Production process of audio earphone pins

An audio earphone and production process technology, which is applied to the production process field of audio earphone pins, can solve the problems of long injection molding channel, less glue, waste products, etc., and achieve the effects of improving production efficiency, improving uniformity, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

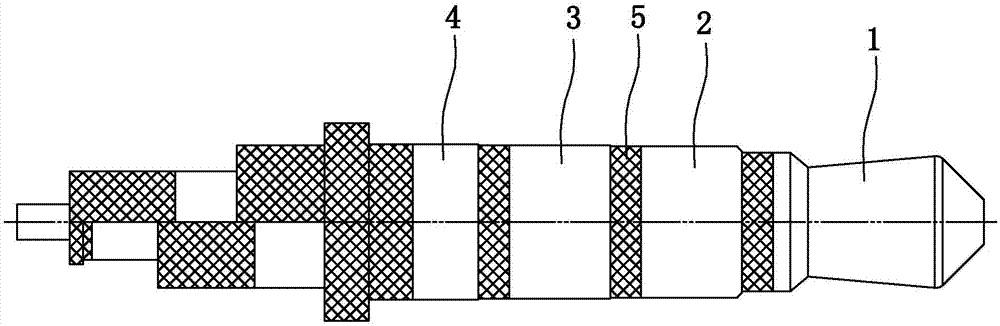

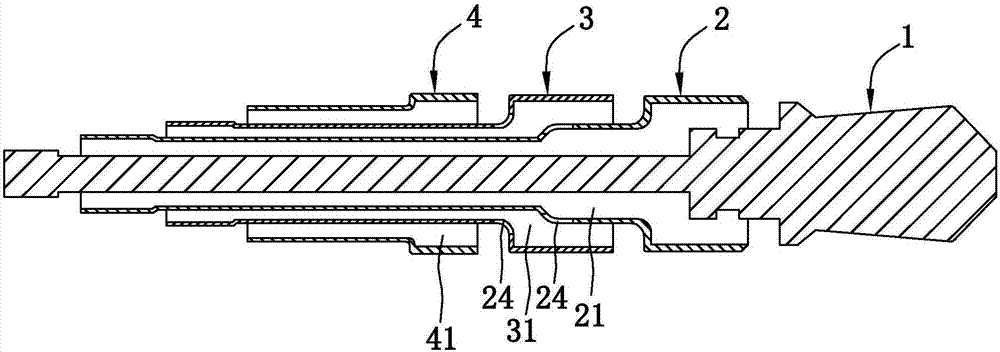

[0062] A production process for an audio earphone pin, comprising the following processing steps:

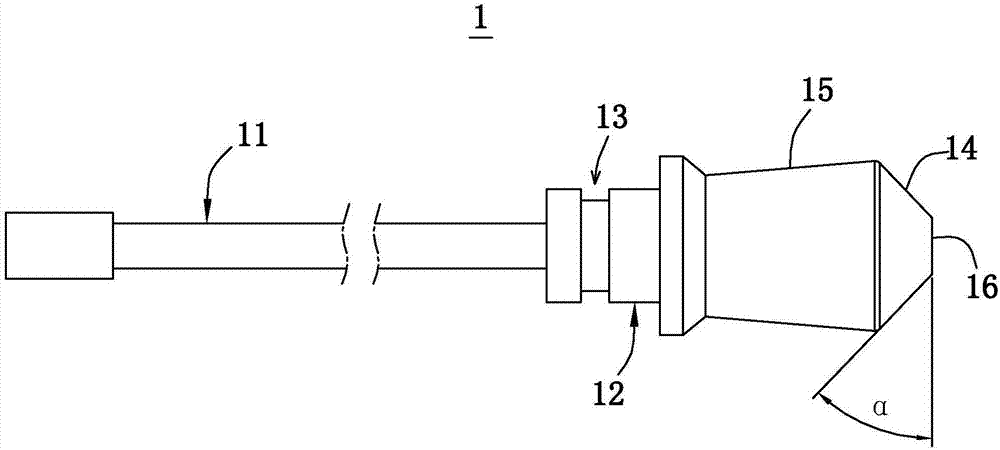

[0063] Step A: See figure 1 , respectively independently process the PIN needle 1, the second-level middle tube 2, the third-level middle tube 3 and the fourth-level large sleeve 4. The details of PIN pin 1 include the following steps:

[0064] Step A1-1, turning the small outer diameter: Turning one end of the PIN pin 1 according to the designed size;

[0065] Step A1-2, slotting: open an annular groove 13 on the outer wall of the PIN needle 1;

[0066] Step A1-3, turning large outer diameter: the same end of PIN pin 1 is turned according to the design size;

[0067] Step A1-4, chamfering: turning a chamfer 14 with α equal to 45° at the other end of the PIN pin 1;

[0068] Step A1-5, turning the inclined surface and flattening: turning the inclined surface 15 according to the design size, and completing the end turning process at the same time.

[0069] Both the second-sta...

Embodiment 2

[0097] A production process for audio earphone pins, the difference from Example 1 is that 8 times of stamping and stretching are carried out in step A2-2, 7 times of stamping and stretching are carried out in step A3-2, and the injection molding temperature in step B is 226°C , The mold clamping injection duration is 7s.

Embodiment 3

[0099] A production process of an audio earphone pin, the difference from the first embodiment is that in step B, the clamping pressure is controlled at 101 bar, and the injection molding temperature is 220°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com