Process for preparing UO3 through uranyl nitrate air-blast atomization dry pyrolysis denitration

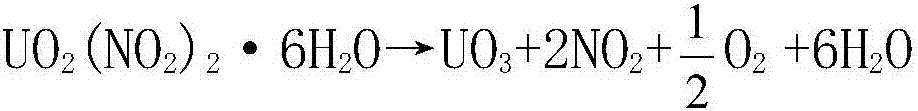

A technology of uranyl nitrate and atomization drying is applied in the field of uranium purification, which can solve the problems of unfavorable reduction and low chemical reaction activity, and achieve the effects of high conversion rate, good chemical reaction activity and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

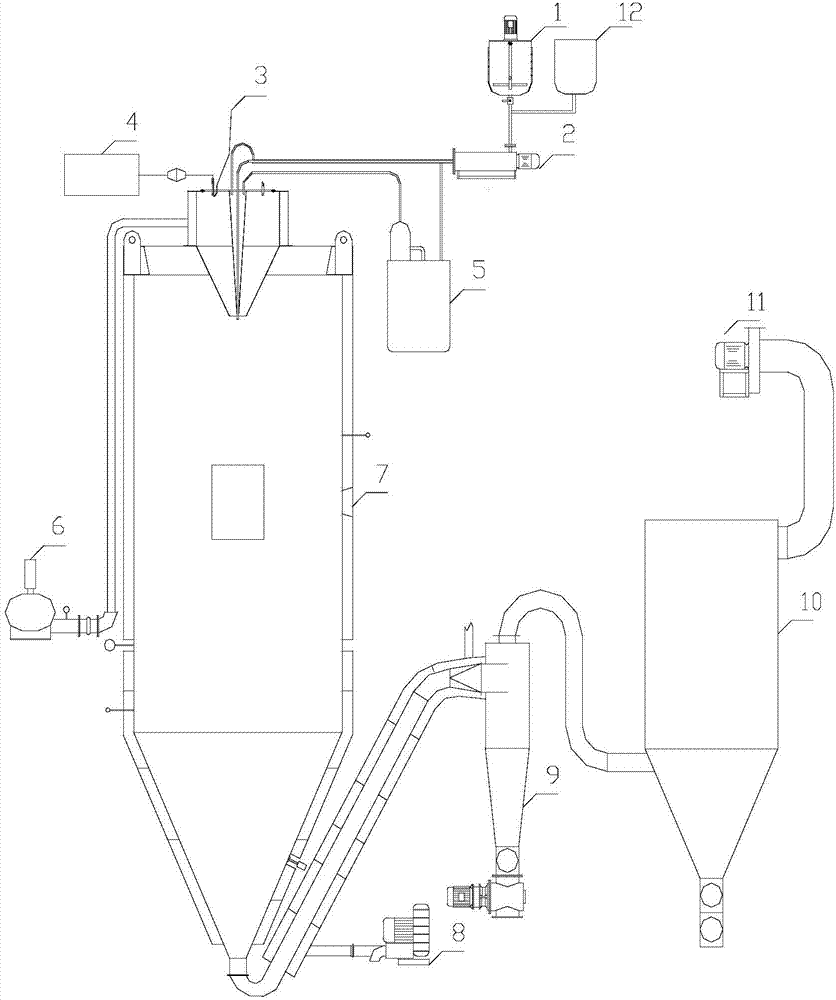

[0063] Establish a process test system for UO3 preparation by uranyl nitrate airflow atomization, drying and pyrolysis; establish a UO3 product sampling and analysis system. The specific implementation is as follows:

[0064] 1. According to the processing capacity of the equipment, design the main equipment such as the combustion chamber and the denitration reactor through the heat balance calculation and material balance calculation.

[0065] 2. Process the corresponding equipment according to the designed equipment structure parameters, select other auxiliary equipment, build support and maintenance platforms according to equipment size and location requirements, install equipment, and establish uranium nitrate with combustion chamber and denitrification reactor as the main equipment Process system for preparing UO3 by acyl denitration.

[0066] 3. Control the optimal temperature, water vapor partial pressure and gas-liquid ratio to achieve the effect of UO3 preparation by uranyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com