Extraction method of uranium in salt lake brine

A technology of salt lake brine and extraction method, which is applied in the field of extraction, can solve problems such as unfavorable environmental protection, and achieve the effects of simple operation, high adsorption capacity, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

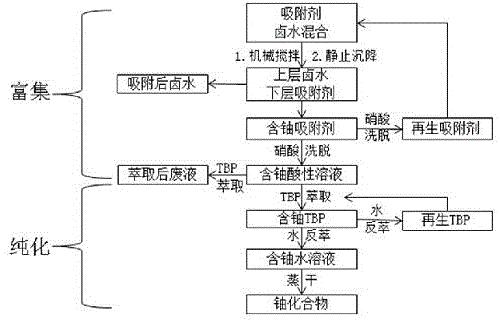

Method used

Image

Examples

Embodiment 1

[0023] A method for extracting uranium in salt lake brine, comprising the steps of:

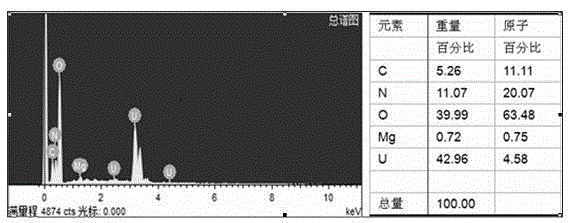

[0024] (1) Preparation of silica adsorbent: Add 100mL tetraethyl orthosilicate to 4.6L 5% ammonia water containing 0.5% cetyltrimethylammonium bromide under stirring at 1500 rpm to obtain a solid For precipitation, the precipitate was extracted with ethanol Soxhlet for 48 hours, and then dried at 50°C. The obtained silica adsorbent has a particle size of 0.2 μm, an average pore diameter of 4 nm, and a specific surface area of 823 m 2 / g;

[0025] (2) Take 100 L of salt field water with a uranium content of 410 μg / L and a pH value of 6.1, and add 10 g of the silica adsorbent obtained in step (1) into the salt field water. 200 rpm mechanical stirring and adsorption for 10 days, and the filter cake is obtained after solid-liquid separation; the adsorption capacity for uranium is 3.0mg / g;

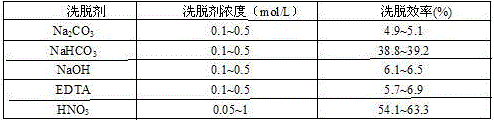

[0026] (3) Elute the filter cake in step (2) with nitric acid at a concentration of 0.1mol / L as the el...

Embodiment 2

[0034] A method for extracting uranium in salt lake brine, comprising the steps of:

[0035] (1) Preparation of silica adsorbent: Add 100mL tetraethyl orthosilicate to 4.6L 10% ammonia water containing 0.3% cetyltrimethylammonium bromide under stirring at 1000 rpm, A solid precipitate was obtained, and the precipitate was extracted by Soxhlet with ethanol for 36 hours, and then dried at 60°C. The obtained silica adsorbent has a particle size of 0.4 μm, an average pore diameter of 6 nm, and a specific surface area of 955 m 2 / g;

[0036] (2) Take 100L of old brine with a uranium content of 208 μg / L and a pH value of 5.7, and add 10 g of the silica adsorbent obtained in step (1) into the old brine. Mechanically stirred at 200 rev / min for 10 days, and a filter cake was obtained after solid-liquid separation; the adsorption capacity for uranium was 1.8mg / g.

[0037] (3) Using 0.5mol / L nitric acid as the eluent to elute the filter cake in step (2) to obtain an eluent containin...

Embodiment 3

[0045] Add 500mL tetraethyl orthosilicate to 2.3L 25% ammonia water containing 0.1% cetyltrimethylammonium bromide under stirring at 1000rpm to obtain a solid precipitate, and extract the precipitate with ethanol Soxhlet After 48 hours, dry at 60°C. The obtained silica adsorbent has a particle size of 0.9 μm, an average pore diameter of 9 nm, and a specific surface area of 725 m 2 / g. Under the condition that the ratio of the prepared silica to the salt lake water sample is 0.4g / L and the adsorption time is 5 hours, the adsorption capacities of silica adsorbents for uranium in intercrystalline brine, salt field water and old brine are shown in the table 3.

[0046] Table 3 The adsorption capacity of silica to salt lake brine and uranium

[0047]

[0048] The experimental results in Table 3 show that the silica adsorbent in this method can effectively adsorb uranium in intercrystalline brine, salt pan water and old brine, and under the same experimental conditions, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com