Self-pressurization double-component pulse working rocket engine

A rocket engine and two-component technology, applied to rocket engine devices, machines/engines, mechanical equipment, etc., can solve problems such as large energy loss, high reliability and safety, and restrict the pressure level of the propulsion system. The effect of less gas volume, improved load capacity and performance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

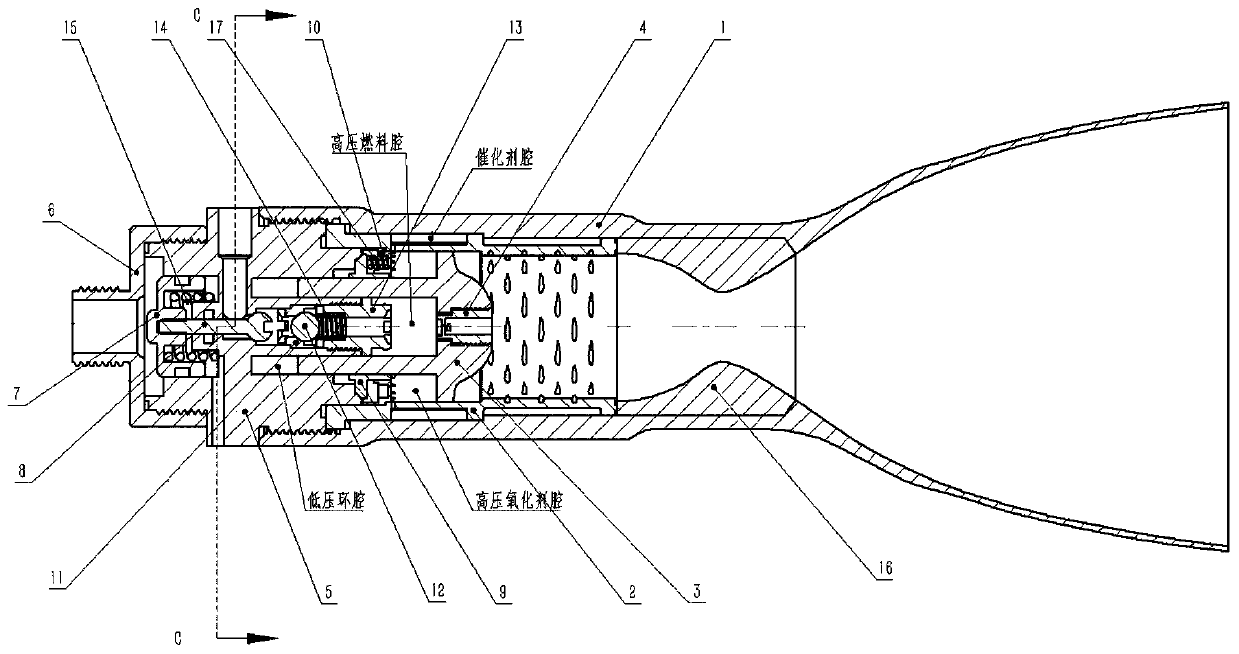

[0022] This embodiment is a self-pressurized dual-element pulse working rocket engine.

