Preparation method of high-clarity uranium solution

A technology of clarity and solution, applied in the field of nuclear chemical industry, can solve the problems of slow filtration speed, low filtration yield, high energy consumption, etc., and achieve the effects of avoiding clogging, reducing cleaning times, and reducing emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

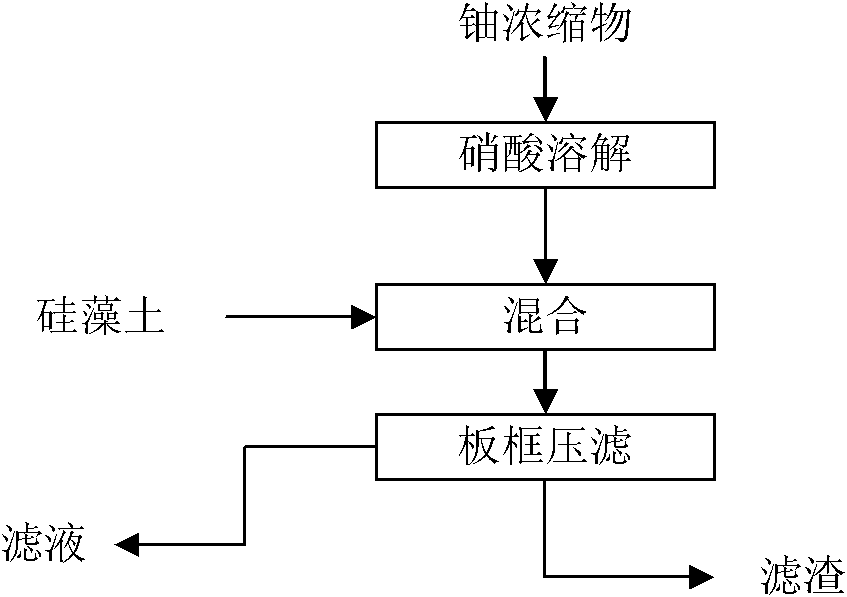

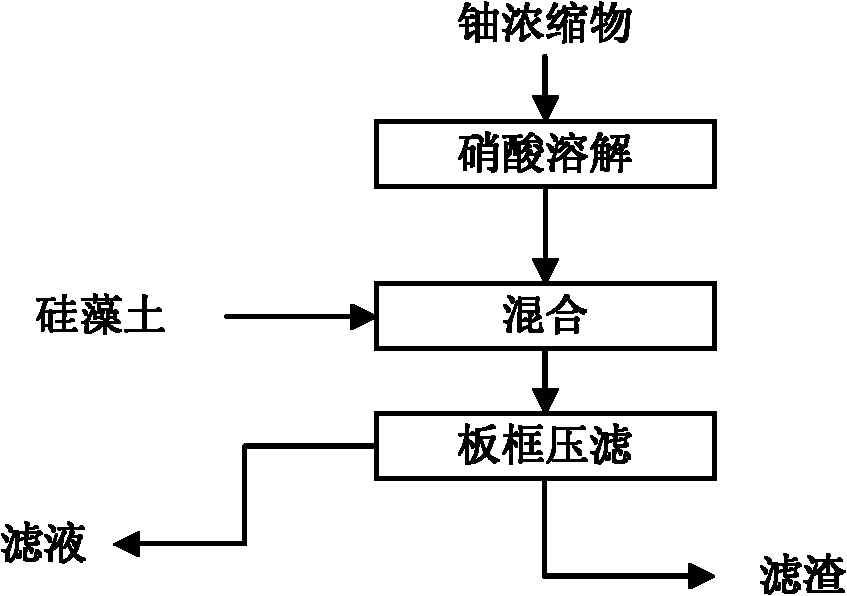

[0022] like figure 1 Shown, adopt the inventive method to obtain high-clarity uranium solution:

[0023] (1) At 75°C, use nitric acid solution to dissolve sodium diuranate, with the concentration of nitric acid in a mass percentage of 63%, until the solid solution of sodium diuranate is completely dissolved, and the acid dissolution ends;

[0024] (2) 0.5 hours at the end of step (1) acid dissolution, add diatomite to the uranium solution obtained in step (1) under stirring conditions, and the diatomite add-on is 20kg per cubic meter of solution; react for 0.5 hours Finish;

[0025] (3) Then step (2) is completed for 0.5 hours, and the uranium solution is filtered by a plate and frame filter press to obtain a uranyl nitrate solution, the uranium concentration is 287g / L, and the solid concentration in the solution is <50mg / L. Among them, the filter cloth of the plate and frame filter press is pre-coated with a layer of diatomite, the thickness of the diatomite coating is 1.5m...

Embodiment 2

[0029] like figure 1 Shown, adopt the inventive method to obtain high-clarity uranium solution:

[0030] (1) At 50°C, use nitric acid solution to dissolve ammonium diuranate; the concentration of nitric acid in mass percentage is 40%, until the diuranate solid dissolves completely, and the acid dissolution ends;

[0031] (2) 24 hours at the end of step (1) acid dissolution, add diatomite to the uranium solution obtained in step (1) under stirring conditions, and the diatomite add-on is 1g per cubic meter of solution; react for 0.5 hours Finish.

[0032] (3) Then step (2) is completed for 5 hours, and the uranium solution is filtered by a plate and frame filter press to obtain a uranyl nitrate solution, the uranium concentration is 255g / L, and the solid concentration in the solution is <50mg / L. Among them, the filter cloth of the plate and frame filter press is pre-coated with a layer of diatomite, the thickness of the diatomite coating is 1mm, and the filtration pressure is ...

Embodiment 3

[0034] like figure 1 Shown, adopt the inventive method to obtain high-clarity uranium solution:

[0035] (1) At 100°C, use nitric acid solution to dissolve sodium diuranate; the concentration of nitric acid in mass percent is 98%, until the sodium diuranate solid dissolves completely, and the acid dissolution ends;

[0036] (2) 10 hours after step (1) acid dissolution, add diatomite to the uranium solution of step (1) gained under agitation, the diatomite add-on is 50kg per cubic meter of solution; react for 1 hour Finish.

[0037] (3) Then step (2) is completed for 3 hours, and the uranium solution is filtered by a plate and frame filter press to obtain a uranyl nitrate solution, the uranium concentration is 315g / L, and the solid concentration in the solution is <50mg / L. Among them, the filter cloth of the plate and frame filter press is pre-coated with a layer of diatomite, the thickness of the diatomite coating is 2mm, and the filtration pressure is 0.6Mpa. The uranium c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com