Method for preparing dichlorodihydrosilane

A technology of dichlorodihydrosilane and trichlorosilane, which is applied in the direction of halosilane and halide silicon compounds, can solve the problems that dichlorodihydrosilane needs to be improved, and achieve the effect of improving efficiency and ensuring reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

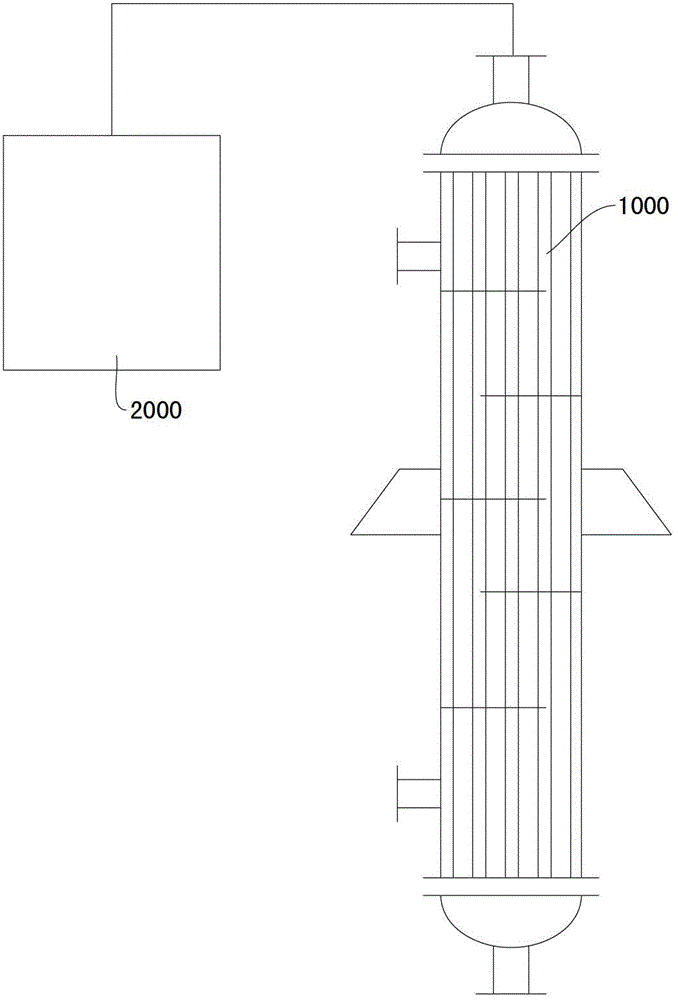

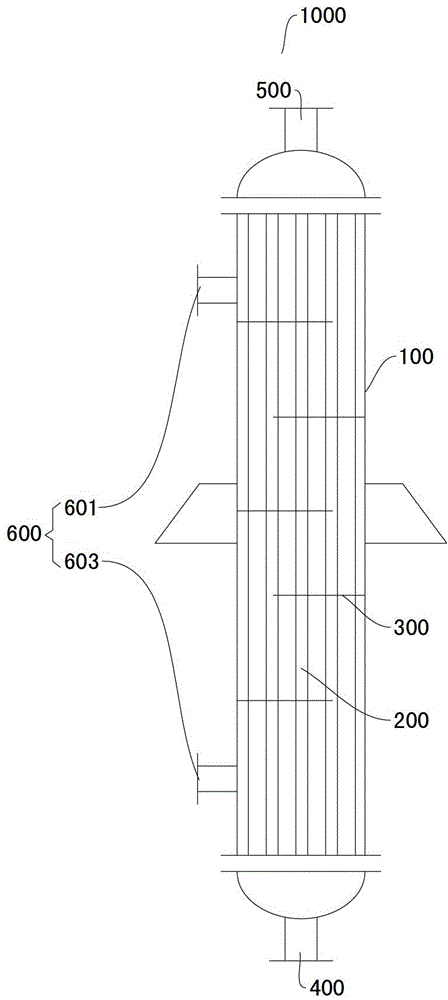

[0057] use figure 1 and figure 2 The shown equipment, according to the method for preparing dichlorodihydrosilane of the present invention, prepares dichlorodihydrosilane according to the following steps:

[0058] The tube side of the disproportionation reactor is filled with a weakly basic anion exchange resin—Albert's catalyst as a catalyst bed. After the replacement of the reactor is completed, the catalyst bed is first replaced with dry hot hydrogen gas until no water is detected in the hydrogen gas leaving the reactor.

[0059] Then trichlorosilane is passed into the lower end of the disproportionation reactor tube, and trichlorosilane passes through the catalyst bed from bottom to top at a flow rate of 4m / s, during which trichlorosilane undergoes a disproportionation reaction to produce dichlorodihydro Silicon and silicon tetrachloride, the reaction product is sent directly to the separation unit to separate dichlorodihydrogen silicon from the reaction product. Where...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com