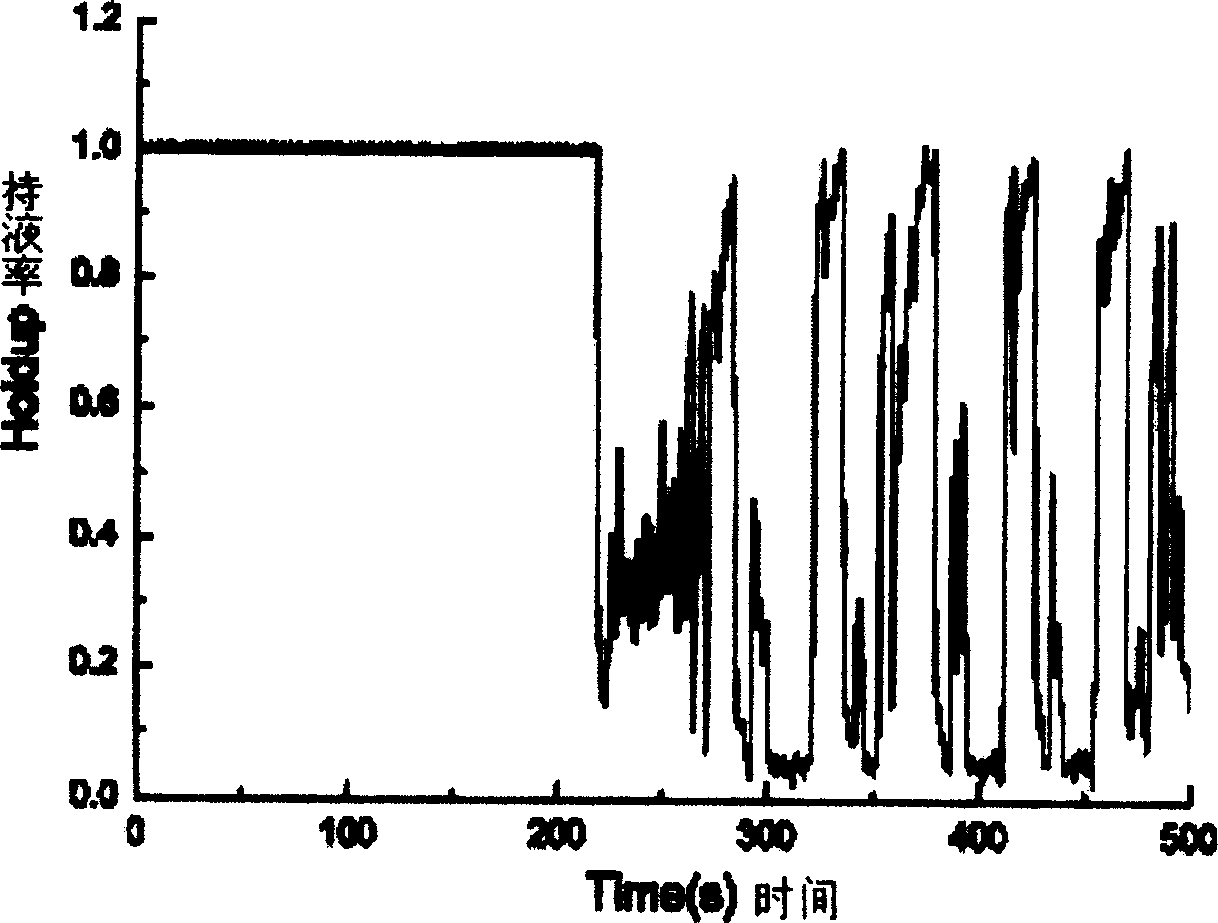

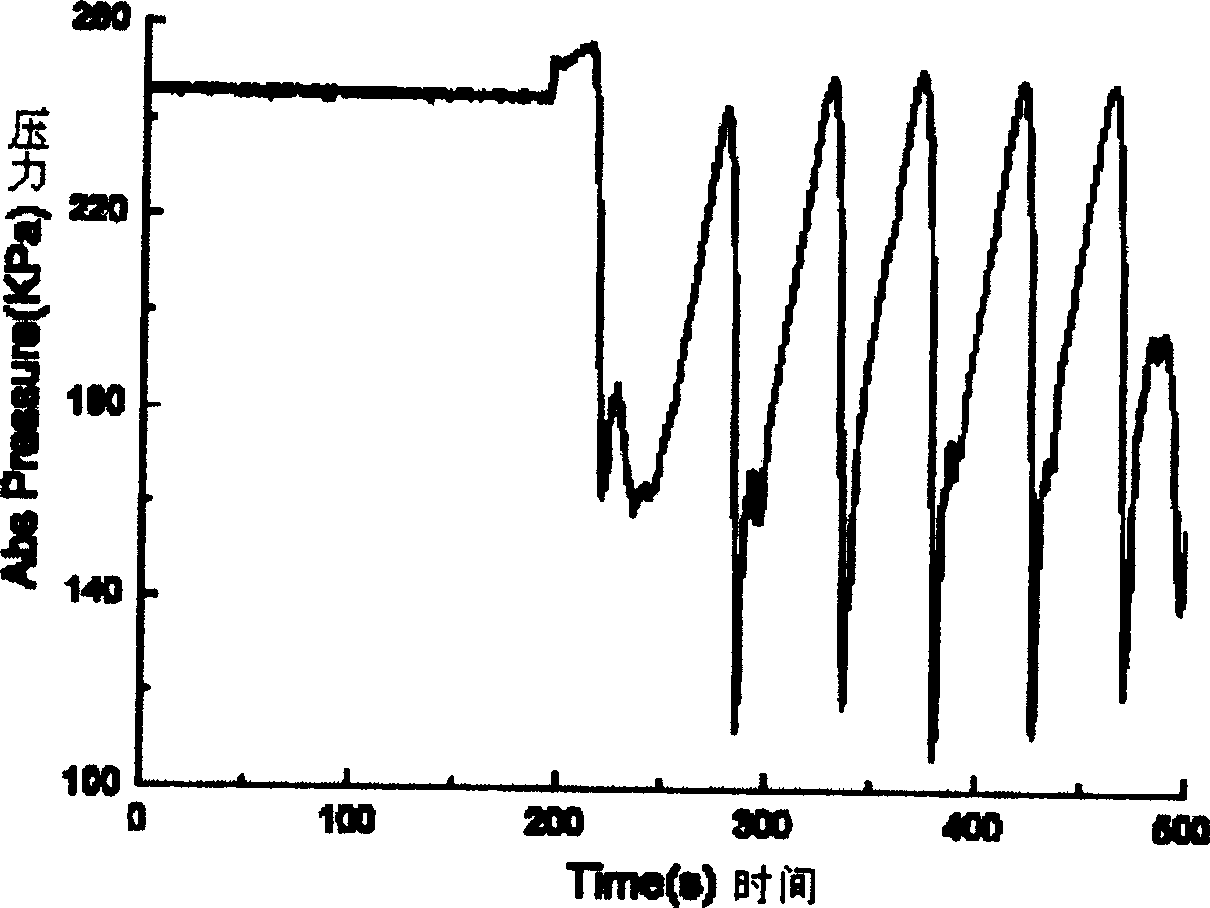

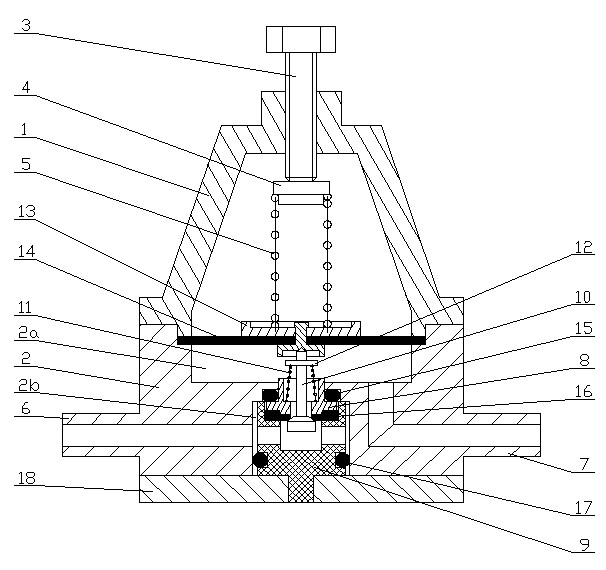

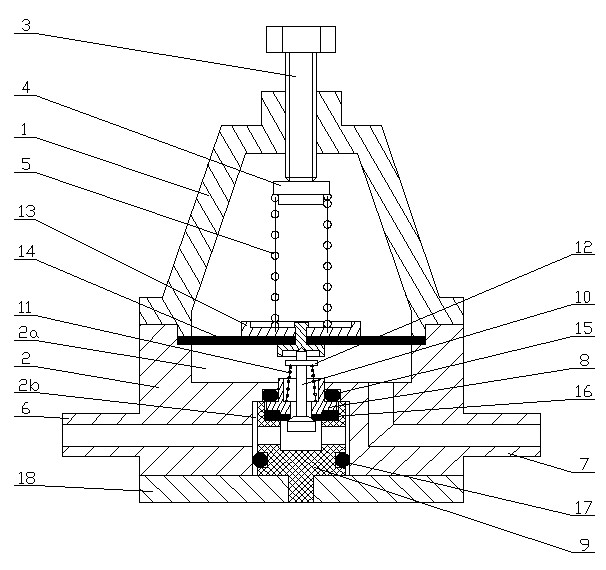

Separator and phase-split conveying method for eliminating plug flow on serious segments by utilizing same

InactiveCN1632369ASimple structureSpeed up the flowLiquid degasificationFluid removalPressure stabilizationLevel sensor

A separator and a phase-splitting conveying method for eliminating severe slug flow by using the separator. The separator includes a shell, which is connected with an incoming flow pipe and a gas riser pipe, and is provided with a liquid level sensor and a pressure sensor on the shell. A riser pipe is inserted and extended to the bottom of the shell, the part of the riser pipe protruding from the shell is provided with a liquid phase pump connected to the riser pipe through a valve, and a control valve is set on the gas riser pipe close to the outlet of the shell. The separator of the present invention is installed at the junction of the mixed pipeline and the rising pipe, the gas-liquid fluid in the mixed pipeline enters the shell of the separator through the incoming flow pipe, and the liquid level signal and pressure signal are used to adjust the control valve. The opening makes the liquid level and pressure stable. After the gas and liquid are separated in the separator, the liquid enters the riser and is pressurized by the liquid phase pump to be transported to the onshore platform device. The gas enters the onshore platform device through the gas riser through the control valve. The invention has a simple structure, can conveniently and accurately control the flow of gas and liquid, and achieves the purpose of eliminating severe slug flow.

Owner:XI AN JIAOTONG UNIV

Absorption heat-transfer system

A waste heat source (100) is used to heat a high temperature heat transfer fluid which is used to heat an absorption heat transfer machine (10) having a generator (20), an absorber (30), a condenser (40), and an evaporator (50) operatively connected together. The high temperature heat transfer fluid can also be used to heat a load (190) such as a room space or a process. The waste heat source (100) can also be used to heat an intermediate heat transfer fluid, which can be used to heat a second load (175) such as a space, a process, or an absorption heat transfer machine. Novel flow control devices (70, 60) for controlling the flow of weak solution from generator (20) to absorber (30) or of refrigerant from condenser (40) to evaporator (50), respectively, are also described.

Owner:COOLING TECH

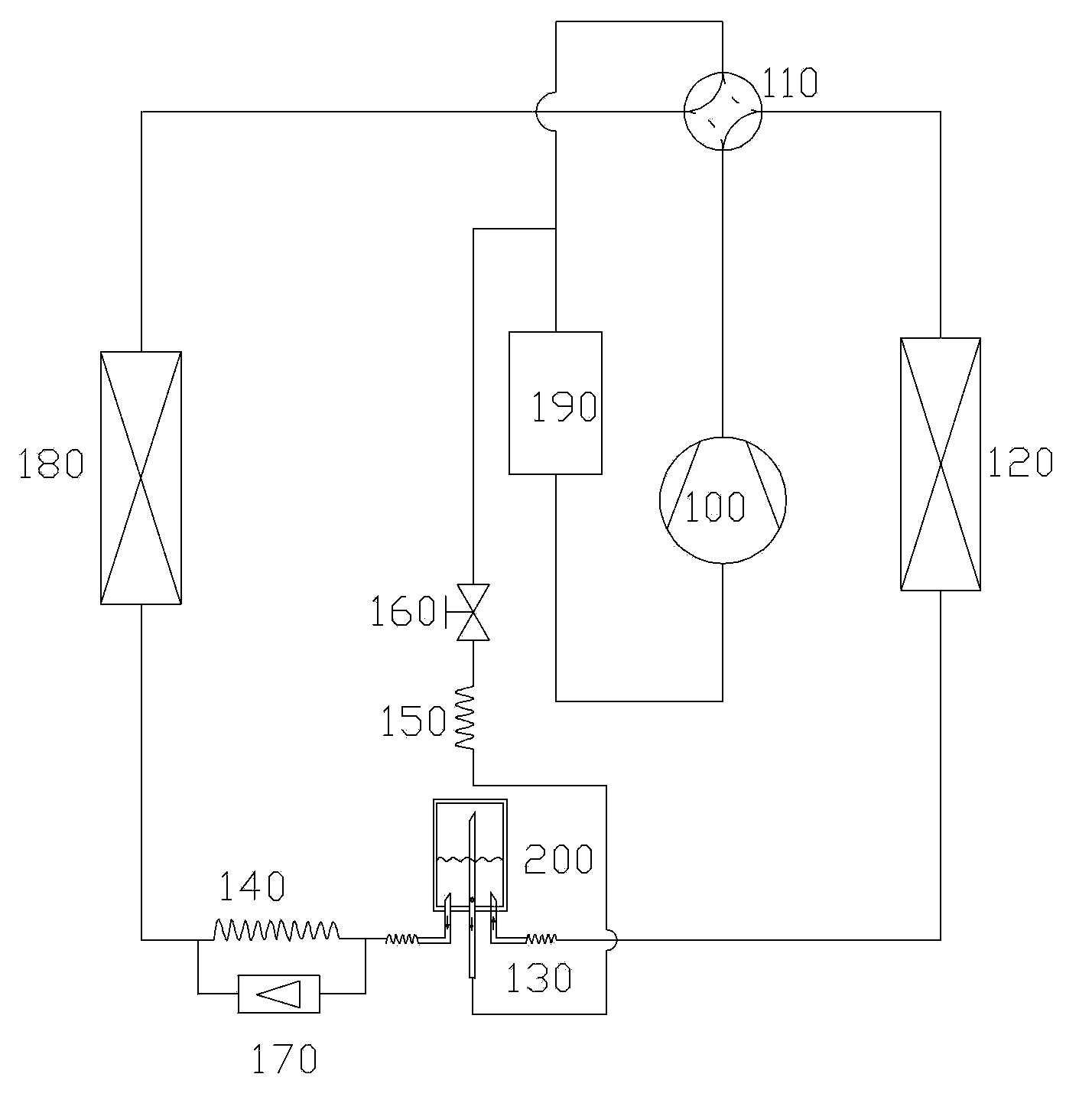

Refrigerating system and air-conditioning system with same

InactiveCN103673424AImprove practicalityReduce exhaust temperatureMechanical apparatusFluid circulation arrangementVapor–liquid separatorEngineering

The invention provides a refrigerating system and an air-conditioning system with the same. The refrigerating system comprises a major refrigerating loop and a liquid injecting cooling loop. The major refrigerating loop comprises a gas-liquid separator, a compressor, a four-way reversing valve, an outdoor heat exchanger, a first capillary pipe and an indoor heat exchanger which are sequentially connected through refrigerating pipelines. The liquid injecting cooling loop comprises a liquid injecting capillary pipe and a valve which are sequentially connected, the first end of the liquid injecting cooling loop is connected between the first end of the first capillary pipe and the indoor heat exchange, the second end of the liquid injecting cooling loop is connected on a pipeline between the four-way reversing valve and the gas-liquid separator or connected on the gas-liquid separator. The refrigerating system effectively solves the problems that a compressor of an existing refrigerating system is too high in exhaust temperature and a liquid injecting capillary pipe is too long in the prior art.

Owner:GREE ELECTRIC APPLIANCES INC

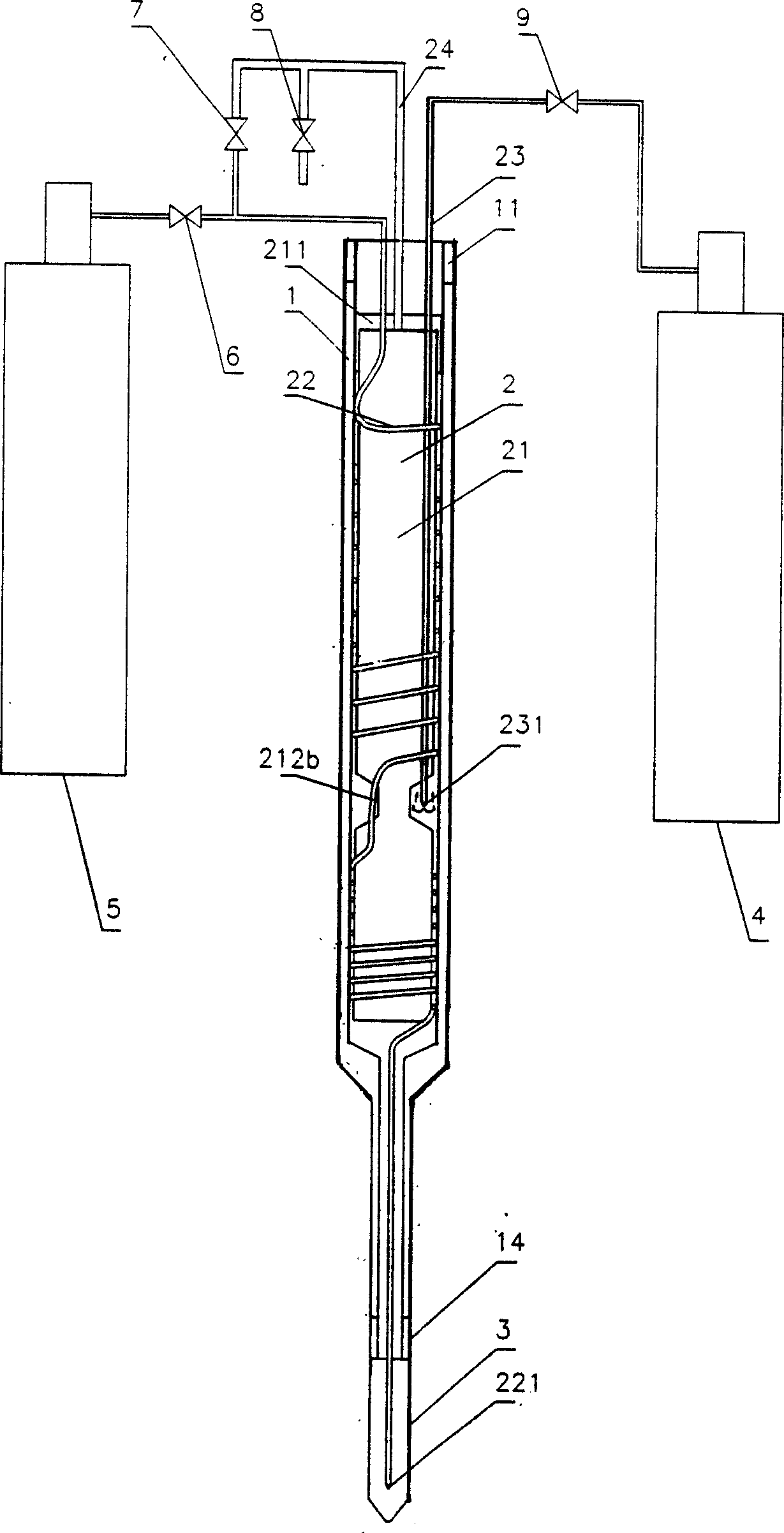

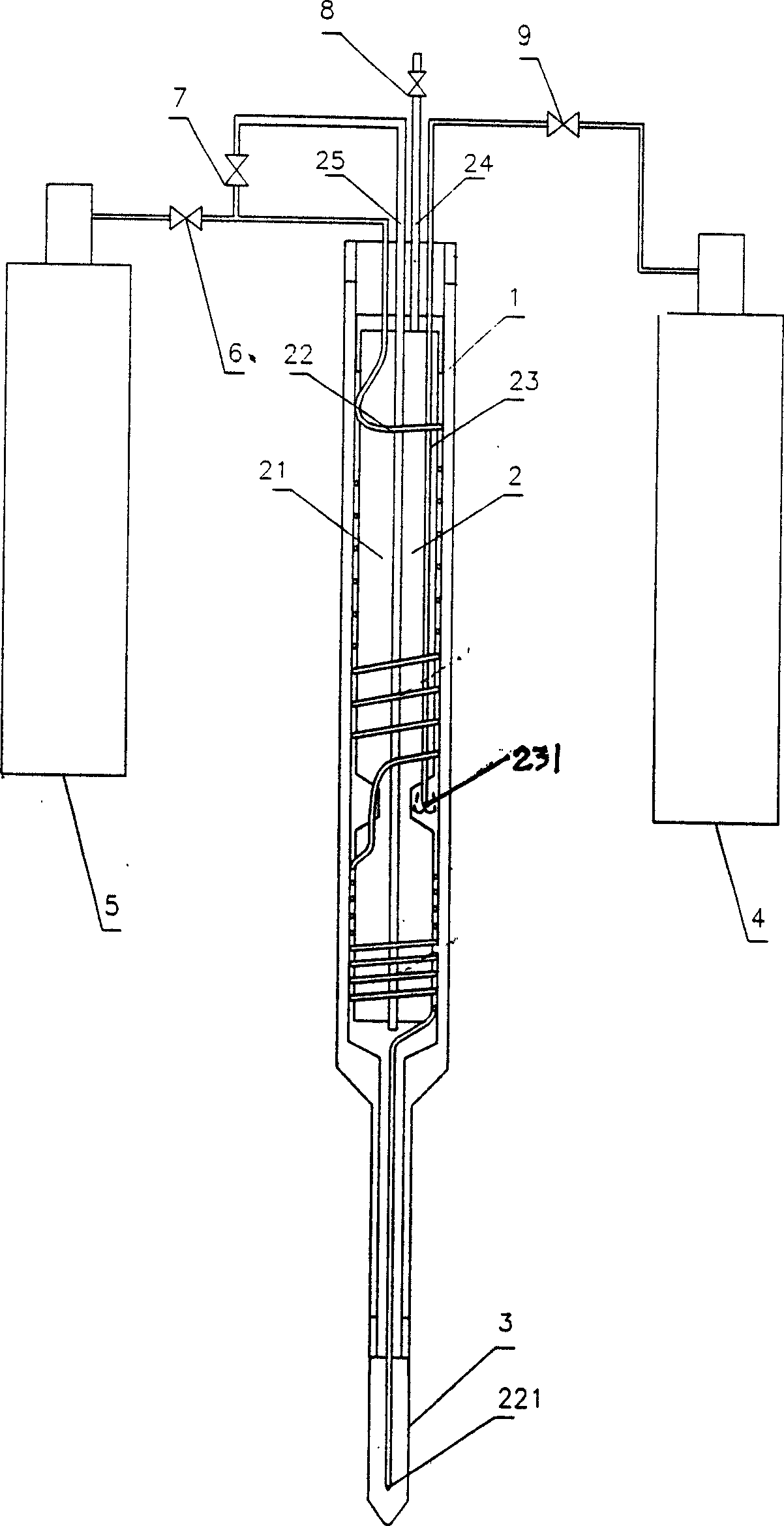

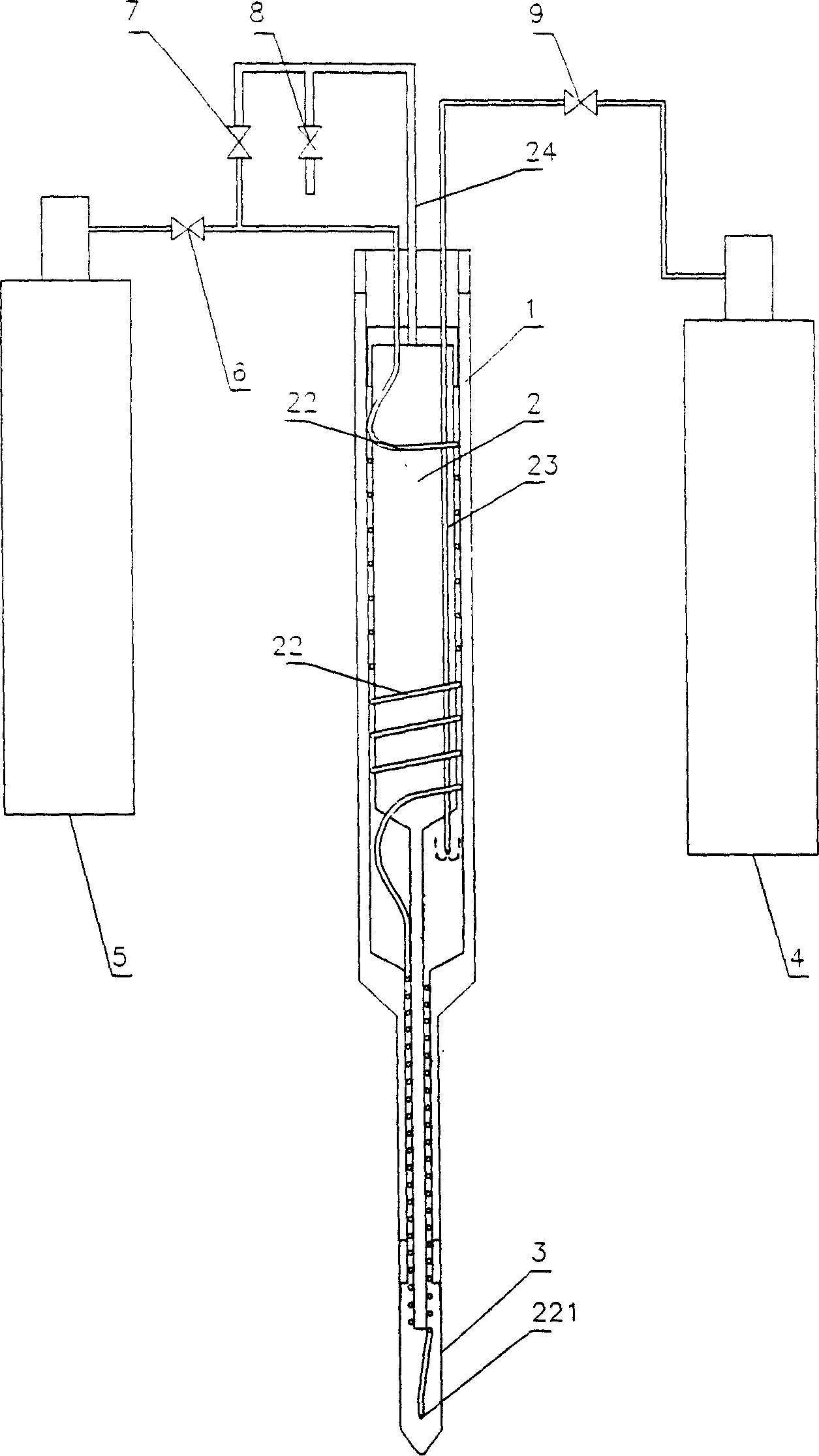

Pre cooling type refrigeration method and pre cooling type treatment device for curing tumour

