Dissolving device

A technology of dissolving device and stirring device, which is applied in the direction of dissolving, dissolving, and mixer with rotating stirring device, etc., which can solve the problems of high acidity of the target solution, incomplete dissolved materials, and unsatisfactory output due to small output, and meet the requirements of mass production , simple structure and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

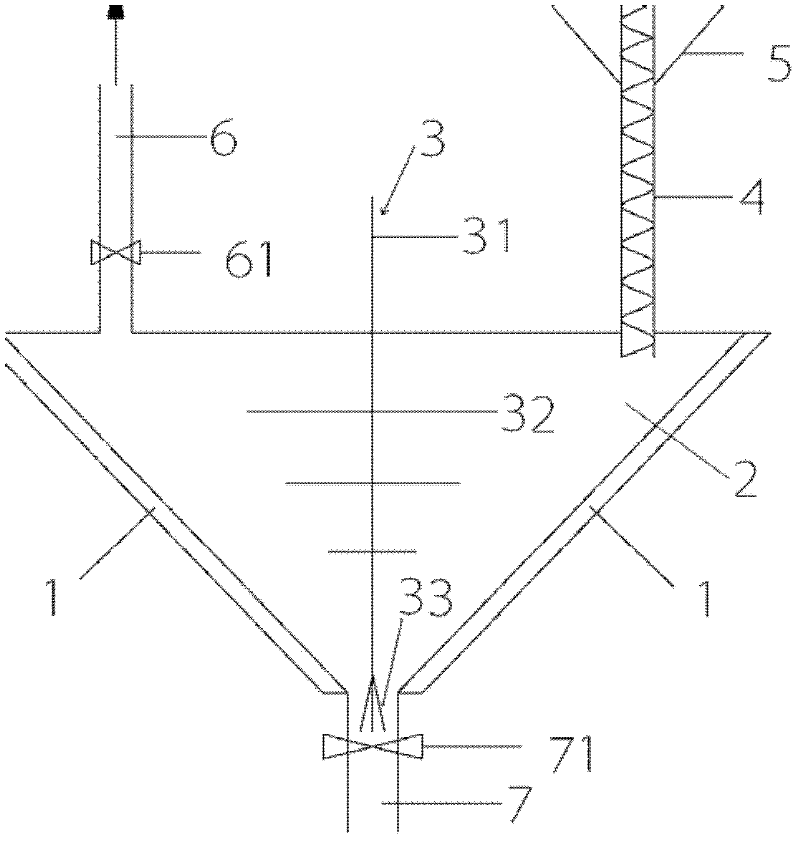

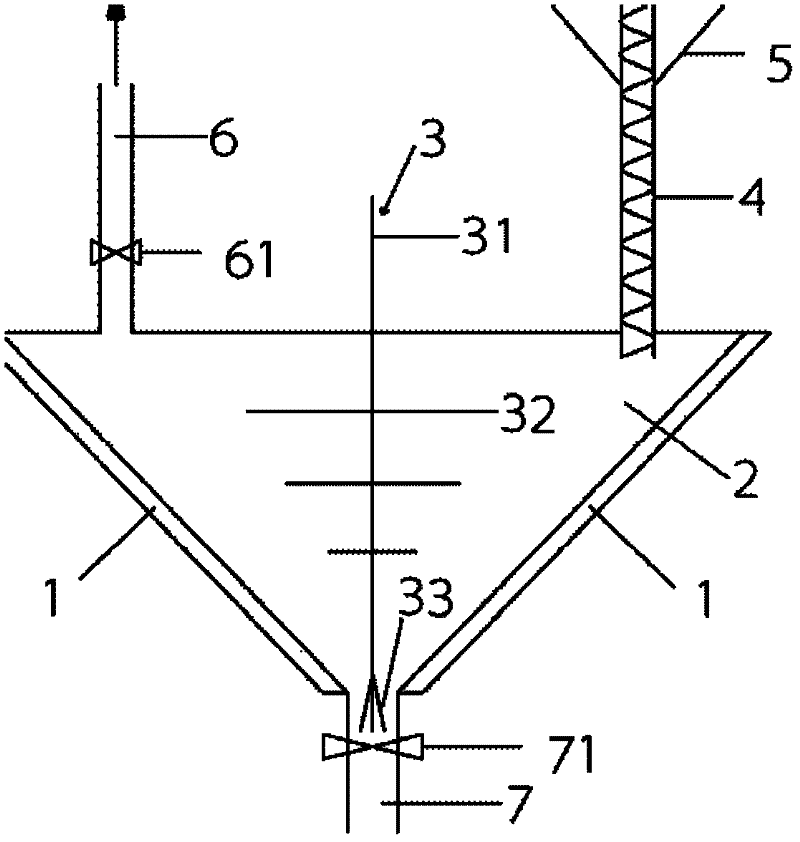

[0033] Such as figure 1 As shown, the dissolving device in the embodiment of the present invention includes: a sealed reaction tank 2, a stirring device 3 connected to the reaction tank 2, a feeder, an exhaust pipe 6 and a discharge pipe 7.

[0034] Wherein, the reaction tank 2 is used to store reactants and provide a reaction place. In order to facilitate loading and unloading, the reaction tank 2 is set as a cone and made of acid-resistant stainless steel.

[0035] The outer wall of the reaction tank 2 is equipped with a heating jacket 1 for providing the required temperature conditions for the reaction. The heating jacket 1 is ring-shaped and adopts water bath heating or oil bath heating to provide a reaction he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com