Pre cooling type refrigeration method and pre cooling type treatment device for curing tumour

A technology of tumor treatment and refrigeration method, which is applied in the direction of cooling surgical instruments, etc., which can solve the problems of difficult air source, hindering the supply of nutrients to cells and the treatment of metabolites, and the great hidden dangers in the safety performance of cold knives, so as to achieve the reduction of air consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

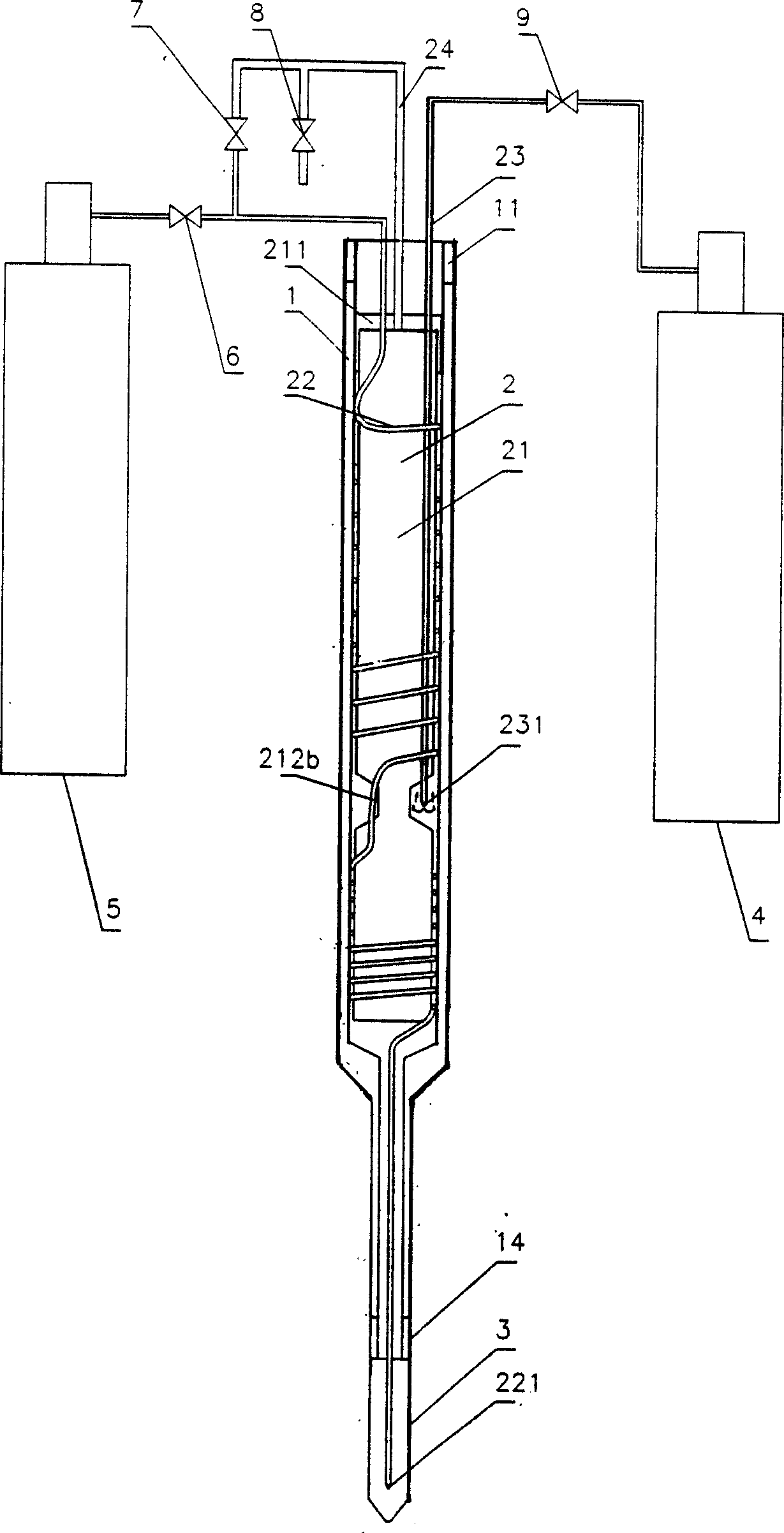

[0050] Such as figure 1 , when freezing, open the control valves 6, 8 and 9, and the high-pressure low-temperature working fluid flows from the gas cylinder 5 through the control valve 6 into the low-temperature working medium delivery pipe 22, and first passes through its front section, where it is combined with the high-temperature working medium from the middle of the connecting block. After heat exchange, it is pre-cooled to a certain temperature, enters the back section of the low-temperature working medium delivery pipe, and is further cooled by the low-temperature working medium that is throttled and returned, and throttles and reduces pressure at the throttle hole 221. Due to the J-T effect, it can Obtain the required low temperature; the high-temperature working medium enters the high-temperature working medium delivery pipe 23 through the control valve 9, and throttles and cools after passing through the orifice 231, and then from the upper inner wall of the outer wal...