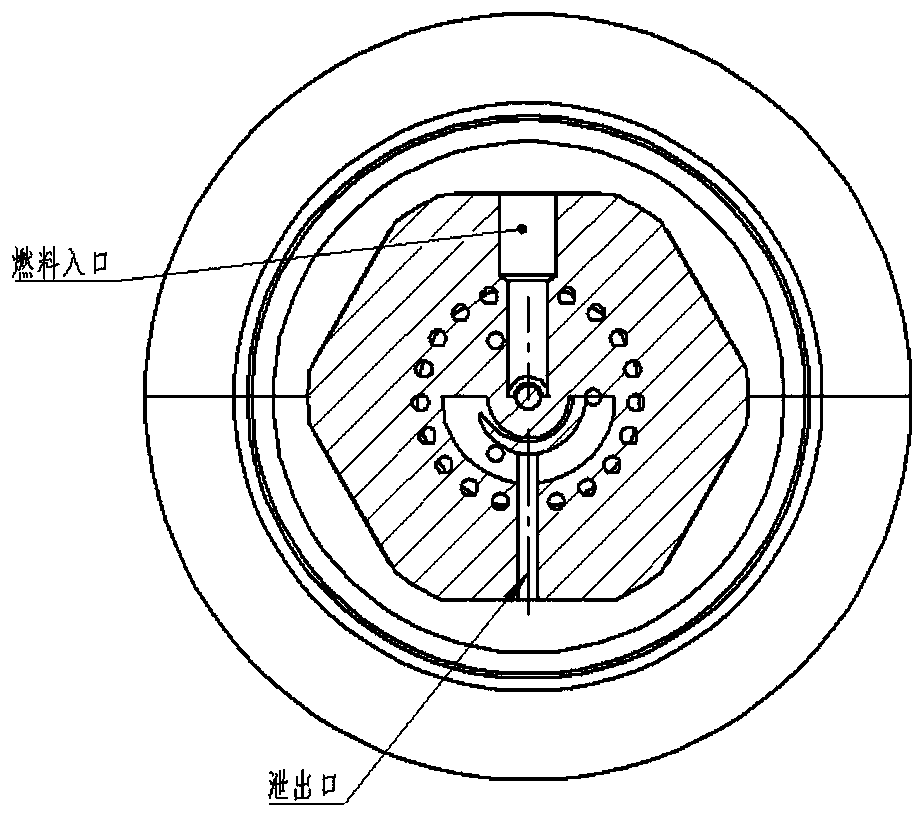

InactiveCN1626047AReduce inlet pressureRapid freeze/thaw cycleSurgical instruments for coolingWorking fluidWorking pressure

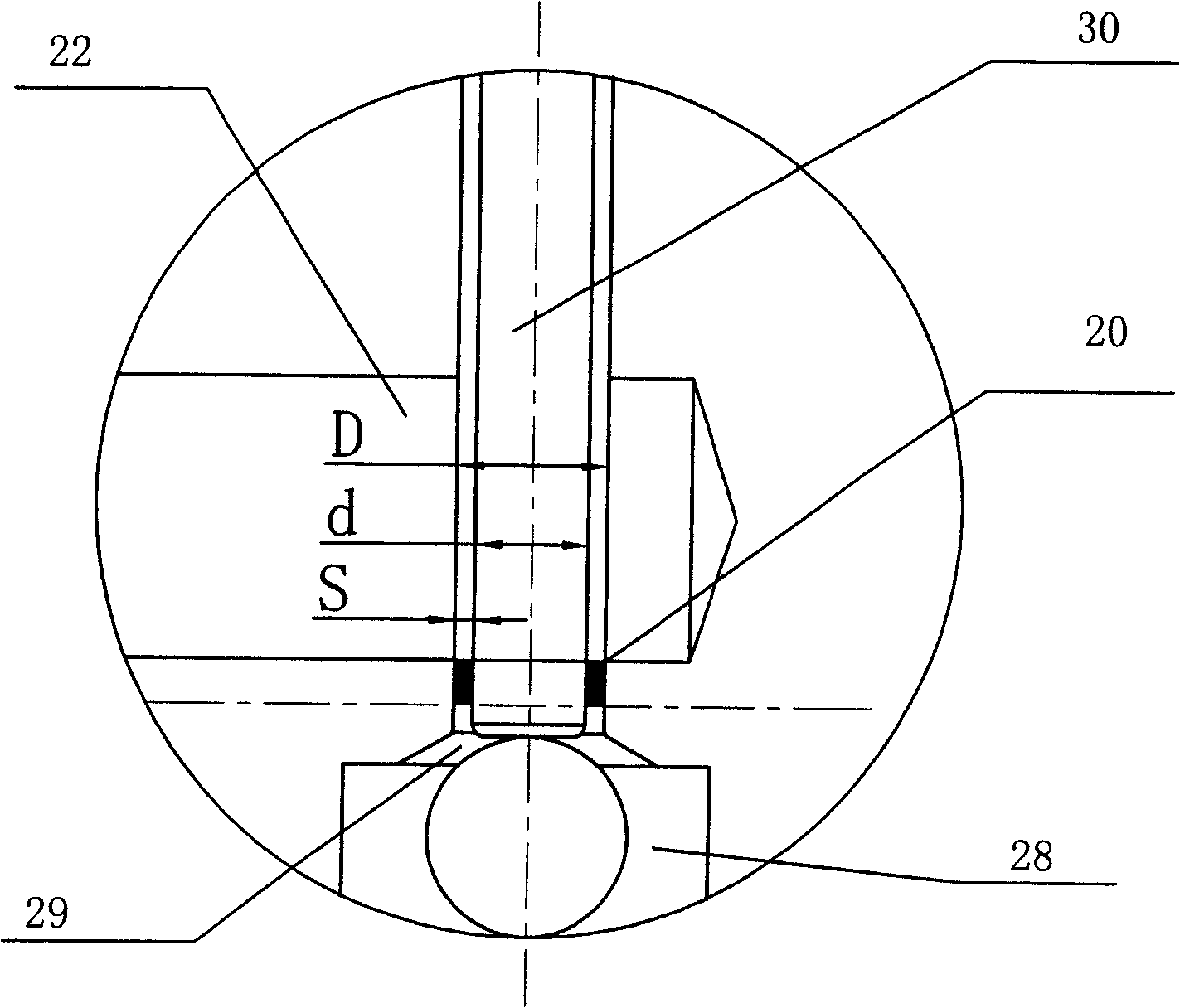

A pre-cooling refrigeration method and device for tumor treatment, comprising a vacuum jacket, a probe head, and a mandrel installed in the jacket, and a spirally arranged low-temperature working fluid connected to a low-temperature working gas source is wound on the peripheral wall of the mandrel. Quality delivery pipe, the front section constitutes the first-stage heat exchanger, the rear section constitutes the second-stage heat exchanger, and the lower end is provided with a small throttling hole and extends to the lower part of the probe head; There is a throttling hole at the end of the tube, and the high-temperature working fluid in it is throttled and refrigerated, and then the low-temperature working fluid in the low-temperature working medium delivery pipe is precooled, and the low-temperature working fluid passes through the throttling hole at the end of the delivery pipeline again. One-time throttling refrigeration, after reaching the predetermined temperature, it is delivered to the probe head for tumor treatment. The device has low working pressure, is easy to obtain, and has high safety, economy and stability.

