Operation method of automobile fuel gas electric control operation control valve

An operation method and operation control technology, applied in the direction of valve operation/release device, valve details, safety valve, etc., can solve problems such as inability to adjust pressure and unsmooth gas delivery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

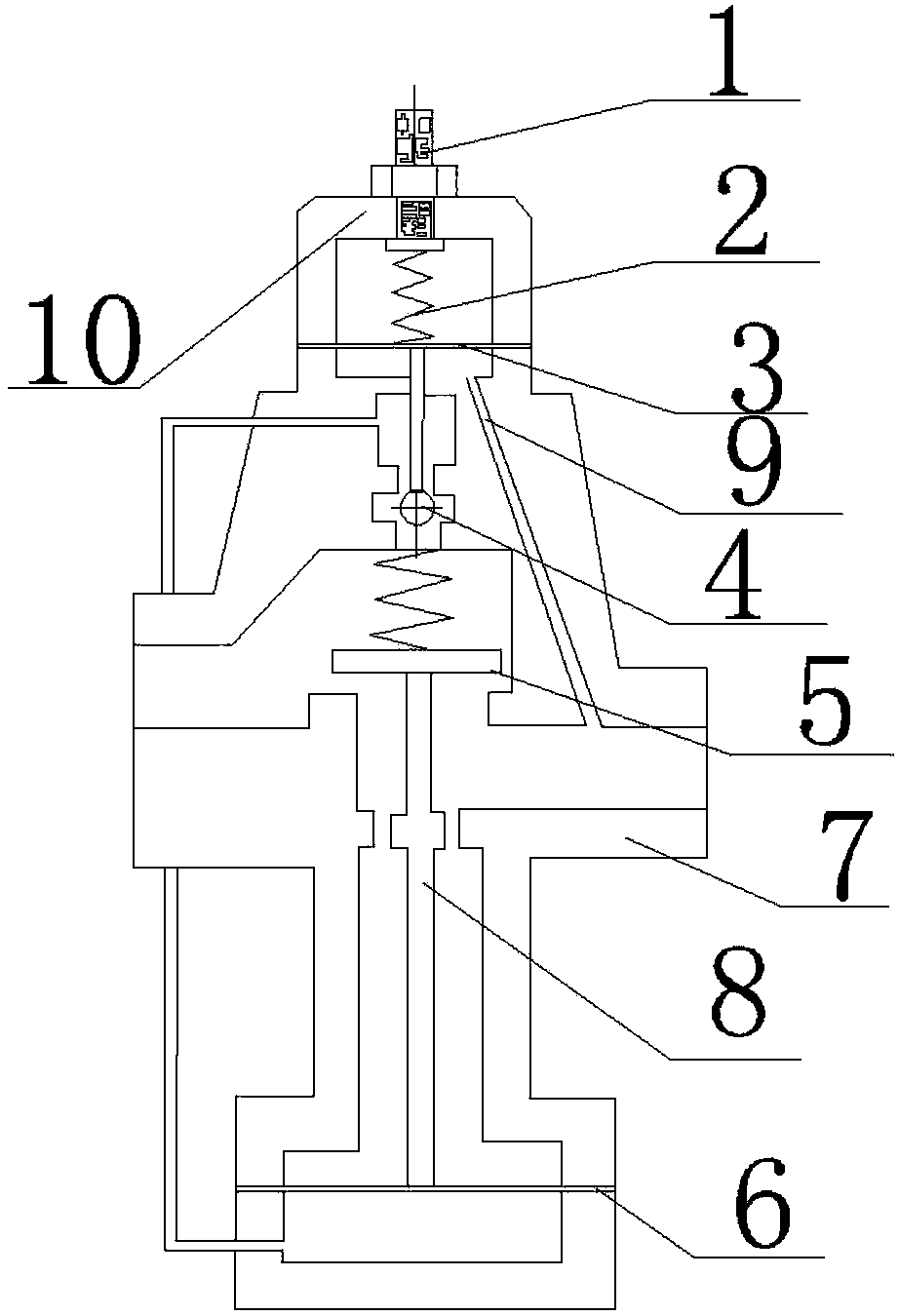

[0019] Such as figure 1 As shown, an operation method of an automobile gas electric control operation control valve includes an adjusting screw 1, an adjusting spring 2, a small diaphragm 3, an auxiliary valve disc 4, a main valve disc 5, and a large diaphragm 6, and the adjusting screw 1 passes through The top cover of the valve seat 10 is connected with the adjustment spring 2, the lower end of the adjustment spring 2 is connected with the auxiliary valve disc 4 through the small diaphragm 3, the auxiliary valve disc 4 is connected with the main valve disc 5 through the spring, and the lower end of the main valve disc 5 is connected with Connecting pipe 8, connecting pipe 8 is connected with large diaphragm 6, and described adjusting spring 2, small diaphragm 3, secondary valve flap 4, main valve flap 5, large diaphragm 6 are all located in valve seat 10.

[0020] Wherein, the chamber where the auxiliary valve disc is located communicates with the chamber where the large dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com