Embodiment 2

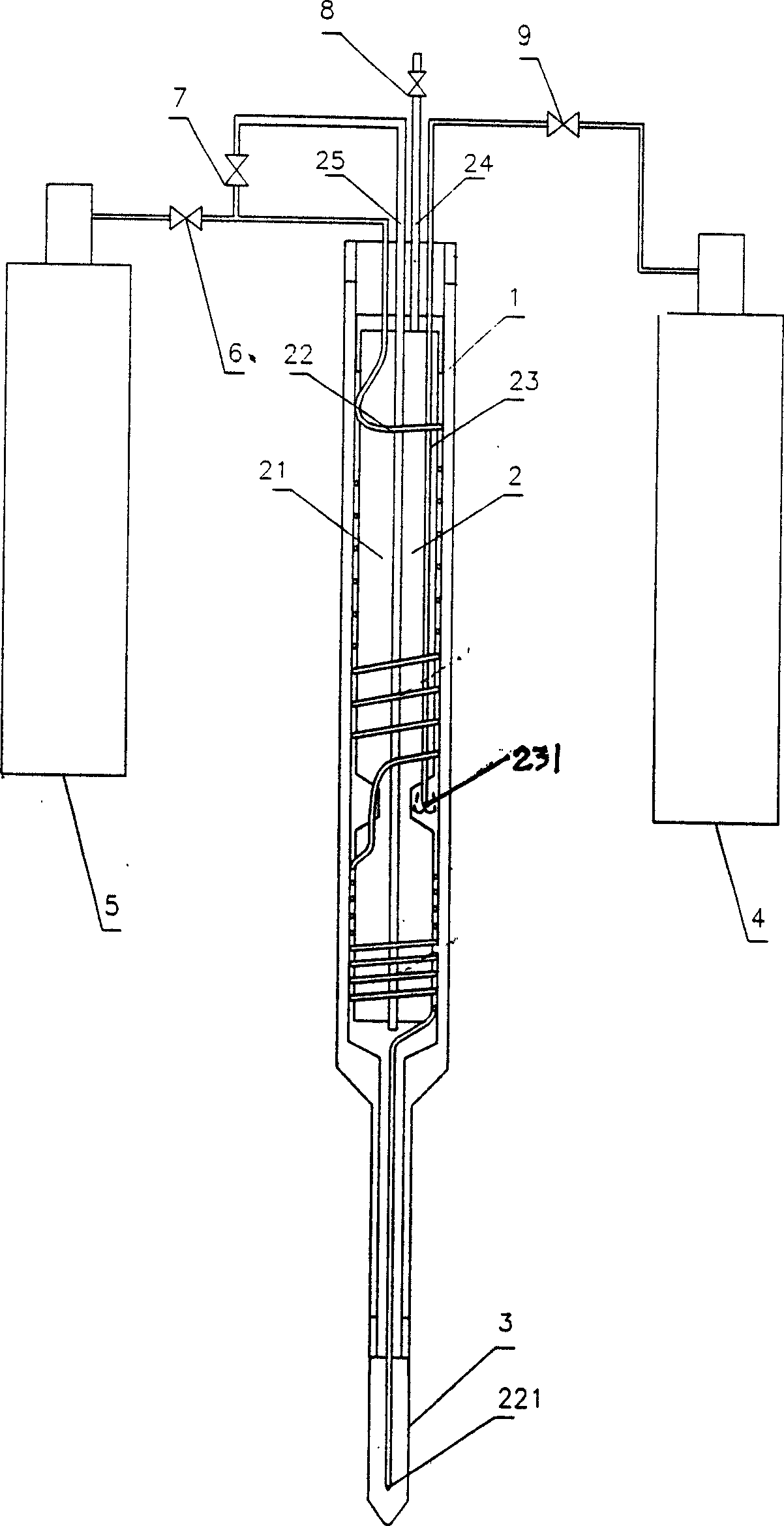

[0052] as attached figure 2 Shown, this is another embodiment of the present invention, this embodiment and the attached figure 1 The principles of the embodiments are basically the same, the low-temperature working medium is pre-cooled twice and reaches the lower part of the inner cavity of the probe head 3 through the delivery pipeline 22, where it is throttled and cooled to reach the required treatment temperature. The difference is that the air return pipe 24 is directly emptied after passing through the control valve 8 , and a return temperature pipe 25 is provided to extend to the lower end of the mandrel 21 . During the freezing process, the control valve 7 is closed, the control valves 6, 8 and the high-temperature working medium control valve 9 are opened, and the low-temperature working medium is sequentially throttled by the high-temperature working medium and returned from the probe head 3 when flowing through the delivery pipeline 22 The low-temperature working ...