Owner:北京库蓝医疗设备有限公司

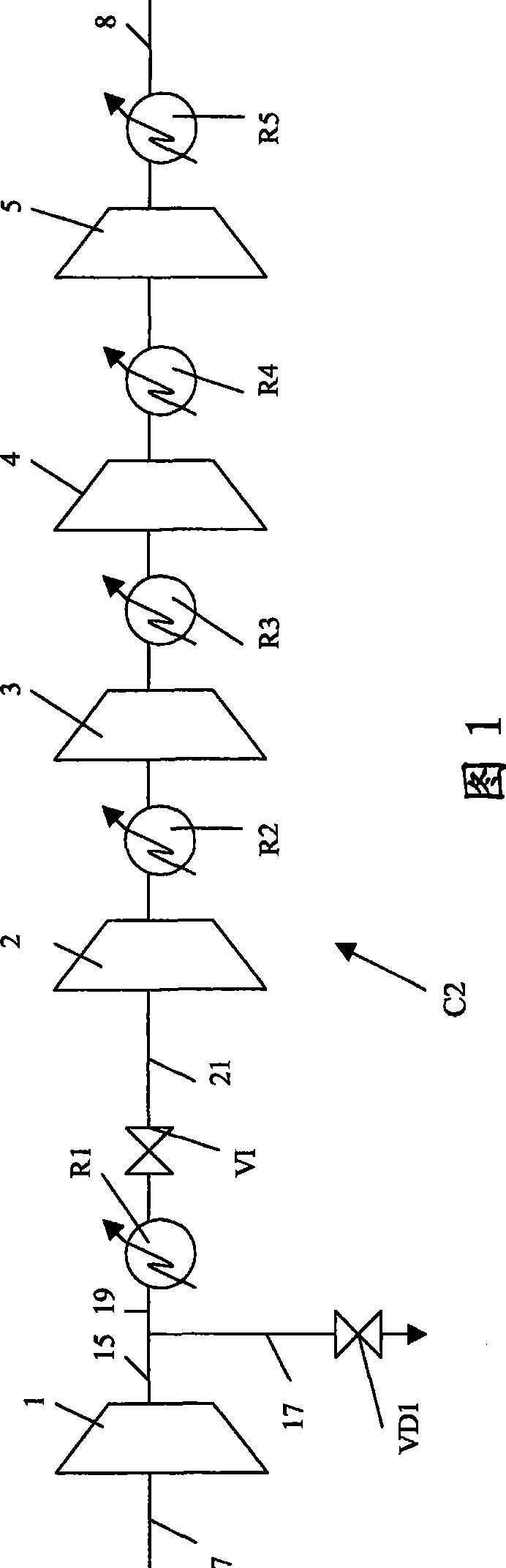

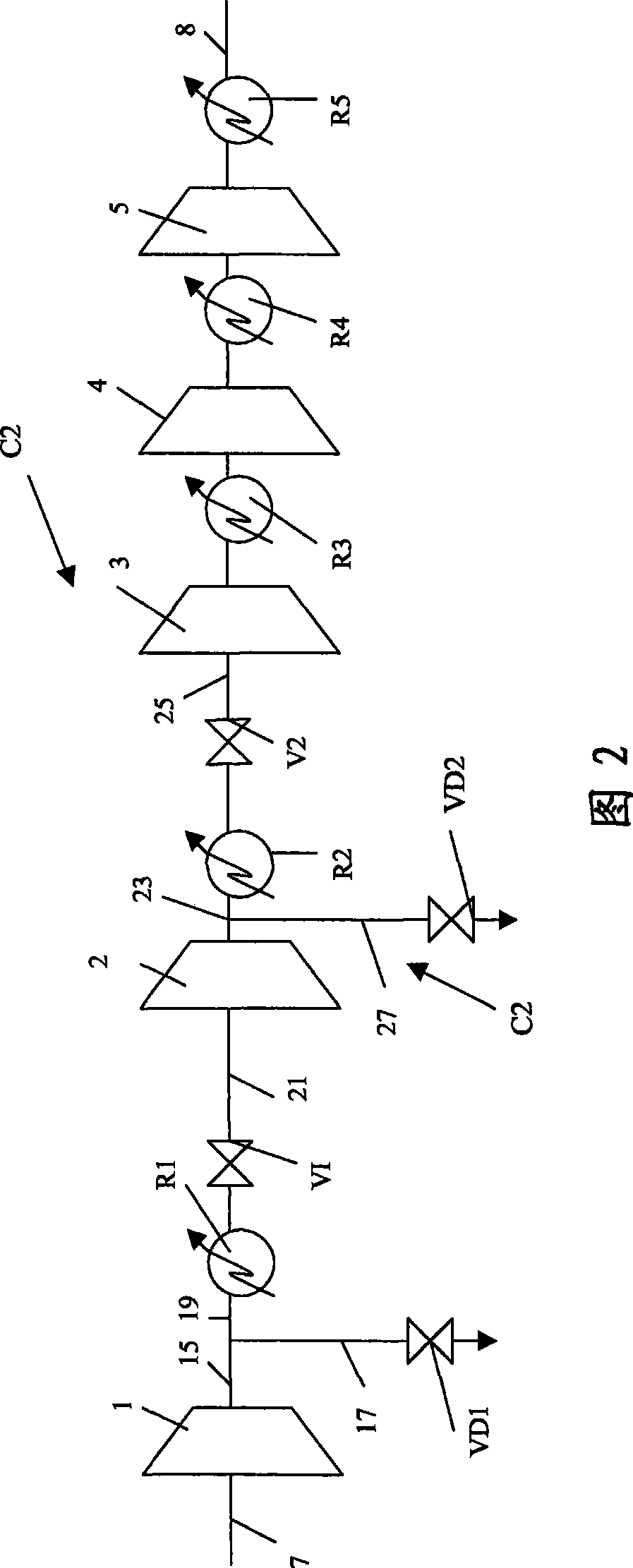

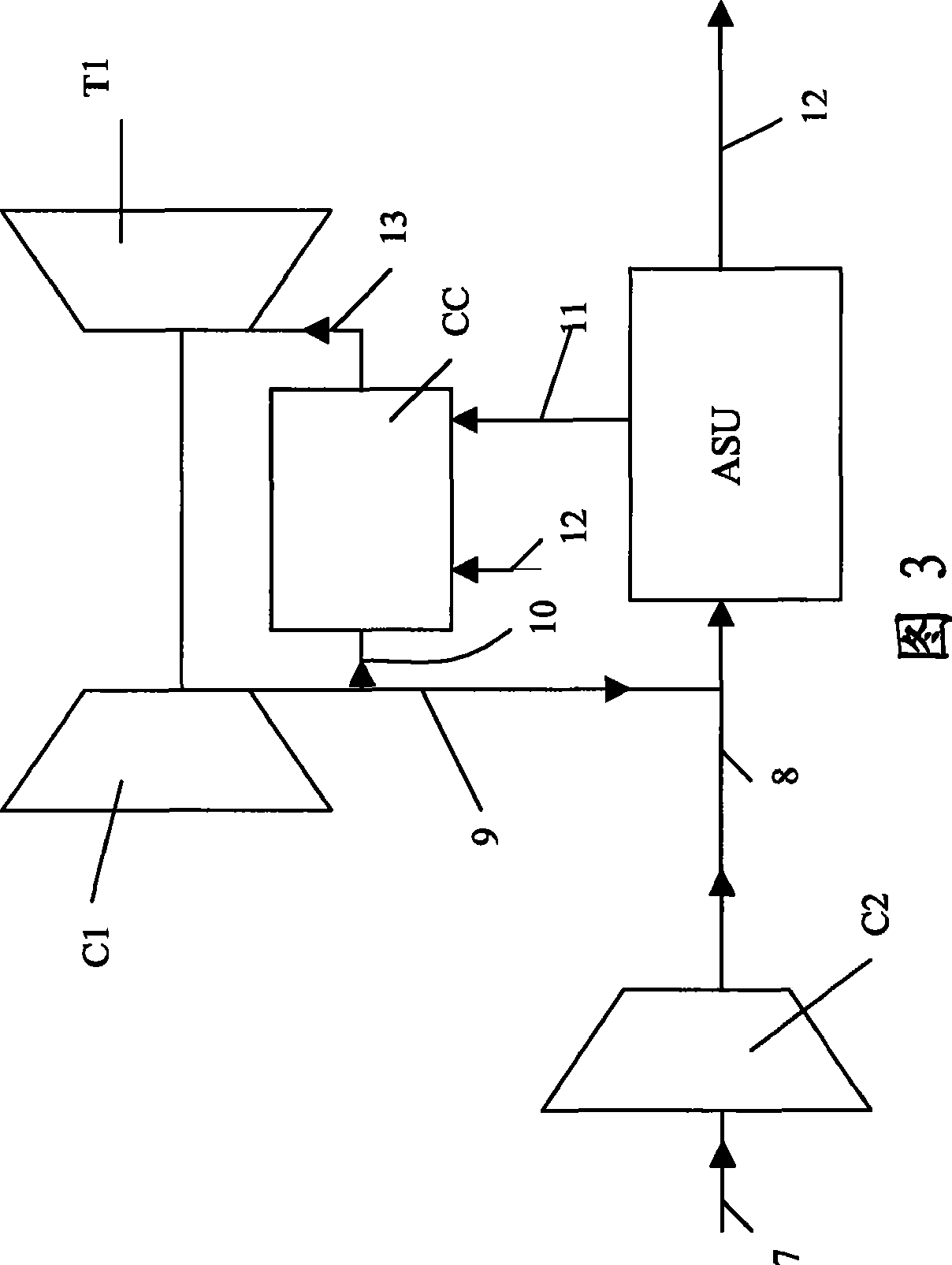

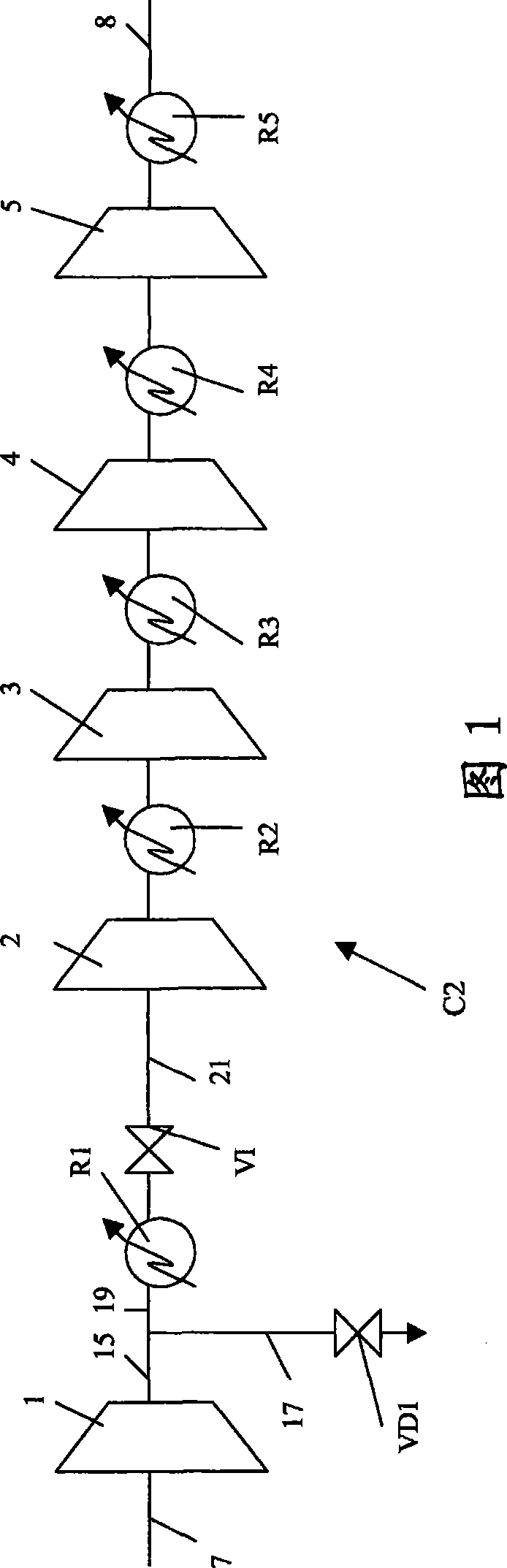

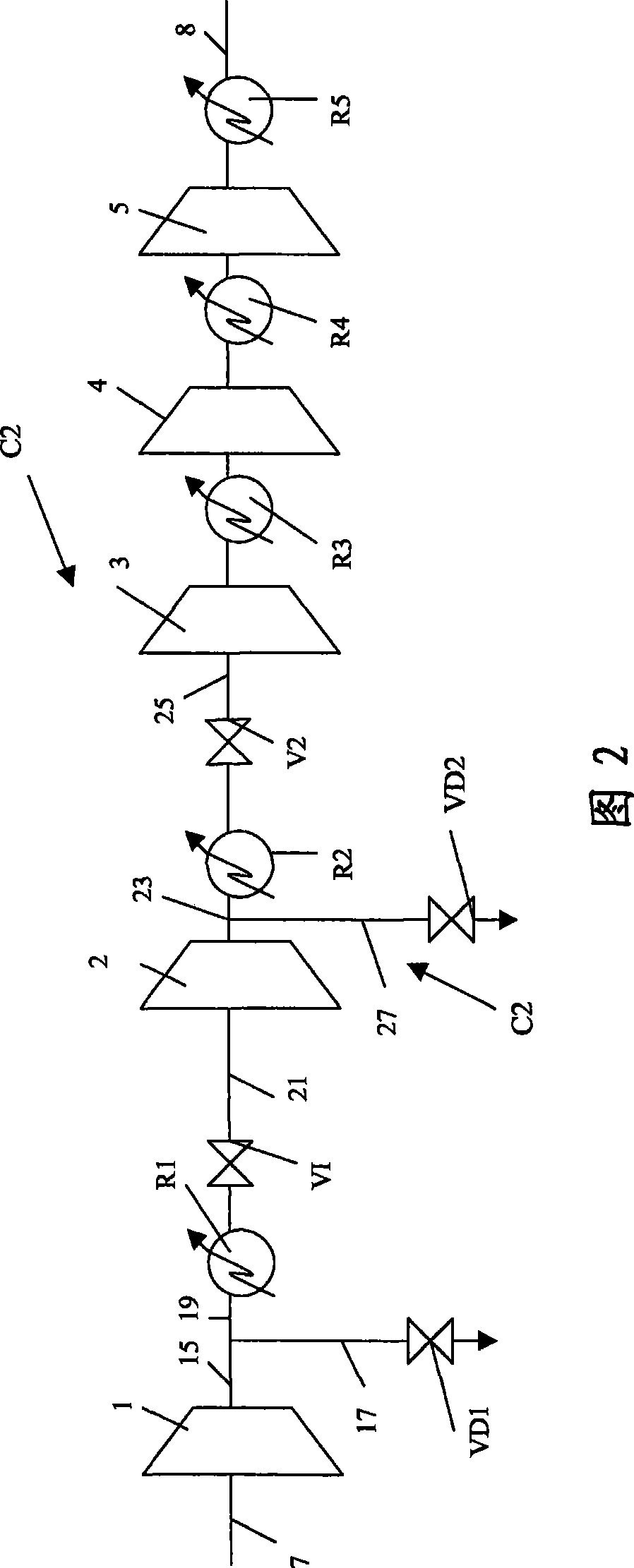

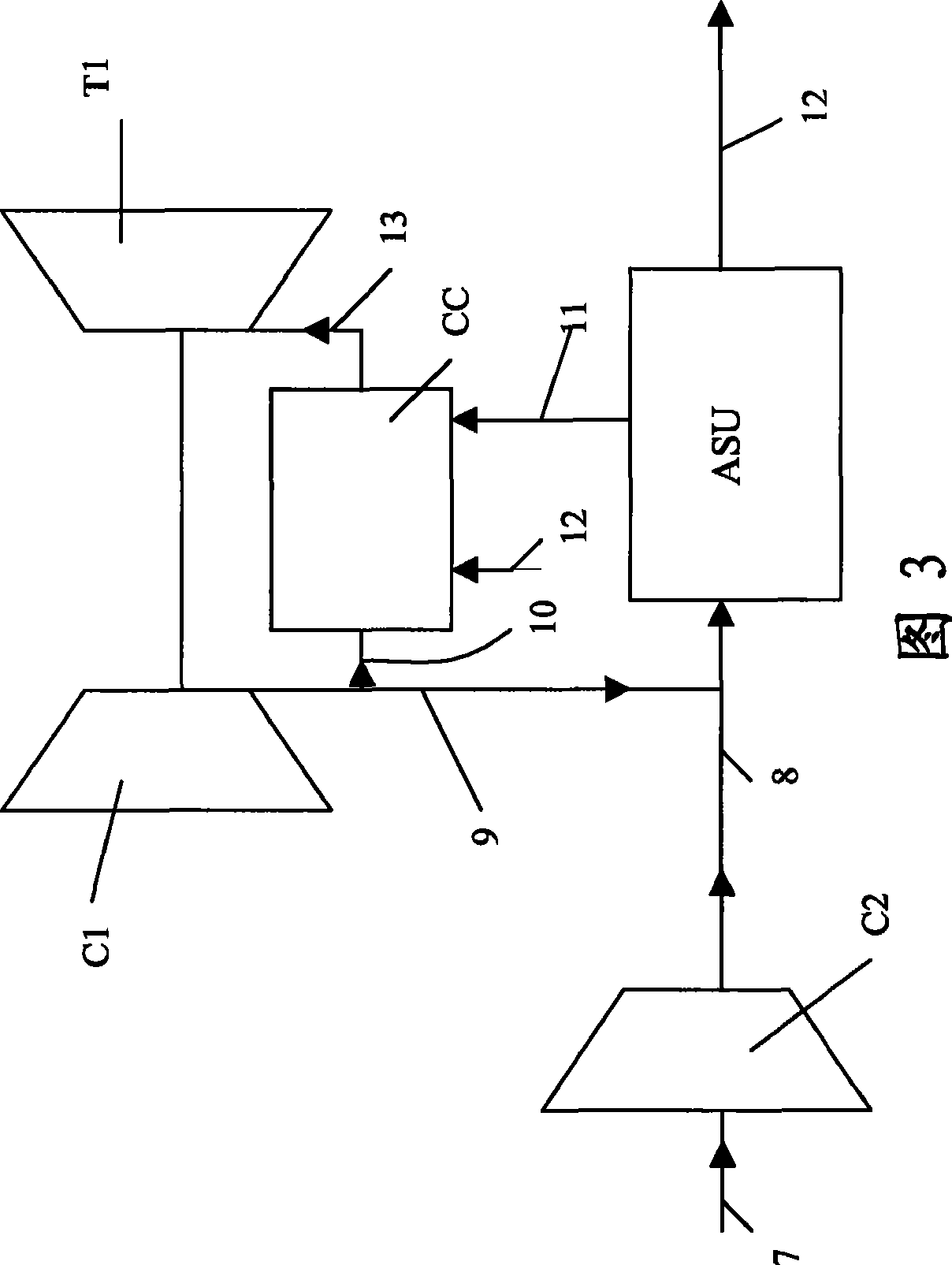

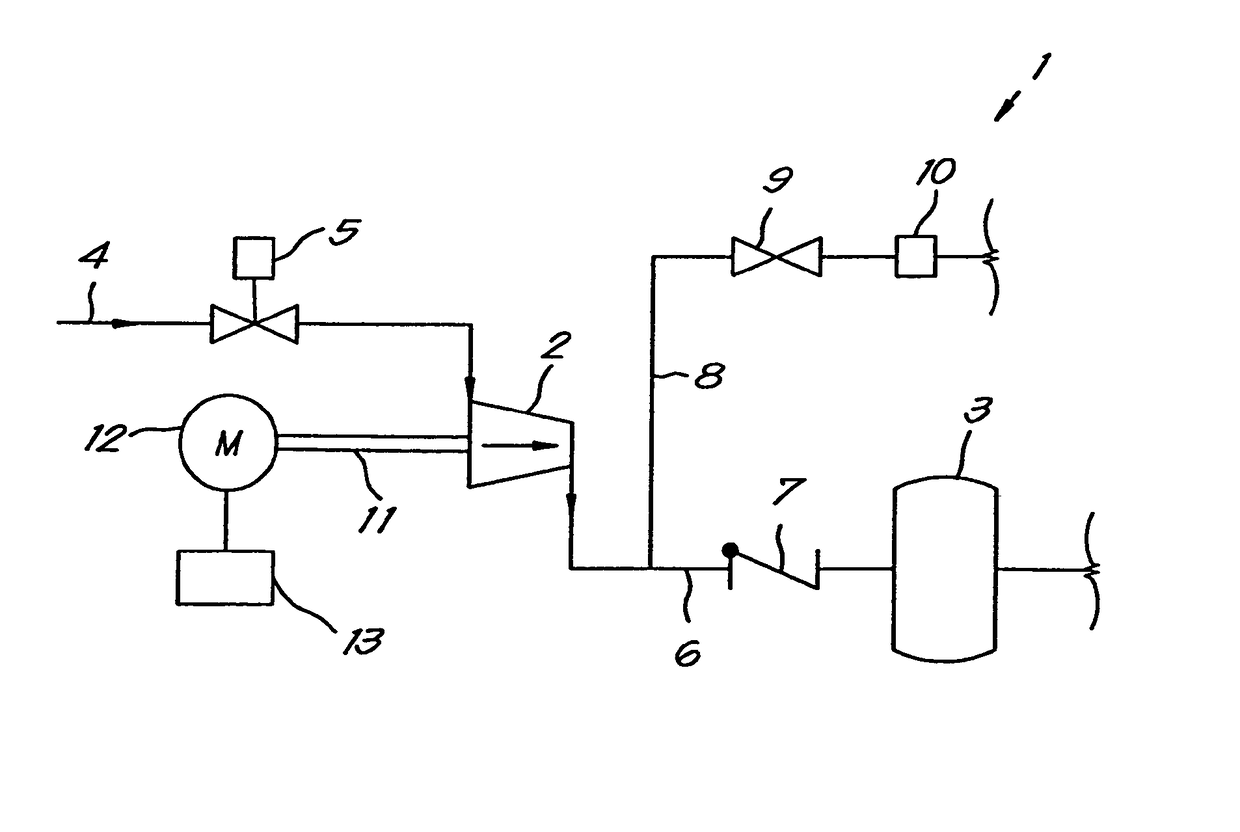

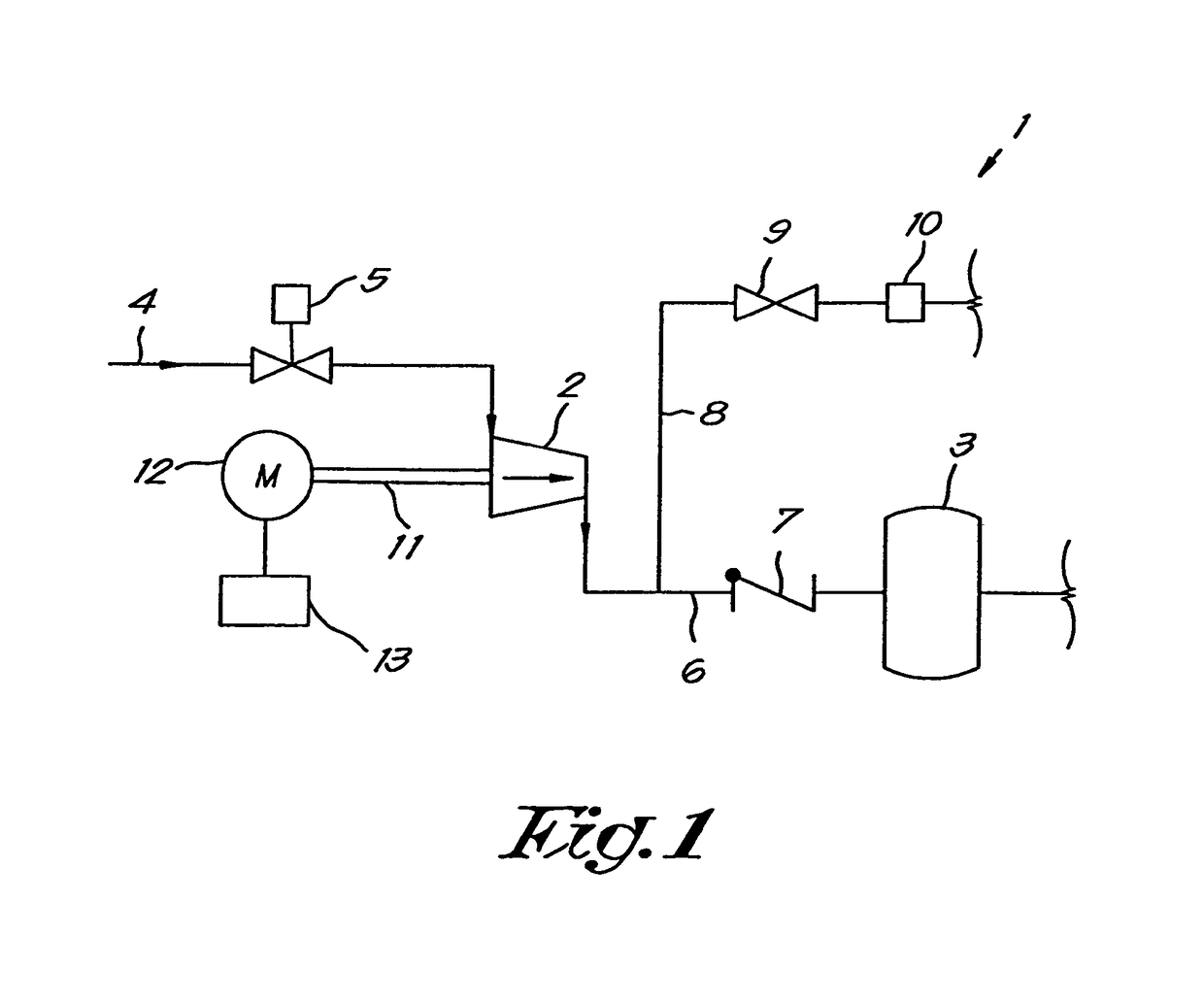

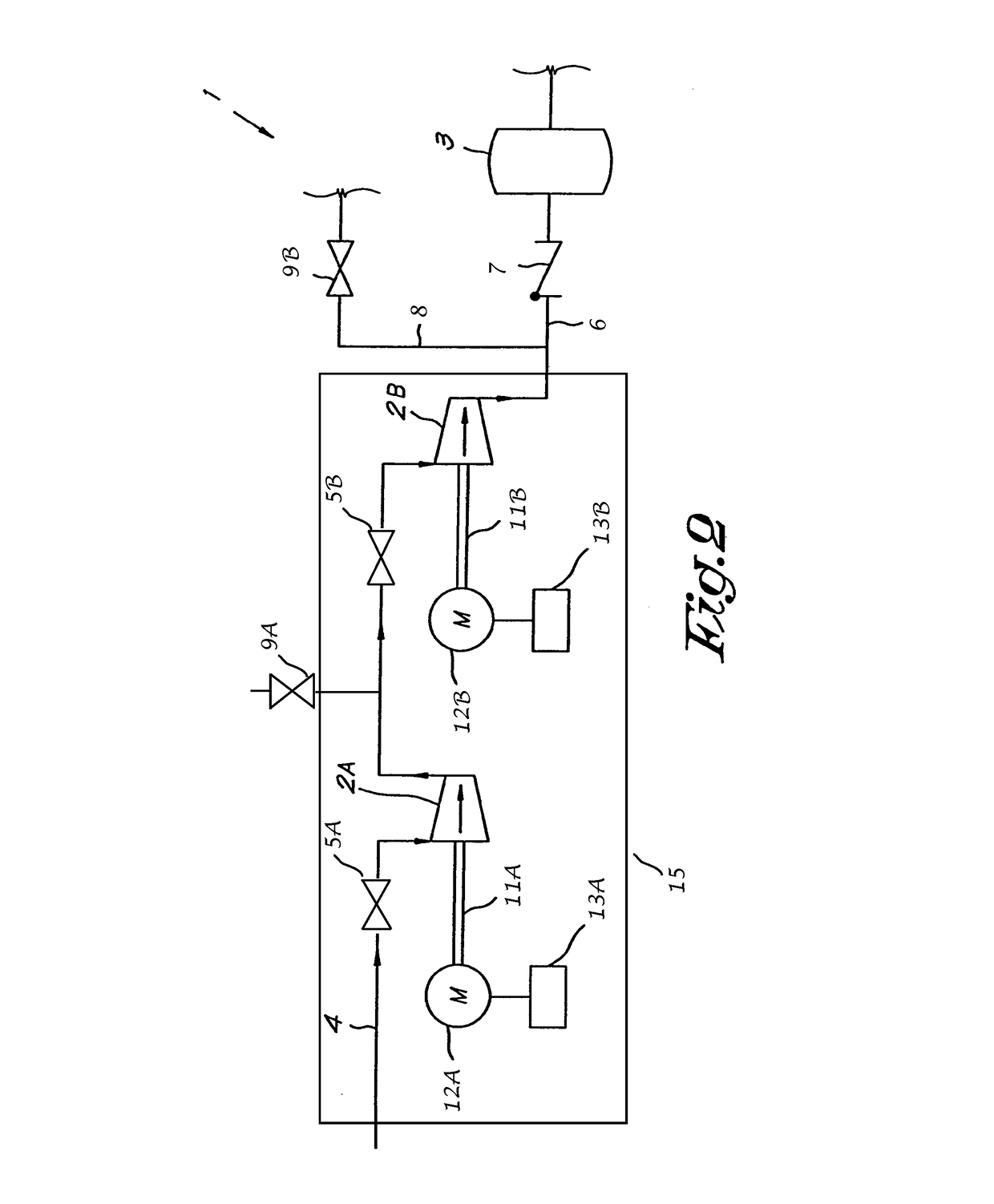

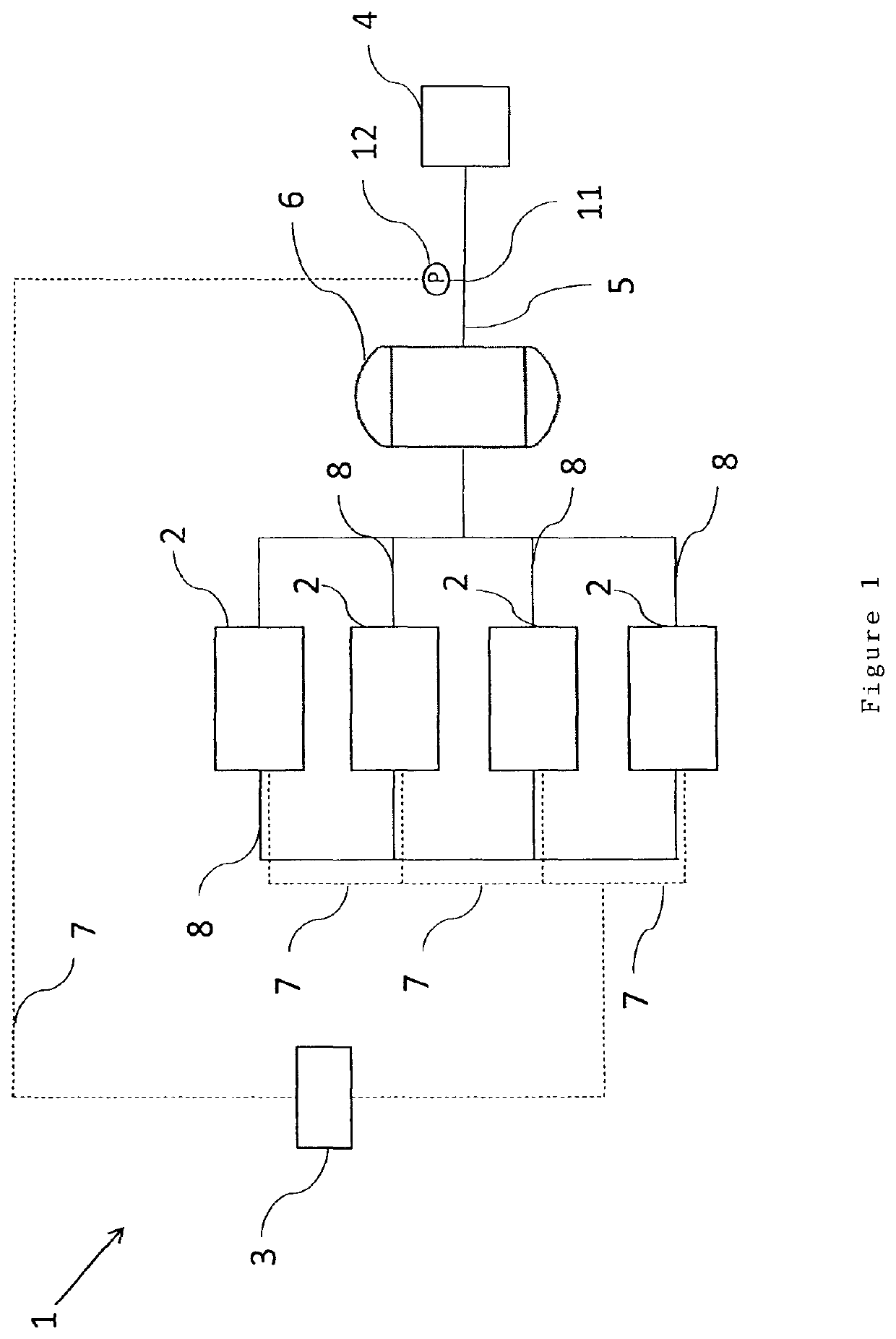

Multi-stage compressor, air-separating apparatus comprising such a compressor, and installation

InactiveCN101443558BReduce inlet pressureReduce delivery pressureSolidificationLiquefactionGas compressorAir separation

A multi-stage compressor, for an air separation unit comprising such a compressor and to an installation is provided.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

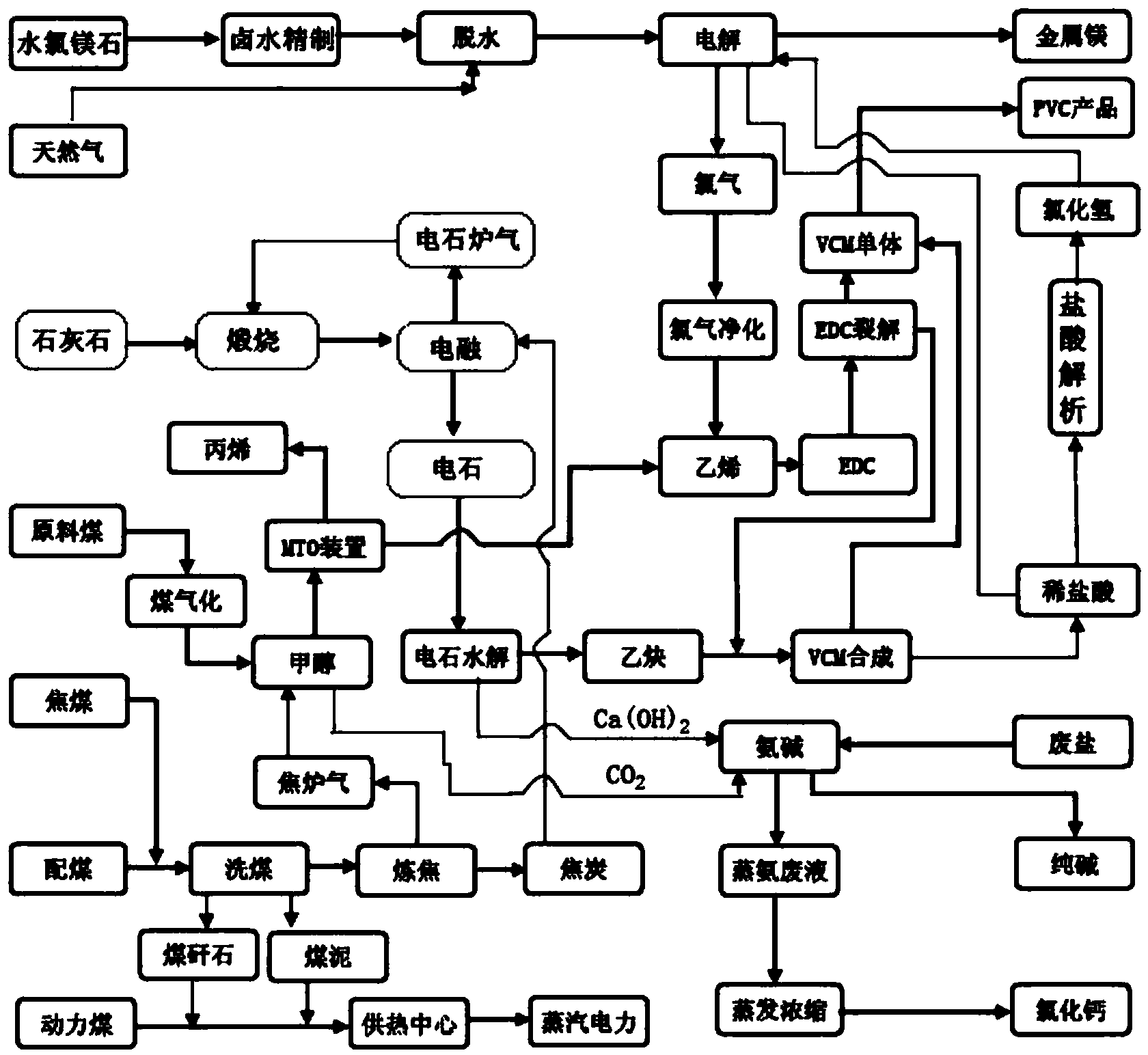

Production system for comprehensively utilizing salt lake resources to achieve magnesium metal integration and method thereof

ActiveCN104060297AImprove reliabilityReduce energy consumptionCalcium/strontium/barium chloridesChemical industrySlagResource utilization

The invention discloses a production system for comprehensively utilizing salt lake resources to achieve magnesium metal integration. The production system comprises a magnesium metal production device, a device for producing PVC through ethylene produced by direct chlorination methanol decomposition, a device for producing PVC with the calcium carbide method, a soda ash production device and a calcium chloride production device, wherein all the devices are connected in sequence, and the product of the last one device is the raw material of the next device. The chlorine in the production system is the byproduct and can be directly used in the PVC production, the production trend of the magnesium metal item chlorine is achieved, the source of the PVC item chlorine is also achieved, and dual purposes are achieved; the raw limestone is firstly used in calcium carbide production and then used in sodium carbonate production through carbide slag, the calcium chloride is produced or the brine is adjusted through the alkali liquor, multi-level combination using is achieved, and the resource utilization ratio is greatly improved.

Owner:QINGHAI SALT LAKE IND

Multi-stage compressor, air-separating apparatus comprising such a compressor, and installation

InactiveCN101443558AReduce inlet pressureReduce delivery pressureSolidificationLiquefactionAir separationEngineering

A compressor comprises a first stage and a second stage (1, 2) which are mounted on a common axis with means for supplying the first stage with a gas that is to be compressed, means for transferring the compressed gas from the delivery side of the first stage to the inlet side of the second stage, means for producing a pressurized gas on the delivery side of the second stage and means for sendingthe compressed gas from the delivery side of the first stage to the inlet of the second stage and a throttle valve (V1) to reduce the pressure of the compressed gas downstream of the delivery side ofthe first stage and upstream of the inlet side of the second stage, means for sending the compressed gas from the delivery side of the first stage to the inlet of the second stage via the throttle valve and means (17, VD1) for sending some of the gas compressed in the first stage to the open air. Application to the production of compressed air for an air separation apparatus.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

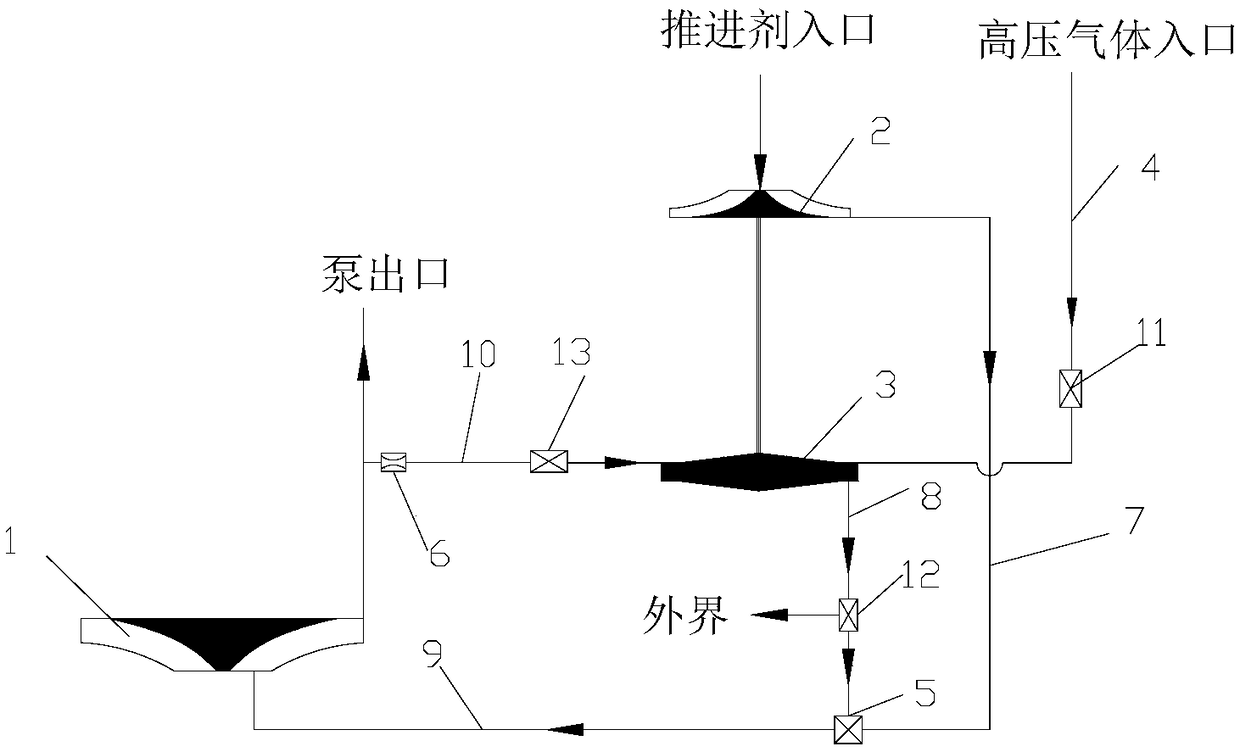

Gas-liquid parallel driving pre-pressurizing system and method started by high-altitude low inlet pressure

InactiveCN109372655AReduce size and weightIncrease carrying capacityRocket engine plantsCarrying capacityProduct gas

The invention relates to a gas-liquid parallel driving pre-pressurizing system and method started by high-altitude low inlet pressure in order to solve the technical problems of main pump cavitation erosion and aircraft carrying capacity reduction caused by storage box pressure increasing. An inlet of a pre-pressurizing pump communicates with an outlet of a propellant storage box, and an outlet ofthe pre-pressurizing pump is connected to one inlet of a mixer through a first pipeline; an outlet of a pre-pressurizing turbine is connected to the other inlet of the mixer through a second pipeline, and an outlet of the mixer is connected to an inlet of a main pump through a third pipeline; part of a propellant at an outlet of the main pump is connected with an inlet of the pre-pressurizing turbine through a fourth pipeline, the flow is controlled through a throttle ring, and the other propellant at the outlet of the main pump enters downstream pipelines; and a high-pressure gas supply system is connected with the inlet of pre-pressurizing turbine through a fifth pipeline, a high-pressure gas one-way valve is arranged in the fifth pipeline, a switching valve is connected to the second pipeline, and a one-way valve is arranged in the fourth pipeline.