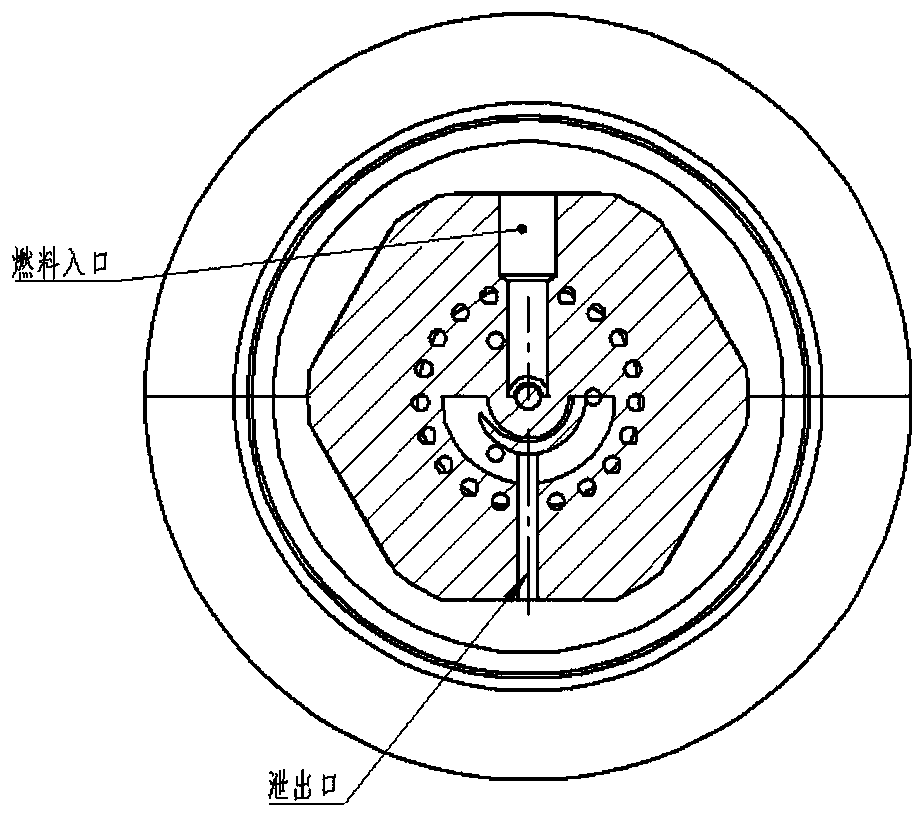

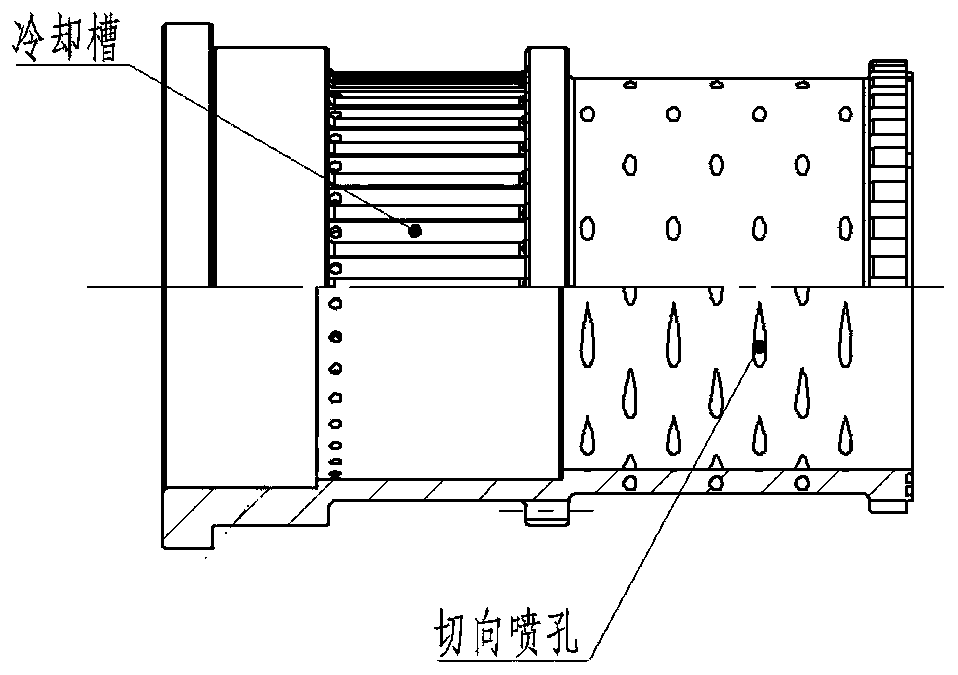

[0023] refer to Figure 1 to Figure 5 , the self-supercharging two-component pulse working rocket engine of this embodiment consists of a thrust chamber 1, a lining 2, an annular piston 3, a fuel nozzle 4, a top seat 5, a connecting screw cap 6, a piston 7, a spool 8, and a ring plug 9. Guide ring 10, one-way valve seat 11, steel ball 12, screw plug 13, first spring 14, second spring 15, third spring 17 and throat plug 16; wherein, throat plug 16 and liner 2 are inserted into thrust The body of the chamber 1 is connected and fixed to the thrust chamber through the top seat 5, and an annular catalyst chamber and an annular gas collection chamber are formed between the inner liner 2 and the thrust chamber 1, and the two chambers are communicated through small holes arranged around the circumference. The annular piston 3 cooperates with the inner liner 2 and the top seat 5 to form an annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com