Uranium-containing material extraction process control method

A process control and extraction technology, applied in the direction of program control, electrical program control, general control system, etc., can solve the problems of difficulty in guaranteeing the quality of extraction and stripping products, high labor intensity of workers, etc., and achieve stable acidity, purity and other indicators. Controllable, reduced uranium content, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

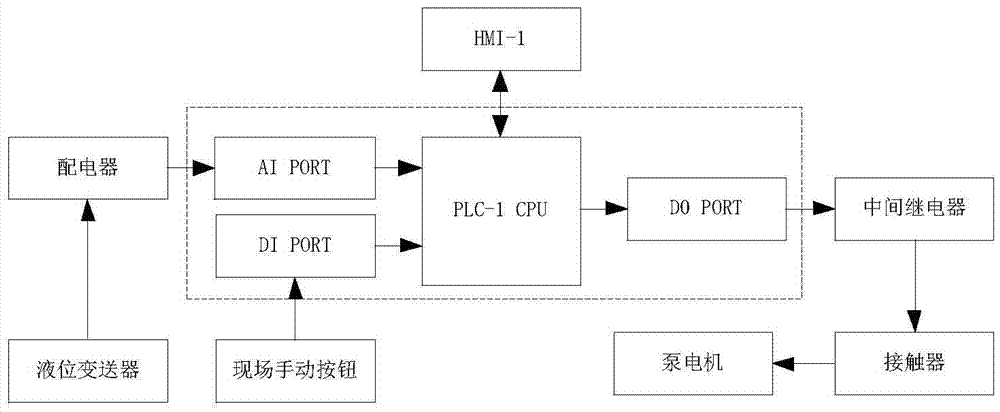

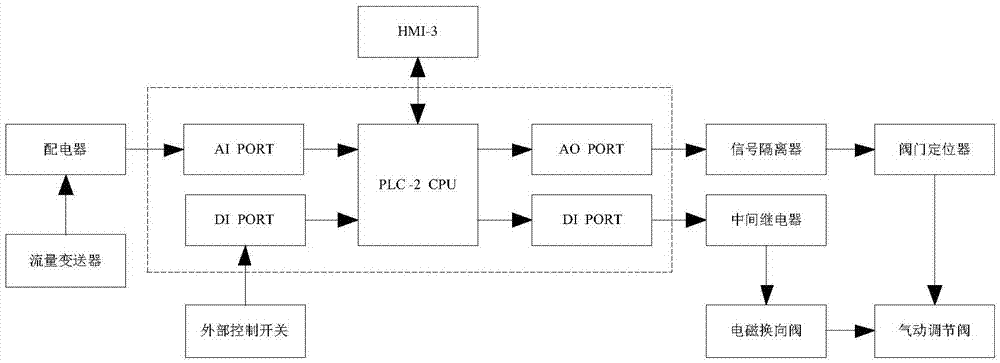

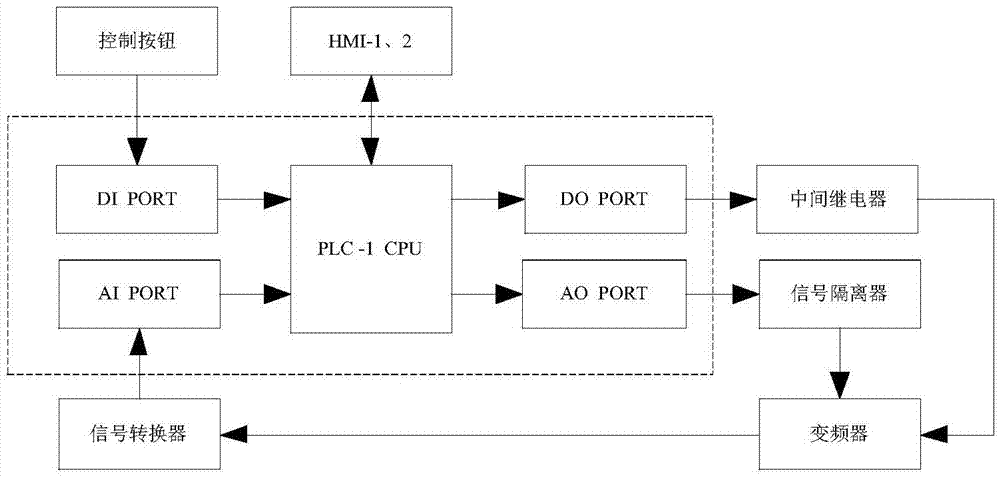

[0024] Such as Figure 1 to Figure 3 Shown, a kind of uranium-containing material extraction process control method of the present invention comprises the following steps:

[0025] For liquid level measurement, capacitive liquid level gauge is used for uranyl nitrate solution and wastewater liquid level measurement with conductive characteristics, an input liquid level gauge is used for non-conductive TBP liquid level, and magnetic flap liquid level is used for highly corrosive nitric acid liquid level count.

[0026] For flow measurement, raw water with conductivity and unstable density uses electromagnetic flowmeters, mass flowmeters are used to measure the flow and density of TBP (mass flowmeters can measure flow and density at the same time), and non-ionized water uses cost-effective metal Rotameter.

[0027] Step 1. Automatic interloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com