Owner:XIAN AEROSPACE PROPULSION INST

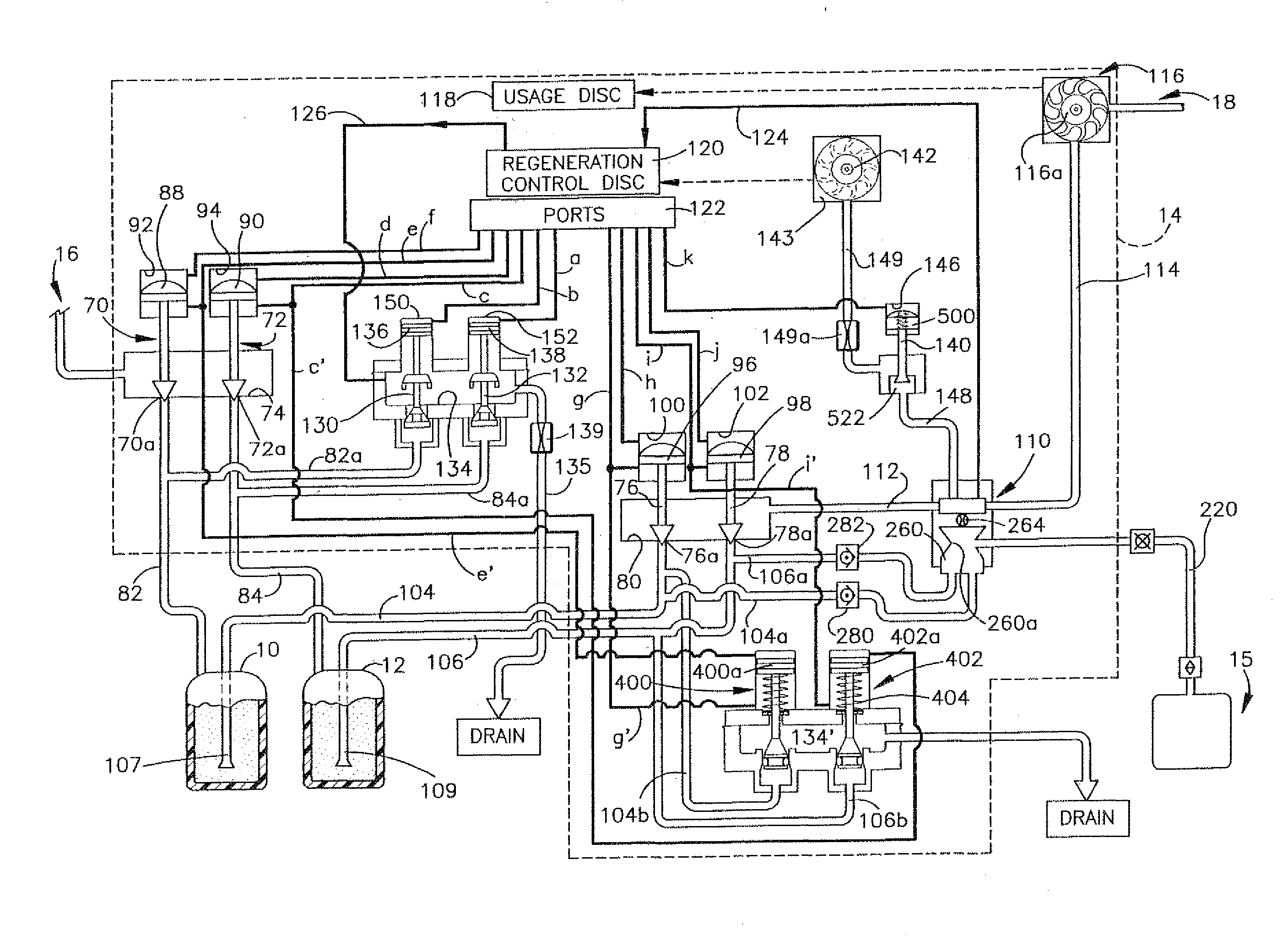

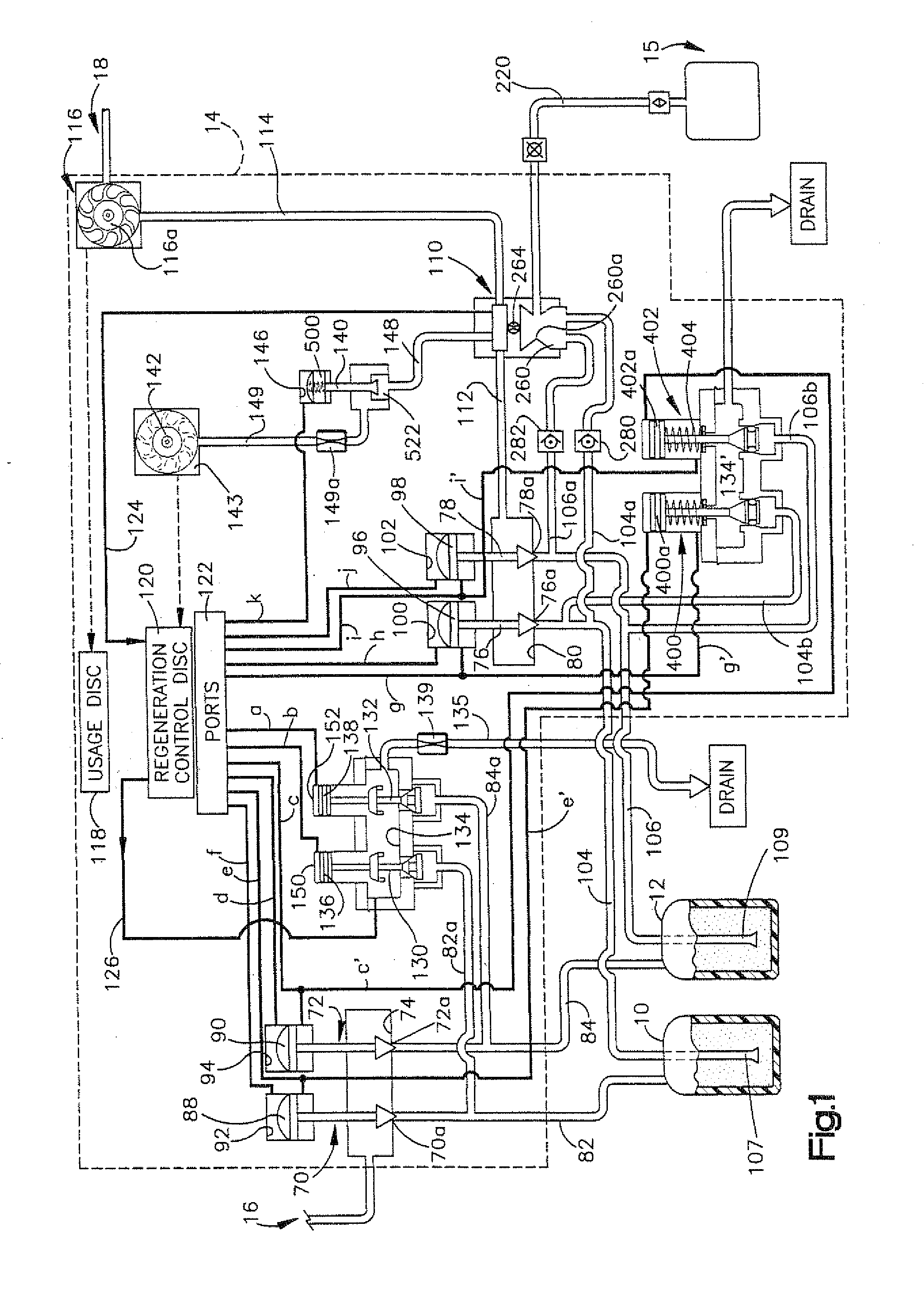

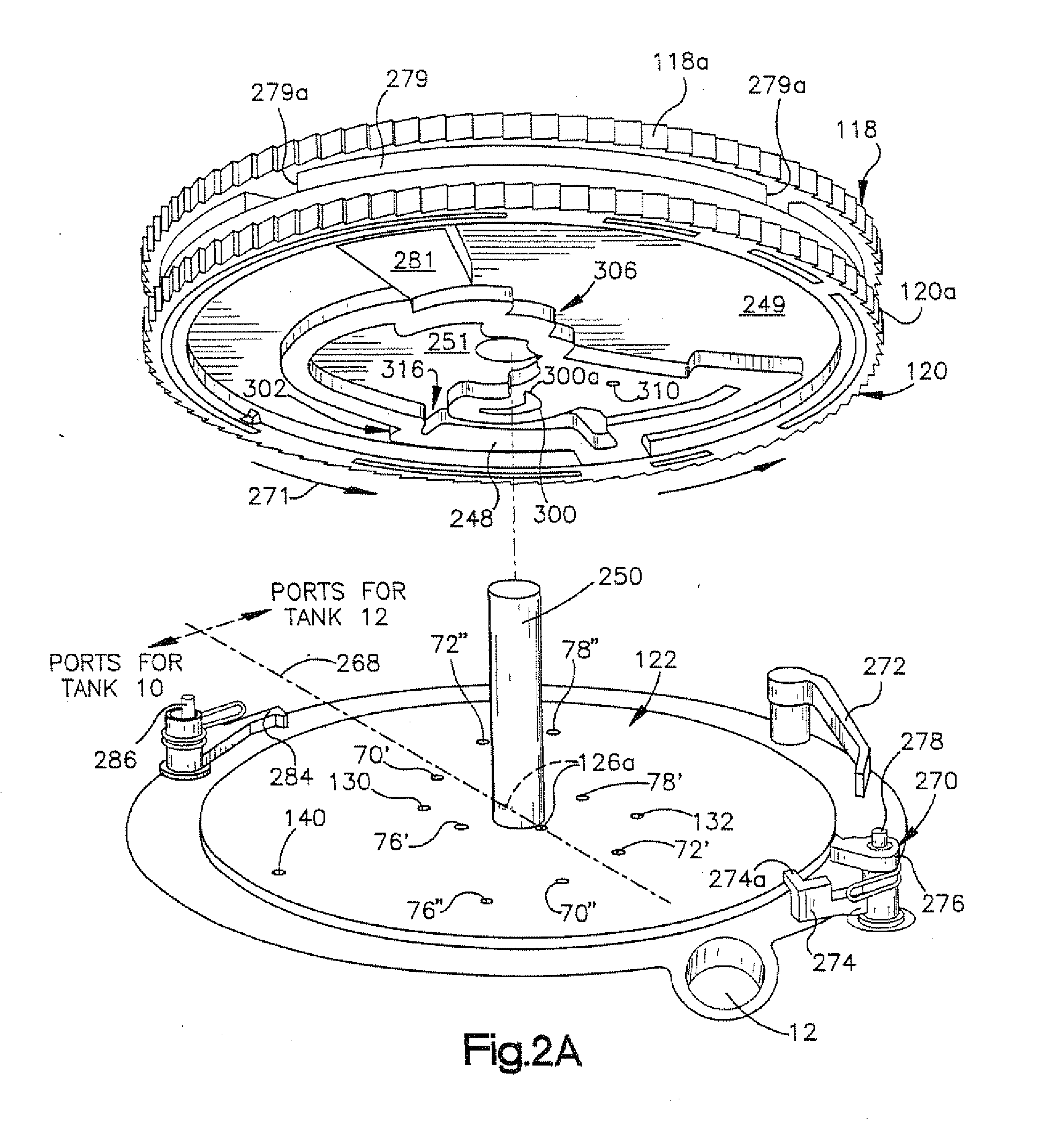

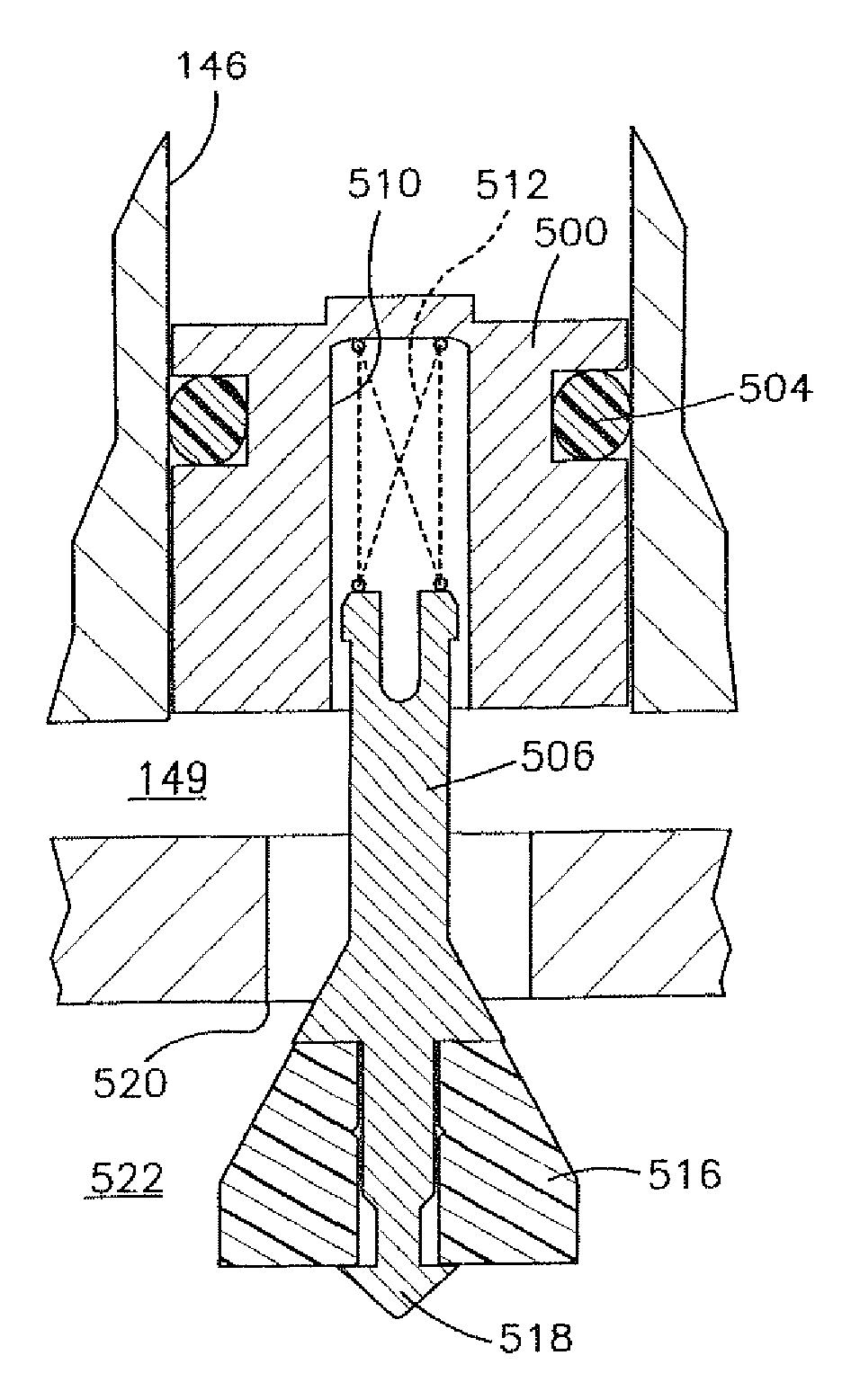

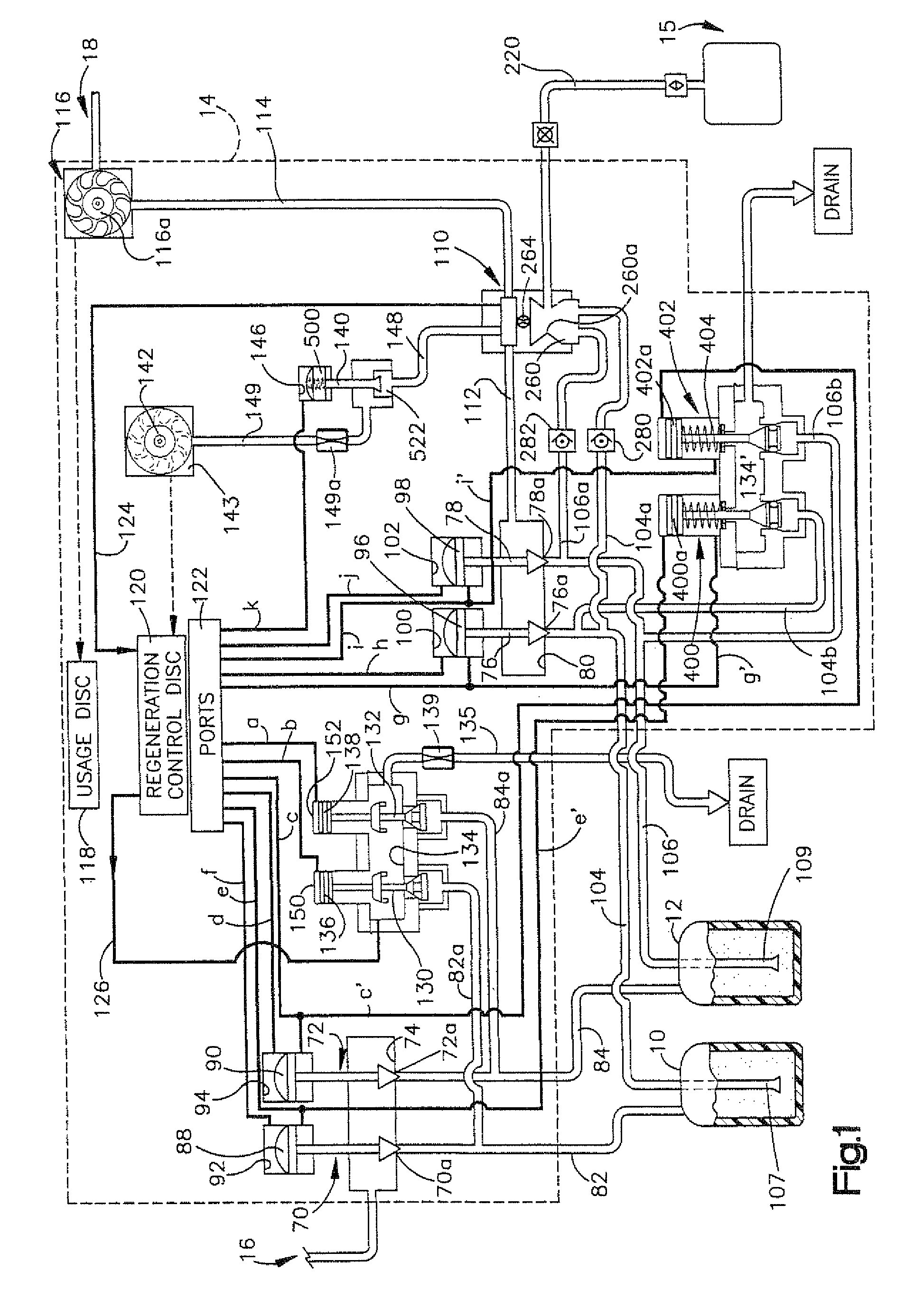

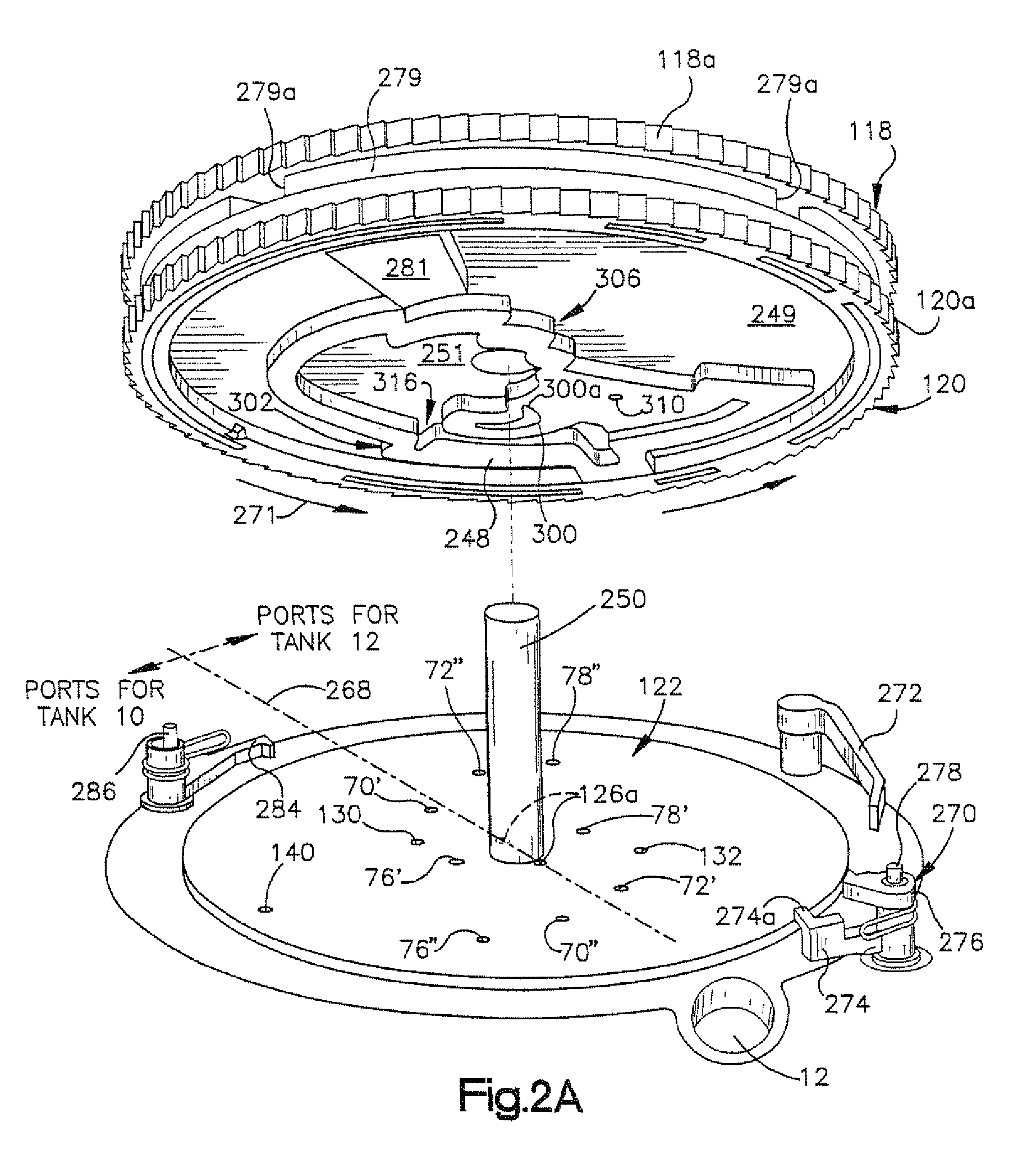

Water treatment system

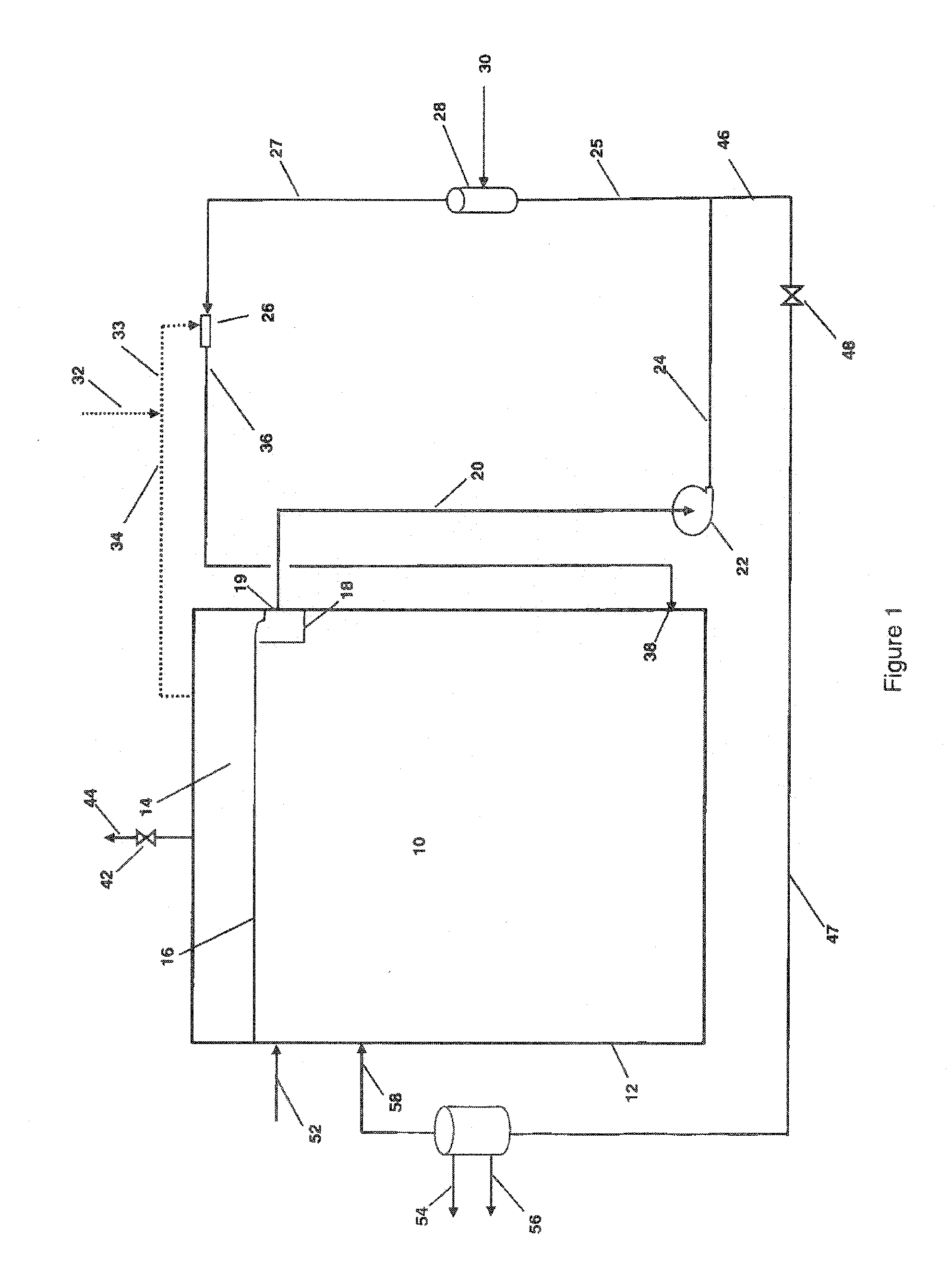

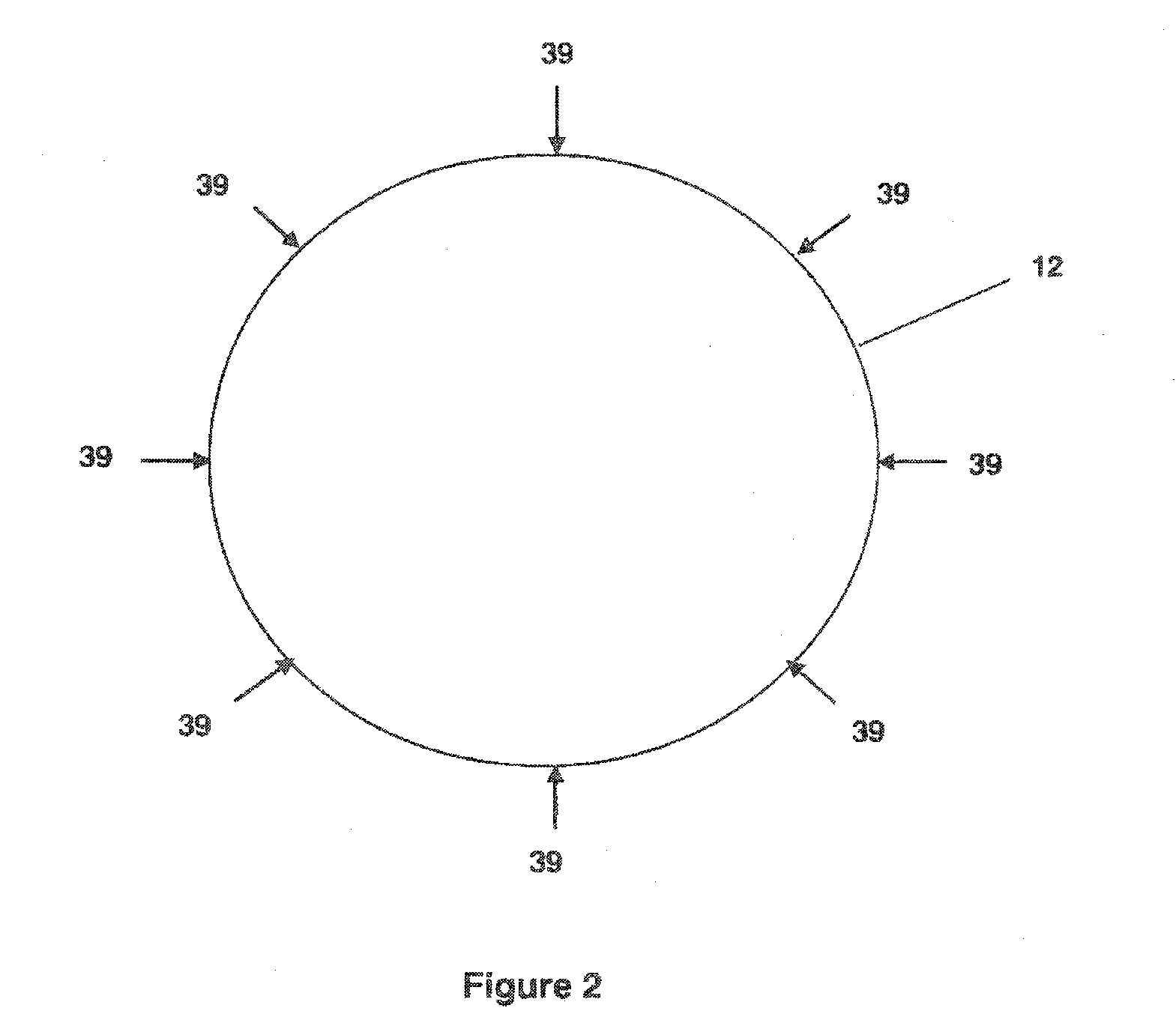

ActiveUS20110284434A1Enhanced operationEasy to operateIon-exchanger regenerationSpecific water treatment objectivesPistonSource water

A water treatment system including a pair of water treatment tanks, each tank defining a flow path extending from a tank inlet to a tank outlet and containing a water treatment material disposed along the flow path for treating water as it travels from the inlet to the outlet. A system controller controls which of the tanks is on-line and which of the tanks is off-line and controls the regeneration of an exhausted tank. A multi-stage, spring-loaded control valve assembly controls the communication of fluid to a regeneration control turbine. The control valve assembly includes a piston head and a seat-carrying stem. An upper end of the stem is coupled to the piston head in an arrangement that allows relative movement between the stem and the piston head. A spring urges the stem away from the piston head. An opposite end of the stem carries a seat. When a signal pressure is applied to the piston head, initial movement of the head compresses the spring but does not produce movement in the stem and, hence, the seat. After a predetermined relative movement of the piston head with respect to the seat, further movement produces movement in the seat, thereby causing the seat to disengage its associated sealing surface, whereupon the spring produces further opening movement in the seat. The present invention improves the operation of the control valve assembly, even in water treatment applications where source water is supplied at a relatively low pressure.

Owner:KINETICO

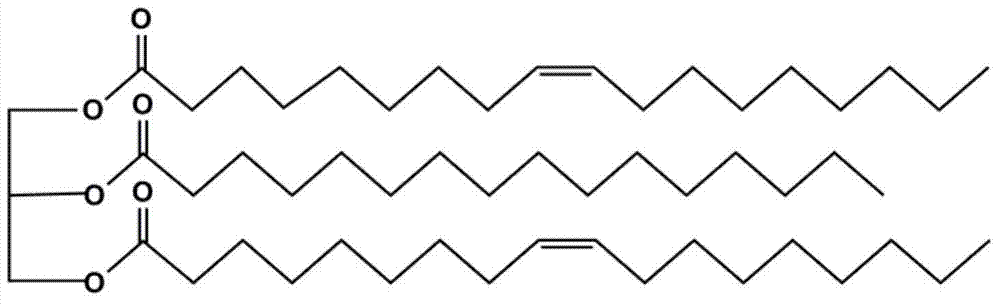

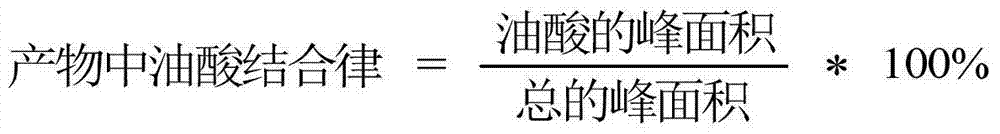

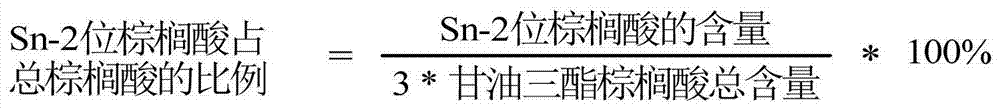

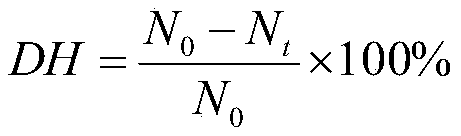

Preparation method of synthetic human milk fat substitute (HMFS) of chrysalis oil source

ActiveCN103689101AReduce import pressureAid in growth and developmentMilk substitutesChemistryFat substitute

The invention discloses a preparation method of a synthetic human milk fat substitute (HMFS) of a chrysalis oil source. The preparation method is characterized by comprising the steps: mixing chrysalis oil with oleic acid, adding lipase, and performing an oscillating reaction in a shaking bath to obtain the synthetic breast milk fat substitute, wherein the weight ratio of the chrysalis oil to the oleic acid is 1:1-1:9, the lipase accounts for 3-12 percent of weight of a reaction system, the reaction temperature is 25-90 DEG C, and the reaction time is 0.5-10h. At the present stage, most of HMFS used in China are in dependence on import, and the HMFS produced in China can not meet the demand of people; and the preparation method is beneficial to self large-scale production and development in China, and thus the import load is reduced. A large quantity of silkworm chrysalises are idle every year, and the rational utilization of resources is facilitated. Compared with a product prepared from a conventional raw material, the HMFS prepared from the chrysalis oil is rich in polyunsaturated fatty acid linoleic acid and alpha-linolenic acid, accounts for 72.25 percent, accords with the national standard, and is conducive to the growth and development of a baby.

Owner:JIANGSU UNIV OF SCI & TECH

Process for preparing diesel synthesized from methanol