Embodiment 4

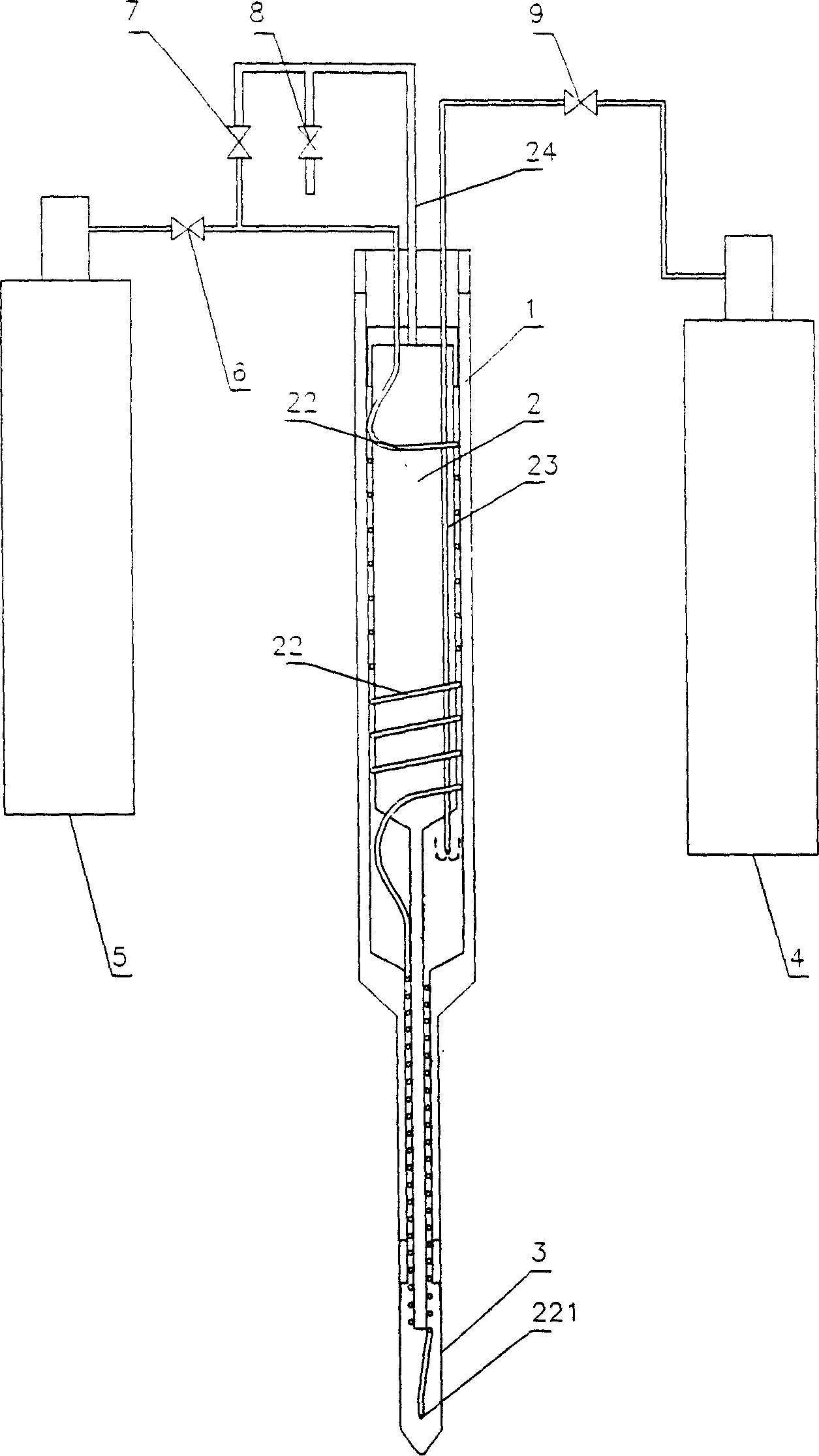

[0056] as attached Figure 4 As shown, this is the fourth embodiment of the present invention. In this embodiment, the mandrel 21 is a hollow cylinder. The air return pipe 24 is directly emptied after passing through the control valve 8, and the temperature return pipe 25 passes through the inner cavity of the mandrel and the outer tube and extends to the upper part of the inner cavity of the probe head 3. The front section of the low-temperature working fluid delivery pipeline is spirally wound on the outer wall of the mandrel 21 and is close to the inner wall of the outer tube to form a first-stage heat exchanger; The inner wall of the outer tube constitutes the second stage heat exchanger. The high-temperature working fluid delivery pipe 23 passes through the sealing plate 211 into the inner cavity of the mandrel 21 and passes through the end thereof. When returning to temperature like this, the high-pressure gas source directly passes through the temperature-returning pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com