Multi-stage compressor, air-separating apparatus comprising such a compressor, and installation

An air separation and compressor technology, applied in the field of multi-stage compressors, can solve problems such as efficiency loss and flow rate increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

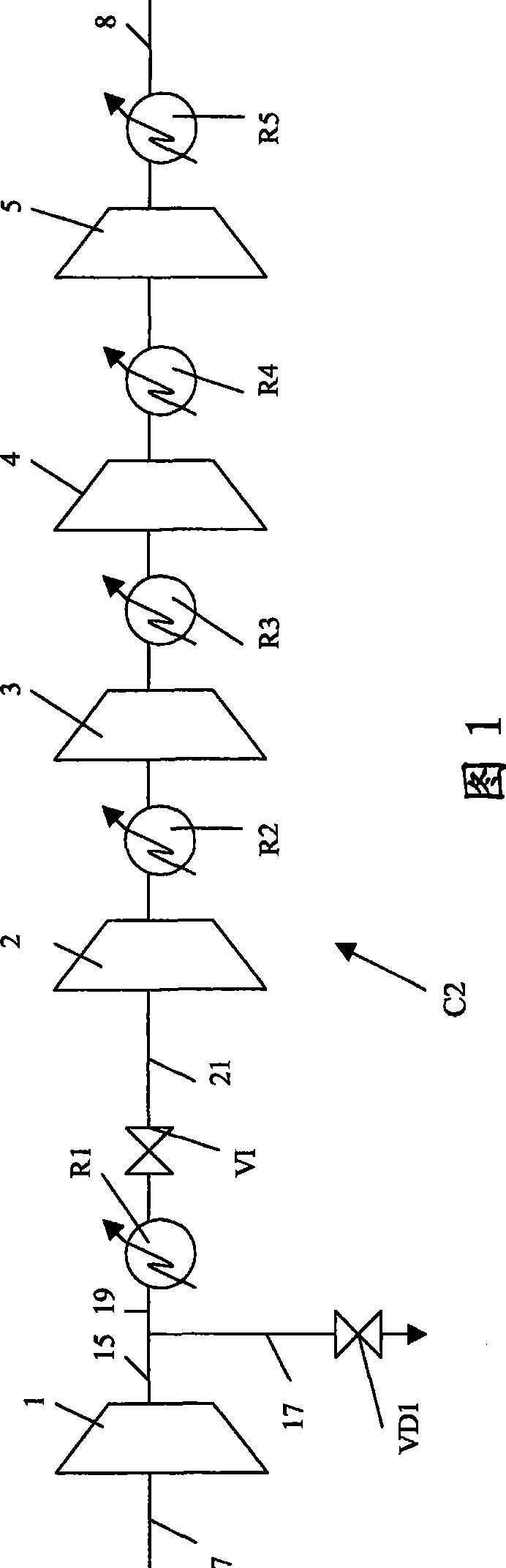

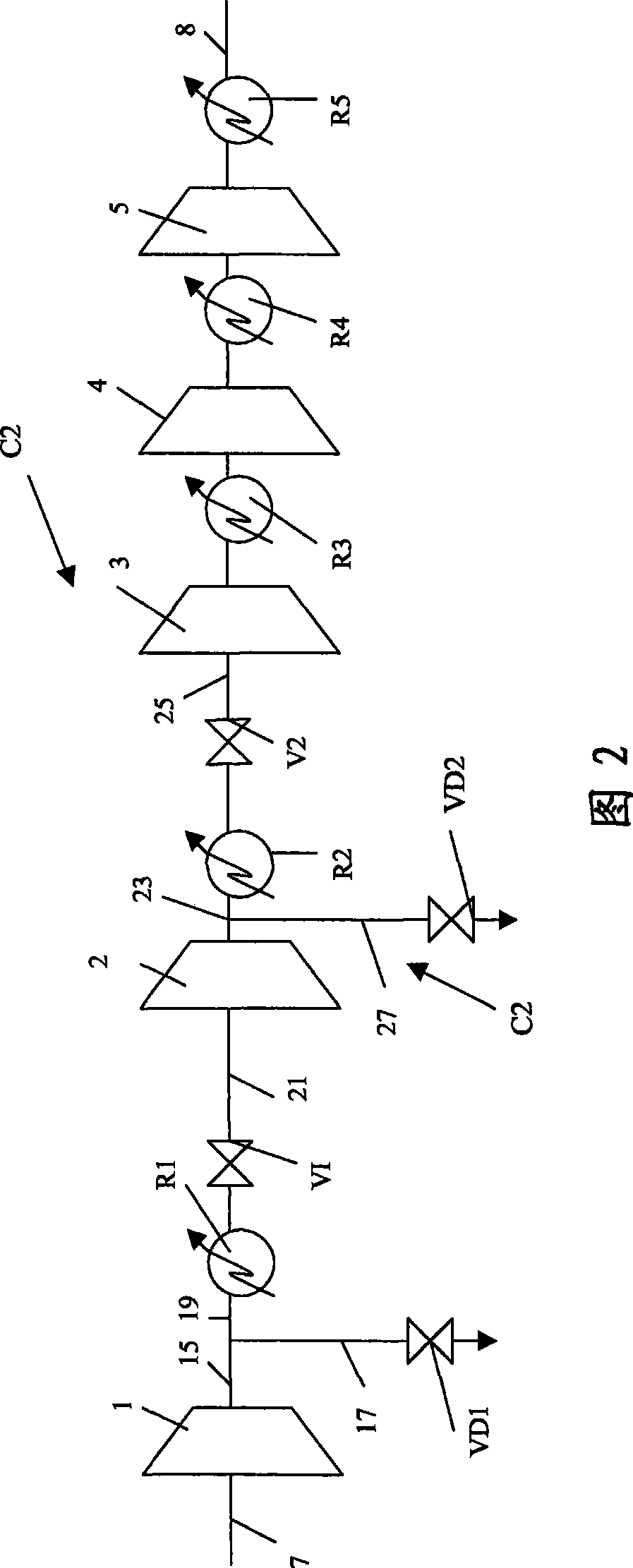

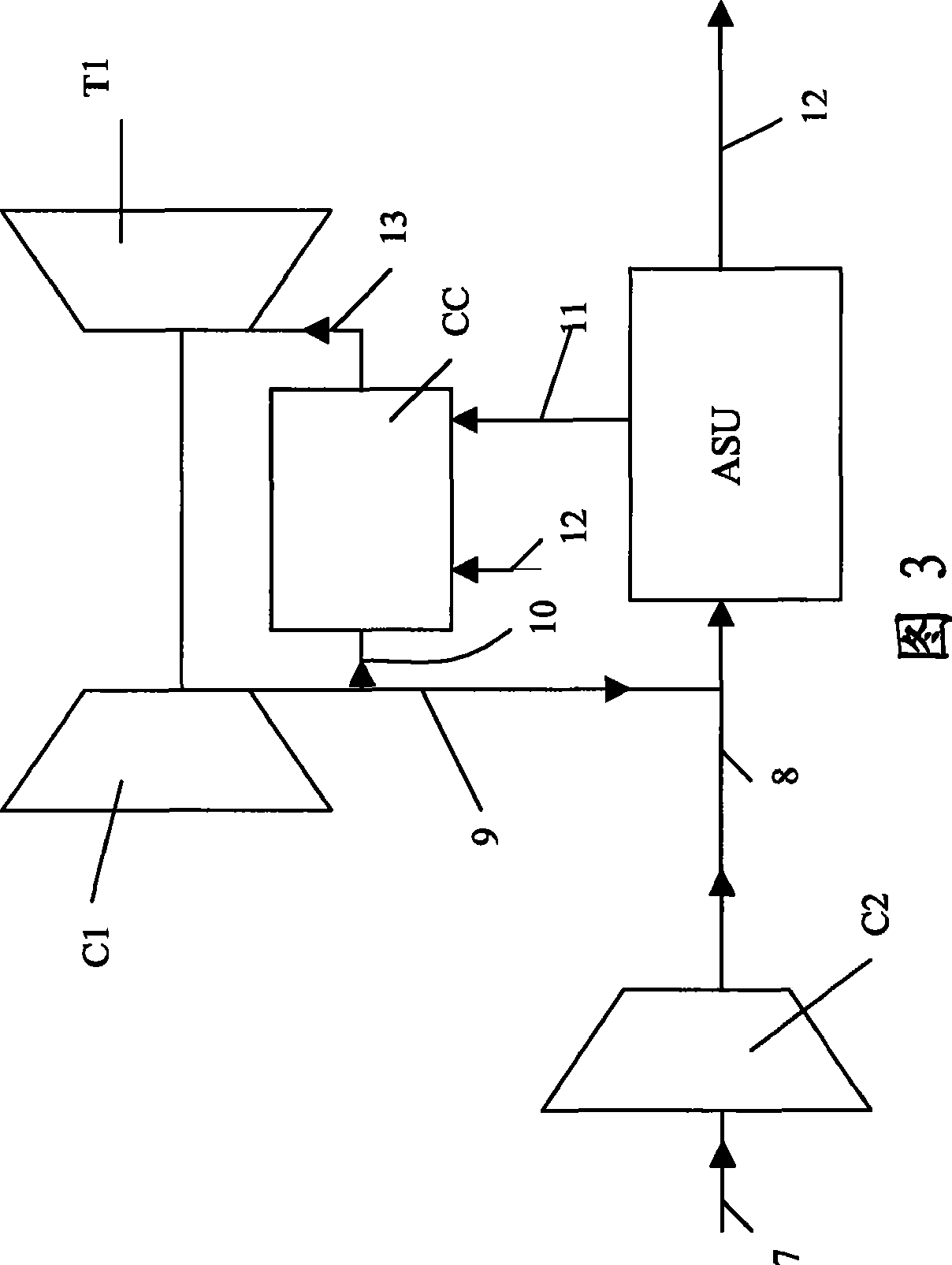

[0024] Figure 1 shows a compressor with five stages 1, 2, 3, 4, 5 on the same axis with cooling means R1, R2, R3, R4, R5 between each stage and downstream of the last stage C2. The air 7 is conveyed to the first stage 1 with flow regulating rotor blades.

[0025] During rated operation, the vanes of stage 1 do not reduce the flow rate, and all air compressed in the first stage 1 enters the conduits 15, 19, 21 and passes through the throttle valve V1 without reducing the pressure. This flow rate is then compressed in stages 2, 3, 4, 5.

[0026] In reduced flow rate operation, the vanes of the first stage 1 reduce the flow rate of the air 7 to 70% of the rated flow rate. A flow rate of 12.2% of the rated flow rate is discharged to the outside through the pipe 17 and the pressure reducing valve VD1. The remaining air, which is 57.8% of the rated flow rate, is sent to the cooler R1 and then to the throttle valve, which reduces its pressure to 57.8% of the rated pressure value. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com