The present invention discloses a confection process of synthesized methanol diesel. The process mainly includes the following steps: (1) the confection of A mixture: naphthenic acid is added with methanol and amine water, stirred for 10 to 20 minutes and sheared by a high-speed shearing machine for 10 minutes so as to obtain the brownish red liquid A mixture; (2) the confection of B mixture: acetone, 8- hydroxyquinoline, positive ethane, polyethylene menthanone, isooctyl ester nitrate and ethanol amine are directly mixed and added with an appropriate amount of diesel or coal oil as the auxiliary agent, thus obtaining the B mixture after even stirring; (3) the confection of C mixture: ferrocene, polyisobutylene and polyethylene-ester acid ethane are directly mixed and added with an appropriate amount of diesel or coal oil as the auxiliary agent, thus obtaining the C mixture after even stirring; (4) the A mixture is added with water and fully stirred, then the B mixture, the diesel and the C mixture are fully stirred after ultrasonic grinding and oil shearing by the high-speed shearing machine for more than ten minutes and finally the confection is completed after several minutes of oil shearing by the high-speed shearing machine. The synthesized methanol diesel prepared by the process has the beneficial technical effects of energy saving, environmental protection, no corrosion, wide application range, stable quality, simple production, etc., which is worth promoting.

Owner:GUANGZHOU BAONENGTE ENVIRONMENTAL PROTECTION TECH CO LTD

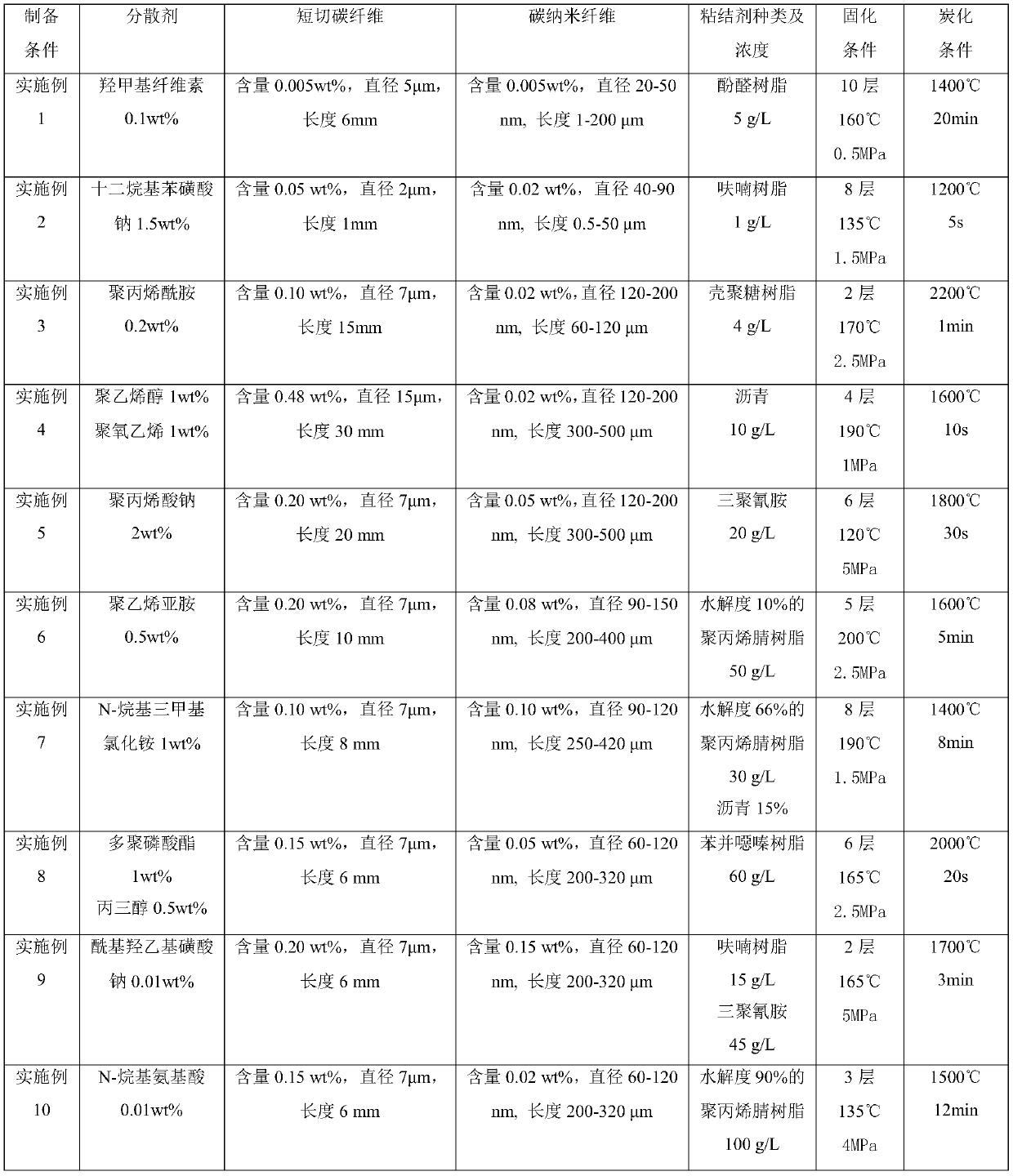

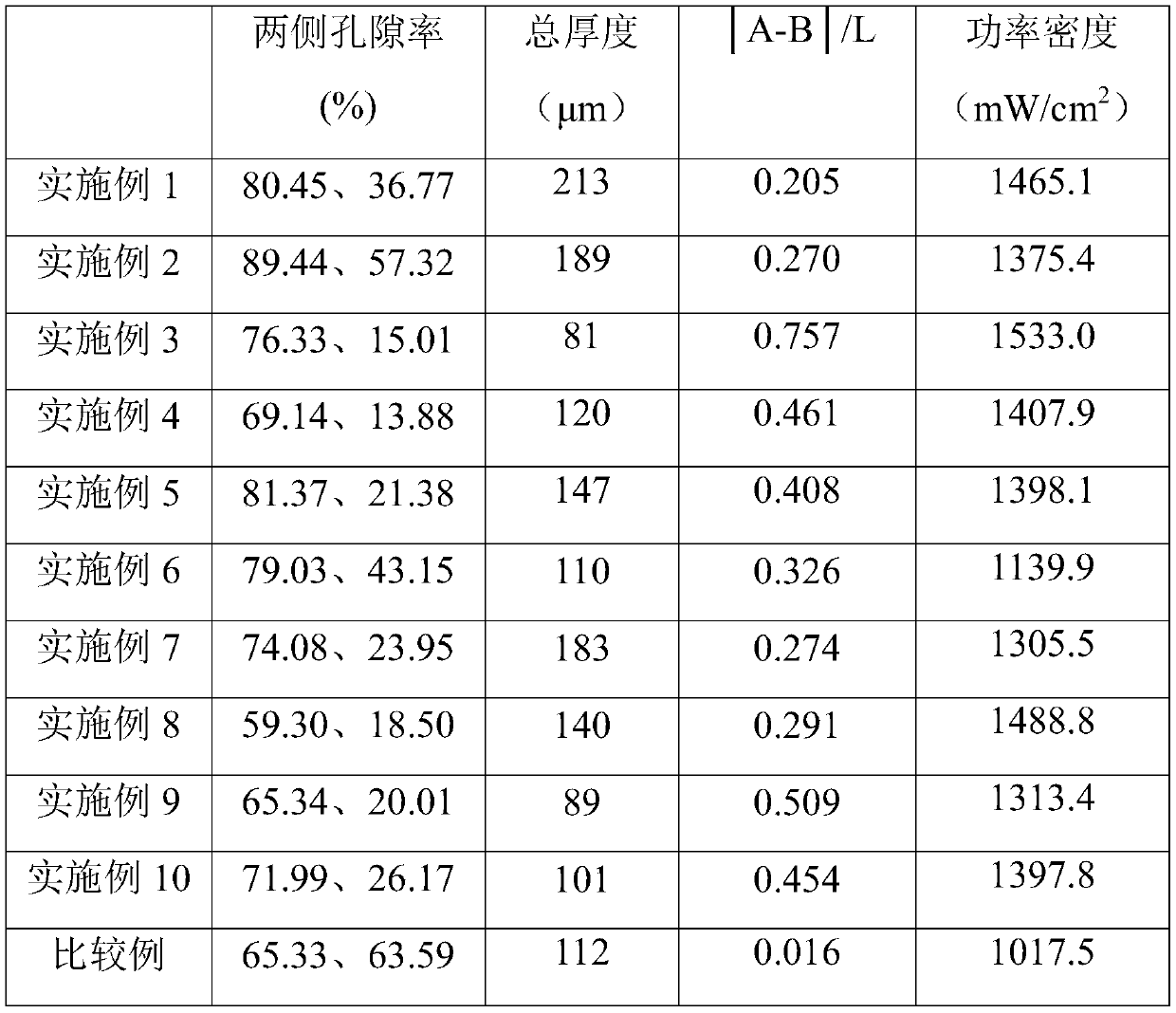

Conductive carbon paper and preparation method thereof

ActiveCN111576079AGas diffusion layer heightThe gas diffusion layer material requires high electrical conductivity and highSpecial paperCell electrodesFiberPolymer science

The invention belongs to the technical field of conductive material preparation methods, and particularly relates to conductive carbon paper and a preparation method thereof. The conductive carbon paper is composed of 2-10 layers of single-layer carbon fiber paper with porosity of 10-80%, wherein the porosity of the single-layer carbon fiber paper on the outermost side is denoted as A, the porosity of the single-layer carbon fiber paper on the outermost side of the other side is denoted as B, the unit of A and B is%, the total thickness of the conductive carbon paper is denoted as L, the unitof L is [mu] m, and the three should meet the following relationship: 0.2 < = | A-B | / L < = 0.8. A mixture containing a dispersing agent, chopped carbon fibers and carbon nanofibers is put into waterand pulped to uniformly disperse the carbon fibers and the carbon nanofibers to form a suspension; the suspension is manufactured by adopting a conventional wet papermaking technology to form carbon fiber base paper and soaked in a binder, dried, and carbonized to obtain the conductive carbon paper.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

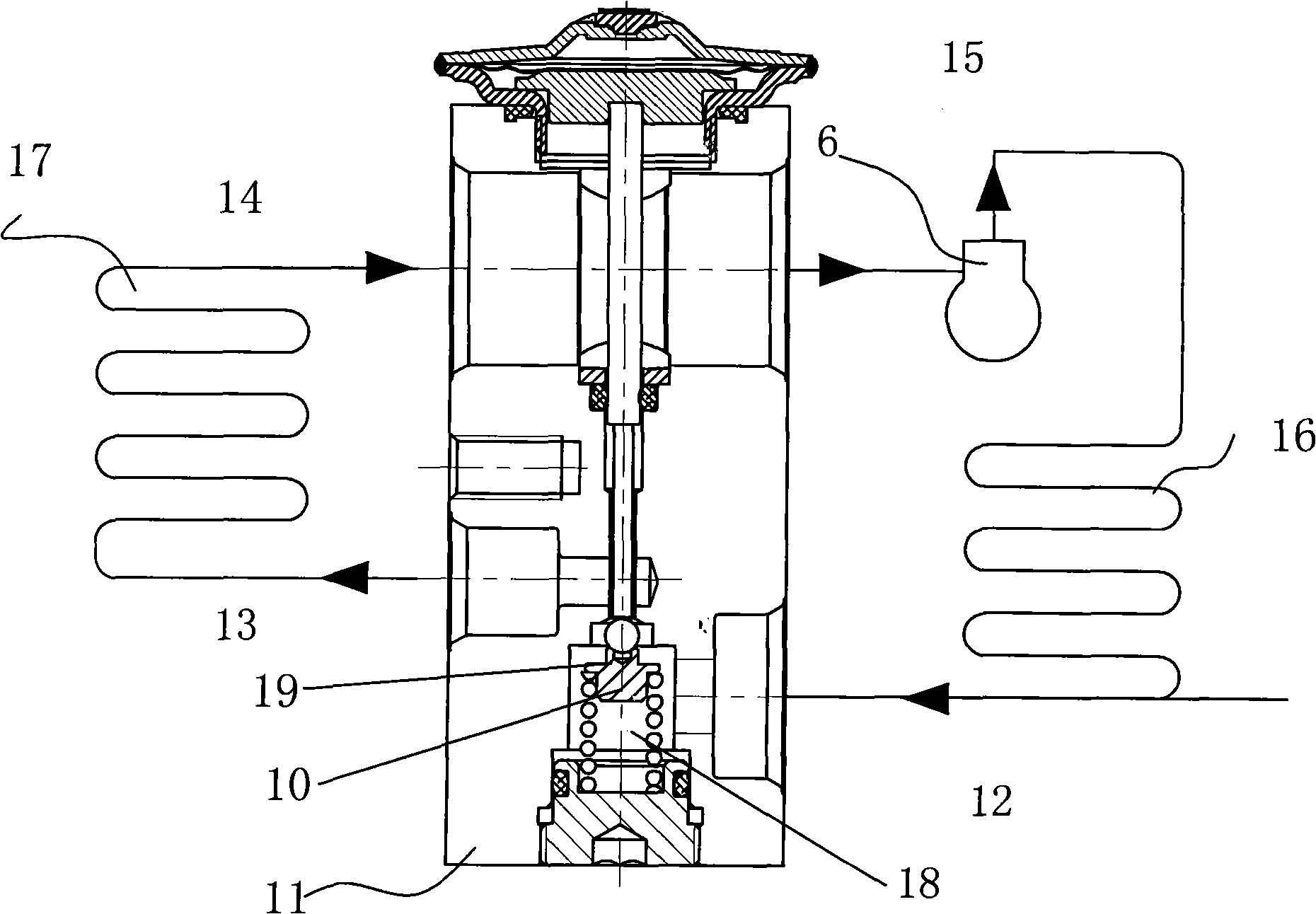

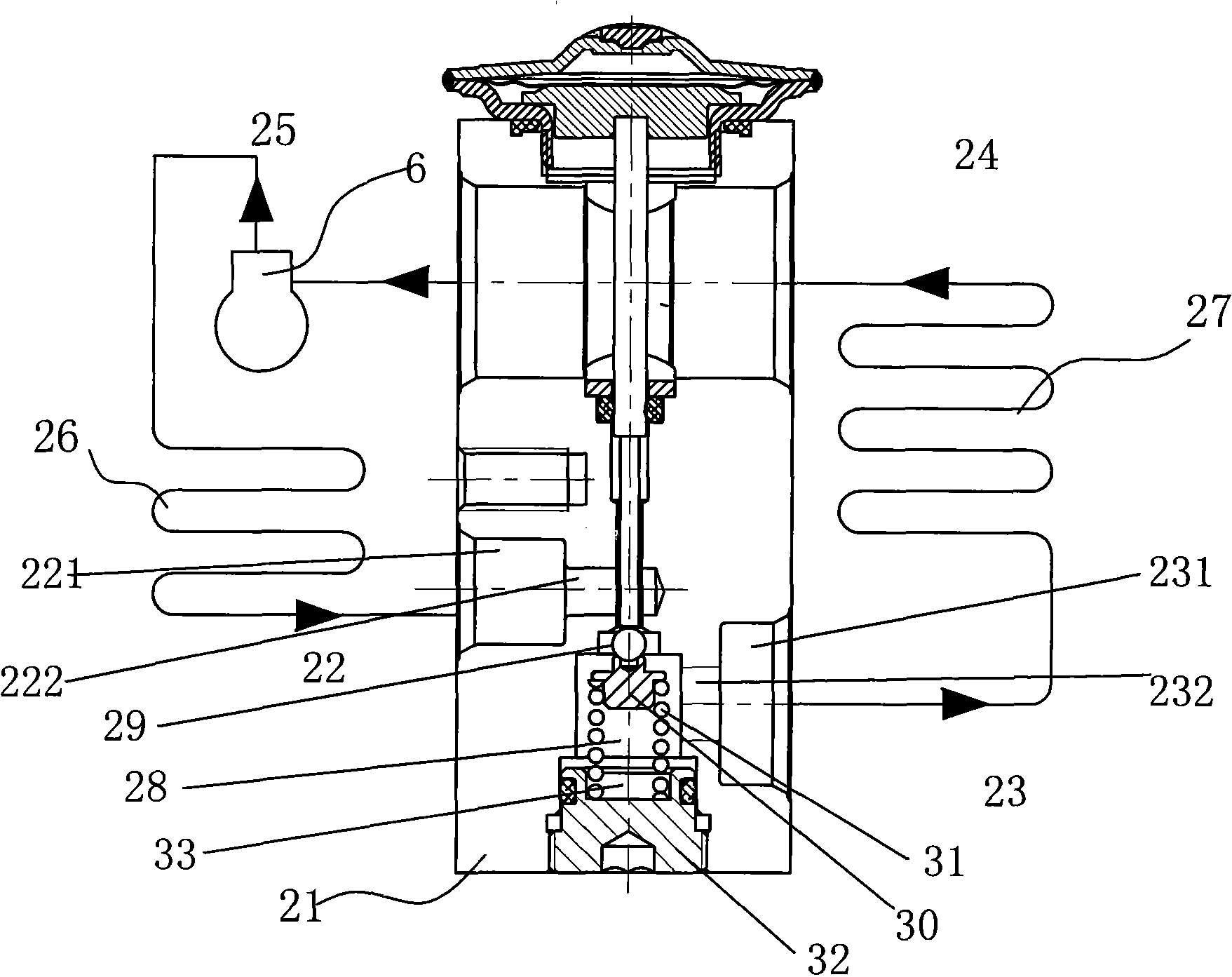

Thermal expansion valve

InactiveCN101493159AReduce vibrationReduce noiseOperating means/releasing devices for valvesValve members for absorbing fluid energyInlet channelSteel ball

The invention discloses an energy-saving heating power expansion valve having low vibration and little noise, comprising a valve body, a first inlet channel and a first outlet channel; wherein, the first inlet channel is communicated with a condenser outlet of an air conditioning refrigeration system, and the first outlet channel is communicated with an evaporator inlet of the air conditioning refrigeration system. A second inlet channel of refrigeration agent is communicated with an evaporator outlet of the refrigeration system, and a second outlet channel of the refrigeration agent is communicated with a compressor inlet of the refrigeration system. As the first inlet channel is positioned above the first outlet channel, the refrigeration agent is led in from the middle part of a transmission rod comprising a steel ball, and the transmission rod is prevented from vibrating; when an air conditioner stops running, the first inlet channel is communicated with the first outlet channel, so that the energy consumption needed for starting the air conditioner is reduced; a gap between the transmission rod and the valve body is controlled to lead the bubble contained in the refrigeration agent to be miniaturized, thus reducing the flow noise of the refrigeration agent.

