A kind of hydrothermal preparation method of supported nickel phosphide catalyst

A technology of nickel phosphide and catalyst, which is applied in the field of preparation of supported nickel phosphide catalyst to achieve the effects of less by-products, improved performance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

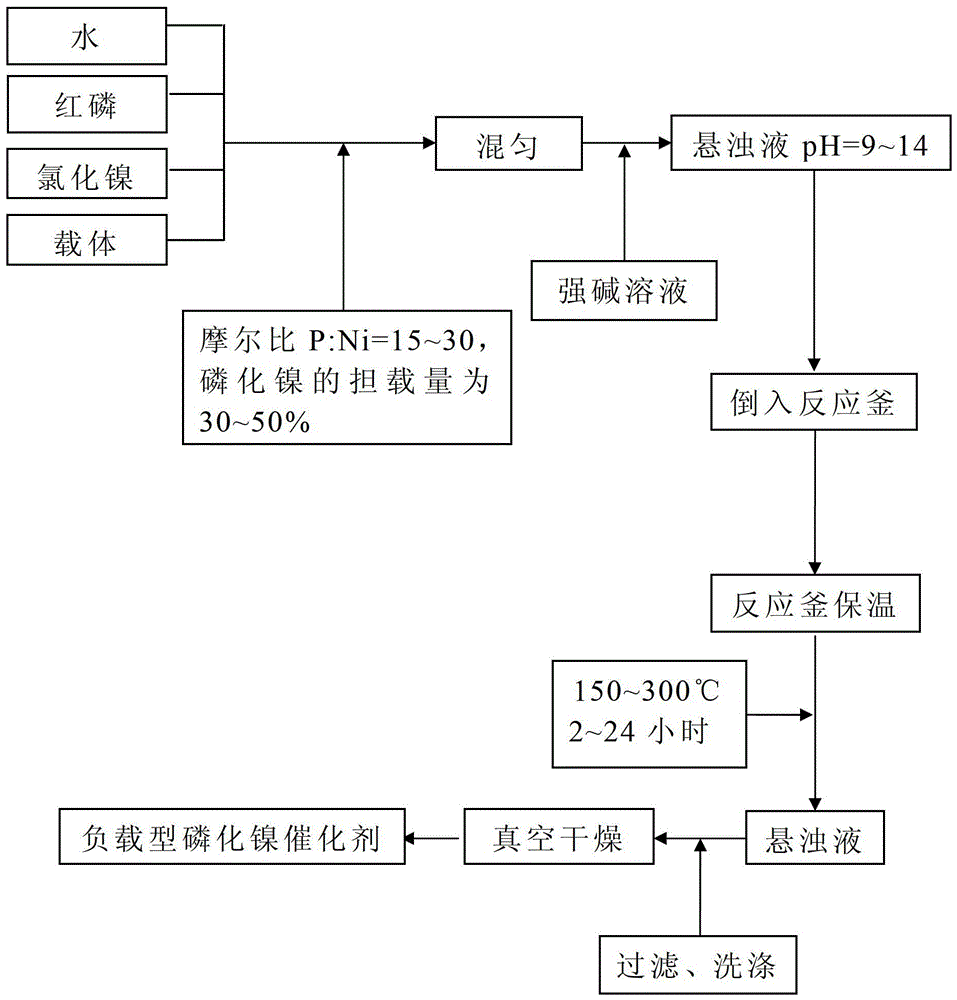

Method used

Image

Examples

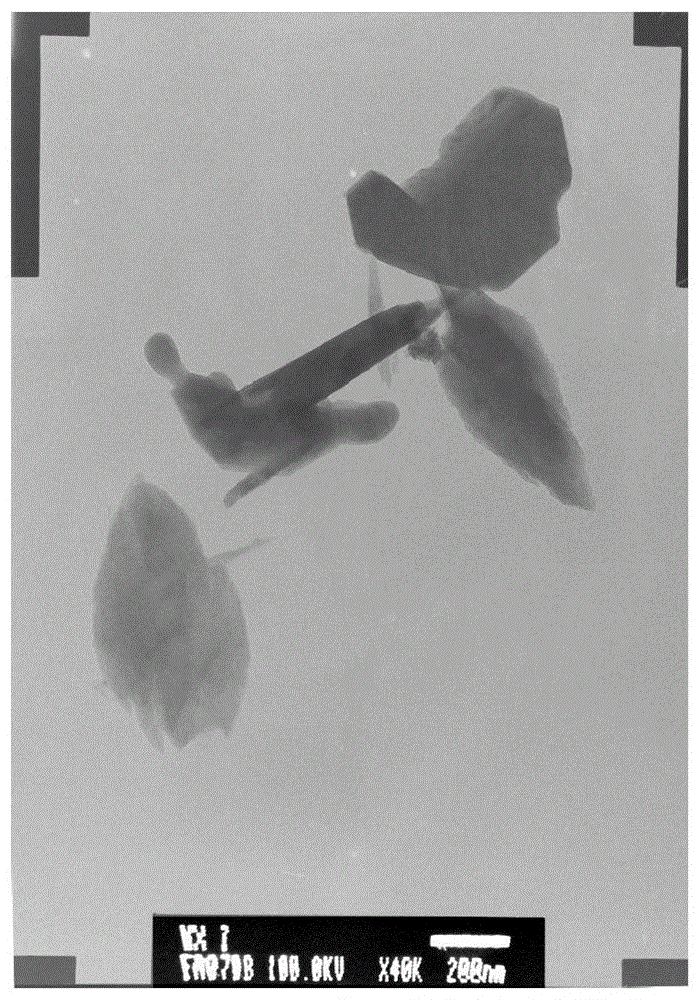

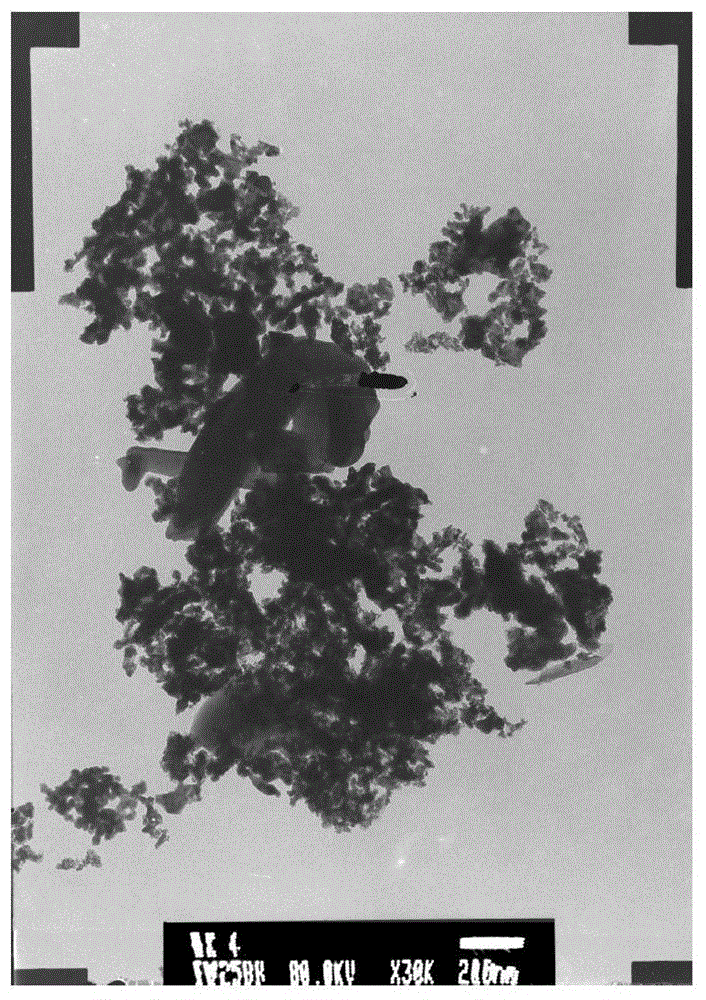

Embodiment 1

[0016] Mix 31Kg of red phosphorus, 9.5Kg of nickel chloride hexahydrate and 4.5Kg of ZSM-5 carrier with 100L of water, then add 1.0mol / L of potassium hydroxide solution, adjust the pH value to 13, and then quickly pour Put it into the reaction kettle and keep it at 200°C for 10 hours. After stopping the heat preservation, let it cool to room temperature, then filter the resulting suspension, wash the filter cake 3 times and then transfer it to a vacuum drying oven. Vacuum drying at 40° C. for 5 hours to obtain a supported nickel phosphide catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com