Owner:杭州通产机械有限公司

Method for injecting a feed gas stream into a vertically extended column of liquid

ActiveUS8795995B2Reduce inlet pressureIncrease pressureBioreactor/fermenter combinationsBiological substance pretreatmentsSyngasLiquid product

Owner:KLA SYST +1

Separator and phase-split conveying method for eliminating plug flow on serious segments by utilizing same

InactiveCN1297778CSimple structureSpeed up the flowLiquid degasificationFluid removalEngineeringControl valves

Owner:XI AN JIAOTONG UNIV

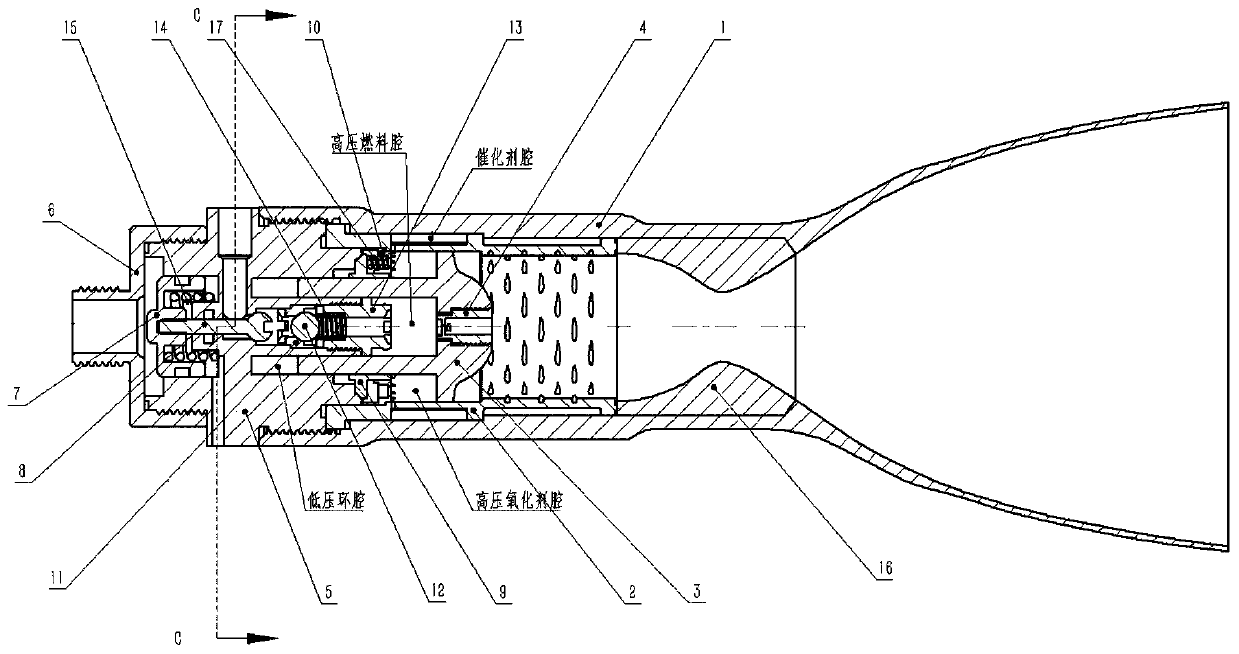

Self-pressurization double-component pulse working rocket engine

The invention discloses a self-pressurization double-component pulse working rocket engine, and belongs to the technical field of aerospace propulsion. A double-cylinder pneumatic plunger pump and a thrust chamber are organically combined into a whole, gas in a combustion chamber is used for driving the double-cylinder plunger pump, the sum of the action areas of the pressure, borne by an annularpiston of the plunger pump, of a propellant is smaller than the action area of the pressure of the gas of the combustion chamber, and therefore the pressure difference is generated. After an oxidizingagent pressurized by the plunger pump is catalytically decomposed, hot gas is generated to enter the combustion chamber to be combusted with fuel, the pressure of the combustion chamber is increased,a positive feedback effect is formed, the combustion chamber works at high-voltage pulses at low inlet pressure, the performance of the engine can be greatly improved, the size, the structure weightand the manufacturing cost of the engine can be reduced, meanwhile, as it is required that the inlet pressure of the propellant is low, the amount of gas pressurized by a propellant storage box is small, the pressure of the storage box is low, the structure weights of the storage box and a pressurization system can be effectively reduced, and therefore the loading capacity and the use performanceof a spacecraft are effectively improved.

Owner:陕西天回航天技术有限公司

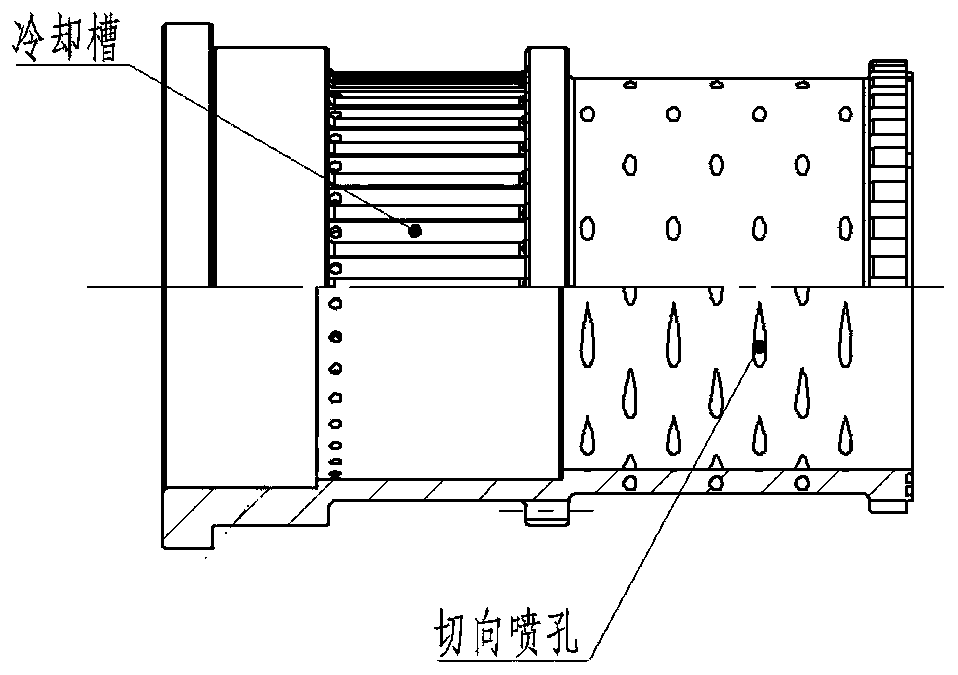

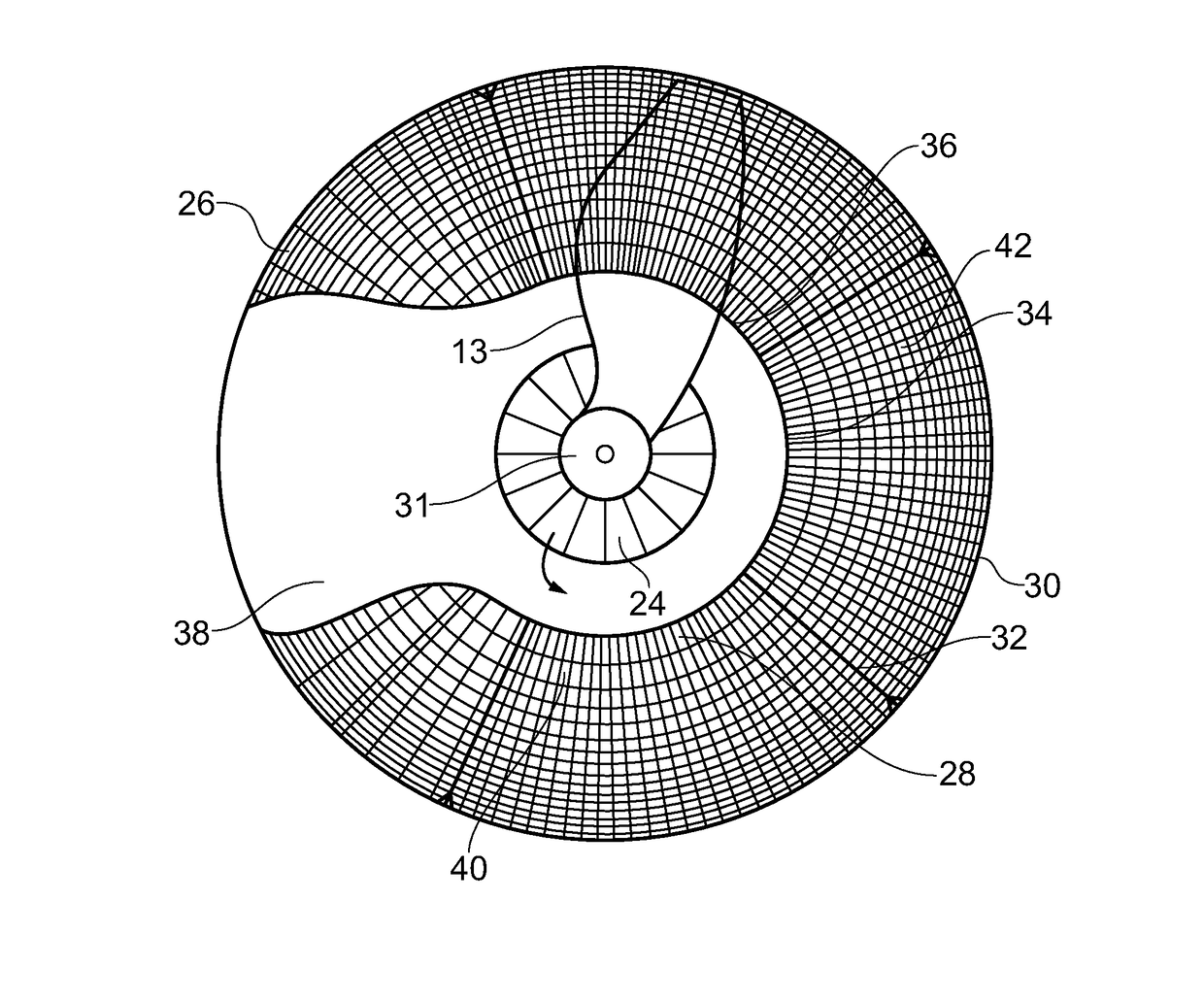

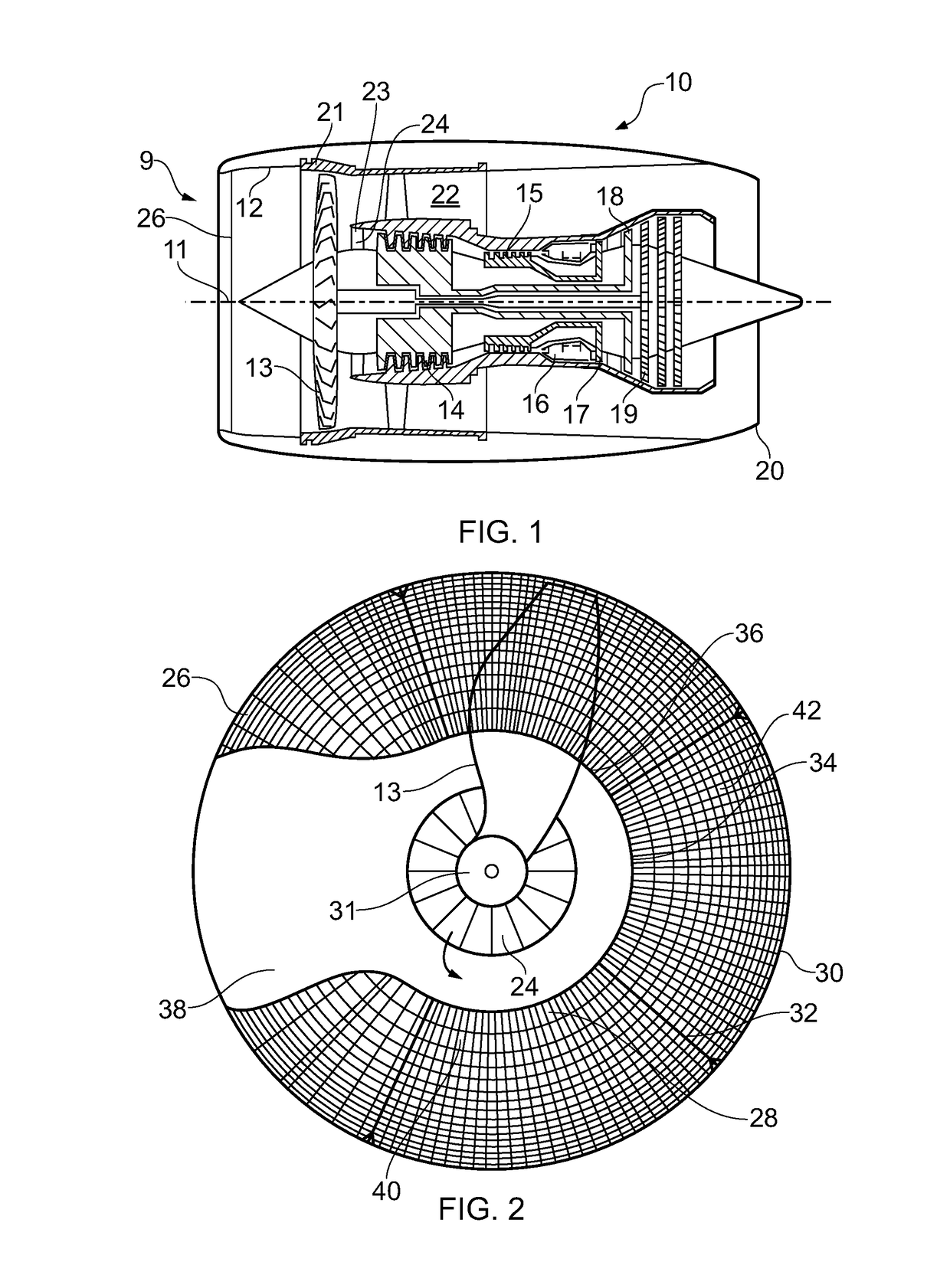

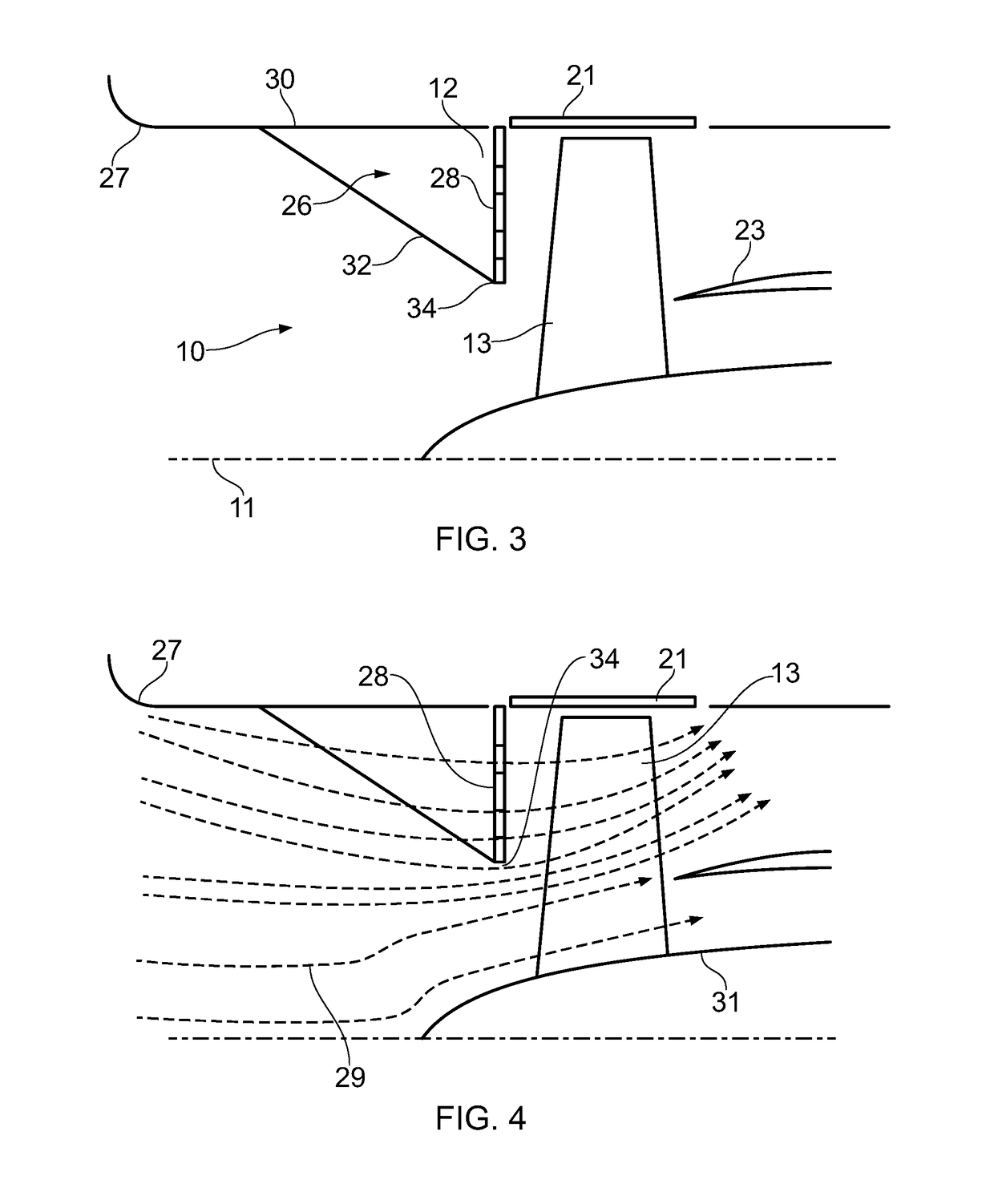

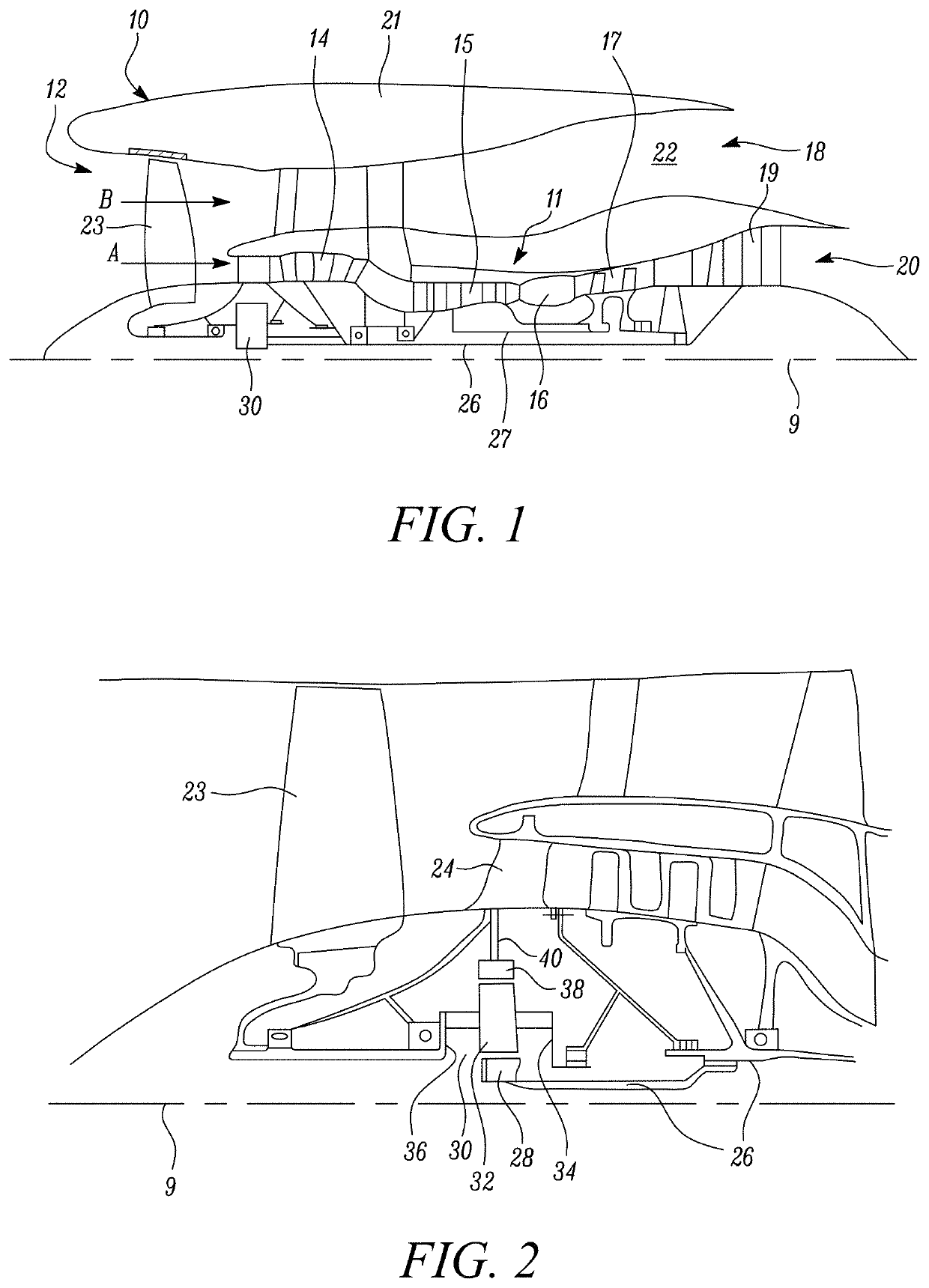

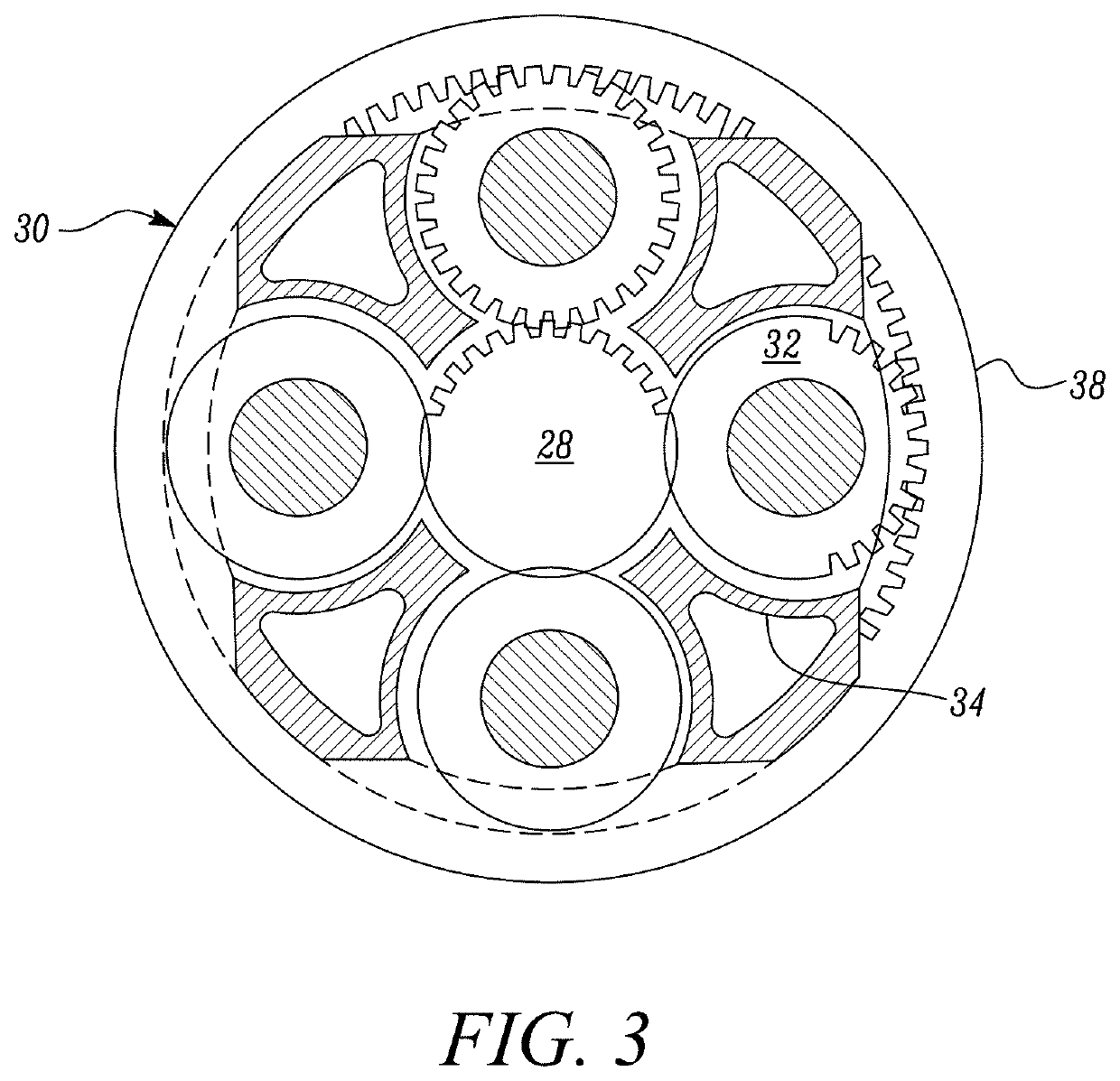

Gas turbine engine arrangement

ActiveUS20180245514A1Increase speedReduce power levelEngine fuctionsGas turbine plantsRadial positionTurbine

A gas turbine engine arrangement comprising a gas turbine engine and an inlet screen. The gas turbine engine comprises an engine core comprising an inlet having a radial extent extending from an engine longitudinal axis to a first radial position, and a fan duct comprising an inlet having a radial extent extending from the first radial position to a fan casing, the inlet screen comprising an at least part annular porous grid radially extending across at least part of the radial extent of the fan duct inlet, and not extending across any substantial part of the radial extent of the core inlet.

Owner:ROLLS ROYCE PLC

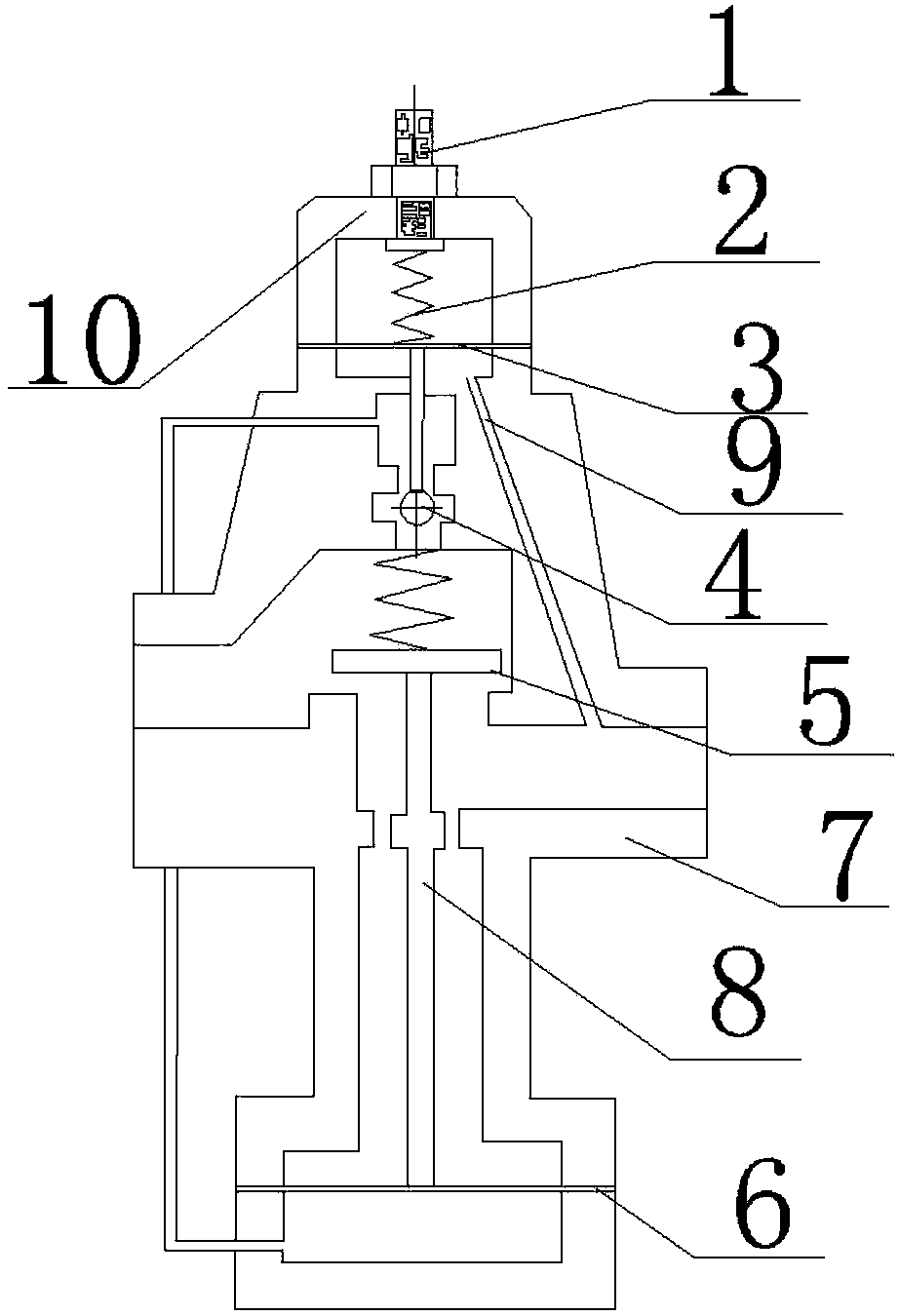

Self reset pressure relief valve for hemodialysis

ActiveCN102125706AWork reliablyReduce inlet pressureDialysis systemsMedical devicesHemodialysisHaemodialysis machine

The invention discloses a self reset pressure relief valve for hemodialysis. An upper chamber and a lower chamber of the lower valve are communicated by a small hole in which a fixing cup is installed, the lower end of the fixing cup is embedded into an inner cavity of a fixing base; a shaft pin is penetrated through a center hole of the fixing cup, the shaft head of the shaft pin can block off the center hole of the fixing cup, a second spring is sleeved on the shaft pin, the upper end of the shaft pin is abutted against the lower end of a fixing block, the upper end of the fixing block is abutted against the lower end of a first spring; and a ring groove is arranged in the middle of the fixing block, and a diaphragm is installed in the ring groove. The self reset pressure relief valve for hemodialysis has good biological performance and can not rust, thus effectively avoiding medical fluid contamination; and the springs are used to substitute a rubber diaphragm for reset and sealing, high reliability of pressure relief can also be ensured after long-time use, and the defect of noise generated due to resonance of a traditional structure is eliminated.

Owner:SWS HEMODIALYSIS CARE CO LTD

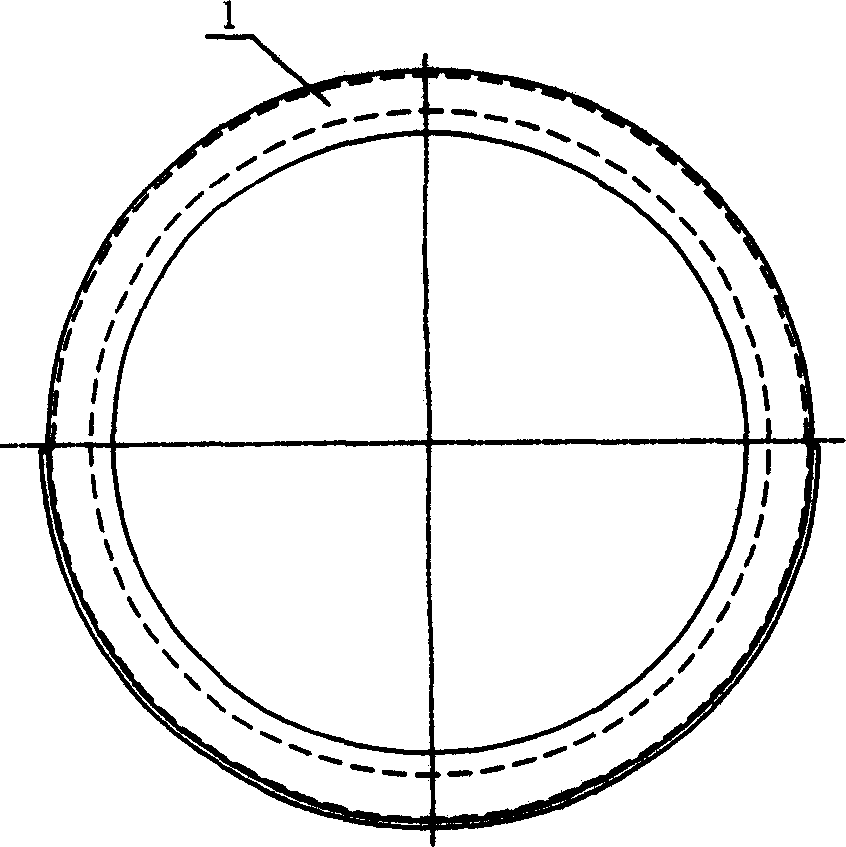

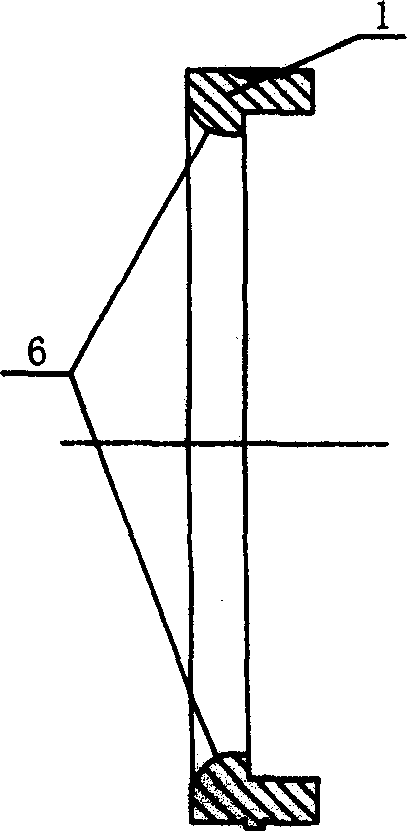

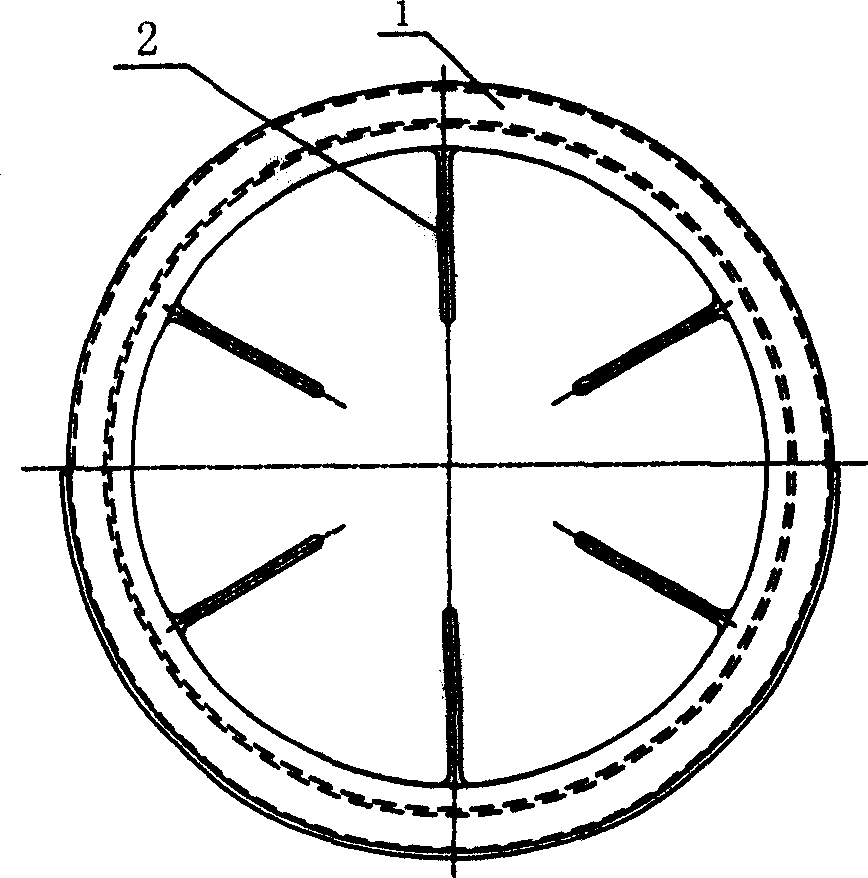

Sealing ring for centrifugal pump

InactiveCN1904381AOvercoming secondary refluxAvoid hydraulic lossPump componentsPumpsCentrifugal pumpEngineering

The invention relates a sealing ring for a centrifugal pump, on whose inner wall is uniformly distributed at least more than two commutator bars. The number of the commutator bars is less than or equal to the number of the impeller vanes. In the open-entry position of fitting the sealing ring with the impeller is opened a sealed groove.

Owner:SHANGHAI KAIQUAN PUMP IND GROUP

Water treatment system

ActiveUS9315395B2Easy to operateReduce clamping forceIon-exchanger regenerationSpecific water treatment objectivesWater treatment systemEngineering

A water treatment system including a pair of water treatment tanks, each tank defining a flow path extending from a tank inlet to a tank outlet and containing a water treatment material disposed along the flow path for treating water as it travels from the inlet to the outlet. A system controller controls which of the tanks is on-line and which of the tanks is off-line and controls the regeneration of an exhausted tank. A multi-stage, spring-loaded control valve assembly controls the communication of fluid to a regeneration control turbine and includes a piston head and a relatively movable seat-carrying stem. A spring urges the stem away from the piston head such that initial movement of the head compresses the spring but does not produce movement in the seat. Sufficient movement of the piston head produces movement in the seat, thereby causing the seat to open pressure.

Owner:KINETICO

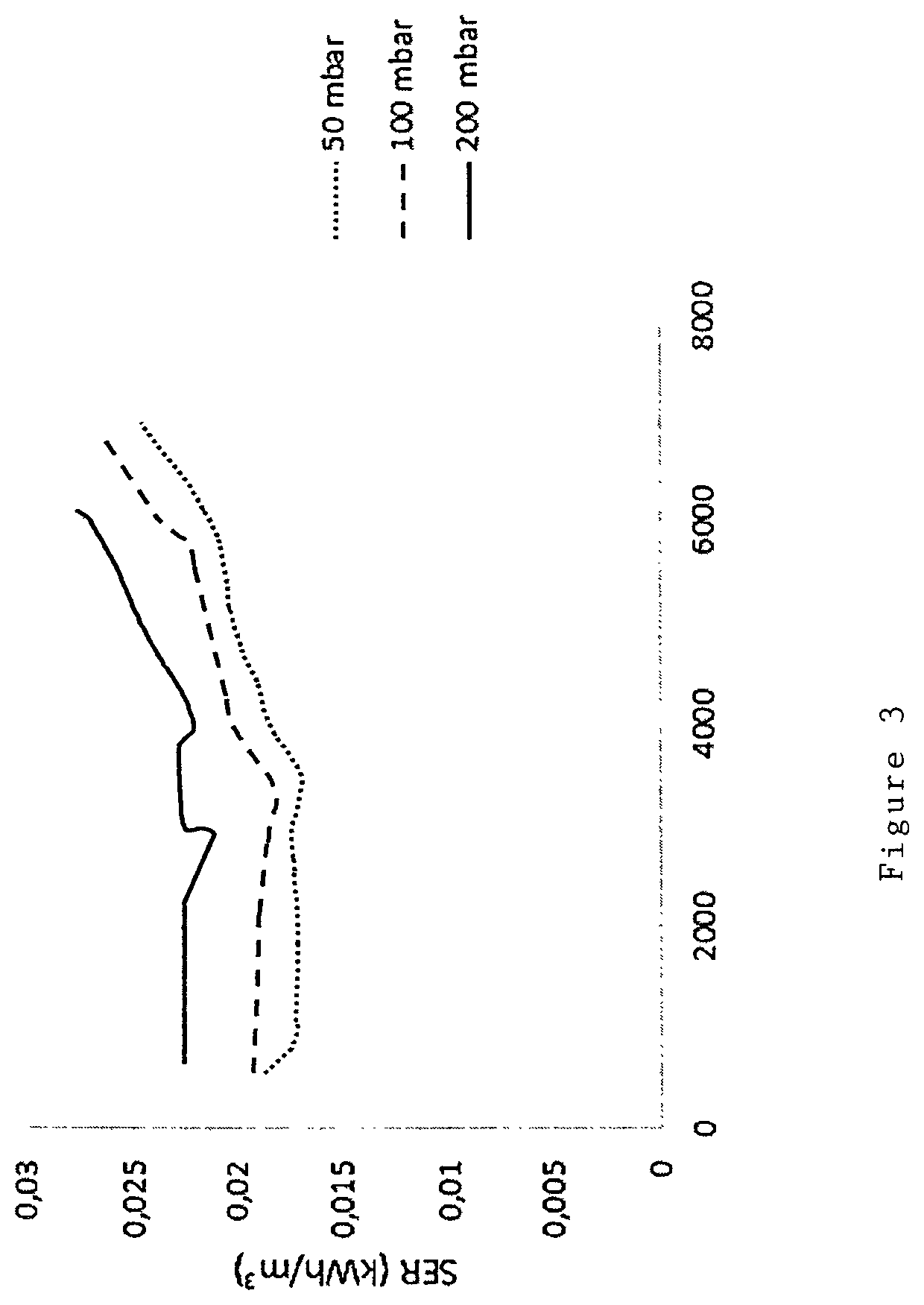

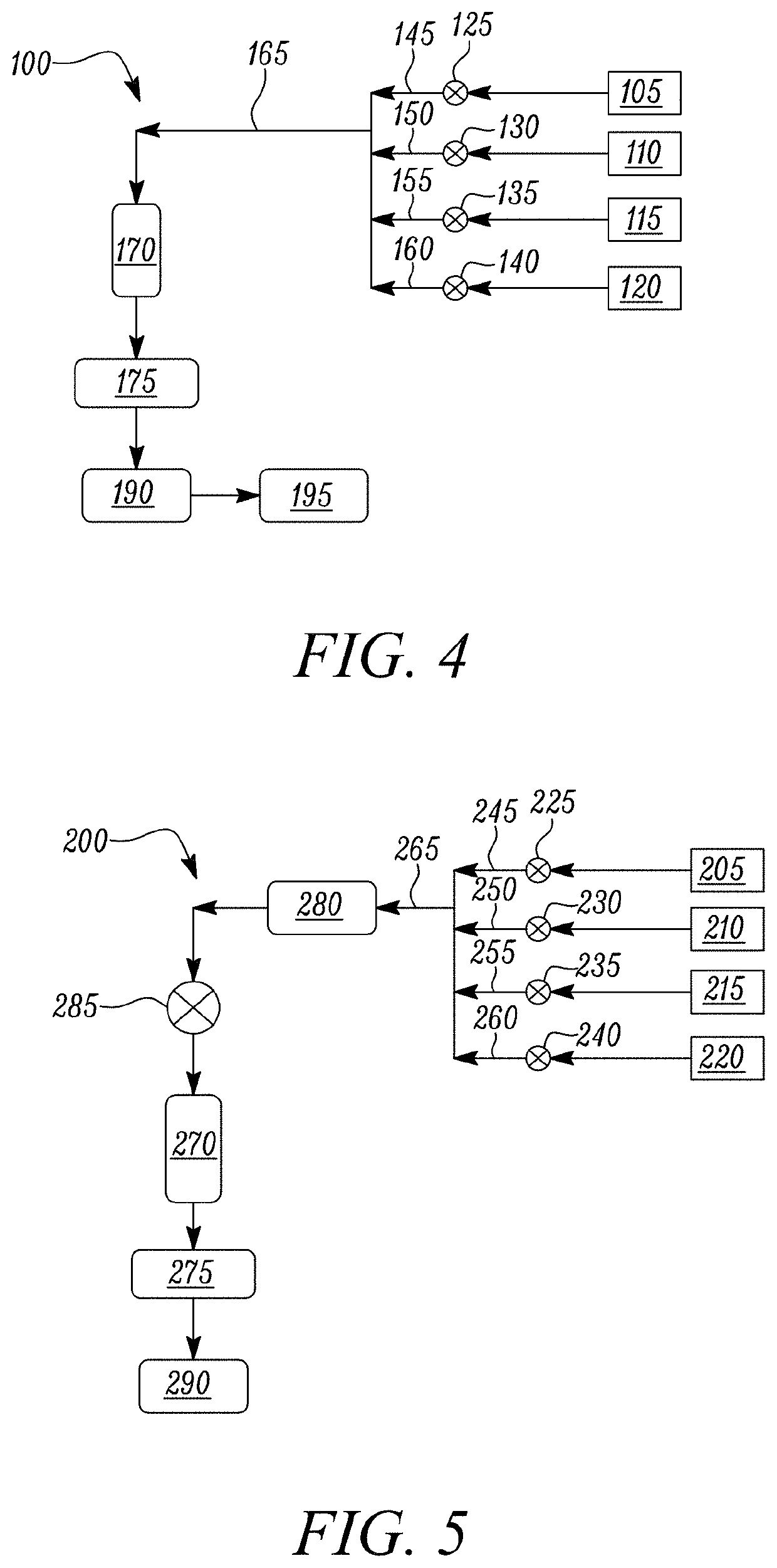

Method for controlling a compressor

ActiveUS10087944B2Less energyKeep energy smallWorking fluid for enginesEfficient regulation technologiesInlet pressureControl theory

A method for controlling a compressor that includes a compressor element, whereby during a transition from full load or partial load to zero load, a process A is followed that involves: (1) reducing the inlet pressure; and (2) reducing the speed and / or the drive torque. During a transition from zero load to part load or full load, a process B is followed that involves: (3) increasing of the speed or drive; and (4) increasing the inlet pressure.

Owner:ATLAS COPCO AIRPOWER NV

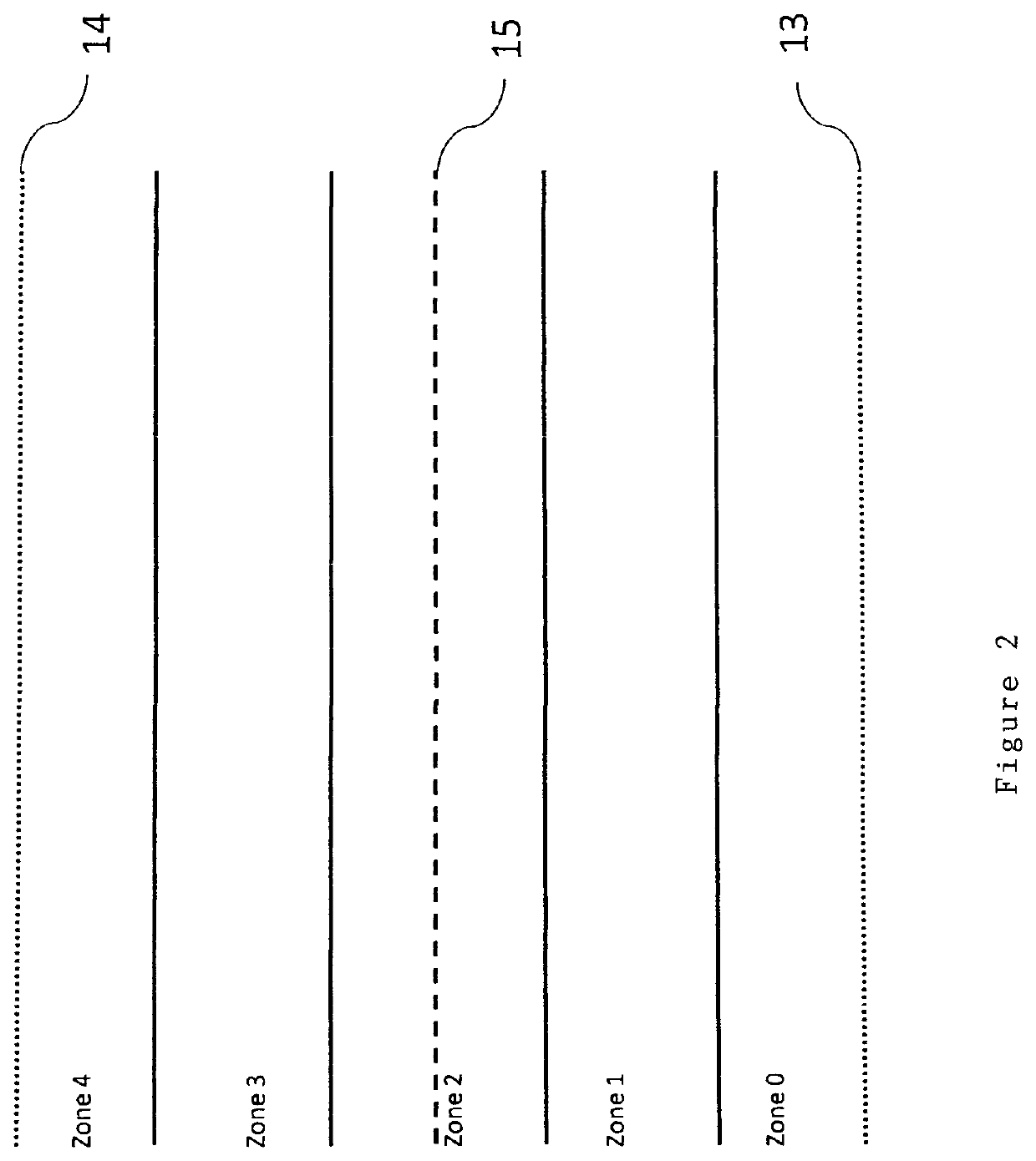

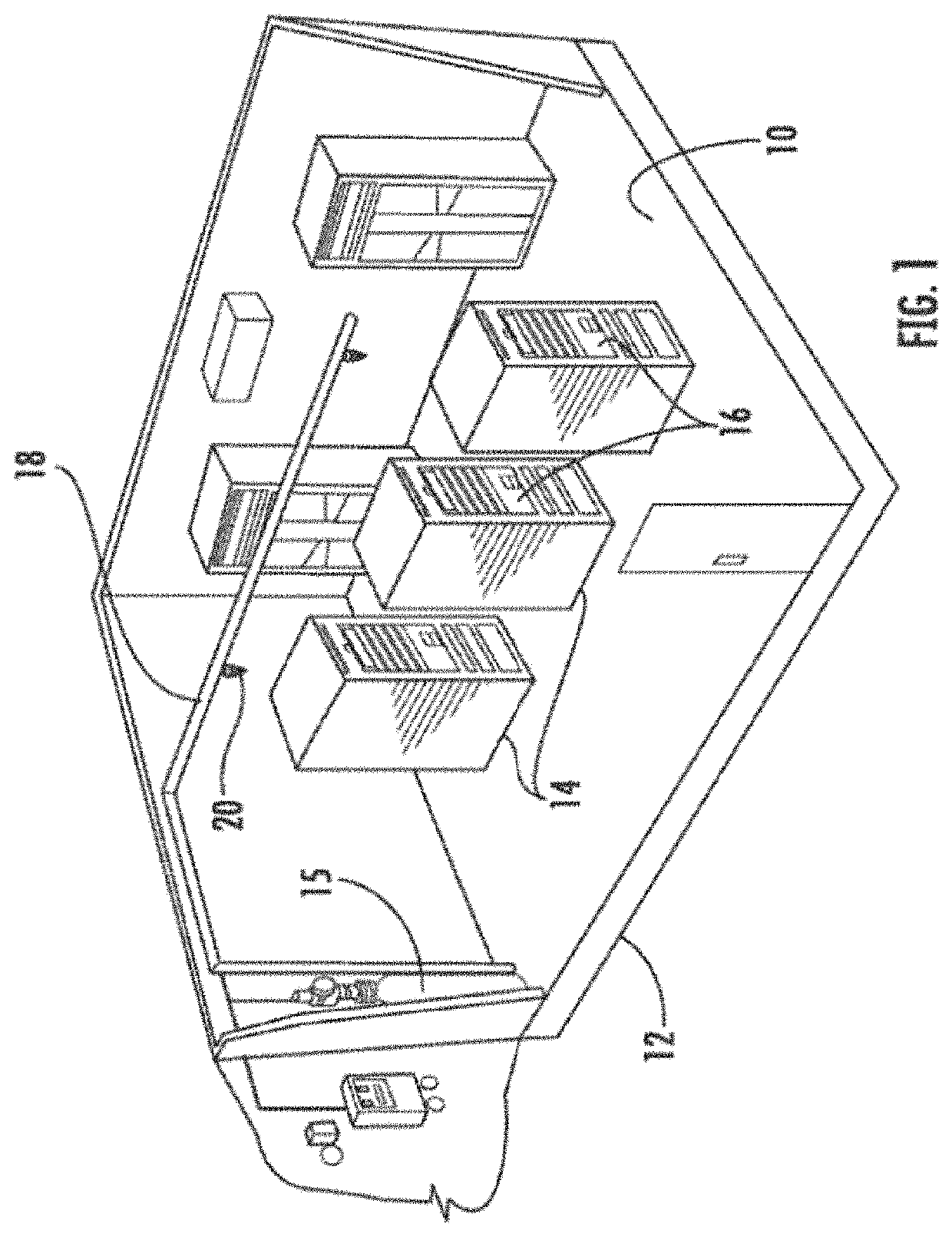

Method for operating a vacuum pump system and vacuum pump system applying such method

ActiveUS11111922B2Reduce inlet pressureEasy to adaptRotary/oscillating piston combinations for elastic fluidsPump controlElectric machineryEngineering

A method of operating a vacuum pump system, the method including the steps of: operating a primary vacuum pump having a variable speed motor; connecting at least two secondary vacuum pumps in parallel with said primary vacuum pump; dividing the secondary vacuum pumps in groups, each group including at least one secondary vacuum pump; and assigning a priority for each of said groups. The method further includes the steps of measuring the inlet pressure p1, comparing the measured inlet pressure p1 with a predetermined pressure value p0, and if p1 is higher than p0, starting the secondary vacuum pump at a first predetermined startup load Sstartup,1 if it includes a fixed speed motor, and / or starting the secondary vacuum pump at a second predetermined startup load Sstartup,2, if it includes a variable speed motor.

Owner:ATLAS COPCO AIRPOWER NV

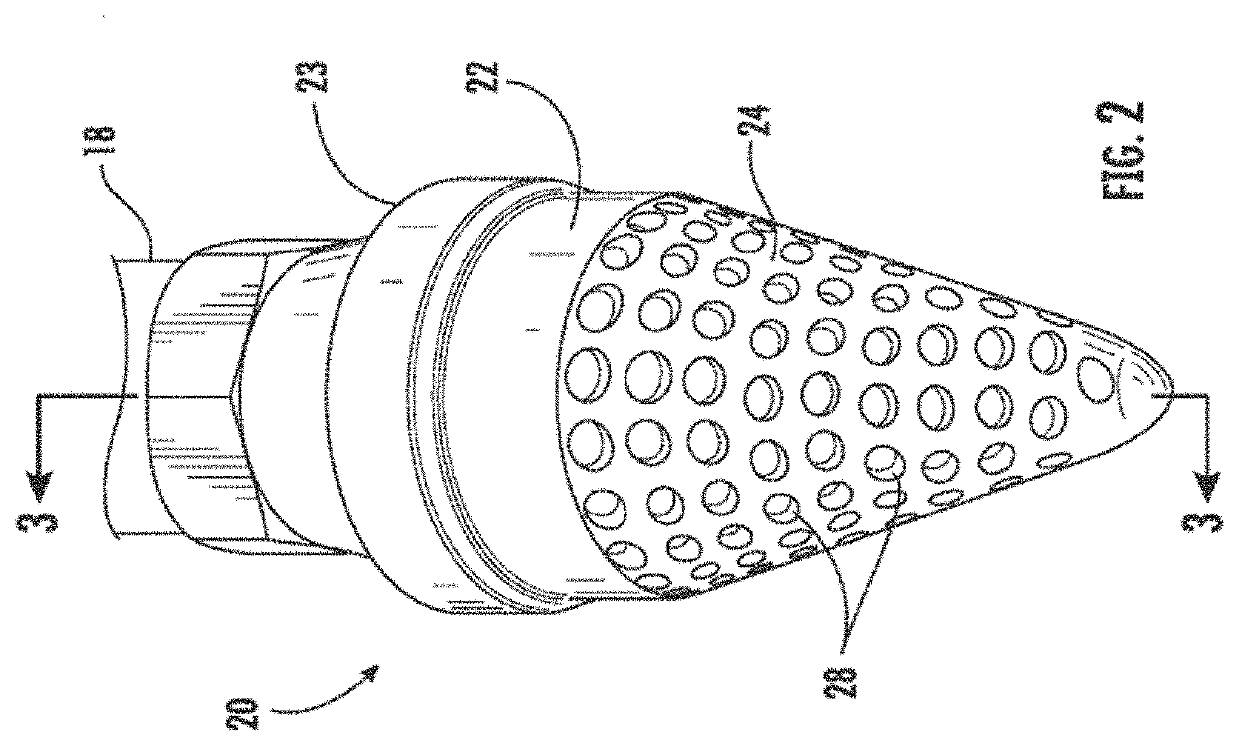

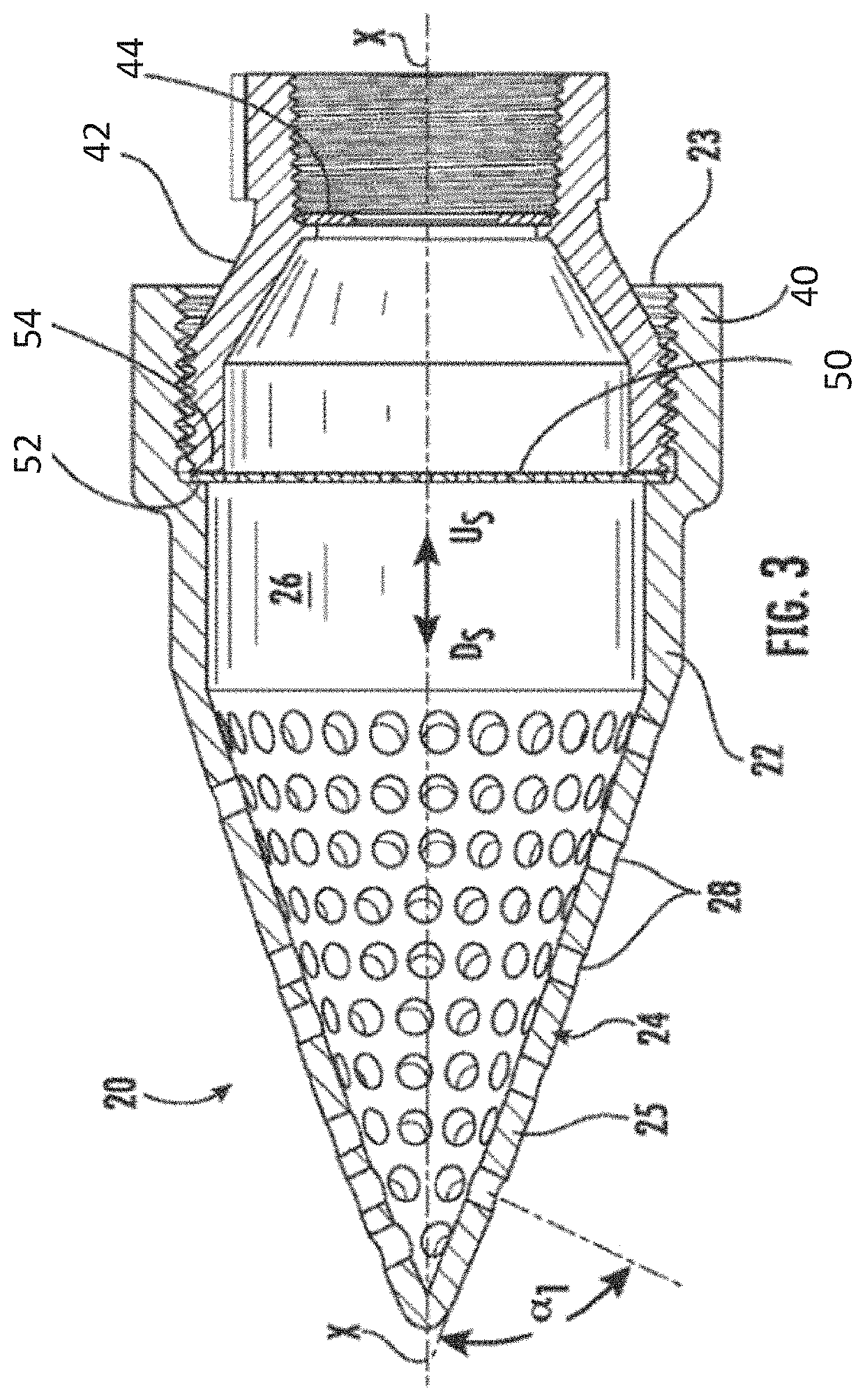

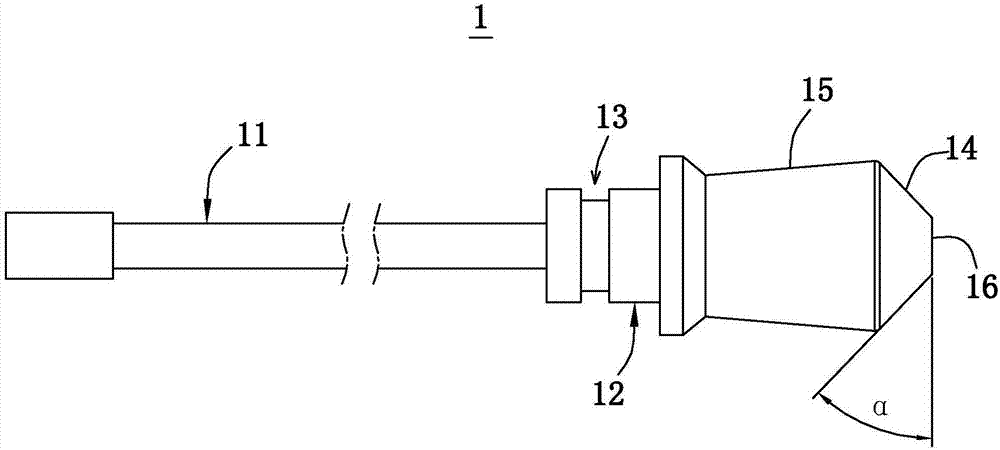

Low noise discharge nozzle

A nozzle assembly for a fire suppression system includes a body having an inlet end for receiving a flow of fire extinguishing agent from the fire suppression system at an inlet pressure and a nozzle portion extending from the body. The nozzle portion includes an interior cavity having an outlet end, a center body arranged within the interior cavity adjacent the outlet end, and a plurality of exit orifices formed in an outer wall of the nozzle portion, in communication with the interior cavity, for vectoring the flow of fire extinguishing agent exiting therefrom and to reduce a noise level of the nozzle assembly. At least one perforated filter member is positioned upstream from the plurality of exit orifices formed in the nozzle portion, for reducing the inlet pressure of the flow of fire extinguishing agent.

Owner:CARRIER CORP

Operation method of automobile fuel gas electric control operation control valve

InactiveCN107795716AReduce inlet pressureOperating means/releasing devices for valvesEqualizing valvesInlet pressureElectric control

The invention discloses an operation method of an automobile fuel gas electric control operation control valve. The method comprises the steps that an adjusting screw is unscrewed to open an auxiliaryvalve clack, fuel gas enters the position below a large membrane, the large membrane is moved to open a main valve clack, gas enters the position below a small membrane at the same time, and outlet pressure is adjusted. According to the technical scheme, inlet pressure of fluid is pressed by one half through the throttling principle and automatically kept to an adjusting value with certain neededoutlet pressure. A speed reducing valve is mainly applied to steam, gas, water and oil supply systems.

Owner:SICHUAN SENJIE GAS EQUIP CO LTD

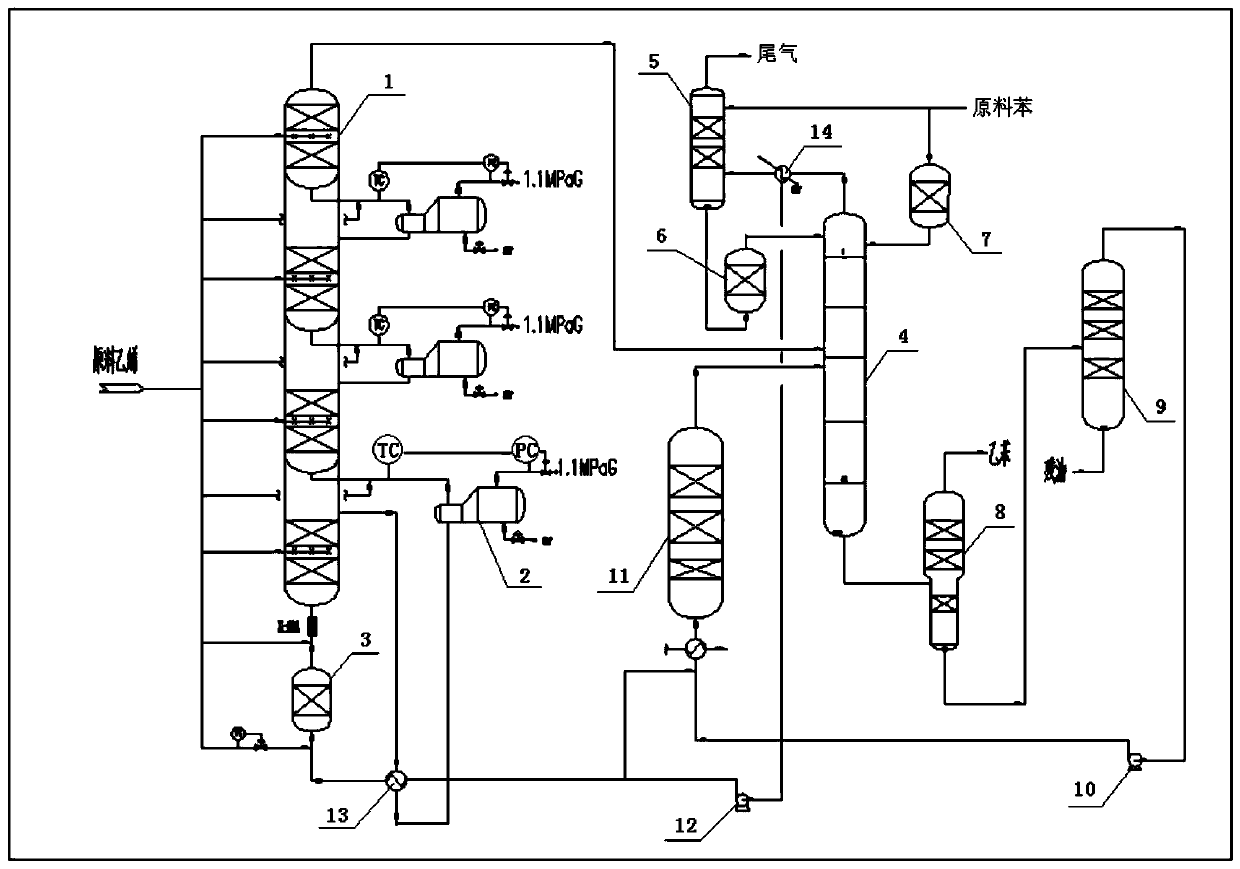

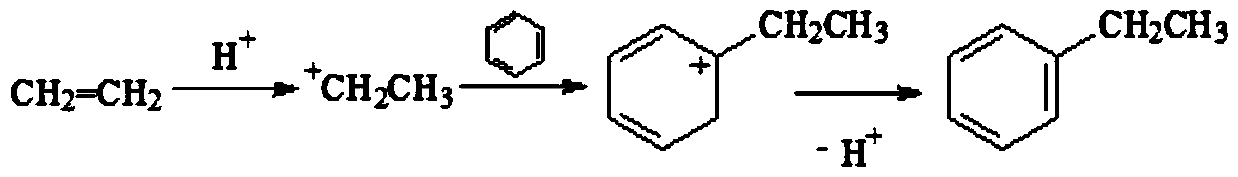

Energy-saving reaction process for producing ethylbenzene from pure ethylene

ActiveCN111574318AReduce in quantityReduce the probability of leakageDistillation purification/separationHydrocarbonsChemistryProcess engineering

The invention relates to an energy-saving reaction process for producing ethylbenzene from pure ethylene. The process comprises the following steps: treating raw material benzene to enable the water content of benzene discharged from the tower top of a benzene recovery tower to be 30-600PPM; carrying out protective adsorption reaction to enable the content of basic nitrogen in a material enteringan alkylation reactor to be less than 0.001 PPM; carrying out alkylation reaction, correspondingly arranging a steam generator on every two catalyst bed layers, enabling a staged discharge material formed after the reaction of every two catalyst bed layers to enter the steam generator for heat exchange, and then entering the next stage of alkylation reaction; recovering benzene; carrying out ethylbenzene recovery; recovering polyethylbenzene; and carrying out anti-alkylation reaction. According to the process provided by the invention, the influence of raw material impurities on the device iseliminated, the stability of an ethylbenzene reaction system is improved, and the production cost is reduced.

Owner:CHANGZHOU RUIHUA CHEM ENG&TECH

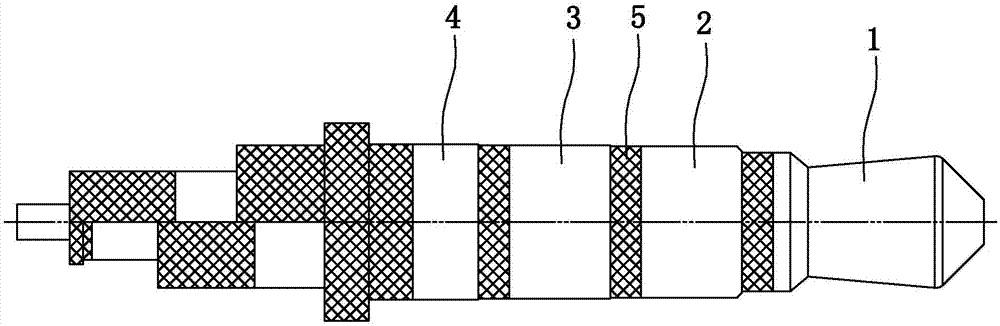

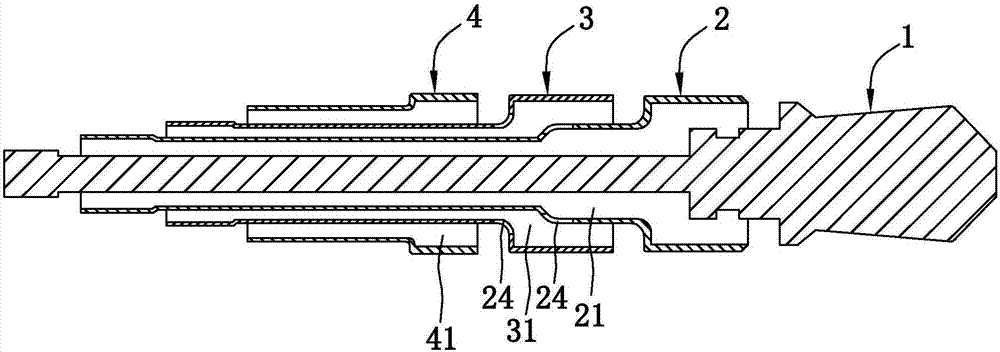

Production process of audio earphone pins

ActiveCN107351311AIncrease success rateGuaranteed flatnessDomestic articlesEngineeringInjection molding machine

The invention discloses a production process of audio earphone pins. The production process comprises the following steps: A. a PIN, a second-grade middle pipe, a third-grade middle pipe and a fourth-grade large sleeve are independently machined, respectively; and in the machining process of the second-grade middle pipe and / or the third-grade middle pipe, feed holes communicating with the internals are formed on the pipe walls and near one sides of the large ends; B. the Pin, the second-grade middle pipe, the third-grade middle pipe and the fourth-grade large sleeve are assembled to put in a mold hole of a mold bar for injection molding; and plastic is fed from one sides far from the large ends; and C. the earphone pings molded by injection are taken out from the mold bar for unloading and trimming; part of the plastic can be fed in an injection molding channel of the inner layer from a feed hole for feeding; and as the internal injection molding channel and the external are consistent in air pressure through the feed hole, the plastic is effectively prevented from passing through the outer-layer injection molding channel, meanwhile, the injection molding pressure can be reduced, and the yield is increased.

Owner:JOLLYKING ELECTRONICS

Oil scavenge system

ActiveUS20200232343A1High outlet pressureAvoid cavitationAircraft componentsTurbinesAir pumpDeaerator

An oil scavenge system for a gas turbine engine comprising an oil tank and at least one bearing chamber. The oil scavenge system comprises at least one primary scavenge pump, a manifold, a secondary scavenge pump, a deaerator and a filter unit. The at least one primary scavenge pump is configured to pump oil from the at least one bearing chamber to the manifold whilst raising the pressure of the oil from a starting pressure to a first pressure elevated with respect to the starting pressure. The manifold is pressurised to substantially maintain the oil at said first pressure. The secondary scavenge pump is configured to pump oil from the manifold at the first pressure and to raise the pressure of the oil to a second pressure elevated with respect to the first pressure before pumping the oil to the deaerator and through the filter unit to the oil tank.

Owner:ROLLS ROYCE PLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com